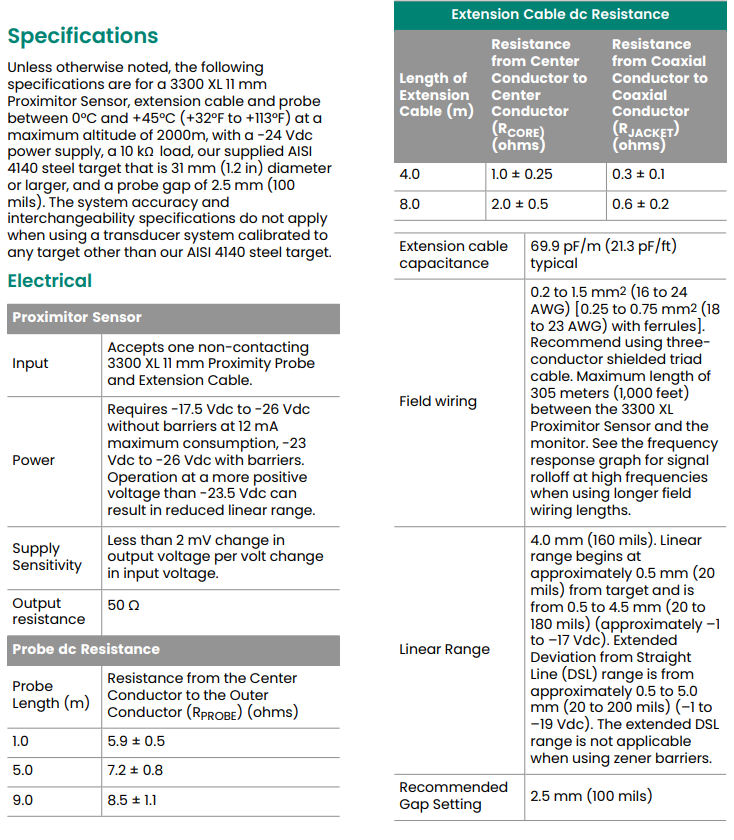

The 330780 Proximitor Sensor belongs to the 3300 XL 11mm Proximity Transducer System and is primarily designed for non-contact vibration and displacement measurements on fluid-film bearing machines.

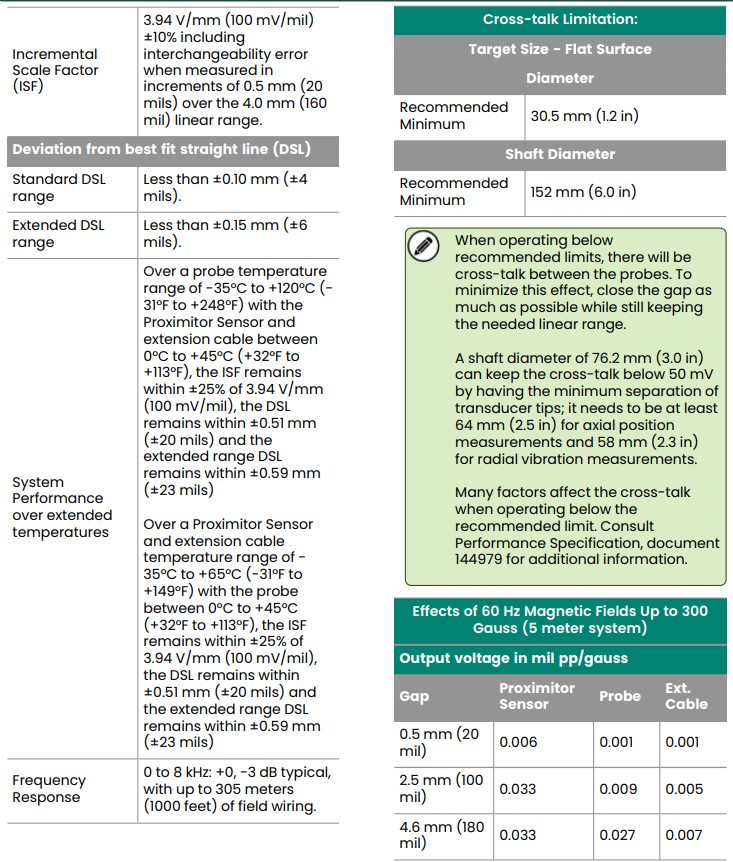

The 330780 Proximitor Sensor acts as the electronic interface, powering the probe, conditioning the signal, and providing a stable output proportional to the gap between the probe tip and the target material. The system has a standard output sensitivity of 3.94 V/mm (100 mV/mil), making it particularly suitable for applications requiring a longer linear range—significantly greater than that of the standard 8 mm system.

Below is a parameter comparison between the 330780 and the 330180:

| Specification | 330780 Proximitor Sensor | 330180 Proximitor Sensor | Description and Differences |

| System Belongs To | 3300 XL 11mm Proximity Transducer System | 3300 XL 8mm Proximity Transducer System | Core difference, determines the application scenario. |

| Incremental Scale Factor (ISF) | 3.94 V/mm (100 mV/mil) | 7.87 V/mm (200 mV/mil) | The most critical difference. The 11mm system has lower sensitivity, meaning it measures twice the physical displacement distance for the same voltage change compared to the 8mm system, resulting in a longer linear range. |

| Linear Range | 4.0 mm (160 mils) | 2.0 mm (80 mils) | The linear range of the 11mm system is twice that of the 8mm system, suitable for large displacement measurements. |

| Recommended Gap Setting | 2.5 mm (100 mils) | 1.27 mm (50 mils) | Corresponds to the center point of the linear range. |

| Frequency Response | 0 to 8 kHz: +0, -3 dB | 0 to 10 kHz: +0, -3 dB | The 8mm system has slightly better high-frequency response, making it more suitable for high-frequency vibration measurement; the 11mm system focuses on static and low-frequency measurements. |

Key Features and Advancements

High Immunity to Environmental Interference

The 330780 Proximitor Sensor is designed with enhanced resistance to radio frequency interference (RFI) and electromagnetic interference (EMI). This allows it to meet European CE compliance without requiring special installation arrangements. Such immunity ensures consistent performance even in electrically noisy industrial settings, preventing false readings or signal degradation caused by nearby high-frequency sources.

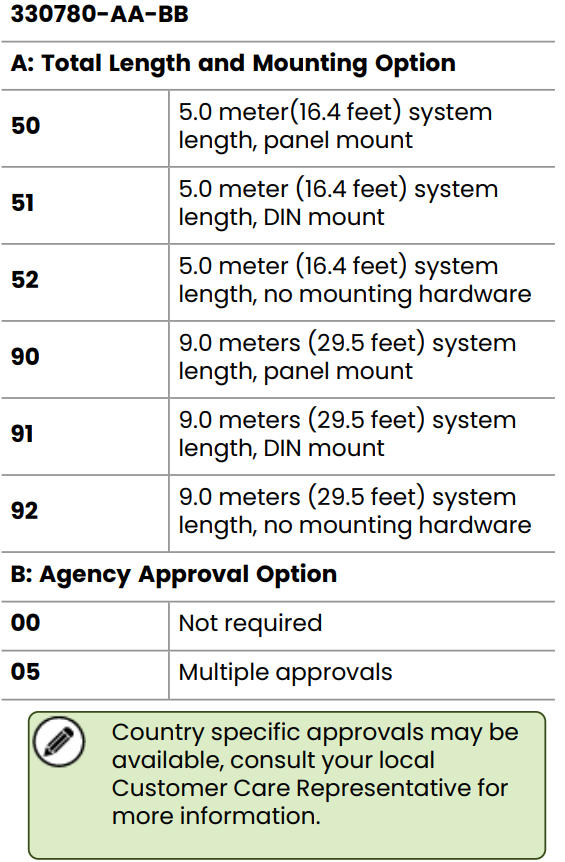

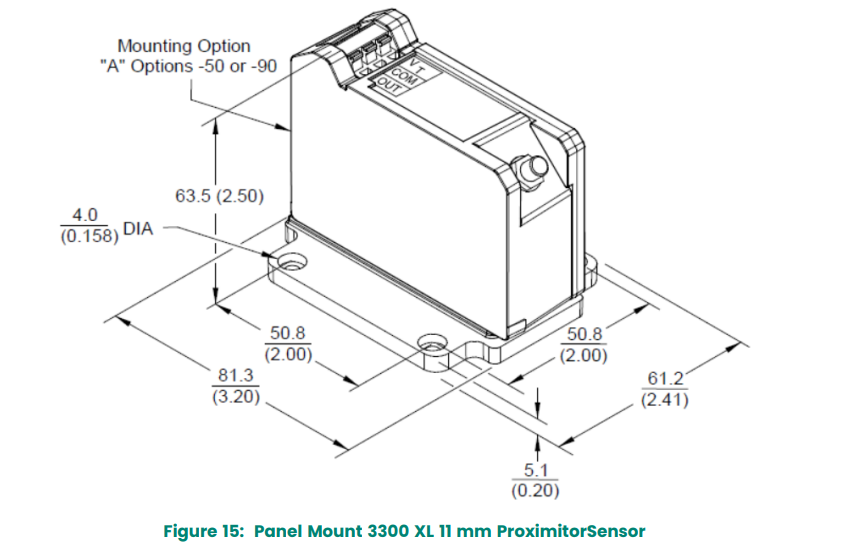

Flexible Mounting Options

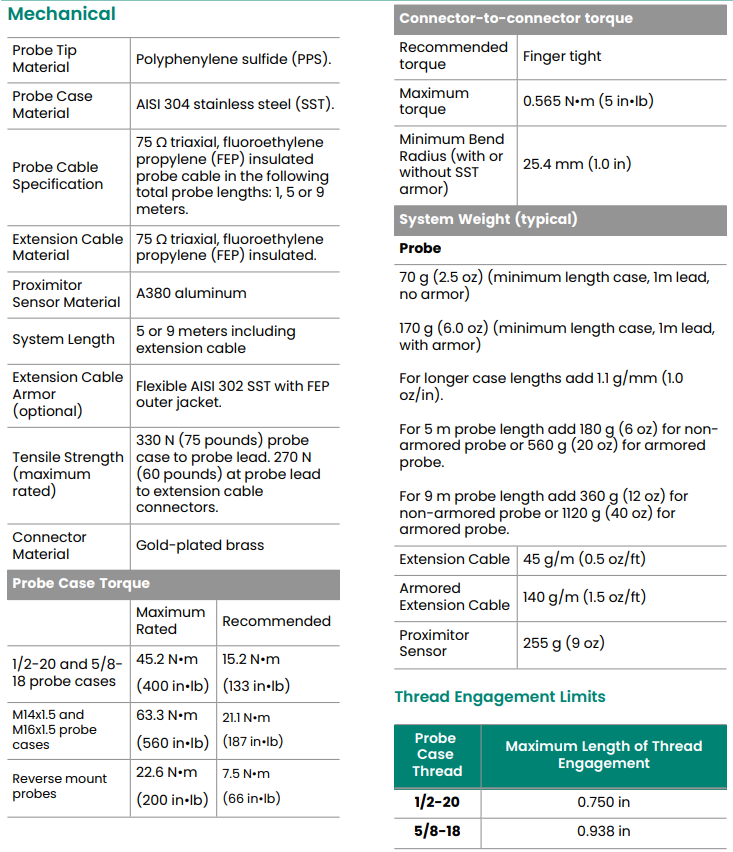

Thanks to its slim form factor, the sensor can be installed in high-density DIN rail configurations or traditional panel-mounted enclosures. This flexibility makes it suitable for both new installations and retrofits in space-constrained environments.

User-Friendly Connectivity

Equipped with SpringLoc terminal strips, the sensor enables quick, robust, and tool-free field wiring connections. This reduces installation time and minimizes the risk of loose connections, enhancing overall system reliability.

The 330780 Proximitor Sensor operates effectively within a frequency range of 0 to 8 kHz, making it suitable for both slow-moving displacement and higher-frequency vibration measurements. When integrated with the recommended 3300 XL 11 mm probe and extension cable, the system provides:

Linear Range: 0.5 mm to 4.5 mm (20–180 mils)

Extended Range: Up to 5.0 mm (200 mils) under specific conditions

Recommended Gap Setting: 2.5 mm (100 mils) for optimal performance

The sensor requires a power supply of –17.5 to –26 V DC (without barriers) and draws a maximum of 12 mA. Its output impedance is 50 Ω, ensuring compatibility with most monitoring systems.

Calibration and Interchangeability

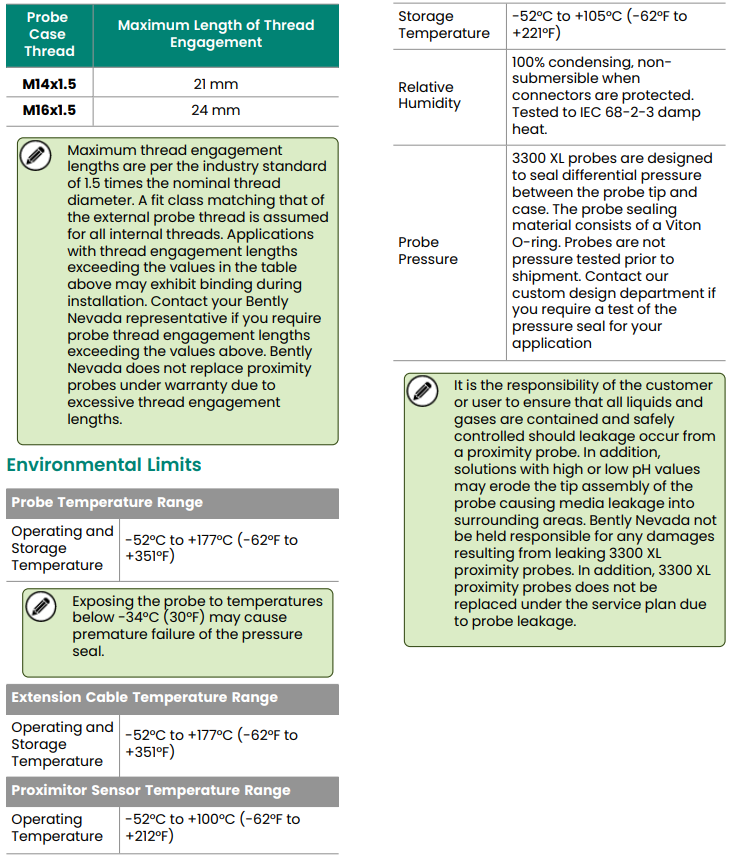

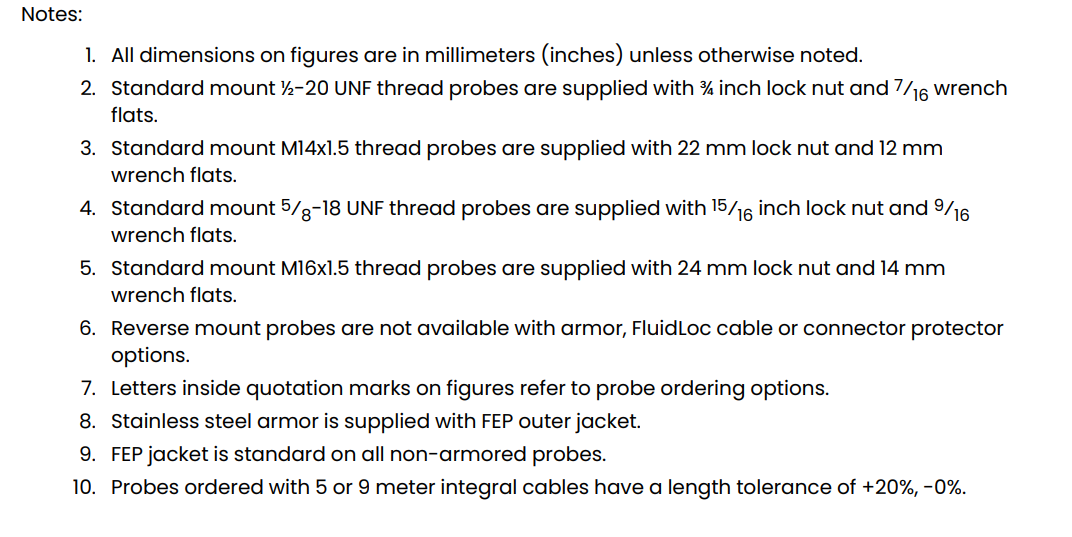

Each Proximitor Sensor is factory-calibrated for use with AISI 4140 steel targets. Calibration to other materials is available upon request. Please note that system accuracy and interchangeability are only guaranteed when using the sensor with the specified target material and within defined environmental conditions.

Frequently Asked Questions:

What is the difference between the 7200 series Proximitor Sensor and this product?

A: The 330780 Proximitor Sensor is designed to replace the corresponding sensors from the older 7200 series. It incorporates a completely new design. Please refer to the specifications for details.

What should be noted when replacing a 7200 series sensor with the 330780 Proximitor Sensor?

A: A complete upgrade requires replacing all system components—probe, cable, and sensor—and updating the monitoring system software (e.g., 3500 Monitoring System) to ensure compatibility.

What is Electrostatic Discharge (ESD) Protection?

A: The sensor's connectors and terminals have protection against electrostatic discharge (ESD), which is part of our latest design. However, users must follow proper handling procedures during installation or maintenance to avoid potential damage.