330701 is a specific probe model within the 3300 XL 11 mm Proximity Transducer System. This probe is equipped with a 1/2-20 UNF thread (1/2-20 UNF belongs to the Unified Fine Thread series in the Unified Inch standard. Its nominal diameter is 1/2 inch (approximately 12.7 mm), with 20 threads per inch (TPI)) and is supplied without armor.

The output scale factor of the 330701 Proximity Probe is 3.94 V/mm (100 mV/mil). This means that for the same change in output voltage, it can measure twice the physical displacement distance compared to an 8 mm system (which has a scale factor of 7.87 V/mm or 200 mV/mil).

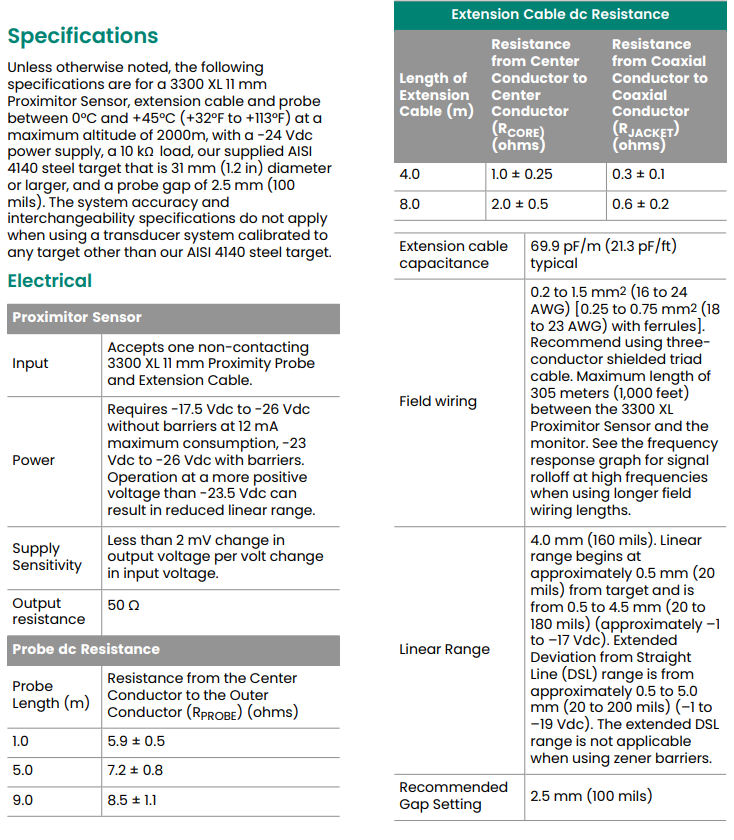

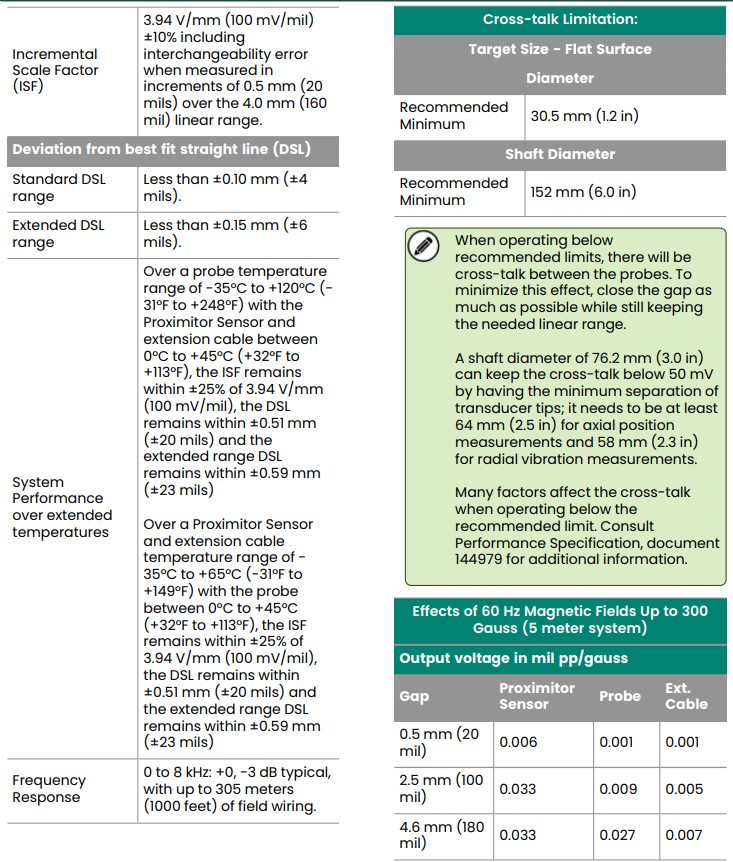

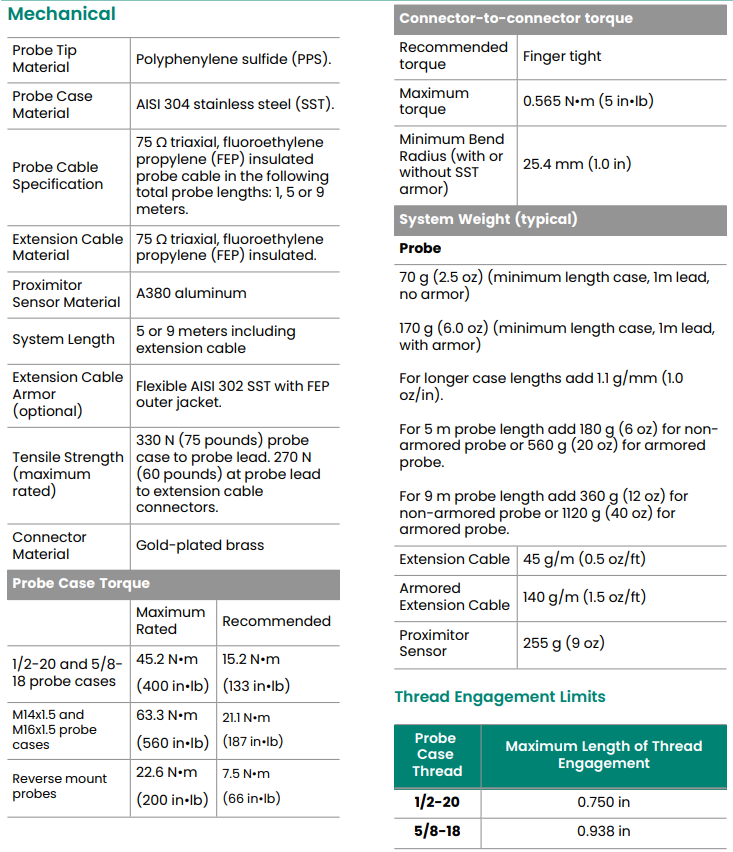

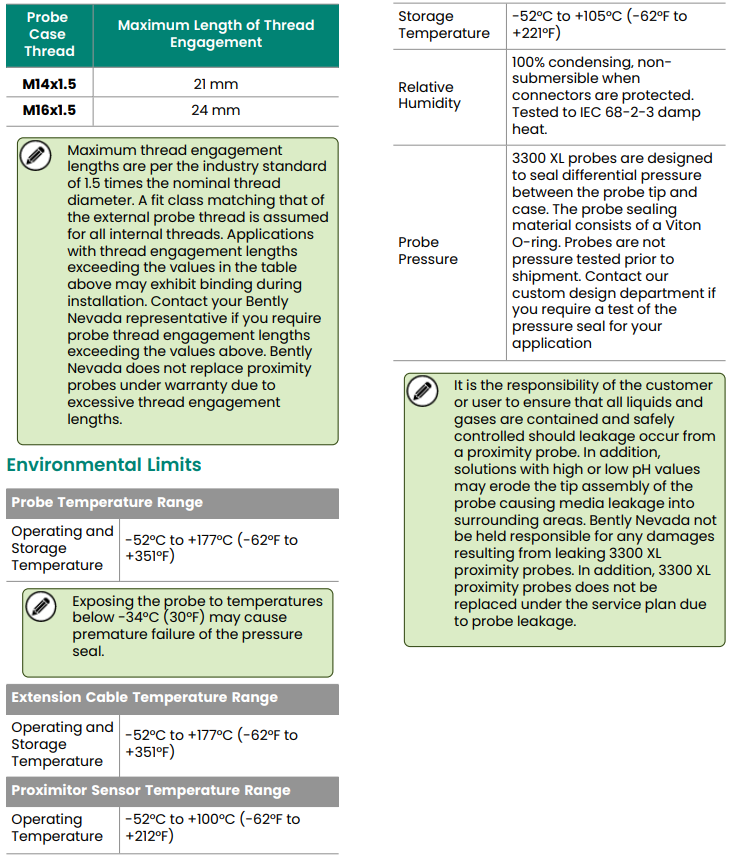

Below is a comparison of core parameters between the 330701 and the 330101:

| Probe Diameter | 11 mm(330701) | 8 mm(330101) | The 11 mm probe has a larger physical size, which is the physical basis for all its performance differences. |

| Linear Range | 4.0 mm (160 mils) | 2.0 mm (80 mils) | Core difference! The 11 mm probe's linear range is twice that of the 8 mm. Ideal for large displacement scenarios like turbine differential expansion. |

| Extended DSL Range | Up to 5.0 mm (200 mils) | Not Applicable | Provides an additional safety margin by allowing measurement in a wider range while maintaining acceptable accuracy. |

| Scale Factor (ISF) | 3.94 V/mm (100 mV/mil) | 7.87 V/mm (200 mV/mil) | Sensitivity difference! The 8 mm probe has higher sensitivity (more voltage change per unit displacement). The 11 mm trades sensitivity for doubled range. |

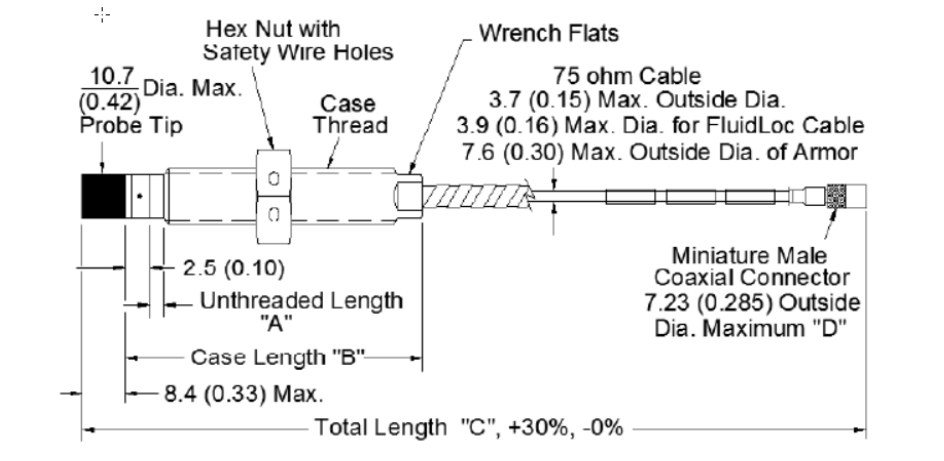

| Recommended Gap | 2.5 mm (100 mils) | 1.27 mm (50 mils) | The 11 mm probe requires a larger initial installation gap to utilize the center of its linear range. |

| Frequency Response | 0 - 8 kHz (+0, -3 dB) | 0 - 10 kHz (+0, -3 dB) | The 8 mm probe has superior high-frequency response, capable of capturing higher frequency vibrations, making it more suitable for detailed vibration analysis. |

| Min. Target Size (Flat) | 30.5 mm (1.2 in) | 15.2 mm (0.6 in) | The 11 mm probe requires a larger target area to ensure measurement accuracy and linearity, otherwise edge effects can influence readings. |

| Recommended Min. Shaft Dia. | 152 mm (6.0 in) | 76.2 mm (3.0 in) | For radial vibration measurement, the 11 mm probe requires a larger shaft diameter to minimize measurement errors and cross-talk due to curvature. |

| Cross-Talk Requirement | Axial: ≥64 mm (2.5 in) | Axial: ≥40 mm (1.6 in) | To prevent signal interference (cross-talk) between two probes, the 11 mm requires a larger minimum separation between probe tips. |

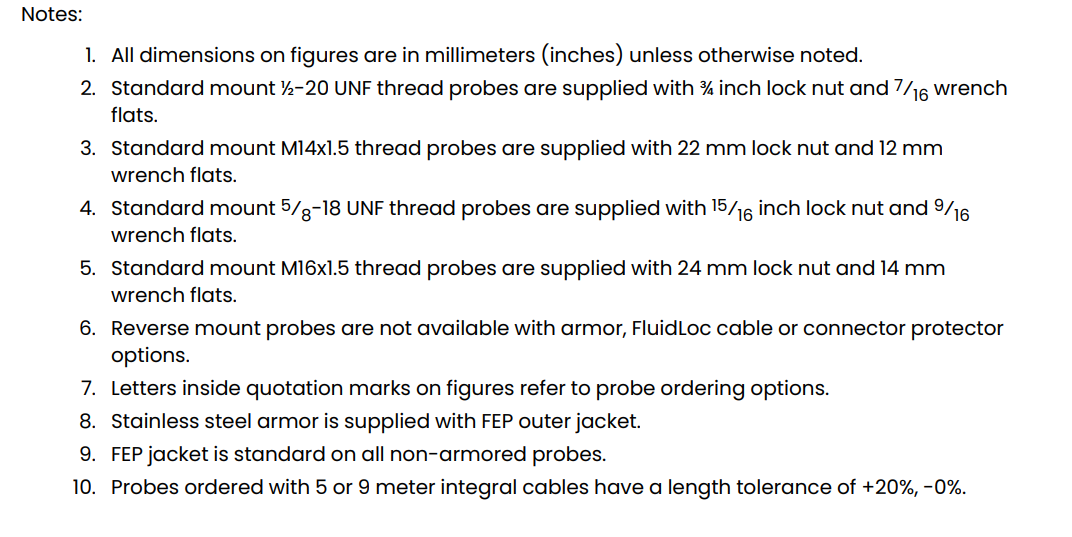

| Mechanical Interface | ½-20 UNF, 5/8-18 UNF, M14x1.5, M16x1.5 | 3/8-24 UNF, M10x1 | The 11 mm probe uses larger, more robust mounting threads, accommodating its larger size and potentially harsher mechanical environments. |

| Primary Application | Axial Pos., Differential Expansion, Large Displacement, Low-Freq. Monitoring | Radial Vibration, Keyphasor, General Position Monitoring | Fundamental application difference. The 11 mm specializes in large displacement, low frequency; the 8 mm excels in general vibration, high frequency. |

As shown above, the 330701 is more suitable for the following application scenarios:

Large measurement range: Displacement changes exceeding 2 mm, up to 4-5 mm.

Low frequency: Primarily focused on static or slowly changing displacement; high-frequency vibration components are not the priority.

Ample space: Sufficient space is available to install the larger probe and meet its minimum target size and spacing requirements.

Typical applications: Axial position and differential expansion measurements in steam/gas turbines, rod position or rod drop measurements on large reciprocating compressors, swing monitoring of large hydraulic turbines.

Frequently Asked Questions:

Q: How is the 330701 installed?

A: It is equipped with gold-plated brass ClickLoc connectors. These ClickLoc connectors lock into place, preventing the connection from loosening. Furthermore, the 330701 probe comes standard with a locknut featuring pre-drilled safety wire holes.

Q: What are the machine requirements for the 330701?

A: The machine must meet the minimum target size and spacing requirements specified for the 330701 probe.

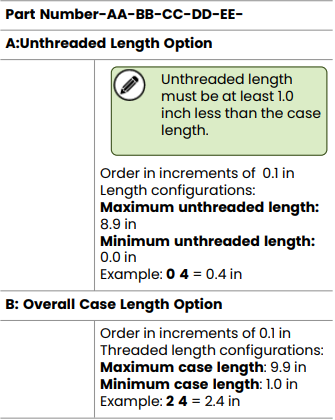

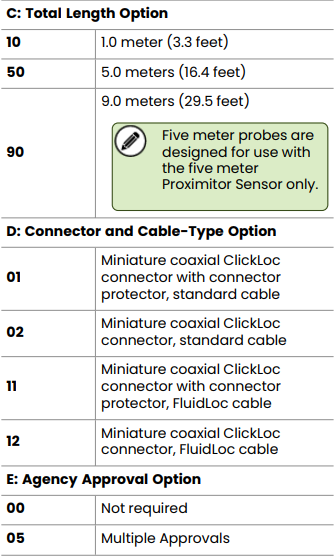

Q: How do I order the 330701?

A: The complete part number format and ordering details for the 330701 can be found in the Ordering Information section.

Additional Information:

1/2-20 UNF is a Unified Fine Thread in the US customary system. Its nominal diameter is 1/2 inch (approximately 12.7 mm), it has 20 threads per inch, and a pitch of 1.27 mm. Its thread angle is the standard 60 degrees.

This thread typically uses Class 2A tolerance (for external threads), with a tolerance zone width of approximately 0.206 mm. It is suitable for applications requiring high-precision fits. Due to its fine pitch design, it offers better self-locking and anti-loosening performance, making it commonly used in mechanical applications with strict fit requirements, such as machine screws and drill chucks.