The 330400 Accelerometer is a high-performance piezoelectric accelerometer designed by Baker Hughes Bently Nevada for condition monitoring of critical machinery. It is specifically used to measure vibration acceleration on machine casings or bearing housings and is a key tool for identifying incipient faults and preventing unplanned downtime. This model is designed in strict compliance with the American Petroleum Institute (API) Standard 670 requirements for accelerometers, making it a preferred solution for monitoring high-speed, high-reliability equipment in industries such as oil and gas, chemical, and power generation.

This sensor is engineered to capture high-frequency vibrations transmitted to the machine casing by internal dynamic forces (e.g., rotor unbalance, misalignment, bearing defects, gear mesh issues). Complementing proximity probe systems that primarily monitor relative rotor vibration, the 330400 provides information about the absolute vibration of the machine structure itself. This is crucial for diagnosing certain types of faults, such as gearbox problems, high-frequency bearing failures, and blade pass frequencies.

With its 100 mV/g nominal sensitivity and 50 g peak acceleration range, the 330400 achieves an excellent balance between sensitivity and measurement range, enabling it to accurately capture a wide spectrum of vibration signals from low to high frequencies.

II. Detailed Core Functions

The core function of the 330400 accelerometer is to accurately and linearly convert the mechanical vibration (acceleration) of the surface on which it is mounted into a standardized electrical signal (voltage) for subsequent analysis, display, and alarm generation by monitoring systems.

Machine Protection and Fault Early Warning

As part of a machinery protection system, the 330400 continuously monitors the vibration level of the machine casing. When the vibration amplitude exceeds pre-set safety thresholds, it triggers alarms or shutdown signals in the monitoring system. This prevents the equipment from operating under abnormal conditions, avoiding catastrophic failures and protecting high-value assets.

Condition Monitoring and Fault Diagnosis

This represents its more advanced function. By analyzing the vibration signal output from the 330400, technicians can:

Identify Fault Types: Different machine faults generate vibration signals with distinct characteristics. For example, rotor unbalance primarily manifests as 1X vibration; misalignment generates 2X and even higher harmonics; rolling element bearing faults produce high-frequency impact signals; and gear defects reveal gear mesh frequencies and their sidebands.

Locate the Fault Source: By installing multiple sensors at different locations on a machine (e.g., drive end, non-drive end, gearbox input and output), data can be compared to help pinpoint the specific location of a fault.

Trend Analysis: Continuously recording vibration data over the long term allows for the observation of changes in machine health. A gradual increase in vibration often indicates component deterioration, such as bearing wear or gear pitting, enabling predictive maintenance.

Gear Mesh Monitoring

The datasheet specifically notes the sensor's suitability for "gear mesh monitoring." Faults in gearboxes (e.g., broken teeth, pitting, wear) generate high-frequency vibration components. The 330400's wide frequency response range (10 Hz to 15 kHz) allows it to effectively capture these high-frequency signals, providing critical data for gearbox health assessment.

Capture of High-Frequency Dynamic Phenomena

The initial symptoms of many machine faults, especially early-stage failures in rolling element bearings and gears, are high-frequency, low-energy impact pulses. The 330400's mounted resonant frequency of up to 30 kHz ensures it can sense these high-frequency events without distortion, providing reliable raw data for advanced diagnostic techniques such as shock pulse or envelope demodulation analysis.

III. In-Depth Working Principle: Piezoelectric Effect and IEPE Technology

The core operating principle of the 330400 accelerometer is based on the Piezoelectric Effect and incorporates Integrated Electronics Piezo-Electric (IEPE) technology, a mature and reliable design.

Piezoelectric Effect: Converting Mechanical Energy to Electrical Energy

Core Sensing Element: The heart of the sensor is a piezoelectric crystal (typically quartz or specialized piezoelectric ceramic). This material possesses a unique physical property: when subjected to mechanical stress (e.g., compression or tension), it generates an internal electrical charge proportional to the applied force. This is known as the Direct Piezoelectric Effect.

Seismic Mass and Force Application: Inside the sensor, a seismic mass is mounted onto the piezoelectric element. When the sensor's base vibrates with the machine casing, according to Newton's Second Law (F=ma), the seismic mass generates an inertial force proportional to the vibration acceleration. This force is continuously applied to the piezoelectric crystal.

Charge Generation: Since the force (F) on the piezoelectric crystal is proportional to acceleration (a) (F = m·a, with mass m being constant), the electrical charge (Q) generated by the piezoelectric crystal is also proportional to the measured acceleration (a). Thus, the mechanical vibration acceleration information is converted into a variation of electrical charge.

Built-in Microelectronics and IEPE System

The raw piezoelectric charge signal is very weak and has high impedance, making it highly susceptible to cable noise and difficult to transmit over long distances. The 330400 employs IEPE (also known as ICP®) technology to solve this problem.

Signal Amplification and Impedance Conversion: A miniature charge amplifier or impedance converter circuit is integrated within the sensor. This circuit converts the high-impedance charge signal from the piezoelectric crystal into a low-impedance voltage signal. This is the origin of the sensor's sensitivity (100 mV/g) – for every 1g of acceleration input, the circuit outputs a 100 millivolt signal.

Constant Current Power Supply & Signal Transmission: A key feature of the IEPE system is the two-wire system. The same cable is used both to provide DC power to the sensor's internal electronics (typically -24 Vdc, as required by the 330400) and to output the AC vibration signal. The monitoring system or proximitor supplies a constant current to the sensor (for the 330400, the bias current is 2 mA nominal). The internal electronics modulate this current, superimposing the vibration voltage signal onto the DC power supply. At the receiving end, the monitoring system uses a coupling capacitor to block the DC component, extracting the pure AC vibration signal.

Bias Voltage: Under static (zero acceleration) conditions, the sensor outputs a stable DC voltage, known as the Bias Voltage (for the 330400, it is -8.5 ± 0.5 Vdc). This voltage is a reference point required for the internal circuitry to function correctly, and the monitoring system must provide a DC path for it.

Frequency Response and Resonance

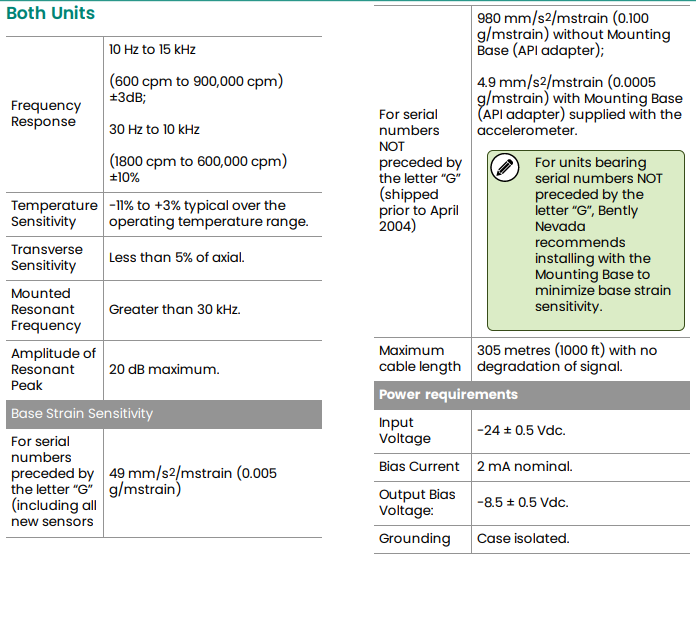

Operating Frequency Band: The specified 10 Hz to 15 kHz (±3 dB) is the frequency range within which the 330400 can perform accurate measurements. Below 10 Hz, the sensor's response rolls off; above 15 kHz, the response rises sharply as it approaches its resonant frequency.

Mounted Resonant Frequency: Every accelerometer has a natural resonant frequency. The 330400's mounted resonant frequency is greater than 30 kHz. This is a desirable characteristic because it lies far above its operating band (15 kHz), ensuring a flat amplitude response and linear phase response within the operating band, avoiding signal distortion caused by resonance. The resonant peak is controlled to a maximum of 20 dB.

Environmental Compensation and Interference Immunity Design

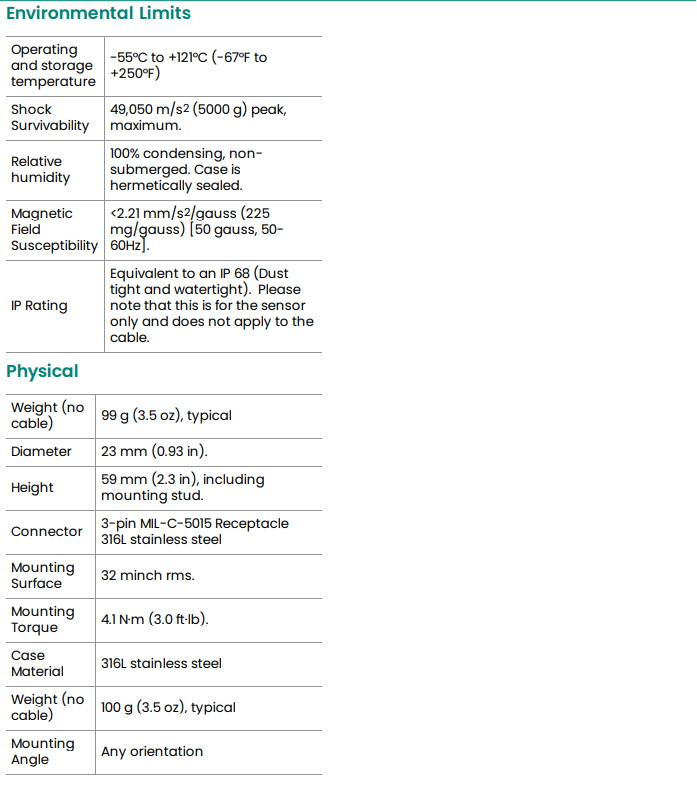

Temperature Compensation: The properties of electronic components and piezoelectric materials change with temperature. The 330400 is designed to maintain stable performance over a wide temperature range, with typical temperature sensitivity of -11% to +3% over its operating temperature range.

Transverse Sensitivity: The sensor also has some sensitivity to vibrations perpendicular to its main axis. The 330400's transverse sensitivity is less than 5%, an excellent figure indicating low sensitivity to vibrations in non-measurement directions, ensuring data accuracy.

Base Strain Sensitivity: When mounted on a surface that deforms due to mechanical load or thermal expansion, the sensor's case itself can transmit this strain to the piezoelectric element, generating a false signal. For 330400 units with serial numbers preceded by "G" (including all new models), the base strain sensitivity is significantly reduced to 0.0005 g/µε (when using the supplied API mounting base). This is crucial in applications with high thermal gradients or on structures prone to deformation.

EMI Immunity: The metal case and shielded cable provide good electromagnetic shielding. Its magnetic field susceptibility is less than 225 mg/gauss, meaning it can operate stably even in strong magnetic field environments.

Environmental Sealing: The sensor case is made of 316L stainless steel and is hermetically sealed, achieving an IP68 Rating (dust-tight and watertight), allowing it to withstand 100% condensing humidity and harsh industrial environments.

IV. Key Performance and Technical Characteristics

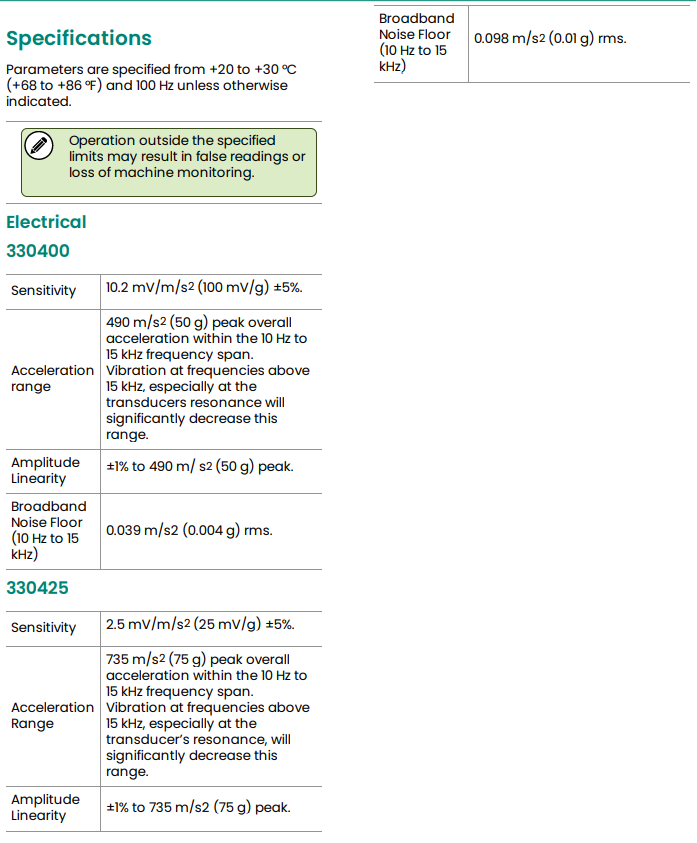

Electrical Characteristics

Sensitivity: 100 mV/g ±5%, providing a high signal-to-noise ratio output.

Range: 50 g peak, suitable for vibration monitoring in the vast majority of industrial machinery.

Amplitude Linearity: High accuracy of ±1% up to full scale.

Broadband Noise Floor: As low as 0.01 g rms, enabling detection of very weak vibration signals.

Output Impedance: Low impedance voltage output, allowing the use of cables up to 305 meters long without significant signal degradation.

Mechanical and Physical Characteristics

Robust Construction: 316L stainless steel case offers excellent corrosion resistance.

High Shock Survivability: Can withstand 5000 g peak shock, ensuring survival under extreme conditions.

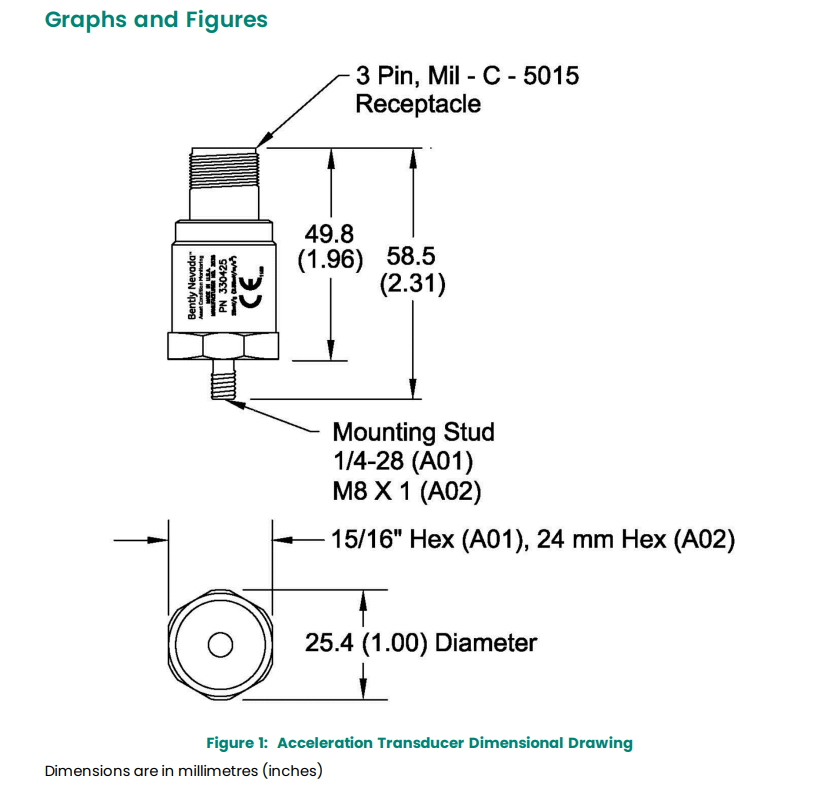

Compact Design: 23 mm diameter, 59 mm height (including mounting stud), ~99 g weight, facilitating installation in space-constrained locations.

Reliable Connection: Uses a 3-pin MIL-C-5015 stainless steel connector, providing a secure, corrosion-resistant connection.

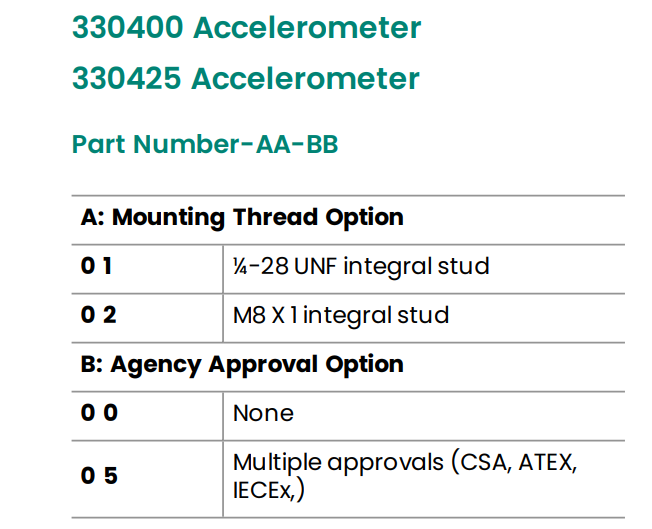

Installation Flexibility: Offered with 1/4-28 UNF or M8x1 integral stud options to suit different mounting needs. Mounting torque is 4.1 Nm.

Safety and Certifications

Functional Safety: Supports SIL 2 level for use in safety instrumented systems.

Hazardous Area Certifications: Possesses multiple explosion-proof certifications including ATEX, IECEx, cNRTLus, permitting use in hazardous areas with explosive atmospheres (e.g., Class I, Division 1, Groups A, B, C, D) when connected via appropriate intrinsic safety barriers.