The IS200TBCIH1B Contact Input Terminal Board (Terminal Board Contact Input with Group Isolation) is a critical discrete input interface component within the GE Mark VI turbine control system, specifically designed for the control and monitoring of industrial gas and steam turbines. This board provides 24 channels of dry contact inputs, featuring electrical isolation, noise suppression, and high reliability, making it suitable for demanding industrial environments. The IS200TBCIH1B version is optimized for the Mark VI system, working in conjunction with VCCC/VCRC processor boards, and supports both Simplex and Triple Modular Redundancy (TMR) architectures. It is widely used in automation control systems for power generation, oil & gas, marine, and other fields.

2. Functional Features

2.1 High-Reliability Isolation Design

The IS200TBCIH1B employs a Group Isolation architecture, using optocoupler isolators to provide complete electrical isolation between field contact signals and the internal control system circuitry. This effectively prevents ground loop interference, voltage surges, and common-mode noise from affecting the system, ensuring accurate signal acquisition and equipment safety.

2.2 Noise Suppression and Filtering

Each input channel is equipped with hardware noise suppression circuitry, effectively suppressing high-frequency noise and transient voltage surges. With a filter time constant of approximately 4 ms, it ensures stable contact state acquisition in industrial electromagnetic interference environments.

2.3 Flexible Power Supply Configuration

Supports floating DC excitation power supply with a voltage range of 100–145 V DC. The power supply includes current limiting protection in the distribution module to prevent short-circuit damage. The board design is compatible with different voltage levels in the TBCIH series (e.g., H2: 24 V DC, H3: 48 V DC), allowing users to select based on field signal types.

2.4 Maintainability Design

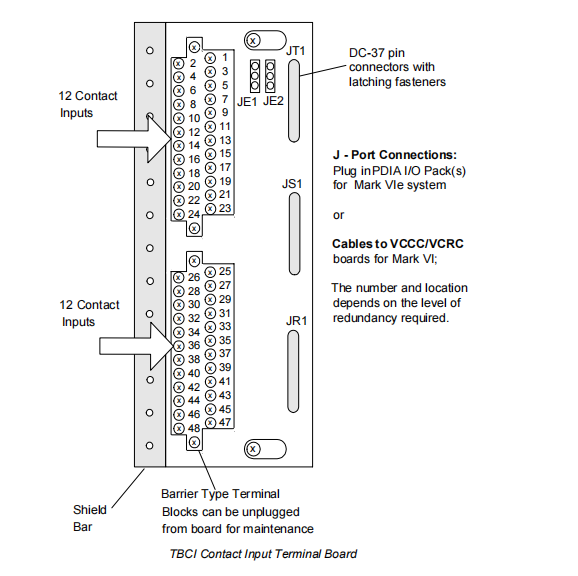

Pluggable Terminal Blocks: Two 24-point terminal blocks are secured with screws, allowing for quick field replacement and wiring maintenance.

Shield Grounding Bar: A shield terminal strip attached to chassis ground is located next to each terminal block, facilitating cable shield grounding and improving noise immunity.

Modular Connection: Connects to processor boards or PDIA I/O Packs via standard DC-37 pin connectors (JR1, JS1, JT1), supporting hot-plugging (where permitted by the system).

2.5 Multi-Layer Diagnostics and Protection

Excitation Voltage Monitoring: Real-time monitoring of the input power supply. If the voltage drops below 40% of the nominal value, a diagnostic alarm is triggered and latched by the I/O pack/board.

Contact State Test: Supports a software-forced test mode that sets all inputs to the "open" (fail-safe) state to verify contact response.

TMR Voting Verification: In redundant systems, if an input does not match the voted value from the triple-redundant boards, a fault is logged.

Intelligent Identification: Each terminal board connector has a built-in read-only ID device containing the board's serial number, type, revision, and connector location (JR1/JS1/JT1). The controller reads this chip and generates a hardware incompatibility fault if a mismatch is detected.

3. Detailed Working Principle

3.1 Signal Input and Conditioning

Field dry contacts (e.g., relay contacts, switches) are connected via a two-wire system to the terminal blocks: one wire to the positive (+) terminal and one to the return (-) terminal. When the contact closes, current flows from the excitation power supply through a current-limiting resistor and the input filter to the input of the optocoupler. The input filter circuit uses an RC structure to effectively suppress high-frequency noise and surges, ensuring a stable signal.

3.2 Optoelectronic Isolation and Signal Conversion

Each filtered input signal enters a high-speed optocoupler isolator. The input side of the optocoupler shares a ground with the field side, while the output side shares a ground with the system side. The signal is transmitted via a light beam between them, achieving electrical isolation. The isolation voltage rating complies with the NEMA Class G standard, capable of withstanding high transient voltages.

The optocoupler output signal is shaped by a Schmitt trigger and converted into a digital logic level signal, which is then sent to the I/O processor (VCCC/VCRC or PDIA). The isolation reference voltage is set to 50% of the applied floating supply voltage, ensuring accurate contact state judgment even during power supply fluctuations.

3.3 Power Supply and Threshold Management

The excitation power supply uses a floating design and is not directly grounded, reducing ground loop interference. The system incorporates a voltage tracking and clamping circuit that forces all contacts to be recognized as "open" when the supply voltage drops below 13% of its nominal value, implementing fail-safe protection.

3.4 Redundancy Architecture Support

Simplex System: Uses only connector JR1 to connect to one I/O processor.

Dual Redundancy: Uses connectors JR1 and JS1 to connect to two separate processors.

Triple Modular Redundancy (TMR): Uses connectors JR1, JS1, and JT1 to connect to three independent processors, implementing a two-out-of-three voting logic to enhance system availability.

3.5 Communication and Data Transfer

The processed discrete signals are transmitted via the backplane bus (e.g., VME bus or Ethernet) to the system controller (e.g., Mark VI controller) to participate in logic operations, protective interlocking, and status monitoring. In Mark Vle systems, the PDIA I/O Pack plugs directly into the TBCI and communicates with the controller via Ethernet.

4. System Integration and Applications

4.1 Application in Mark VI Systems

The IS200TBCIH1B works with the VTCC (VCCC) or VCRC processor board, connected via shielded cables with latching fasteners to the VME rack. Typical applications include:

Steam turbine valve position monitoring

Generator circuit breaker position feedback

Protection system contact inputs

Auxiliary equipment run status acquisition

4.2 Application in Mark Vle Systems

Requires the use of PDIA I/O Packs, supporting Simplex, Dual, or TMR configurations. One TBCI can accommodate up to three PDIA Packs, secured by side-mounting brackets. Suitable for distributed I/O architectures, simplifying wiring and improving system scalability.

4.3 Typical Wiring Example

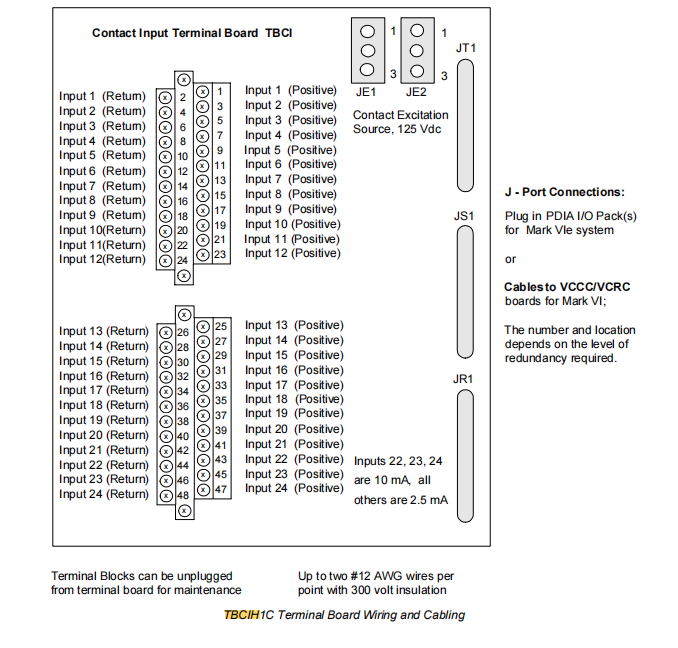

Power Connection: Connect the 125 V DC floating power supply via JE1 and JE2.

Signal Connection: Connect the 24 contact pairs to the two terminal blocks, observing polarity.

Shield Grounding: Connect cable shields to the grounding bar next to the terminal blocks.

Communication Connection: Use connectors JR1, JS1, and JT1 as needed based on the redundancy level to connect to processor boards or PDIA Packs.

5. Installation and Maintenance Guide

5.1 Installation Notes

Ensure the power supply voltage is within the 100–145 V DC range.

Use wires with 300 V insulation rating; maximum wire size is #12 AWG.

Cable shields should be grounded at a single point to avoid ground loops.

In TMR systems, the three communication cables should be of equal length to minimize transmission delay differences.

5.2 Maintenance Operations

Terminal Block Replacement: Loosen the securing screws to unplug the terminal block without disconnecting wires.

Firmware Update: For Mark Vle systems, the latest firmware can be downloaded to the PDIA Pack using the ToolboxST software.

Diagnostics Viewing: View input status, alarms, and fault records via the system HMI or ToolboxST software.

5.3 Troubleshooting Suggestions

If an input channel shows no signal, check if the contact is closed, wiring is secure, and power is present.

For an "Excitation Voltage Loss" alarm, check the power module output and connections at JE1/JE2.

For a "Hardware Mismatch" fault, verify connector ID recognition; replace the board if necessary.