The IS200VSVOH1B Servo Control Board is a core component of the GE Mark VI gas turbine control system, designed for high-precision, high-reliability industrial control applications. As the control core of electro-hydraulic servo valves, the IS200VSVOH1B is responsible for precisely regulating the opening of steam and fuel valves, thereby enabling accurate control of gas turbine power, speed, and process parameters.

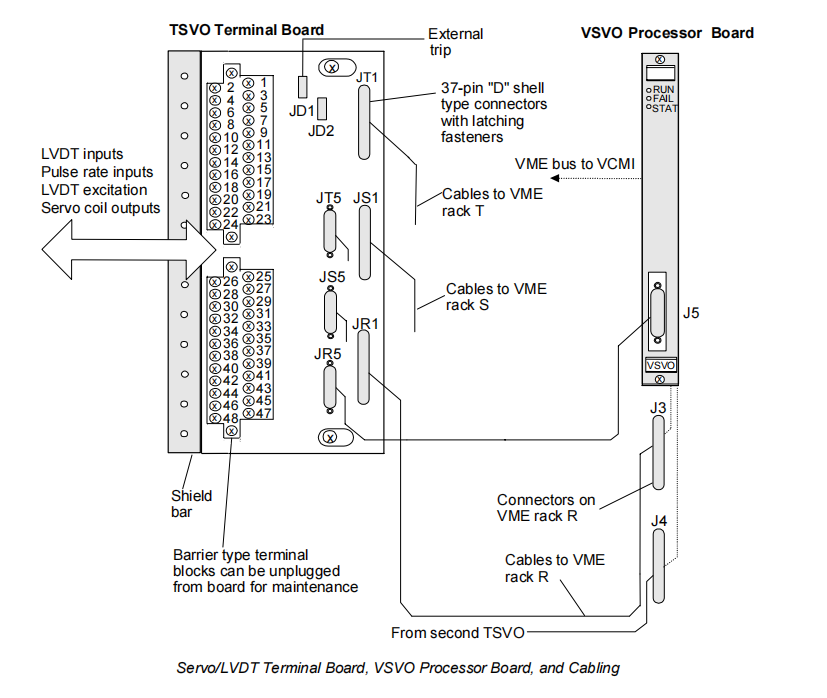

This system adopts a modular, highly integrated board design, integrated into a standard VME rack, and connects to field sensors and actuators via TSVO (or DSVO) terminal boards. The core of the VSVO lies in its advanced digital servo regulation algorithm and powerful hardware support. It can simultaneously handle up to four independent servo control channels and supports different system architectures from Simplex to Triple Modular Redundancy (TMR), meeting application requirements from conventional to extremely high safety levels.

Core Functions and Features

The IS200VSVOH1B Servo Control Board possesses a series of powerful functions and design features, ensuring its stable, precise, and safe operation in harsh industrial environments.

1. Multi-Channel Independent Control:

The IS200VSVOH1B board can simultaneously control four independent servo control channels. Each channel includes bidirectional servo current output, LVDT position feedback signal processing, LVDT excitation source, and pulse rate flow input. This means a single board can manage multiple critical valves, improving system integration and cabinet space utilization.

2. High-Precision Position Feedback and Excitation:

LVDT/LVDR Support: The system uses Linear Variable Differential Transformers (LVDT) or Linear Variable Differential Reluctance sensors (LVDR) as the primary feedback devices for valve position, providing non-contact, highly reliable position measurement. Each TSVO terminal board can connect and process up to 6 LVDT winding signals.

Integrated Excitation Source: The VSVO provides an isolated 3.2 kHz, 7 Vrms sine wave excitation signal specifically for powering LVDTs. This excitation source features low harmonic distortion (<1%) and can operate under common-mode voltages as high as 35V DC or RMS, offering strong anti-interference capability.

Flexible Configuration: The control loop can be flexibly configured to use 1, 2, 3, or 4 LVDTs as feedback based on application requirements. In TMR systems, LVDT signals are fanned out to three independent control racks through terminal boards (JR1, JS1, JT1), enabling redundant input.

3. Pulse Rate Input Monitoring:

A dedicated J5 connector on the front panel of the IS200VSVOH1B board provides two pulse rate input channels for connecting active probes or passive magnetic pickups (MPU) in gas turbine flow measurement applications.

Supports a high-frequency range (2 Hz - 30 kHz). High-speed counting is performed via the onboard FPGA and converted into flow or speed signals, serving as feedback for flow regulation loops or for monitoring.

4. Powerful and Configurable Servo Output Drive:

Each servo output channel can drive single-coil (simplex applications) or up to three-coil (TMR applications) servo valves.

By configuring jumpers (JP1, JP2, JP3, etc.) on the TSVO terminal board, various standard bidirectional current source output ranges (e.g., ±10mA, ±20mA, ±40mA, ±80mA, ±120mA) can be selected to match servo coils of different impedances (e.g., 22Ω, 89Ω, 1kΩ).

Supports long-distance transmission, with servo cable lengths up to 300 meters (maximum two-wire resistance of 15Ω).

5. Comprehensive Fail-Safe and Diagnostic Protection:

Suicide Relay: Each servo output is equipped with a firmware-controlled "suicide" relay. Upon detection of a severe fault (e.g., loss of current control, feedback exceeding limits), the relay activates, shorting the servo output to signal common, forcing the valve to a safe position (typically closed). A manual reset command is required for recovery.

External Trip Protection: Receives external trip signals from the protection module (<P>) via the JD1/JD2 connectors on the terminal board. In emergencies such as overspeed, the K1 relay on the terminal board activates, disconnecting the IS200VSVOH1B output and applying a closing bias to the valve, providing an additional layer of hardware protection (primarily for simplex systems).

Online Diagnostics: The system continuously monitors key parameters such as servo output voltage, current, suicide relay status, LVDT excitation voltage, and A/D calibration voltage. Features open/short circuit detection to identify open circuits or high-impedance faults in servo coil wiring.

TMR Differential Comparison: In TMR systems, input signals from three racks are compared. If the difference exceeds the set limit, a fault indication is generated, aiding in locating sensor or channel issues.

6. Digital Servo Regulator:

The core of the IS200VSVOH1B is its digital servo regulator firmware. It divides the control loop into software (in the controller) and hardware (on the VSVO board) portions, supporting multiple regulator types (RegType). Users can select based on the control object (position, flow) and redundancy requirements, such as single LVDT position loop, dual LVDT min/max selection, three LVDT median selection, and the specialized 4_LV_LM mode for specific machinery.

Working Principle

The IS200VSVOH1B Servo Control System constitutes a complete closed-loop control circuit. Its working principle can be summarized as a cyclical process of "Measurement - Comparison - Calculation - Drive - Feedback."

1. Signal Input and Acquisition:

Position Feedback: The LVDT mounted on the valve actuator outputs a 3.2 kHz AC voltage signal (Vrms) proportional to the displacement of its core, which moves with the valve stem. This signal is fed through the TSVO terminal board, undergoes noise suppression and conditioning, and is sent to the VSVO board.

Pulse Rate Feedback (Optional): Pulse signals from flow meters or speed sensors are directly connected to the J5 port on the VSVO front panel. The onboard FPGA performs high-speed counting and frequency calculation, converting them into flow or speed values in engineering units (e.g., GPM, RPM).

2. Feedback Processing and Selection:

For Position Loops: Based on the configured RegType, the system processes the input LVDT signals. For example, in 2_LVposMIN mode, the system compares the feedback values from two LVDTs and selects the smaller one as the valid position signal, implementing a "fail-small" safety logic (e.g., preventing excessive valve opening). The system also performs boundary checks and calibration on the raw LVDT voltage, converting it into an engineering value representing the actual physical position (0-100%).

Calibration Function: During maintenance, calibration mode can be initiated via the Toolbox. By driving the valve to its minimum and maximum mechanical stops, the system automatically records the corresponding MnLVDTx_Vrms and MxLVDTx_Vrms values for each LVDT and calculates internal scaling and offset parameters to ensure accurate position measurement.

3. Control Algorithm Execution:

The controller (VCMI) generates the valve position setpoint (Regn_Ref) based on the control strategy and sends it to the VSVO via the IONet.

The VSVO's digital servo regulator compares the received position setpoint with the processed actual position feedback (Regn_Fdbk) to calculate the position error (Regn_Error).

The error signal is amplified by a configurable proportional gain (RegGain), and a null bias (RegNullBias) used to balance the valve spring force is added. In some complex modes (e.g., 4_LV_LM), it may also undergo dynamic compensation like lead-lag filtering.

Finally, a servo current command (mA_cmdn) is generated, representing the magnitude and direction of current required to be injected into the servo coil to achieve the target position.

4. Current Drive and Output:

The current command is sent to the hardware current regulator (D/A converter and power amplifier circuit) on the VSVO board.

The current regulator produces a precise bidirectional analog current, which is output to the coil of the electro-hydraulic servo valve via the TSVO terminal board.

Based on the magnitude and direction of the current, the servo valve regulates the direction and flow of hydraulic fluid, thereby driving the hydraulic actuator to move the valve toward the target position.

5. Real-Time Monitoring and Protection:

Servo Current Monitoring: The system continuously monitors the output current feedback (IMFBKn) and compares it with the current command. If the error consistently exceeds the Sui_Margin setpoint, the current loop is deemed out of control, triggering the "suicide" logic.

Position Feedback Monitoring: Continuously checks if the position feedback value is within the reasonable range defined by MinPOSvalue and MaxPOSvalue (with an additional Fdbk_suicide_margin safety margin). If limits are exceeded, it similarly triggers servo suicide or generates a diagnostic alarm.

Hardware Self-Test: The VSVO board periodically checks the status of its key hardware, such as the A/D converter calibration voltage and LVDT excitation source voltage. Any anomalies are recorded in onboard diagnostic variables and reported via front panel LED indicators (RUN green flash, FAIL solid red, STATUS steady orange) and the composite diagnostic signal (L3DIAG_VSVO) sent to the controller.

Application & Maintenance

Typical Applications:

The VSVO Servo Control System is primarily applied in GE Frame series gas turbines and steam turbines to control fuel valves (gas valves, fuel oil valves) and steam valves (inlet control valves, bypass valves, etc.). It is a key actuation control unit ensuring safe, efficient, and flexible operation of the unit.

Configuration & Maintenance:

Configuration: Using the dedicated Toolbox software, engineers can flexibly configure each channel's regulator type (RegType), gain, limits, alarm parameters, redundancy strategy, etc., to adapt to different valve characteristics and control requirements.

Installation: The board uses standard VME installation, with connectors featuring latching mechanisms for reliable connection.

Diagnostics: Rich diagnostic functions facilitate rapid fault location, including a detailed fault code table (e.g., Flash CRC error, board ID mismatch, LVDT voltage out of limits, servo current anomaly), significantly reducing Mean Time To Repair (MTTR).