The CA901 piezoelectric accelerometer is a high-performance vibration monitoring device developed by VM for extreme environment applications. This product utilizes advanced single-crystal piezoelectric materials and technology, offering exceptional temperature adaptability and reliability, capable of stable operation within an extreme temperature range of -186°C to +700°C. The CA901 is particularly suitable for demanding industrial sectors such as nuclear power plants, aerospace, and petrochemical industries, meeting vibration monitoring requirements in various harsh environments.

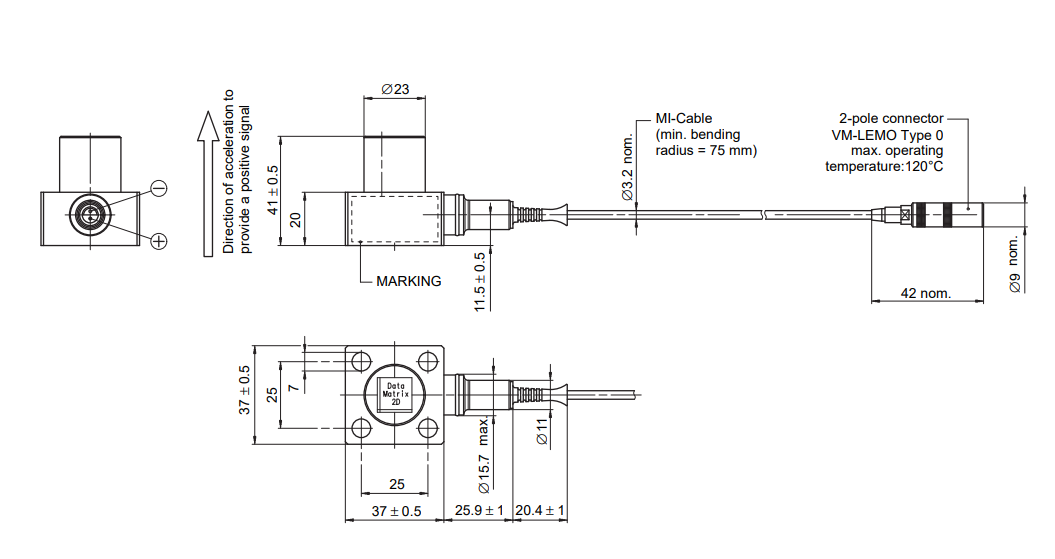

This accelerometer employs a compression mode design equipped with integral mineral insulated cable, providing excellent electrical insulation performance and mechanical durability. The product complies with NRC Guide 1.133, IEEE 323-1974 standards, and is certified according to DIN 25.475.1, while also obtaining explosion-proof certification for safe use in potentially explosive atmospheres. Its compact structural design and rugged housing material enable it to withstand extreme conditions including high pressure and high radiation.

The CA901 offers a frequency response range of 3Hz to 2800Hz and sensitivity of 10pC/g, enabling precise capture of various mechanical vibration signals. Whether for long-term online monitoring or development testing applications, this device can provide reliable and accurate measurement data, serving as crucial evidence for equipment condition monitoring and fault diagnosis.

Working Principle

The CA901 piezoelectric accelerometer operates based on the piezoelectric effect principle, incorporating multiple sophisticated technical aspects. The working mechanism can be elaborated in detail through the following aspects:

1. Piezoelectric Effect and Single-Crystal Material Characteristics

The device core utilizes VC2-type single-crystal piezoelectric material, which offers excellent piezoelectric properties and temperature stability. When the accelerometer experiences mechanical vibration, the mass applies compressive force to the piezoelectric crystal. According to the direct piezoelectric effect principle, electrical polarization occurs within the crystal, lattice structure deforms, causing displacement of charge centers, thereby generating charge signals proportional to the applied force on the crystal surface. Single-crystal materials compared to polycrystalline materials exhibit higher piezoelectric constants and better temperature stability, maintaining stable sensitivity output in extreme temperature environments.

The special lattice structure of VC2 single-crystal material enables it to maintain stable piezoelectric characteristics in high-temperature environments, with its Curie temperature far exceeding conventional piezoelectric materials, which is key to achieving +700°C high-temperature operation. The crystal orientation is optimally designed to maximize the piezoelectric coefficient while minimizing the temperature coefficient, ensuring consistent performance throughout the entire operating temperature range.

2. Compression Mode Design and Mechanical Structure

Employing a compression mode design, the piezoelectric element is preloaded between the base and the mass, forming a stable mechanical structure. This design provides high stiffness, giving the sensor a high resonant frequency (>17kHz), ensuring flat response across a wide frequency range. The compression mode offers better high-temperature performance compared to shear mode, making it more suitable for extreme temperature environment applications.

The mechanical structure uses a symmetrical design to reduce measurement errors caused by thermal stress. The housing employs Inconel 600 alloy material, offering excellent high-temperature strength and corrosion resistance. The overall structure is optimized through finite element analysis to maintain stable mechanical characteristics during thermal cycling, avoiding performance drift due to thermal expansion coefficient mismatch.

3. Signal Generation and Transmission Mechanism

The device generates charge output signals with sensitivity of 10pC/g±5%. The charge output mode offers the advantage of being unaffected by cable capacitance, particularly suitable for long-distance signal transmission. The internal sensor capacitance is 80pF (between poles) and 18pF (between pole and case), while cable capacitance is 200pF/m (between poles) and 300pF/m (between pole and case).

Charge signals are transmitted through mineral insulated cable, which uses magnesium oxide insulation and stainless steel sheath, offering excellent high-temperature performance and mechanical strength. The cable is connected to the sensor using hermetic welding, forming a completely sealed structure that prevents moisture and contaminant intrusion. This design ensures long-term reliability in extreme environments.

4. Temperature Compensation and Stability Control

VC2 single-crystal material has an extremely low temperature coefficient, maintaining stable sensitivity within the operating temperature range of -54°C to +650°C. Special crystal cutting direction and electrode design further improve temperature characteristics, reducing the impact of temperature changes on measurement accuracy.

The device uses a thermally symmetric structure design to minimize the impact of temperature gradients on measurements. The selection of housing material considers thermal expansion matching to avoid performance changes caused by thermal stress. These design features collectively ensure measurement stability in extreme temperature environments.

5. Environmental Protection and Sealing Technology

The sensor uses hermetic sealing welding technology, with the housing completely sealed to resist humidity, chemical corrosion, and radiation effects. The Inconel 600 housing material offers excellent corrosion resistance, suitable for various harsh industrial environments.

The mineral insulated cable not only provides electrical insulation but also mechanical protection. The stainless steel sheath of the cable can withstand pressure of 140bar (at 23°C) and 80bar (at 300°C), ensuring reliable operation in high-pressure environments.

6. Explosion-Proof Safety Design

The device is certified through EC type examination (LCIE 08 ATEX 6017 X II 1 G), meeting usage requirements for Zone 0/1/2 hazardous areas. Using intrinsic safety (Ex ia) design, ignition sparks are prevented under fault conditions by limiting circuit energy.

Protection measures include energy limiting circuits and safety barriers, ensuring compliance with explosion-proof requirements under all operating conditions. This design enables safe application in potentially explosive atmospheres.

7. Radiation Resistance Design

VC2 single-crystal material has excellent radiation stability, able to withstand γ radiation flux of 10^11 erg/g and neutron radiation flux of 10^18 n/cm^2 without any effects. This radiation hardness makes it particularly suitable for applications in radiation environments such as nuclear power plants.

Material selection and structural design both consider long-term stability in radiation environments, ensuring reliable performance under radiation conditions.

Features

The CA901 piezoelectric accelerometer offers multiple outstanding features to meet vibration monitoring needs in extreme environments:

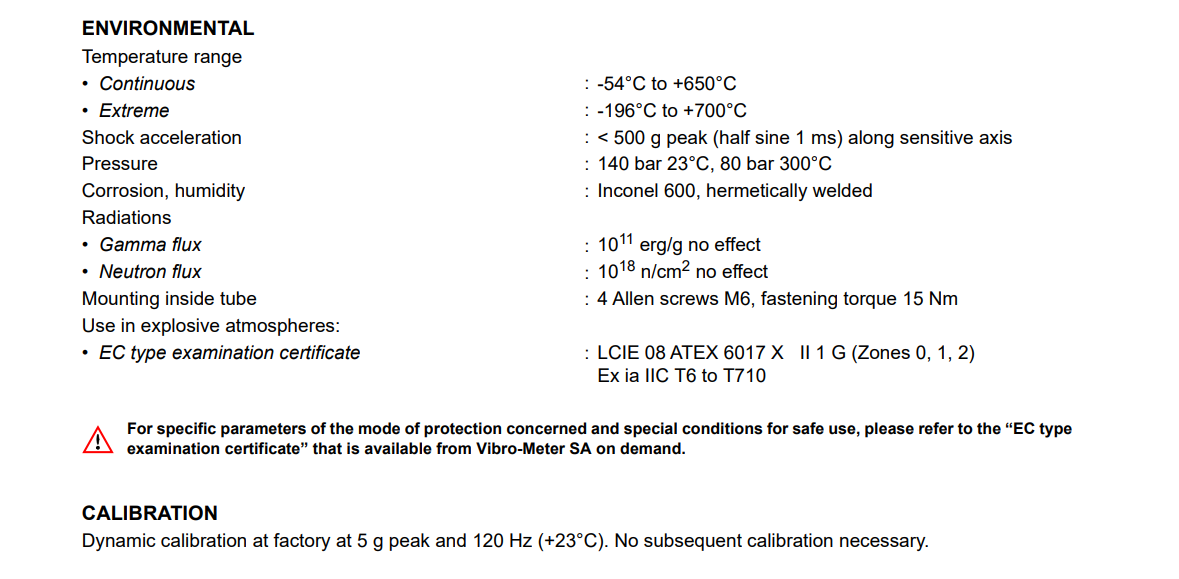

1. Extreme Temperature Adaptability

Extremely wide operating temperature range: continuous operation -54°C to +650°C, extreme conditions -196°C to +700°C. This temperature range covers most industrial extreme environments, including cryogenic and high-temperature application scenarios.

2. High-Precision Measurement Performance

Provides sensitivity of 10pC/g, dynamic measurement range 0.001g to 200g peak. Excellent linearity, achieving ±1% throughout the dynamic range. Transverse sensitivity less than 5%, ensuring measurement accuracy.

3. Excellent Environmental Durability

Inconel 600 housing provides excellent corrosion resistance, hermetic sealing design resists moisture and contaminants. Can withstand working pressure of 140bar, meeting high-pressure environment application requirements.

4. Strong Radiation Resistance

Can withstand high doses of γ radiation and neutron radiation, suitable for use in radiation environments such as nuclear power plants. Material selection and structural design are optimized for long-term stability under radiation conditions.

5. Comprehensive Safety Certification

Certified through multiple international standards: NRC Guide 1.133, IEEE 323-1974, DIN 25.475.1, and ATEX explosion-proof certification. Meets requirements of various stringent industrial standards.

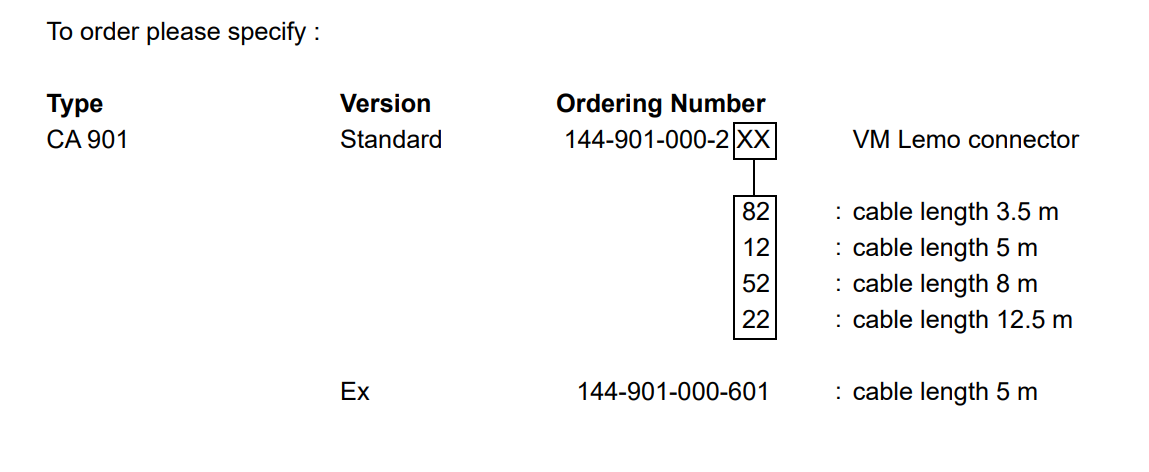

6. Flexible Configuration Options

Offers multiple cable length choices: 3.5 meters, 5 meters, 8 meters, 12.5 meters, equipped with Lemo or high-temperature connectors. Standard and explosion-proof versions available to meet different application needs.

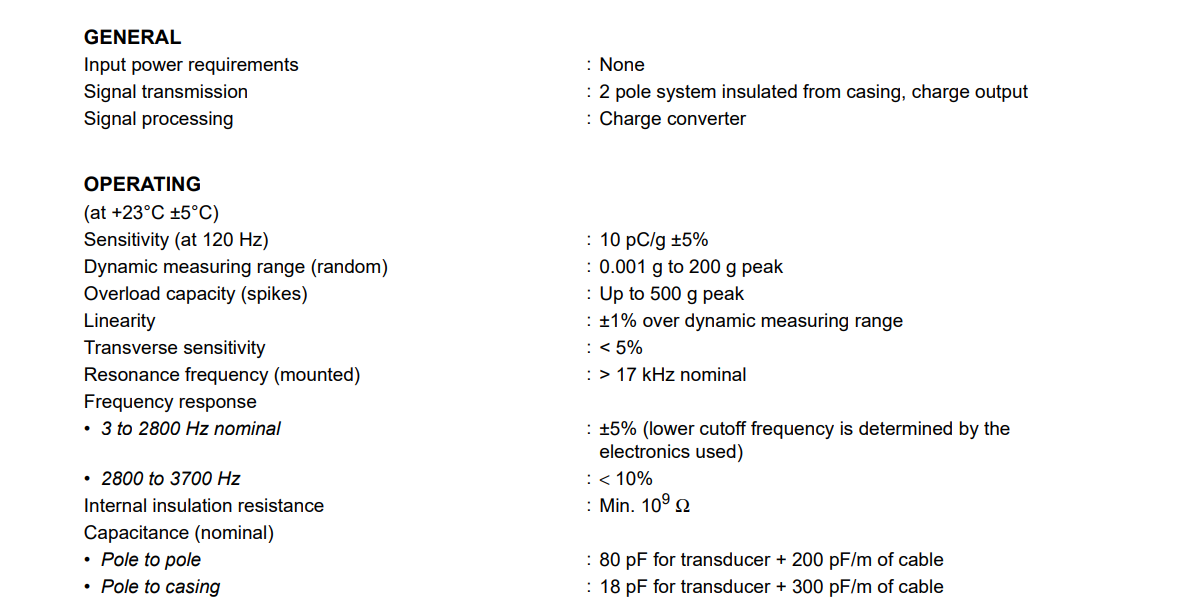

Technical Specifications Summary

| Item | Specification |

| Sensitivity | 10 pC/g ±5% |

| Frequency Response | 3 to 2,800 Hz (±5%) |

| Dynamic Range | 0.001 to 200 g peak |

| Operating Temperature | -54°C to +650°C (continuous) |

| Resonant Frequency | >17 kHz |

| Linearity | ±1% (full scale) |

| Protection Rating | Hermetically sealed |

| Explosion-Proof Certification | Ex ia IIC T6 to T710 |

Application Areas

The CA901 piezoelectric accelerometer is mainly used in the following fields:

Nuclear Power Plants: Vibration monitoring of internal and peripheral equipment in reactors

Aerospace: Vibration testing of engines and high-temperature components

Petrochemical Industry: Equipment condition monitoring in high-temperature and high-pressure environments

Energy Industry: Vibration monitoring of gas turbines and steam turbines

Research Fields: Material and behavior research in extreme environments