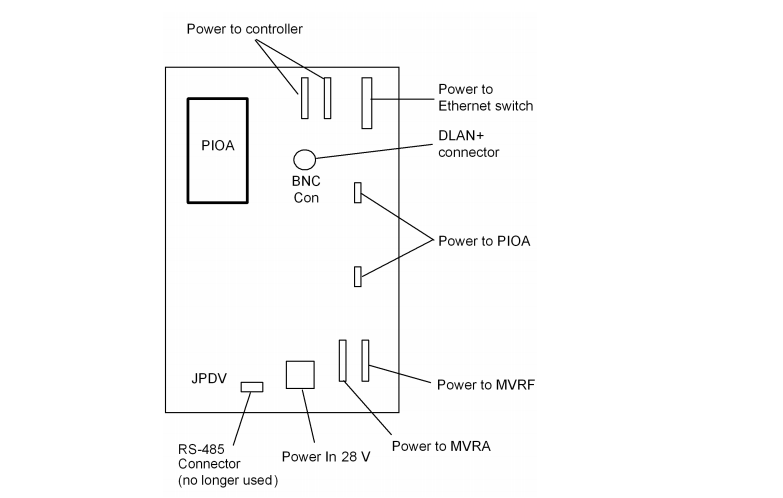

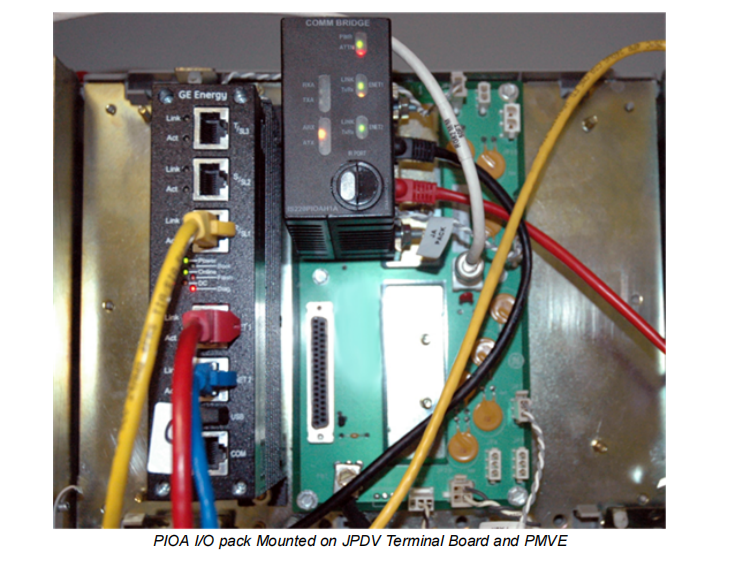

The IS220PIOAH1A (ARCNET Interface Module) is a specialized input/output interface module designed for excitation control systems and is part of the distributed I/O family in the Mark Vle control system. This module communicates with the excitation control system via the ARCNET (DLAN+) protocol, enabling monitoring and control of generator excitation systems. The IS220PIOAH1A module is mounted on the JPDV terminal board and connects via a 37-pin DC connector. It features dual RJ-45 Ethernet ports and a 3-pin power connector, supporting both simplex and redundant configurations. It is suitable for control systems in various generating units, such as gas turbines and steam turbines.

2. Key Functions

2.1 ARCNET Communication Interface

The core function of the IS220PIOAH1A module is to provide an ARCNET (DLAN+) communication interface for high-speed and reliable data exchange with the excitation control system. ARCNET is a token-ring network protocol known for its high real-time performance and strong anti-interference capability, making it ideal for industrial control environments. The IS220PIOAH1A receives command data from the controller via the DLAN+ channel and feeds back field signals (e.g., breaker status, speed, voltage) to the control system.

2.2 Support for Redundant and Simplex Configurations

Simplex Applications: In non-redundant systems, the IS220PIOAH1A is installed only in the <C> core.

Redundant Applications: In systems requiring high reliability, the IS220PIOAH1A can be installed in both the <R> and <C> cores to provide redundant communication paths and enhance system reliability.

2.3 Multi-Protocol Support

Although the RS-485 channel is no longer used in current systems, the IS220PIOAH1A retains its hardware interface for backward compatibility. The module primarily relies on ARCNET for data communication, while the Ethernet ports (ENET1 and ENET2) are used for system-level communication and network redundancy.

2.4 Power Management and Soft-Start Capability

The IS220PIOAH1A module includes an integrated power management circuit with soft-start functionality, effectively suppressing inrush current during power-up. It also features a fast current-limiting function to prevent failures in the I/O pack or terminal board from affecting the 28V DC power system. A green PWR indicator lights up when power is normal.

2.5 Electronic ID Recognition and Hardware Matching

Both the IS220PIOAH1A module and the connected JPDV terminal board are equipped with electronic ID chips. During system power-up initialization, the controller reads these IDs to verify the compatibility between the I/O pack and the terminal board, as well as the consistency of hardware versions, ensuring correct system configuration.

2.6 Status Diagnostics and LED Indicators

The IS220PIOAH1A module provides multiple LED indicators for real-time status display:

The module also supports self-diagnostics, including memory tests, communication loss detection, and power monitoring.

2.7 Sequence of Events Recording

The IS220PIOAH1A can be configured to generate Sequence of Events (SOE) records, which log changes in excitation logic input signals for troubleshooting and system analysis.

3. Working Principle

3.1 Hardware Architecture

The IS220PIOAH1A module consists of a processor board and an acquisition board:

Processor Board: Handles protocol processing, communication scheduling, self-diagnostics, and data exchange with the controller.

Acquisition Board: Equipped with an ARCNET controller chip, UART (for RS-485), and a CPLD for logic control and signal conditioning of hardware interfaces.

3.2 Communication Mechanism

The IS220PIOAH1A communicates with the excitation control master via DLAN+ (ARCNET). ARCNET is a token-passing LAN protocol with deterministic response characteristics, making it suitable for real-time control systems. The IS220PIOAH1A acts as a node in the network, addressed by a unique DropNumber (in hexadecimal).

During communication:

The controller sends control commands to the IS220PIOAH1A via ARCNET;

Upon receiving commands, the IS220PIOAH1A relays signals to excitation devices through the JPDV terminal board;

The IS220PIOAH1A simultaneously collects field status signals (e.g., breaker status, speed frequency) and feeds them back to the controller via ARCNET.

3.3 Power and Signal Isolation

The IS220PIOAH1A module is powered by 28V DC, with a soft-start circuit controlling the power-up process to prevent impact on the system power supply. The DLAN+ signals are electrically isolated via transformers, with termination resistors located on the BIOA board to ensure signal integrity.

3.4 Electronic ID System

Each IS220PIOAH1A module and JPDV terminal board connector contains a readable ID chip storing hardware type, serial number, revision, and installation location. During system power-up, the controller reads this information to verify hardware compatibility; mismatches trigger hardware fault alarms.

3.5 Fault Detection and Diagnostics

The IS220PIOAH1A module features multi-level diagnostic capabilities:

Power-On Self-Test: Includes RAM, Flash, Ethernet ports, and processor hardware checks;

Continuous Monitoring: Covers internal power status and communication link status;

Communication Loss Detection: Triggers alarms when ARCNET or IONet-485 communication is interrupted;

Hardware Configuration Check: Verifies consistency between software configuration and hardware settings, such as TCEA/TCDA EPROM versions and jumper settings.

4. Installation and Configuration

Installation Steps:

Secure the JPDV terminal board to the core board holder.

Insert the IS220PIOAH1A into the JA1 connector (only JA1 supports ARCNET protocol).

Mechanically secure the I/O pack using threaded studs to avoid lateral force on the connector.

Connect one or two Ethernet cables (ENET1 is typically connected to the R controller network).

Connect the 28V power supply; the module supports hot-plugging.

Configure the module using the ToolboxST software.

Software Configuration:

In the ToolboxST "Component Editor":

Select "Add Module";

Set network redundancy type (e.g., TMR) and module redundancy (Simplex only);

Select the IS220PIOAH1A module type;

Configure the terminal board connector as JA1;

Set parameters such as ARCNET address, network type, and SOE recording.

5. Typical Applications

The IS220PIOAH1A module is widely used in the following control systems:

Gas Turbine Excitation Control

Steam Turbine Protection Systems (medium-pressure, large, and extended types)

Generator Breaker Control and Synchronization Check

Flame Detection and Combustion Management

Speed Monitoring and Overspeed Protection