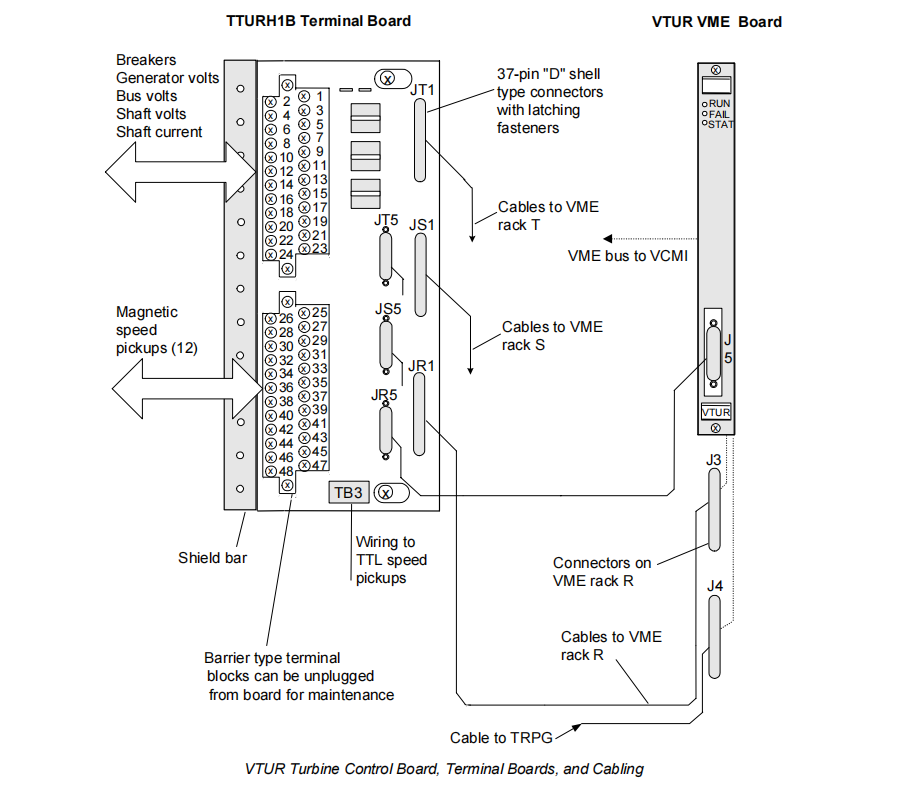

The VTUR Turbine Specific Primary Trip system is a core protective component of the Mark VI gas and steam turbine control system, designed as the first line of defense to ensure the safe operation of turbine units. The IS200VTURH1B is a critical terminal board within this system, acting as the interface hub between the main VTUR control board and field sensors/actuators. It is responsible for aggregating critical signals such as speed, voltage, and flame status, and executing trip and synchronizing commands from the controller. Known for its high reliability, rapid response, and comprehensive diagnostics, this system is widely used in the energy and industrial sectors where the highest safety standards are required.

2. Core Functions & Detailed Principles

The IS200VTURH1B terminal board works in concert with the main VTUR board to implement a multi-layered, redundant protection and control system for turbines.

2.1 Primary Overspeed Protection & Speed Measurement

This is the most critical protection function of the VTUR system, designed to prevent turbine speed from exceeding mechanical design limits and avoiding catastrophic failure.

Technical Principle:

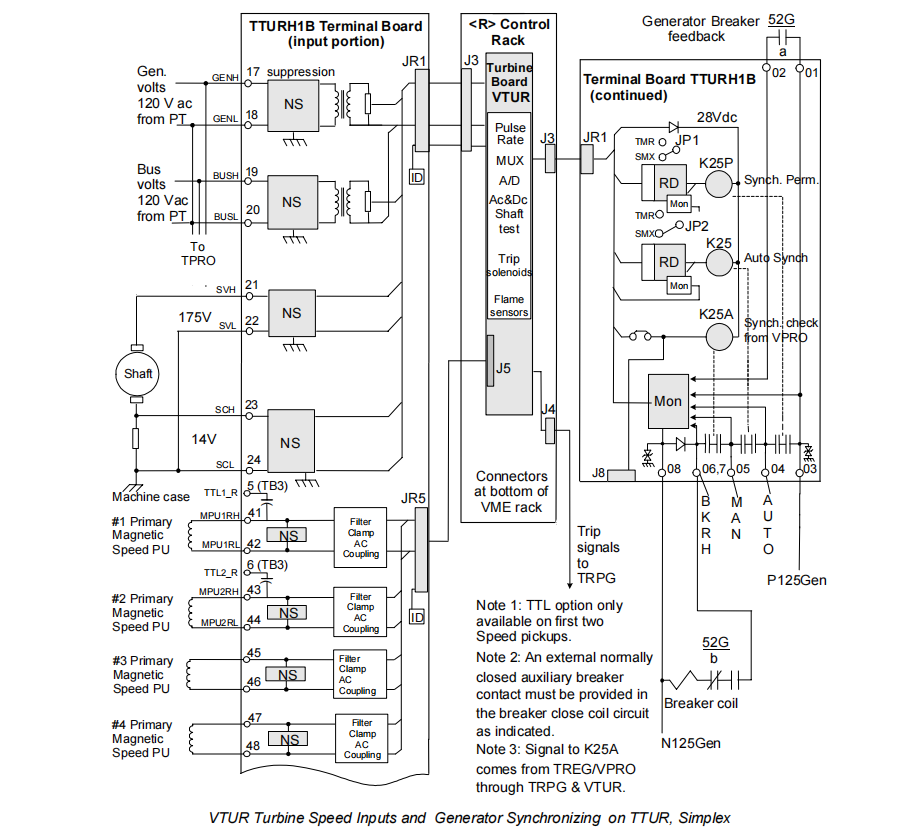

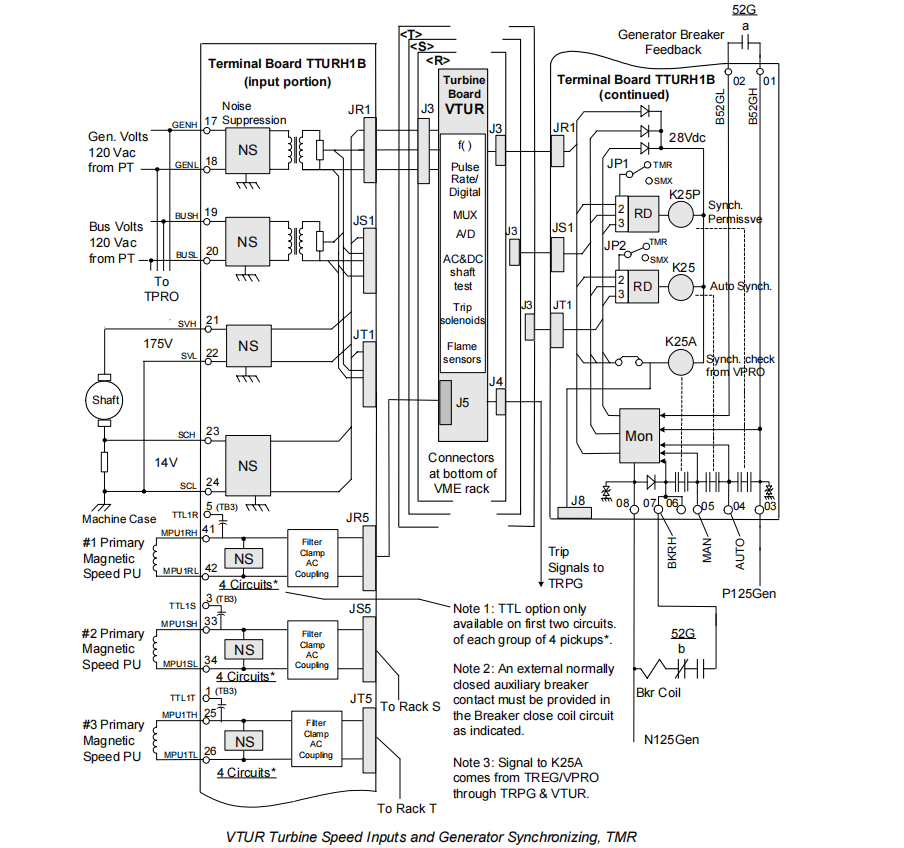

Signal Acquisition: The system connects to four independent passive magnetic speed pickups via the IS200VTURH1B terminal board. These sensors are mounted adjacent to a sixty-tooth speed wheel rotating with the turbine shaft. The alternating tooth and gap change the magnetic flux, generating an AC voltage signal with a frequency proportional to the speed. This design is advantageous as it requires no external power, is robust, and has strong noise immunity.

Signal Processing: The weak sinusoidal signals from the sensors are transmitted via shielded cables to the IS200VTURH1B and then to the VTUR main board. The VTUR contains pulse rate to digital circuits, which first filter the signal (removing high-frequency noise), clamp it (limiting voltage amplitude to protect subsequent circuits), and apply AC coupling (removing DC offset). A Schmitt trigger then converts the sine wave into a square wave pulse train, where each pulse represents the passing of one tooth.

Speed Calculation & Voting: The controller (VCMI) calculates the real-time speed (RPM) by measuring the pulse frequency. In a TMR (Triple Modular Redundant) system, three controller modules calculate the speed independently, and a median value selection is performed—the middle value of the three readings is used as the final valid speed for control and protection. This mechanism can tolerate a failure in any single module or sensor, significantly enhancing system reliability.

Overspeed Trip Logic: The primary overspeed trip calculation is primarily performed in the controller. The controller compares the voted median speed against a preset overspeed trip setpoint. Once the speed exceeds the setpoint, the controller immediately generates a trip signal. This signal is sent to the VTUR board, which then drives the primary trip relays on the TRPx trip terminal board. These relays control the power circuit of the Emergency Trip Solenoids (ETDs). Relay de-energization causes the solenoid to vent pressure, triggering the mechanical hydraulic system to rapidly close the turbine's fuel or steam valves, achieving a shutdown.

2.2 Fast Overspeed Trip

For applications like gas turbines that require extremely fast response, the standard primary overspeed protection may not be sufficiently rapid. Therefore, VTUR incorporates a Fast Overspeed Trip algorithm that runs directly on the VTUR hardware, bypassing the controller and reducing the trip response time to 30 milliseconds or less.

Technical Principle:

PR_Single (Pulse Rate - Single): This algorithm splits two redundant speed sensor signals to two redundant VTUR boards. Each board uses its single sensor signal to make an independent overspeed decision. The system remains operational only if neither board triggers a trip. This provides redundancy at both the sensor and VTUR board level and is the preferred algorithm for LM series gas turbines.

PR_Max (Pulse Rate - Maximum): This algorithm connects two redundant speed sensor signals to a single VTUR board. The board continuously compares the speed values and always uses the higher of the two speeds for overspeed judgment. This method effectively protects against trip failure in cases of "broken shaft" or severe deceleration where one sensor signal fails or erroneously drops, while also avoiding nuisance trips from a single sensor failure.

Algorithm Options: VTUR offers two fast trip algorithms.

Hardware Interlock: The fast trip signal is issued via dedicated outputs (PTR1 to PTR6) on the VTUR board and is connected to the primary trip relay circuit through an OR-gate logic. This ensures that the trip relays will activate whether the standard primary trip OR the fast trip is triggered.

2.3 Shaft Voltage & Current Monitoring

This function protects turbine-generator bearings from electrical erosion damage caused by shaft currents.

Technical Principle:

AC Test: Initiated by the R controller, it injects a 1 kHz test signal into the shaft voltage measurement circuit. The healthy S and T controllers should detect this specific frequency offset. This test verifies the integrity of the entire circuit from VTUR to the measurement point.

DC Test: Also initiated by the R controller, it applies a 5 V DC voltage to the external shaft-to-ground loop and measures the resulting DC current. By calculating the loop resistance, the system can determine if the brush contact resistance (Brush Limit) and the shunt loop (Shunt Limit) are within normal range. Excessively high resistance typically indicates brush wear, poor contact, or an open circuit.

Phenomenon & Hazard: During turbine operation, voltage can build up on the rotor shaft relative to ground due to steam charging (water droplet impingement on blades), generator field ripple, or magnetic circuit asymmetry. When this voltage accumulates enough to break down the bearing oil film, instantaneous discharge currents occur, causing electrical erosion on bearing races and balls (known as frosting), ultimately leading to bearing failure.

Monitoring System: Carbon brushes installed on the shaft guide the shaft voltage to the VTURH1B terminal board. The system monitors both the shaft-to-ground voltage and the shaft current flowing through the brushes (measured via the voltage drop across a precision shunt resistor). VTUR uses high-impedance instrumentation circuits to ensure the original shaft grounding system is not affected.

Self-Diagnostic Tests:

2.4 Flame Detection

In gas turbine applications, VTUR works with the TRPG board to monitor up to eight Geiger-Müller flame detectors.

Technical Principle:

Detector Operation: In the absence of flame, the detector's internal capacitor charges to the 335 V DC supply voltage. When ultraviolet radiation is present, the gas within the detector ionizes, causing the capacitor to discharge rapidly through the TRPG board.

Signal Processing: VTUR and TRPG convert each discharge event into a voltage pulse. Higher flame intensity leads to a higher discharge frequency, with a pulse frequency range of 0 to 1000 pulses per second. VTUR counts the pulses over a 40-millisecond window and compares the pulse rate to a setpoint to determine flame presence and intensity. The voltage pulses are fanned out to all three controller modules (R, S, T), ensuring redundant protection.

2.5 Automatic Synchronization

This function automatically matches the generator's state to the power grid for a smooth, shock-free connection (closure of the main circuit breaker).

Technical Principle:

K25P (Synchronizing Sequence Permissive): From VTUR, it checks whether the turbine's own sequence status permits synchronization.

K25 (Auto Sync Relay): From VTUR, it employs zero-voltage crossing techniques and compensates for the breaker closing time. It predicts the exact moment to close the breaker so that the contacts make when the phase difference is near zero, accounting for the mechanical delay.

K25A (Sync Check Relay): From the VPRO protection board, it acts as an independent backup. It checks against a fixed synchronization window (typically ±10° phase difference, ±0.27 Hz frequency difference). Its contacts close only if all parameters are within this window.

Signal Input: Generator and bus voltages are brought in via two sets of single-phase Potential Transformers (PTs), stepped down to approximately 115 V AC signals for measurement on the VTURH1B board.

Synchronization Process:

Triple Permissive & Breaker Closure: Issuing the automatic closure command requires the simultaneous permission of three independent functions:

Closure & Feedback: When all three permissives are satisfied, VTUR issues the close command to the main generator breaker. A 52G/a auxiliary contact from the breaker itself (not an intermediate relay) feeds the actual closing time back to the system, used to optimize future closure predictions.

Frequency Matching (Speed Adjustment): VTUR compares generator and bus frequencies, generating "Raise" or "Lower" speed commands sent via the controller to the governor system to adjust the generator speed into synchronism with the grid.

Voltage Matching (Excitation Adjustment): VTUR compares generator and bus voltages, sending commands via the UDH network to the EX2000 excitation system to adjust the generator field current, matching the voltage to the grid.

Phase Synchronization: VTUR precisely captures the zero-crossing points of the generator and bus voltage waveforms, calculating the real-time phase difference between them.

3. Hardware Interface & Installation

4. Diagnostics & Maintenance

The VTUR system features comprehensive online diagnostics.

Front Panel LED Indication: RUN (Operating - Flashing Green), FAIL (Fault - Solid Red), STATUS (Normal - Off, Diagnostic Alarm - Steady Orange).

Key Diagnostic Items:

Relay Driver/Feedback Mismatch: Compares the trip relay command signal with its actual feedback state.

Solenoid Power Absent: Monitors the trip circuit power on the TRPx board.

Flame Detector Voltage Abnormal: Monitors if the 335 V DC supply is within tolerance (314.9 V - 355.1 V).

Synchronizing Relay Slow or Locked Up: Monitors the actuation timing of relays K25, K25A, and K25P.

Terminal Board Identification: Reads the ID chip on terminal boards (e.g., TTURH1B) to verify hardware compatibility and correct connection, preventing misconfiguration.

Fault Handling: All diagnostic information triggers a composite L3DIAG_VTUR alarm. Specific fault codes and potential causes can be viewed on the HMI, guiding maintenance personnel to quickly locate the issue.