The Model 330850 25 mm Proximitor Sensor is the core signal conditioning unit of the Bently Nevada 3300 XL 25 mm Proximity Transducer System. This sensor works in concert with a dedicated 25 mm proximity probe and extension cable to form a complete measurement system. Its primary design purpose is to meet the demanding requirements of Differential Expansion measurement on mid-size to large steam turbine generators, while also being suitable for other machinery condition monitoring applications that require an exceptionally large linear measurement range.

Differential Expansion refers to the relative axial growth difference between a turbine rotor and stator (casing) caused by their differing rates of thermal expansion and contraction. Accurate measurement of DE is critical for preventing catastrophic rubbing contact between rotating and stationary components, thereby ensuring the safe and stable operation of large rotating equipment. The 330850 sensor is engineered for this crucial measurement, with its key characteristics being a wide 12.7 mm (500 mils) linear range and an output sensitivity of 0.787 V/mm (20 mV/mil), enabling it to precisely capture and convert micron-level gap changes into a standardized voltage signal.

As part of the 3300 XL series, the 330850 sensor is designed to be electrically and mechanically interchangeable with previous-generation 7200 series and 25 mm DE Integral systems. This allows users to perform a direct upgrade of legacy systems without requiring any changes to the monitor configuration, while benefiting from the enhanced performance and reliability of the XL series.

2. System Working Principle: Eddy Current Sensing and Signal Conditioning

The operation of the 330850 sensor is based on the Eddy Current Sensing Principle, a sophisticated process that accurately converts physical gap (distance) into a linear voltage signal. The working principle can be broken down in detail as follows:

2.1 RF Field Generation and the Eddy Current Effect

The sensor contains a precision Radio Frequency (RF) oscillator. This oscillator supplies a high-frequency (typically on the order of MHz) alternating current to the coil of the connected 25 mm proximity probe via the extension cable. When this current flows through the coil at the probe tip, it generates a high-frequency alternating electromagnetic field that radiates forward from the probe.

When the probe is installed and aimed at a conductive target surface (typically a collar or ramp on a turbine rotor), this alternating electromagnetic field induces circulating, vortex-like electrical currents, known as eddy currents, on the surface of the target. The strength and distribution of these eddy currents are not fixed but are highly dependent on the distance between the probe tip and the target surface.

2.2 Detection of Impedance Change

According to the laws of electromagnetic induction, these induced eddy currents generate their own magnetic field, which opposes the original field from the probe coil (Lenz's Law). This opposing magnetic field acts to cancel out a portion of the probe's original field, and the direct physical effect is a change in the effective impedance of the probe coil.

Specifically:

Decreasing Gap: As the probe moves closer to the target, the electromagnetic coupling strengthens, the eddy current effect becomes more significant, and the coil's impedance decreases substantially.

Increasing Gap: As the probe moves away from the target, the electromagnetic coupling weakens, the eddy current effect diminishes, and the coil's impedance increases accordingly.

Thus, the mechanical change in the gap between the probe and the target is transduced in real-time and with high fidelity into an electrical parameter change: the impedance of the probe coil.

2.3 Signal Demodulation, Amplification, and Standardized Output

The core function of the 330850 sensor is to detect and process this subtle impedance change. Its internal circuitry first demodulates the gap-containing information from the high-frequency carrier signal, resulting in a raw voltage signal that has a non-linear relationship with the gap. Subsequently, through precision linearization circuits, this raw signal is compensated and corrected to produce a strict linear proportional relationship between the output voltage and the physical gap over the specified 0.63 mm to 13.33 mm (25 to 525 mils) linear range.

The final output is a standardized, easy-to-process DC voltage signal:

Linear Range: 0.63 mm to 13.33 mm (25 to 525 mils).

Corresponding Output Voltage: Approximately -1.5 Vdc to -11.5 Vdc.

Average Scale Factor: 0.787 V/mm (20 mV/mil). This means for every 1 millimeter of target movement, the sensor's output voltage changes by 0.787 volts. This lower sensitivity is optimally designed to achieve the wide 12.7 mm linear range.

The system is capable of measuring both static position (e.g., a fixed gap setting) and dynamic changes (e.g., axial shaft float), providing comprehensive data for machinery protection and analysis.

2.4 Complete Interchangeability and Factory Calibration

A key advantage of the 3300 XL system is complete interchangeability. Any 3300 XL 25 mm probe, extension cable, and 330850 sensor can be combined in any order without the need for field calibration or matching. This greatly simplifies spare parts management and field maintenance. This is achieved through:

All components being manufactured to strict, unified specifications.

The sensor being precisely calibrated at the factory for a standard AISI 4140 steel target material. (Calibration to other target materials is available upon request).

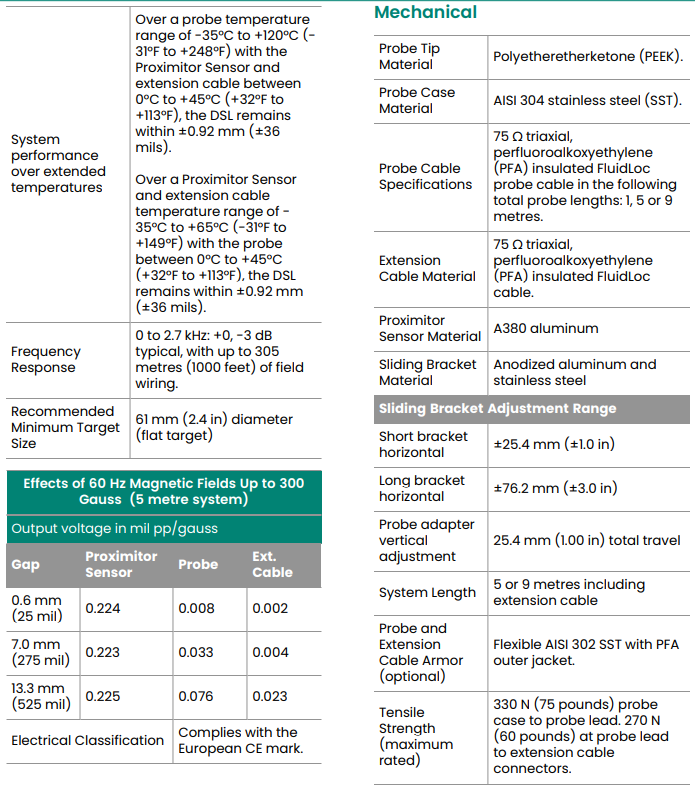

3. Structural and Design Features

3.1 Mechanical Construction and Installation Flexibility

Housing Material: Constructed from A380 aluminum alloy, balancing strength, light weight, and good electromagnetic shielding properties.

Form Factor: A thin design that supports two primary mounting methods:

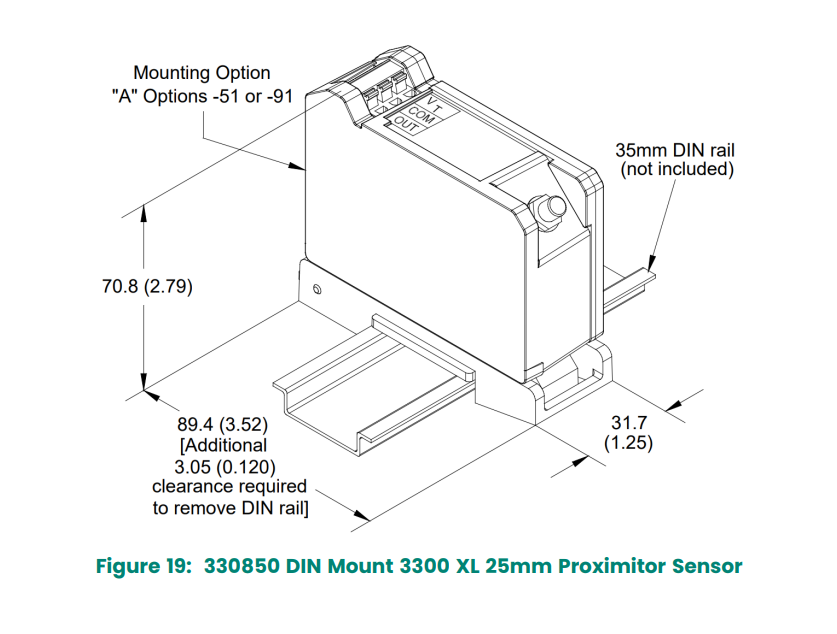

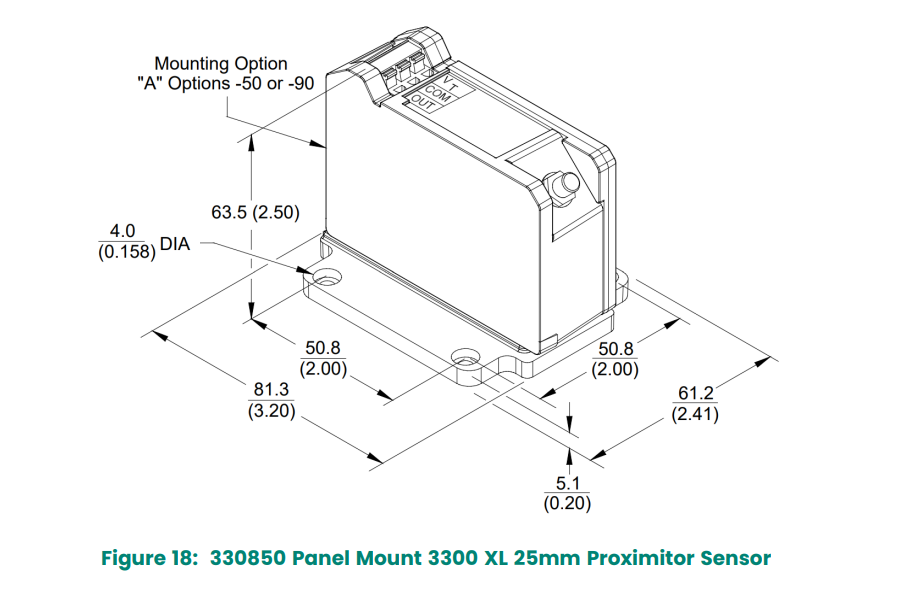

DIN-rail Mount: Ideal for high-density control panel layouts, saving space and enabling easy installation.

Panel Mount: Suitable for traditional mounting methods, providing more robust mechanical fixation.

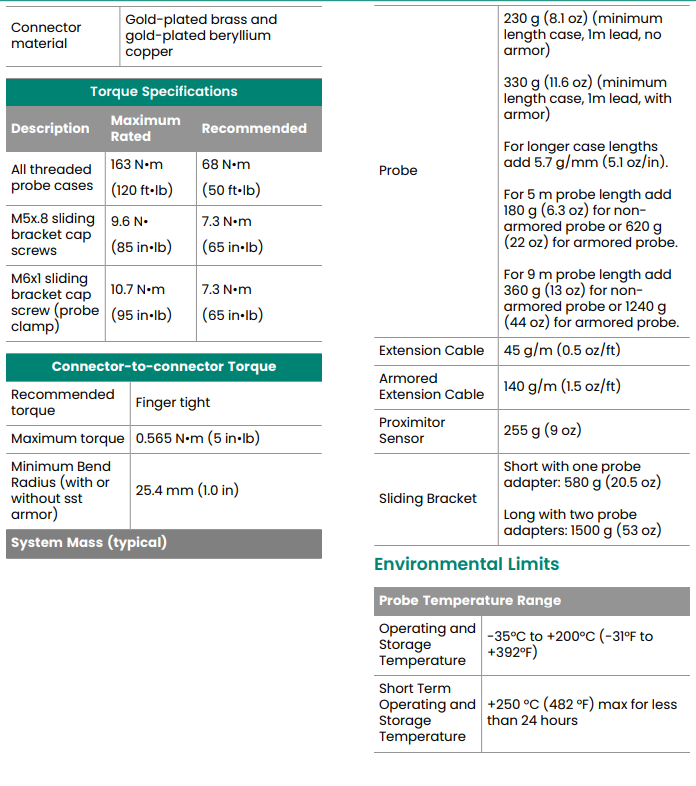

Terminal Connections: Features SpringLoc spring-clamp terminal blocks. This design allows for field wiring without special tools, significantly increasing connection speed and reliability, and effectively preventing wire loosening due to vibration.

3.2 Environmental Ruggedness and Robustness

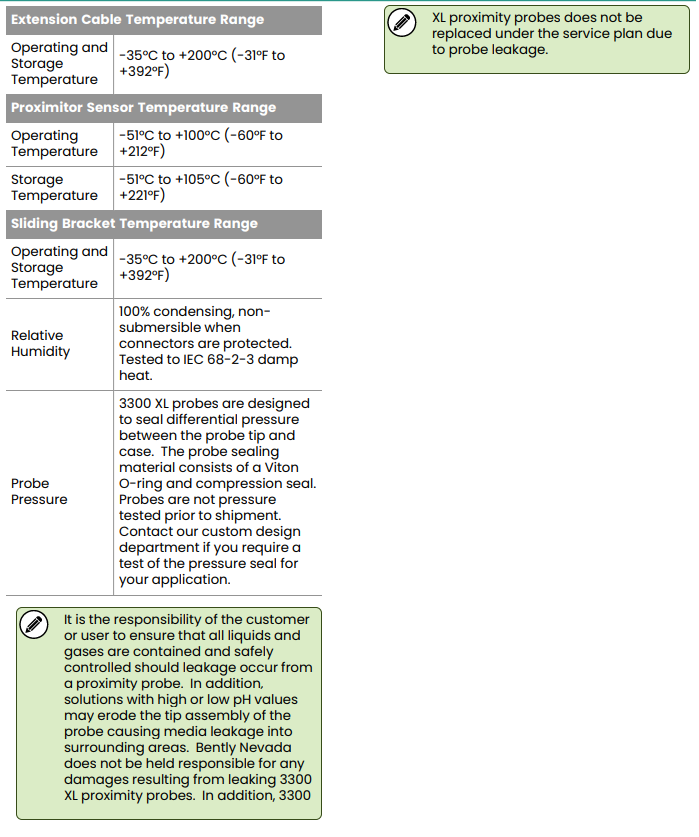

Operating Temperature Range: -51°C to +100°C (-60°F to +212°F), ensuring stable operation in harsh industrial environments.

RFI/EMI Immunity: Optimized design provides excellent immunity to Radio Frequency and Electromagnetic Interference, protecting the output signal from corruption by common high-frequency radio signals on-site. This allows it to readily comply with and achieve European CE mark approvals.

Connectors: The interfaces for the probe and extension cable use special high-temperature ClickLoc connectors, which are corrosion-resistant and vibration-proof, ensuring long-term connection reliability.

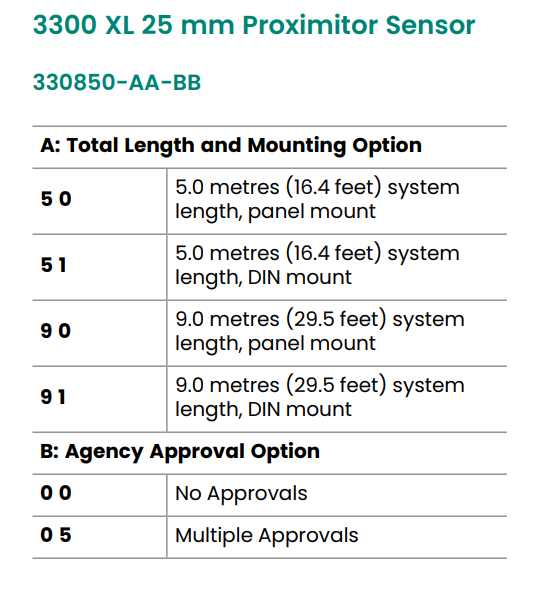

3.3 System Length Options

The 330850 sensor is offered in two preset "system length" options. The user must select the option that matches the total combined length of the probe cable and extension cable for their specific application:

5.0-meter system length

9.0-meter system length

This design ensures the electrical characteristics (e.g., capacitance, resistance) of the entire loop remain within predetermined limits, guaranteeing system performance meets specification sheet metrics.

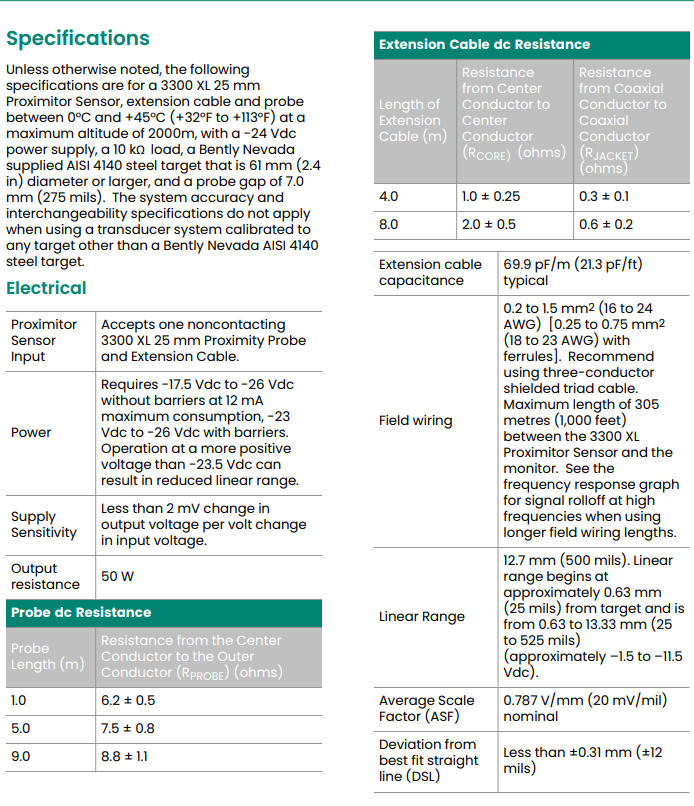

4. Electrical Performance and Technical Specifications

4.1 Power Supply and Consumption

4.2 Output Characteristics

4.3 Accuracy and Linearity

Linear Range: 12.7 mm (500 mils).

Average Scale Factor: 0.787 V/mm (20 mV/mil) nominal.

Deviation from Best Fit Straight Line (DSL): < ±0.31 mm (±12 mils). This specifies the maximum deviation of the actual output curve from an ideal straight line across the entire linear range.

4.4 Frequency Response

4.5 Certifications and Compliance

Complies with CE marking requirements.

Certified to EMC Directive.

Compliant with RoHS Directive.

Holds various Hazardous Area Approvals such as ATEX and IECEx, supporting use in Zone 0/1/2 areas (requires connection to appropriate intrinsic safety barriers or galvanic isolators).

5. Application Scenarios and System Integration

5.1 Core Application: Differential Expansion Measurement

The 330850 sensor system is primarily used for DE monitoring in large turbomachinery like steam turbines and gas turbines. Typical mounting configurations include:

Two Transducers Observing the Same Side of a Collar: Provides redundant measurement, enhancing system reliability.

Complementary Input Configuration: Two transducers observe opposite sides of a collar, effectively doubling the measurable DE range.

Observing a Ramp: Suitable for even longer DE measurement ranges, though it may introduce some error from radial rotor movement.

5.2 Dedicated Accessory: Sliding Bracket

To facilitate installation, calibration, and subsequent verification, Bently Nevada provides a dedicated 3300 XL Sliding Bracket. This bracket allows an operator to easily slide the entire probe and sensor assembly axially after installation, simulating rotor movement. This enables verification of the measurement system's accuracy and linearity under real-world conditions, ensuring the probes remain perpendicular and properly aligned with the target.

5.3 System Verification Tools

Dial Indicator Verification Kit: Provides a mechanical reference to precisely calibrate the movement of the sliding bracket, allowing comparison against the sensor's electrical output.

3300 XL Test Plug: Allows for convenient performance checks of the sensor via its test pin holes without disconnecting the field wiring.

6. Key Product Advantages Summary

Exceptionally Wide Linear Range: 12.7 mm range, specifically designed for DE measurement on large turbomachinery.

High Accuracy and Stability: Maintains superior measurement precision across a wide temperature range and in demanding electromagnetic environments.

Complete Interchangeability: No component matching or calibration required, drastically reducing spare parts costs and maintenance downtime.

Superior Environmental Ruggedness: High-temperature capability, vibration resistance, and excellent RFI/EMI immunity.

Easy Installation and Maintenance: SpringLoc terminals, ClickLoc connectors, and sliding bracket design make installation, wiring, and verification efficient and reliable.

Backward Compatibility: Directly replaces legacy systems, protecting the user's original investment.

Comprehensive Safety Certifications: Equipped with hazardous area certifications for global markets.