The IS220PPRFH1A PROFIBUS Master Gateway is a critical communication interface device within the Mark VIe control system, belonging to the special member of the distributed I/O module family. It is essentially a PROFIBUS DP-V0 Class 1 Master, acting as a protocol conversion bridge between the Mark VIe controllers via the IONet network and the widely distributed PROFIBUS slave devices in the field. The core function of this I/O pack is to seamlessly map process data from the PROFIBUS network into the Mark VIe controller's database, significantly expanding the control system's device access capability and fieldbus integration scope.

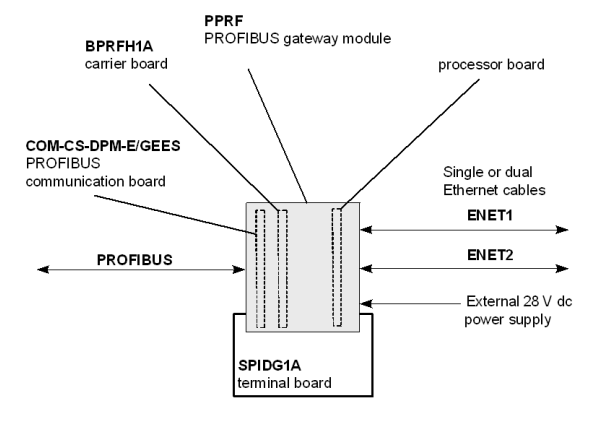

The IS220PPRFH1A consists of a BPPB processor board and a carrier board equipped with a Hilscher GmbH COM-C PROFIBUS communication module. It is installed and powered via the dedicated SPIDG1A terminal board. Its design meets the high demands of industrial environments for reliability, real-time performance, and flexibility, making it a key component for integrating heterogeneous networks in factory automation and process control.

2. System Architecture and Core Functions

2.1 Protocol Conversion and Data Mapping Core

The core value of the IS220PPRFH1A lies in its powerful protocol conversion capability. It facilitates interaction between two network domains within a single physical device:

IONet Domain: As part of the Mark VIe system, the IS220PPRFH1A connects to the IONet via one or two Ethernet ports, enabling high-speed data exchange with controllers like UCVx, adhering to the system's frame period and communication rules.

PROFIBUS DP Domain: As the master of the PROFIBUS network, it provides an RS-485 interface via a DE-9 D-sub connector, managing all communication on the PROFIBUS network.

Data mapping is its primary operating principle: The IS220PPRFH1A packages input data read from PROFIBUS slave devices and transmits it to the Mark VIe controller via the IONet. Conversely, it unpacks output commands sent by the controller via the IONet and writes them to the corresponding PROFIBUS slave devices. This mapping relationship is configured in the ToolboxST software. From the perspective of the control logic, remote PROFIBUS slaves are as visible and operable as local I/O points.

2.2 PROFIBUS DP-V0 Master Function

As a Class 1 Master, the IS220PPRFH1A is responsible for the active management and control of the PROFIBUS network:

Network Management and Initialization: Responsible for starting and initializing the PROFIBUS network, including baud rate detection (supporting 9.6 Kbps to 12 Mbps), slave address recognition, and network parameter configuration.

Cyclic Data Exchange: Performs cyclic data exchange with all configured slaves at a deterministic polling cycle. This is the core of the DP-V0 protocol, ensuring real-time updates of process data.

Slave Diagnostics: Actively reads diagnostic information reported by slave devices and passes it to the upper-level control system, enabling rapid fault localization and device health monitoring.

Robust Network Scale: Supports up to 124 slaves, with each slave configurable for up to 244 bytes of input and 244 bytes of output, demonstrating strong network expansion capability.

2.3 Flexible Redundancy Configuration

The IS220PPRFH1A supports various system configurations to meet the availability requirements of different application scenarios:

Simplex Configuration: Uses a single IS220PPRFH1A module, configurable with single or dual IONet connections. Dual IONet connections provide network path redundancy, enhancing communication reliability.

Hot Backup Configuration: This is the key solution for high availability. The system uses two IS220PPRFH1A modules, one acting as the active master, responsible for all PROFIBUS communication, and the other as the backup master, operating in a standby state, continuously monitoring the active master and network status.

Switchover Mechanism: If the active master fails, the backup master can automatically take over within 200 milliseconds, becoming the new active master, thereby minimizing production interruption.

Controller-Transparent Switchover: The Mark VIe controller defines a single application variable for each PROFIBUS I/O point. Regardless of which PPRF module is active, the controller exchanges data with this active master. The switchover process is transparent to the control application, eliminating the need to configure separate variables for each master, simplifying engineering design and maintenance.

3. Hardware Composition and Specifications

3.1 Module Hardware Composition

Processor Board: Utilizes the BPPB processor board, responsible for running the PPRF firmware, handling IONet communication with the controller, and managing the COM-C module.

Communication Carrier Board and COM-C Module: The carrier board integrates Hilscher's COM-C PROFIBUS communication coprocessor. This module, based on proven Siemens ASPC2 technology, is specifically responsible for executing the underlying PROFIBUS protocol stack, offloading the main processor.

Terminal Board: The SPIDG1A terminal board primarily provides mechanical mounting support, power interface, and electronic identification for the module. It does not connect to the PROFIBUS field cables itself; the PROFIBUS network connects directly to the D-sub interface on the side of the module.

3.2 Key Hardware Specifications

PROFIBUS Interface: RS-485, via a DE-9 D-sub connector.

IONet Interface: 1 or 2 10/100Base-TX Ethernet ports, RJ-45 connectors.

Power Supply: External 28V DC, input via the side connector. The module features soft-start capability to suppress inrush current.

Dimensions: 8.26 cm (H) x 4.19 cm (W) x 12.1 cm (D), compact design.

Operating Temperature: -20°C to 55°C, suitable for standard industrial control cabinet environments.

4. Operating Principle and Data Flow

4.1 Data Flow Architecture

The data flow between the IS220PPRFH1A and the Mark VIe controller can be divided into two types:

Fixed I/O: This is a predefined dataset common to all I/O modules, including the module's own diagnostic status and temperature. This data volume is independent of the PROFIBUS network configuration.

PROFIBUS I/O: This is the application-dependent, dynamically configured data, i.e., the process variables mapped from the PROFIBUS slaves. Its quantity and type depend entirely on the PROFIBUS network configuration.

4.2 Frame Period and I/O Throughput

The operation of the IS220PPRFH1A is tightly coupled with the system's frame period. It supports various frame periods (20, 40, 80, 160, 320 ms), but its I/O processing capacity is affected by the frame period.

Data Exchange Timing: At the beginning of each frame period, the IS220PPRFH1A packages the received PROFIBUS input data and sends it to the controller via the IONet. Simultaneously, it receives the output data calculated by the controller in the previous frame period.

PROFIBUS Communication Timing: Within the frame period, the IS220PPRFH1A asynchronously sends output data to the PROFIBUS slaves and polls for input data via the COM-C module. The speed of this process depends on the PROFIBUS network baud rate, number of slaves, data packet size, and slave response time.

Recommended I/O Capacity: For example, at a 40ms frame period, the IS220PPRFH1A is recommended to handle a maximum of 1000 total I/O points. It is crucial to note that total input data cannot exceed 3584 bytes and total output data cannot exceed 3584 bytes, with the combined total not exceeding 7168 bytes. While there is no hard architectural limit on the number of points, exceeding recommended values requires rigorous validation.

4.3 Input Event Detection

The IS220PPRFH1A offers an advanced feature – Input Event Detection, which can be used for sequence of events logging. It can timestamp Boolean input state changes with a resolution of 10 milliseconds, aiding in post-event analysis of fault sequences and rapid root cause identification.

5. Diagnostics and Status Indication

The IS220PPRFH1A provides comprehensive diagnostic information and intuitive LED indicators, enabling maintenance personnel to quickly understand the system status.

5.1 LED Indicator Details

SYS RUN: Green.

Solid On: COM-C module has established communication with at least one PROFIBUS slave.

Fast Cyclical Flashing: PROFIBUS master is configured but unable to communicate with slaves.

Non-Cyclical Flashing: COM-C module lacks configuration or watchdog timeout.

NOT RDY: Yellow.

Slow Flashing: Waiting for firmware load.

Fast Flashing: Firmware download in progress.

Non-Cyclical Flashing: Serious COM-C hardware or firmware error.

COMM OK: Green. Mimics the COM-C module's COM LED (when it is yellow).

COMM ERR: Red. Mimics the COM-C module's COM LED (when it is red).

ACTIVE / STANDBY: Green. Mutually exclusive display, indicating the module's role in a Hot Backup pair.

5.2 Health Monitoring

Each PROFIBUS input point has an associated "health" bit in the EGD data exchange. The IS220PPRFH1A sets the input health bit to "unhealthy" when:

Communication loss with the corresponding slave.

The COM-C module is not in READY/RUN status.

Standard IONet input validation error.

This mechanism ensures the controller is aware of data validity and can take safety measures.

5.3 Diagnostic Data Access

Using the "Advanced Diagnostics" tool in the ToolboxST software, users can delve into the detailed diagnostic bytes reported by slave devices. This diagnostic information follows the PROFIBUS standard, containing critical status bits, and is the first-hand information for troubleshooting field device issues.

6. Configuration and Installation Key Points

6.1 Network Configuration Process

The key to using the IS220PPRFH1A lies in correctly configuring the PROFIBUS network. This process is completed in the ToolboxST software:

GSD File Management: Must first import the GSD files provided by the PROFIBUS slave device vendors. This file describes the slave's characteristics, supported modules, and diagnostic information.

Network Configuration: Add the PPRF module to the hardware tree, then create a PROFIBUS network under it, setting parameters like baud rate.

Slave Addition and Module Selection: Add the required slave devices to the network and configure the input/output modules for each slave, which determines the size and structure of the data mapping.

Download and Reboot: Download the complete configuration and firmware to the IS220PPRFH1A. If the PROFIBUS configuration changes, a restart of the PPRF module is typically required for it to take effect.

6.2 Physical Installation and Wiring

PROFIBUS Cable: Must use dedicated shielded twisted-pair cable. The maximum segment length depends on the baud rate.

Terminating Resistors: Terminating resistors must be enabled at both ends of the network to eliminate signal reflections.

Connectors: Use standard 9-pin D-sub connectors. Pay attention to the wiring.