The IS215VCMIH1B Bus Master Controller is the core communication hub of the Mark VI gas turbine control system. It is a critical board installed in the VME rack, acting as the communication bridge between the controller and the I/O boards, and between the control system and the IONet network. As the VME bus master within the rack, the VCMI H1 is responsible for managing and coordinating communication for all I/O boards, and for managing the identity (ID) of these boards and their associated terminal boards. Its design aims to provide high-speed, highly reliable data exchange capabilities for industrial control applications, forming the foundation for systems ranging from simple simplex to complex triple modular redundant configurations.

2. System Architecture and Core Functions

The IS215VCMIH1B plays a pivotal role in the Mark VI system architecture, with its core functions manifested in three main areas:

2.1 VME Bus Master

Within the control and I/O racks, the IS215VCMIH1B is the sole VME Bus Master. This means it has control over the VME backplane bus and is responsible for initiating and managing all data transfers occurring on the VME bus. Its primary duties include:

Scheduling and Arbitration: Coordinating access to the bus by multiple I/O slave devices, preventing conflicts, and ensuring orderly data transfer.

Block Transfers: Supporting efficient VME bus block transfer modes, enabling rapid movement of large data volumes between the controller and I/O boards, meeting the demands of high-speed control loops.

Rack Management: The IS215VCMIH1B automatically identifies and manages the IDs of all boards in the rack. Each VME I/O board and terminal board contains a unique identification chip. The VCMI reads these IDs to build a "topology map" of the system, ensuring consistency between the software configuration and the physical hardware. If a mismatch is detected, it immediately generates a fault alarm.

2.2 IONet Network Interface

IONet is the Mark control system's private, special-purpose Ethernet network, used for communication between controllers and between controllers and remote I/O racks. The IS215VCMIH1B is the gateway for the controller to access the IONet.

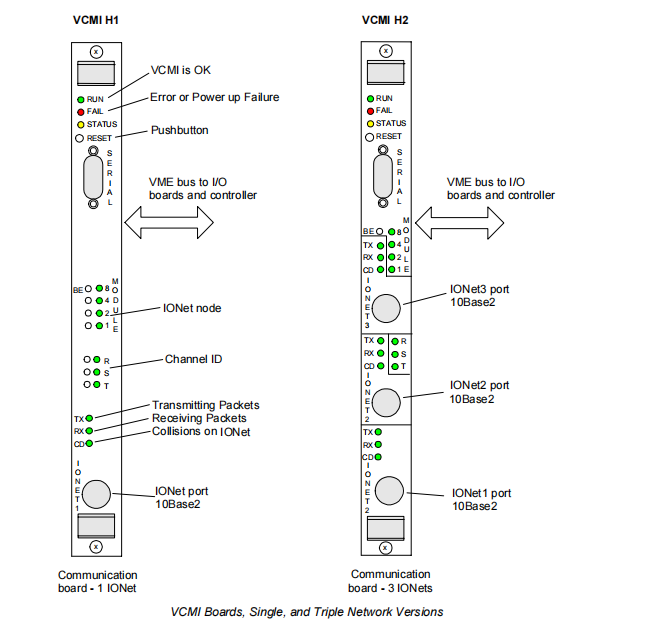

Single Network Interface: Unlike the H2 version which has three IONet ports, the IS215VCMIH1B provides a single 10Base2 standard IONet port, using a BNC connector, with a communication speed of 10 Mbits/sec. This makes it ideally suited for simplex systems.

Role in System Configurations:

Local I/O System: In a simplex system with only local I/O, the IS215VCMIH1B resides in the same rack as the controller (UCVX) and the I/O boards, communicating with the I/O via the backplane and connecting to the external network via IONet.

Remote I/O System: In systems incorporating remote I/O, each remote I/O rack is equipped with its own IS215VCMIH1B board. All these VCMI boards connect to the main controller via IONet, allowing the controller to access I/O points in remote racks as if they were local, greatly enhancing the system's physical layout flexibility.

2.3 System Power and Status Monitoring

The IS215VCMIH1B acts as a "sentinel" for system health, receiving and monitoring analog and digital feedback signals from the Power Distribution Module (PDM) via its backplane connector J301. Its monitoring scope includes:

Internal Power Buses: Continuously monitors the +5V, ±12V, ±15V, and ±28V power buses on the VME backplane. If voltages deviate from preset limits, diagnostic alarms are triggered.

External Power Status: Monitors critical power faults through the digital input channels on J301, such as:

Logic_In_1: Battery bus fault

Logic_In_2: AC1 source fault

Logic_In_3: AC2 source fault

Logic_In_5/6/7: Specific fuse faults

High Voltage Bus Monitoring: Uses dedicated analog input channels (P125_Grd and N125_Grd) to accurately measure the P125 DC bus voltage with respect to ground, calculate the actual bus voltage, and monitor for ground insulation degradation or short-circuit faults.

3. Diagnostics and Fault Management

The IS215VCMIH1B incorporates a comprehensive diagnostic subsystem to detect hardware and communication status in real-time, ensuring operational reliability.

3.1 Power Diagnostics

As mentioned, it continuously monitors all internal power buses and the critical 125V DC bus. Users can flexibly configure alarm limits for each power rail using the ToolboxST software.

3.2 Communication Diagnostics

IONet Communication: The IS215VCMIH1B monitors the link status and data traffic on its IONet port. Communication failure triggers faults.

VME Bus Errors: As the bus master, it can detect transmission errors on the VME bus, logging the error count to help identify potential backplane or board hardware issues.

Controller and I/O Board Communication: The VCMI verifies successful communication with the controller and all configured I/O boards within the host rack. Any communication timeout or interruption results in alarms.

3.3 Hardware Identification and Compatibility Diagnostics

This is a critical feature for Mark VI system reliability. The IS215VCMIH1B reads the ID chip information from all connected boards and terminal boards and compares it against the system configuration file. Any mismatch immediately triggers a fault, preventing control logic errors due to incorrect hardware configuration.

3.4 System-Level Diagnostics

The VCMI also monitors its own operational status, for example:

Watchdog Timer: Ensures the processor is running correctly and has not entered a deadlock.

Task Overtun: Checks whether all calculation and communication tasks are completed within the designated frame time.

Flash Memory CRC Check: Verifies the integrity of the firmware.

When a fault is diagnosed, the VCMI H1 illuminates the "Error" LED on the board and generates specific fault codes and descriptions in the ToolboxST software, guiding maintenance personnel to quickly locate and resolve the issue.

4. Software Configuration

The behavior and parameters of the IS215VCMIH1B can be configured using GE's ToolboxST engineering software. The configuration pages contain numerous parameters, allowing engineers to tailor its functionality to specific applications:

System Limits Enable: Globally or individually enable/disable system and power bus limit checks.

Power Limit Settings: Precisely set the high and low alarm limits for various voltage rails.

125V Bus Monitoring: Set high/low limits for the bus voltage and limits for voltage to ground.

Input Configuration: Define engineering unit scaling, filter bandwidth, etc., for analog input channels.

Digital Input Assignment: Map the 12 digital input channels on J301 to specific fault or status points.

System Limits: Set system-level high and low limits for analog input signals, triggering system-level alarms if exceeded.

These configurations allow the IS215VCMIH1B to be highly adaptable to different application scenarios and field requirements.