The IS200VTURH2B is a dual-slot, high-performance primary trip control board within the GE Mark VI turbine control system. As the advanced version in the VTUR product line, it is specifically designed for complex or large-scale turbine units (such as certain large gas or steam turbines) that require higher redundancy and greater trip capacity. The IS200VTURH2B inherits all the core protection functions of the VTUR series, including primary overspeed protection, automatic synchronization, shaft monitoring, and flame detection. Its core advantage lies in its ability to drive up to six Emergency Trip Solenoids (ETDs) via two independent TRPx terminal boards, supporting more complete signal isolation and voting within a Triple Modular Redundant (TMR) architecture, providing the ultimate protective barrier for critical assets.

2. Core Functions & Detailed Principles

The IS200VTURH2B shares the same fundamental functional principles with the IS200VTURH1B, but its enhanced hardware architecture expands its capabilities. The following elaborates on its functions and principles, noting commonalities and differences with the H1B where appropriate.

2.1 Primary Overspeed Protection & Speed Measurement

This is the core mission of all VTUR boards. The IS200VTURH2B's measurement principle is identical to the H1B, but it offers advantages at the system level.

Technical Principle:

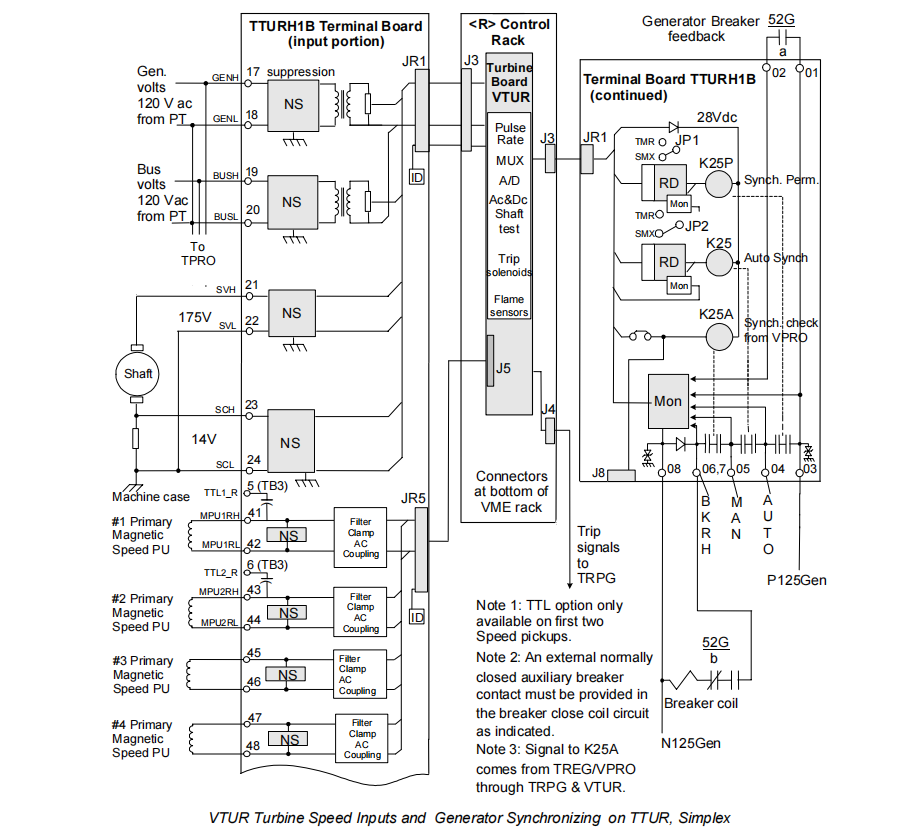

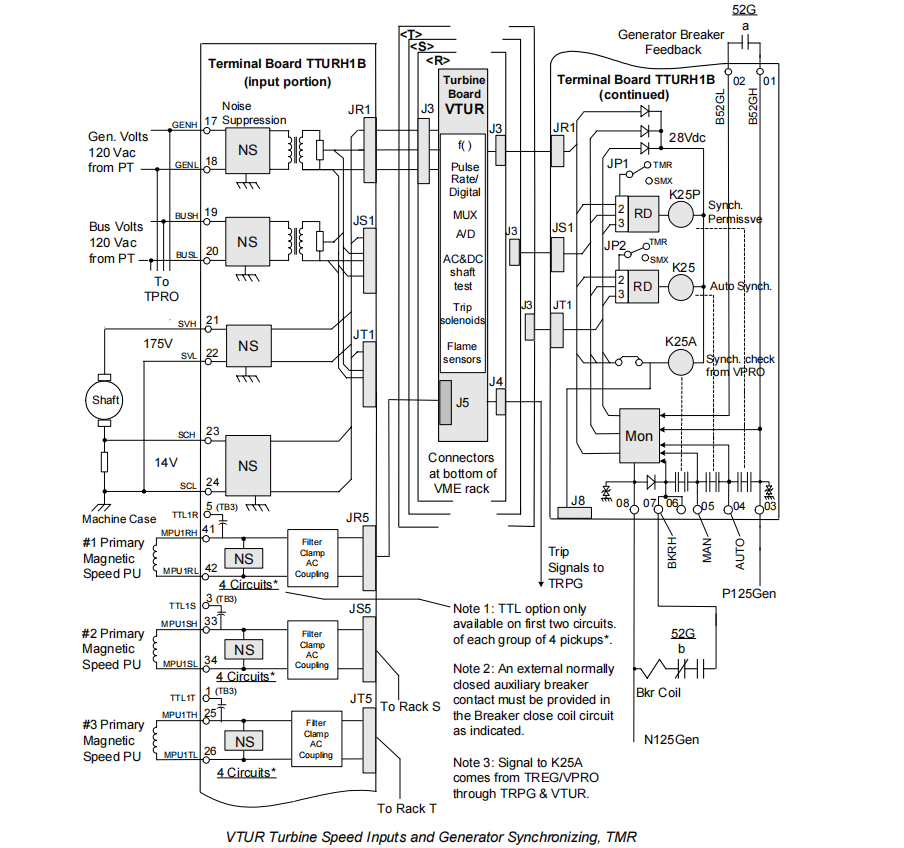

Signal Acquisition & Processing: Like the H1B, the IS200VTURH2B receives signals from four passive magnetic speed pickups via its connected terminal board (e.g., TTURH1B). These sensors monitor a sixty-tooth speed wheel on the turbine shaft. The wheel's rotation causes magnetic flux changes, generating an AC voltage signal with a frequency strictly proportional to the speed. The signal is sent to the VTURH2B via the terminal board and undergoes an identical process of filtering, clamping, AC coupling, and pulse shaping, ultimately being converted into a clean square wave for digital processing.

Speed Calculation & Voting (TMR Advantage): In a TMR system, each of the three controller racks (R, S, T) is equipped with a VTUR board (which can be a IS200VTURH1B or IS200VTURH2B). Each VTUR board sends its four processed speed signals to the corresponding controller (VCMI) via the VME bus. The three controllers independently calculate the speed and perform a median value selection to determine the final valid speed with the highest system reliability. The dual-slot design of the VTURH2B allows it to integrate more naturally into TMR systems, providing powerful and equal interface support for all three racks.

Overspeed Trip Logic: The primary overspeed trip decision logic is executed by the controller software. When the voted speed exceeds the preset overspeed trip setpoint, the controller generates a trip signal. This signal is sent back to the VTUR board, which then drives the relays on its associated TRPx trip terminal board(s). This is the first key difference between the VTURH2B and H1B: The VTURH1B can only connect to one TRPx board, driving three ETDs; whereas the VTURH2B can connect to two TRPx boards (e.g., one on the J4 interface and one on the J4A interface), thereby driving up to six ETDs. This provides direct interface support for complex hydraulic systems with multiple independent trip circuits, significantly enhancing the redundancy and reliability of the trip system.

2.2 Fast Overspeed Trip

To meet the extreme response speed requirements of applications like gas turbines, the VTURH2B also incorporates hardware-based Fast Overspeed Trip algorithms.

Technical Principle:

Algorithm Options: The IS200VTURH2B supports the same two fast trip algorithms as the H1B: PR_Single and PR_Max. The operational details of these algorithms, including the sensor/board-level redundancy of PR_Single and the anti-nuisance/failure-to-trip design of PR_Max, are consistent across both boards.

Hardware Interlocking & Expanded Capability: The fast trip signal is generated within the VTUR board and issued via dedicated output points (PTR1 to PTR6). A key advantage of the VTURH2B is its native support for all six PTR outputs. These outputs can be flexibly assigned to the two TRPx boards. For example, PTR1-PTR3 can be assigned to the three ETDs driven by the first TRPx board, and PTR4-PTR6 to the other three ETDs driven by the second TRPx board. This architecture allows system designers to distribute the fast trip function across different hydraulic loops or protection zones, achieving physical isolation and redundancy of the trip paths, a capability unmatched by the single-path VTURH1B.

2.3 Shaft Voltage & Current Monitoring

The IS200VTURH2B is identical to the IS200VTURH1B in the monitoring principle, testing methods (AC and DC tests), and parameter specifications for this function. Shaft voltage and current input signals are connected via the terminal board and measured with high precision by the VTURH2B for judgment, warning against potential electrical erosion damage to bearings. Its self-diagnostic tests are also led by the R controller, ensuring the integrity of the monitoring circuit.

2.4 Flame Detection

Technical Principle: The IS200VTURH2B works with the TRPG board to monitor the status of Geiger-Müller flame detectors. The charge/discharge frequency of the detectors reflects the flame intensity. However, this is a notable difference between the IS200VTURH2B and H1B: Despite being a more powerful dual-slot board, the IS200VTURH2B still only supports connection to a single TRPG board, i.e., a maximum of eight flame detectors. The documentation explicitly states "VTURH2... but only accepts eight flame detectors." This means that in applications requiring more than eight flame detectors for very large combustors, the IS200VTURH2B does not offer expanded capability, remaining consistent with the VTURH1B. The pulse signals from all flame detectors are similarly distributed to the three controller modules to ensure protective redundancy.

2.5 Automatic Synchronization

The implementation of the automatic synchronization function in the VTURH2B is completely identical to the IS200VTURH1B, with no differences.

Technical Principle: Generator and bus voltages are brought in via Potential Transformers (PTs) to the TTUR terminal board. The IS200VTURH2B is responsible for accurately measuring the magnitude, frequency, and phase difference of these voltages. In automatic mode, it coordinates with the controller and the excitation system (EX2000), sending commands via the Unit Data Highway (UDH) to adjust unit speed and voltage until synchronization conditions are met. The final closure command requires the joint permission of three independent functions: K25P (Synchronizing Sequence Permissive), K25 (Auto Sync Relay), and K25A (Sync Check Relay). After closure, the system uses the breaker's own 52G/a contact to obtain the actual closing time for algorithm optimization. The entire synchronization logic and accuracy requirements are uniform across both boards.

3. Detailed Comparison: IS200VTURH2B vs. IS200VTURH1B

The following table clearly summarizes the core differences between the two boards:

| Comparison Dimension | IS200VTURH1B | IS200VTURH2B | Analysis of Differences & Impact |

| Board Version & Physical Size | Single-Slot Version | Dual-Slot Version | The IS200VTURH2B occupies two slots in the VME rack, requiring more physical space. |

| Trip Solenoid (ETD) Drive Capacity | Drives up to 3 ETDs (via 1 TRPx board) | Drives up to 6 ETDs (via 2 TRPx boards) | This is the most fundamental difference. The H2B provides double the trip output capacity, suitable for systems requiring more trip solenoids or complete physical isolation of trip circuits for high redundancy. |

| Flame Detector Support Quantity | Up to 8 (via 1 TRPG board) | Up to 8 (via 1 TRPG board) | Despite being more powerful, the H2B's flame detection capability is not increased. For applications needing more than 8 flame detectors, both boards require additional solutions. |

| System Architecture & Redundancy | Suitable for Simplex and TMR systems, providing standard redundancy. | More focused on enhancing output redundancy and capability within TMR systems. | The H2B's dual TRPx support allows for the construction of more complex and reliable trip architectures within TMR systems, e.g., providing more balanced load capacity for the three controller racks. |

| Target Application | Suitable for most medium, small, or standard-configured gas/steam turbines. | Suitable for large, complex, or special high-reliability turbine units, especially those with hydraulic systems designed with multiple independent trip solenoids. | Selection depends on specific application needs and the required redundancy level of the trip system. |

Difference Summary: The IS200VTURH2B is essentially an enhanced version of the IS200VTURH1B in terms of trip output capacity and system expandability. By sacrificing an additional rack slot, it gains the ability to drive more trip solenoids, providing unparalleled protection redundancy for top-tier turbine units. However, in input functions like flame detection, it maintains the same level as the H1B.

4. Hardware Interface & Installation

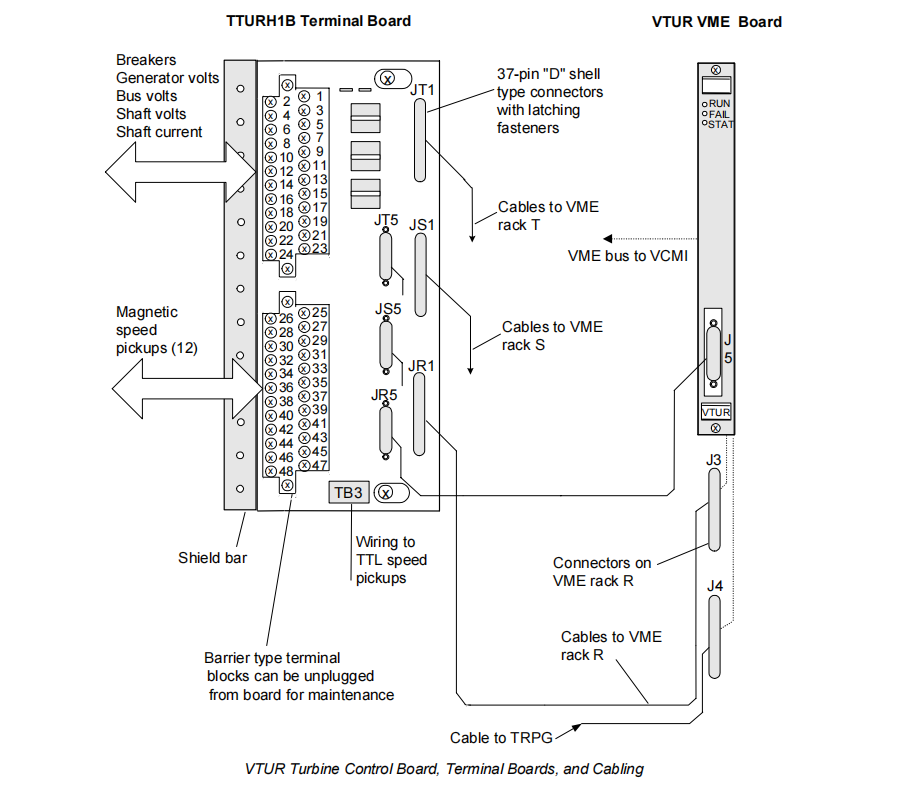

IS200VTURH2B Main Control Board: As a dual-slot board, its installation requires two consecutive slots in the VME rack. Connectors include J3 and J5 for connecting the terminal board (e.g., TTURH1B), and J4 and J4A for connecting the trip terminal boards (TRPx). The presence of J4A is key to supporting the second TRPx board.

Installation: The installation process is similar to that of a single-slot board but requires ensuring space for two slots. Similarly, the rack must be powered down, the board inserted, and the levers and captive screws tightened.

5. Diagnostics & Maintenance

The IS200VTURH2B possesses identical comprehensive diagnostic capabilities to the IS200VTURH1B.

Front Panel LED Indication: RUN (Flashing Green), FAIL (Solid Red), STATUS (Solid Orange indicates a diagnostic alarm).

Diagnostic Scope: Covers relay driver/feedback mismatch, solenoid power loss, flame detector voltage abnormality, synchronizing relay faults, terminal board ID recognition errors, etc.

Enhanced Diagnostic Association: Due to support for two TRPx boards, the VTURH2B's diagnostic information can more precisely locate the source of a fault. For example, it can clearly indicate whether it is a power issue with the first TRPx board (associated with ETDs 1-3) or a relay feedback fault with the second TRPx board (associated with ETDs 4-6).