The VRTD (RTD Input) board is a dedicated temperature signal acquisition module within the GE Mark VI turbine control system, designed for high-precision, high-reliability processing of Resistance Temperature Detector (RTD) signals. Serving as the critical bridge between field temperature sensors and the core controller, the VRTD board is responsible for exciting, sampling, converting, and linearizing 16 channels of 3-wire RTD input signals. It accurately converts resistance changes into digital temperature values and transmits them to the upper-level controller via the VME backplane, enabling continuous monitoring and protection of temperature parameters for critical equipment such as gas turbines and steam turbines.

This board features exceptional measurement accuracy, robust anti-interference capability, and flexible configuration options, supporting a variety of RTD types including platinum, copper, and nickel across a wide temperature range. Notably, the VRTD fully supports Triple Modular Redundancy (TMR) architecture. Through an innovative synchronized scanning and signal distribution mechanism, it ensures data consistency while achieving high system availability and fault tolerance. Paired with TRTD or DRTD series terminal boards, VRTD provides a stable, precise, and scalable temperature monitoring solution for industrial process control.

II. Core Functions and Design Features

1. High-Precision Multi-Channel RTD Signal Processing

Channel Capacity: A single VRTD board processes 16 channels of independent 3-wire RTD inputs, effectively supporting multi-point temperature monitoring.

Intelligent Excitation: Provides a 10 mA DC excitation current for each RTD channel. This current is multiplexed (not continuous), sequentially exciting each sensor through precise timing control. This reduces power consumption and thermal effects while ensuring the independence and accuracy of each signal.

Advanced Conversion Technology: Employs a VCO (Voltage-Controlled Oscillator) type A/D converter, combined with voltage-to-frequency conversion and sampling counter technology. The converter synchronously samples each signal and its excitation current, utilizing sampling intervals related to the power frequency to effectively suppress line frequency interference.

Broad-Range Linearization: The onboard digital signal processor (TMS320C32) runs dedicated linearization algorithms, pre-configured to support linearization curves for up to 15 RTD types. Users can flexibly select the type via software, eliminating the need for hardware jumpers.

2. Exceptional Anti-Interference and Electrical Safety Characteristics

Powerful Noise Suppression: Terminal boards (TRTD/DRTD) are equipped with noise suppression circuits, including high-frequency decoupling to ground at the signal entry point, effectively protecting against surge and high-frequency noise interference.

Excellent Common-Mode Rejection:

AC Common-Mode Rejection Ratio (CMR): 60 dB @ 50/60 Hz.

DC Common-Mode Rejection Ratio: 80 dB.

Common-Mode Voltage Range: ±5 V.

High Normal-Mode Rejection: In normal scan mode, rejection capability against normal-mode interference up to 250 mV RMS at 50/60 Hz is 60 dB.

Electrical Isolation and Safety: The measurement loop design accommodates grounded or floating ground requirements, supports long-distance wiring (up to 300 meters / 984 feet), and allows a maximum two-wire loop resistance of 15 Ω, adapting to complex industrial field environments.

3. Flexible Dual-Mode Scanning and High-Performance Specifications

4. Innovative Implementation of Triple Modular Redundancy (TMR)

The VRTD's design in TMR systems is ingenious, ensuring data reliability and acquisition continuity under redundancy mechanisms:

Signal Fan-Out: The dedicated TRTDH1B terminal board uses six connector sets (JRA, JSA, JTA, JRB, JSB, JTB) to "fan out" the 16 RTD signals simultaneously to three VRTD boards located in the separate R, S, T VME racks.

Redundant Pacemaker Coordination: The three VRTD boards are strictly synchronized via redundant "Pacemaker" signals (PM, Tx/Rx), coordinating the multiplexed scanning sequence.

Interleaved Scanning to Prevent Conflict: The three boards do not read the same RTD simultaneously. They employ an interleaved scanning sequence (e.g., when R reads RTD3, S reads RTD5, and T reads RTD7), ensuring that at any given moment, only one board excites a specific RTD. This completely avoids signal crosstalk and reading errors caused by simultaneous excitation.

Seamless Fault Tolerance: This design ensures that even if a single VME rack, VRTD board, or connecting cable fails, it will not cause the loss of any RTD signal in the control database. The remaining functional boards will continue to provide valid data.

III. System Architecture and Compatible Terminal Boards

1. VRTD Board and System Connection

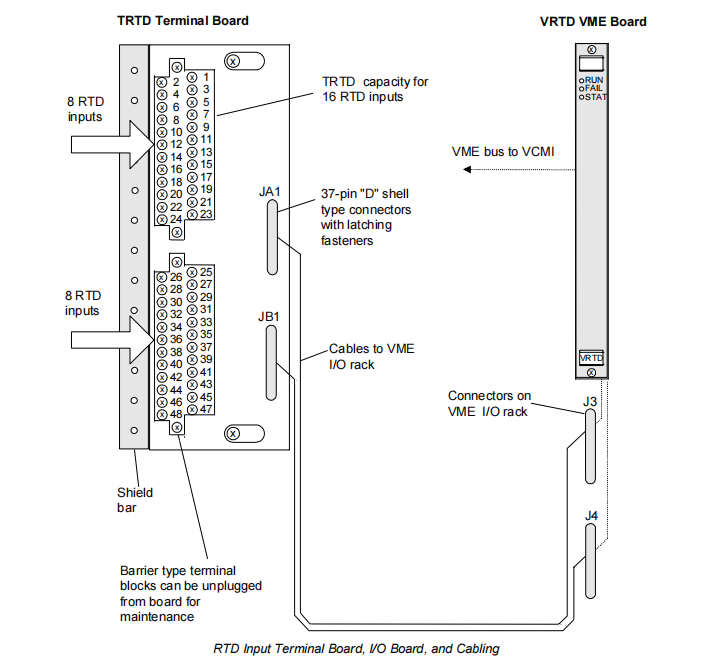

Board Interface: VRTD is a standard VME form factor board, communicating with the VCMI and controller via the VME backplane. Input signals are connected via cables to the terminal boards through the J3 and J4 latching-type connectors at the bottom of the VME rack.

Status Indication: The front panel has three LED indicators: RUN (green flashing, normal operation), FAIL (red steady on, critical fault), STAT (orange steady on, diagnostic alarm present).

2. Compatible Terminal Board Series

VRTD can be paired with various terminal boards to suit different system architectures and installation needs:

| Terminal Board Model | Applicable System | Channels | Key Features & Purpose |

| TRTDH1B | Mark VI | 16 | TMR Version. Equipped with 6 D-type connectors to fan out signals to three VRTD boards. Supports redundant applications. Does not support Fast Scan. |

| TRTDH1C | Mark VI | 16 | Simplex Version. Equipped with 2 D-type connectors (JA1, JB1) to connect to a single VRTD board. Supports simplex applications and single-path connection in TMR systems. |

| TRTDH1D/H2D | Mark VIe | 16 | For Mark VIe systems, works with the PRTD I/O Pack, supports simplex applications only. |

| DRTD | Mark VI | 8 | Compact Simplex Terminal Board. Features DIN-rail mounting for space savings. No shield terminal strip; connects via Euro-Block terminals. Two DRTD boards combined can achieve 16 inputs. |

IV. Diagnostics, Configuration, and Maintenance

1. Multi-Level Intelligent Diagnostics

VRTD integrates comprehensive diagnostic functions from hardware to software, ensuring the health of the measurement chain:

Hardware Limit Checking: Each RTD type has preset, non-configurable high and low hardware limits (near the scale ends). Upon exceeding these limits, the channel is automatically removed from the scan list to prevent the fault from affecting other channels, and a composite diagnostic alarm L3DIAG_VRTD is triggered.

Software System Limit Checking: Users can independently configure for each RTD channel enableable/disableable, latchable/non-latchable high and low temperature alarm limits. Exceeding these limits generates alarms, which can be reset via the RESET_SYS signal.

TMR Voting Difference Detection: In TMR systems, a TMR Diff Limit can be set. When the temperature readings from the R, S, T channels differ by more than this limit, a voting alarm is generated, indicating potential inter-channel deviation.

Loop Integrity Diagnostics:

Open/Short Circuit Detection: Accurately identifies open or short circuit faults in the RTD or cable by detecting abnormal voltage/current readings (too high or too low).

Resistance Calculation Verification: The calculated RTD resistance is compared against the expected range for the selected type. Anomalies generate errors, aiding in identifying RTD type configuration errors or sensor degradation.

Hardware ID Verification: VRTD reads the ID chip information from all connectors (J3, J4, J5, J6, J3A, J4A). Any mismatch triggers a hardware incompatibility fault.

2. Channel Automatic Recovery

For RTD channels removed due to faults like open/short circuits, the system provides an automatic recovery function. Once the fault disappears, the channel is automatically reinstated into the scan after approximately 20 seconds.

Users can also manually restore channels via the configuration tool or globally disable the auto-recovery function.

3. Flexible Software Configuration

The VRTD can be finely configured via the Mark VI Toolbox: