The IS200JPDBG1A, or AC Power Distribution Board, is a core component of the Power Distribution Module (PDM) within the Mark VI, Mark VIe and Mark VIeS Control Systems. Its primary function is to condition, monitor, and distribute AC power, providing reliable, clean, and monitored AC electricity to various components of the entire control system.

The IS200JPDBG1A is essentially an intelligent power distribution center. It does not merely passively distribute power but also integrates comprehensive monitoring circuits that feed real-time power status information back to the superior monitoring system (via the PPDA I/O pack). This enables visual management and fault diagnosis of the entire power chain. Designed for industrial environments, especially high-reliability applications like gas turbine control, its rated parameters and protection mechanisms reflect this design purpose.

2. Detailed Functional Description

The functions of the IS200JPDBG1A can be summarized into three main areas:

Power Conditioning and Distribution

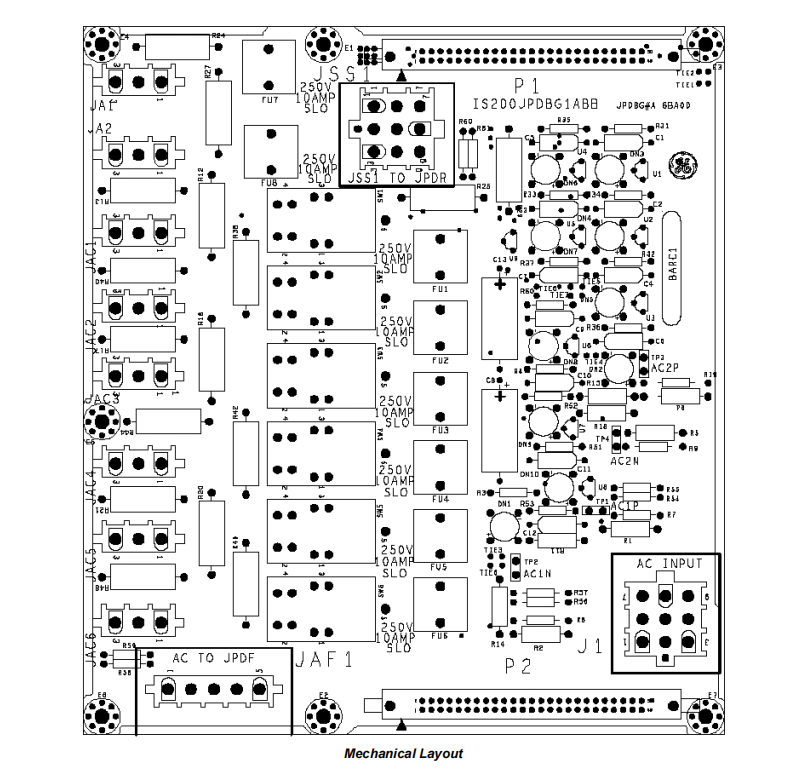

1 Unswitched, Fused Output (JA1 for AC1, JA2 for AC2): Typically used to power critical equipment that cannot be powered down, or to connect to expansion branch circuit boards like JPDA.

3 Switched and Fused Outputs (JAC1, JAC3, JAC5 for AC1; JAC2, JAC4, JAC6 for AC2): These outputs allow operators to manually turn power on or off via front-panel switches, while also being protected by fuses against overcurrent. They are ideal for loads requiring field maintenance or isolation.

Dual-Circuit Design: The JPDB contains two independent AC distribution circuits (AC1 and AC2). Each circuit is rated for 20A and compatible with 115V AC or 230V AC voltages. This dual-circuit design provides inherent redundancy, allowing the system to draw power from two independent sources or, when a single source is input, to be wired in parallel to avoid false alarms.

Multiple Outputs: Each AC circuit provides multiple protected outputs:

Filtering: The module contains two line filters (FL1, FL2) internally to suppress electromagnetic interference (EMI) and radio frequency interference (RFI) on the AC input lines, ensuring power quality supplied to downstream equipment and reducing noise feedback from the equipment back into the grid.

Power Monitoring and Status Feedback

The core intelligence of the JPDB lies in its monitoring capabilities. The IS200JPDB circuit board includes passive monitoring circuits that collect the following key information:

AC Voltage Magnitude Monitoring: Real-time monitoring of the voltage values for the two input AC circuits (AC1 and AC2).

Fuse Status Monitoring: Monitors the status of the fuses for all output branch circuits (including JA1/JA2 and JAC1-JAC6). If any fuse blows, the monitoring circuit detects this state change.

Status Signal Aggregation: All these analog and digital status signals are integrated into the module's 50-pin diagnostic connector (P1).

System Integration and Expansion

Interface with Diagnostic System: By connecting the JPDB's P1 connector via a 50-pin ribbon cable to a board hosting a PPDA I/O pack, all status signals are transmitted to the control system. The PPDA, acting as the power diagnostics unit, decodes and processes these signals, displaying power status, generating alarms, or executing protection logic on the operator interface.

Signal Pass-Through: The JPDB also provides a P2 connector for receiving feedback signals from other power distribution boards (e.g., JPDE, JPDF, JPDS, JPDM) and forwarding these signals, along with its own, via P1 to the PPDA, forming a complete power distribution system monitoring chain.

Integration with DC System: Via the JAF1 connector, the JPDB can directly supply AC power to an optional JPDF (125V DC Distribution Module). The JPDF then uses DACA power conversion modules to convert AC power to 125V DC, which can serve as a backup power source for systems using a 125V DC battery.

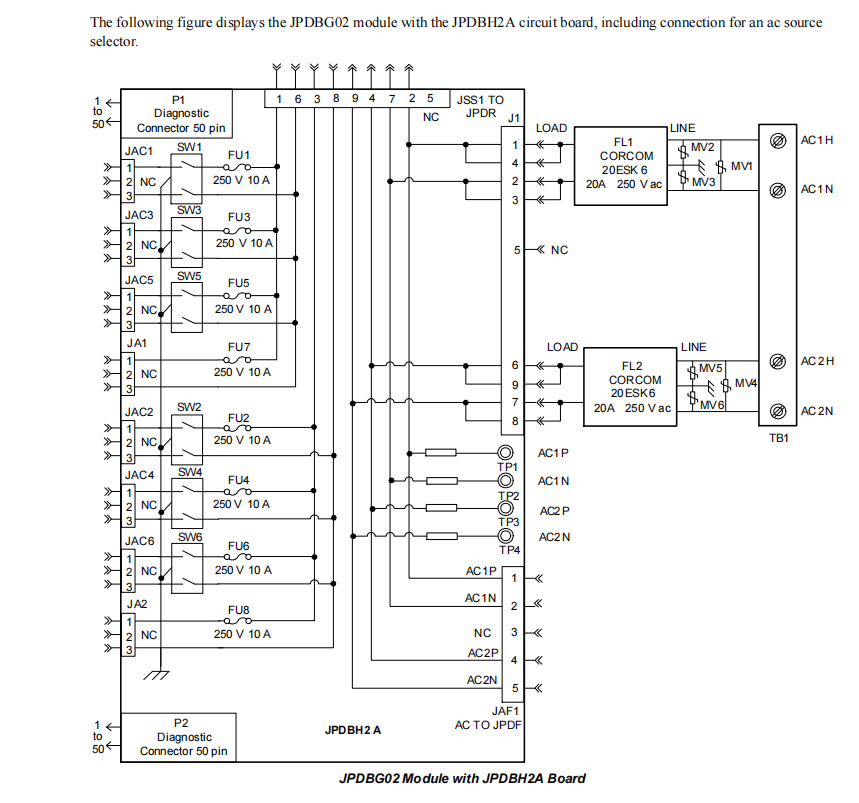

Support for Automatic Source Transfer (G2 Version specific): The IS2020JPDBG2 model provides an additional JSS1 connector. This is designed to connect to an external AC source selector (e.g., JPDR). The two AC sources are routed to JSS1, and the selector's output returns to JSS1 to be distributed to the individual branch circuits, enabling automatic or manual redundant power source switching.

3. In-Depth Working Principle Analysis

The operation of the JPDB follows a clear path of power flow and signal flow.

1. Power Flow Path:

Input: External AC power is first connected to the terminal block (TB1) on the right side of the module, divided into AC1 (AC1H Line, AC1N Neutral) and AC2 (AC2H Line, AC2N Neutral). The document specifically emphasizes that the neutral for both inputs must be grounded.

Filtering: Power from TB1 is fed into two independent line filters (FL1, FL2) located beneath the circuit board. The filters clean the power supply and suppress noise.

Internal Distribution: The filtered AC power is connected via a wire harness to the main board connector J1, entering the IS200JPDB circuit board.

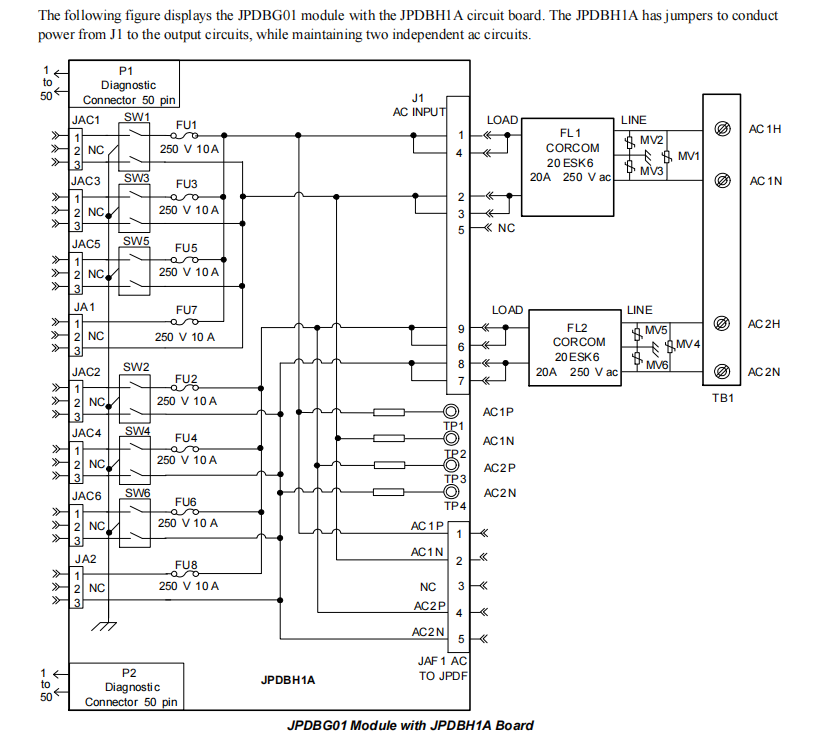

For the G1 version (JPDBH1A board), power is distributed directly to the output connectors via jumpers on the board.

For the G2 version (JPDBH2A board), power is first routed to the JSS1 connector for selection by an external source selector. The selected main power then returns via JSS1 before being distributed.

Output and Protection: Power is distributed to the various output circuits. Each output (JA1, JA2, JAC1-JAC6) is connected in series with a fuse (FU1-FU8) rated at 10A/250V, providing overcurrent protection. The JAC1-JAC6 circuits also have front-panel switches (SW1-SW6) in series, allowing manual control.

2. Signal Flow (Monitoring Principle) Path:

Signal Acquisition: The onboard passive monitoring circuits continuously acquire signals from key points.

Voltage Sampling: Using methods like high-resistance voltage dividers, analog signals representing voltage magnitude are obtained from between the line and neutral of AC1 and AC2.

Fuse Status Detection: This is typically done by detecting the voltage drop across the fuse or using auxiliary contacts to determine if the fuse is intact. When the fuse is normal, the detection circuit presents one state (e.g., closed loop); when the fuse blows, the loop opens, changing the state.

Signal Processing and Transmission: The acquired raw signals are initially conditioned on the board (e.g., scaling, isolation). All this status information – including the two analog AC voltage feedbacks, the six Boolean statuses for the switched/fused outputs, the two Boolean statuses for the unswitched fused outputs, and a local ground signal for analog signal reference – is encoded and sent to the P1 connector.

System Diagnostics: The PPDA I/O pack reads the signals from P1. Analog voltage signals are converted to actual voltage values and compared against set normal ranges to achieve under-voltage and over-voltage alarms. Boolean status signals are used directly to indicate fuse failure or abnormal switch position. These diagnostic results are finally integrated into the control system's alarm and event logging system, providing operational and maintenance personnel with decision-making basis.

3. Grounding Principle:

The grounding design of the IS200JPDBG1A is crucial for system safety and monitoring accuracy.

Protective Earth (PE): The metal enclosure, switch bodies, etc., of the module must be reliably connected to the system's Protective Earth via mounting supports and/or a separate grounding wire. This ensures personnel safety and prevents electric shock.

Functional Earth (FE): The "ground" of the JPDB is defined as an independent local reference point used for generating the feedback signals appearing on P2. The module's sheet metal base is insulated from the mounting surface. This is specifically done so that the JPDB's "ground" can be defined independently of the mounting surface. Typically, the JPDB is mounted to a back base connected to FE, while a separate ground wire from the JPDB module is provided to PE. This design reduces radio frequency impedance, ensures the effective operation of the input line filters, and avoids interference from ground potential differences on precise analog monitoring signals (e.g., AC_Fdbk#/Volt). The ACDiffVoltOff parameter in the PPDA configuration is used to compensate for any potential voltage difference between PE and the AC grounded neutral.

4. Version Differences and Key Configuration

G1 (IS2020JPDBG01) vs. G2 (IS2020JPDBG02): The core difference is that the G2 version supports an external AC source selector and provides the JSS1 connector for this purpose. The G1 version uses internal jumpers for direct connection and does not support this feature. The correct version (G1A or G2A) must be selected in the hardware configuration (e.g., the HW Form dropdown in ControlST) to match the physical hardware.

Single Power Input Application: When the system has only one AC power source, the traditional practice was to wire both inputs (AC1 and AC2) in parallel to this source to avoid "AC Loss" diagnostics on the unused input. However, in ControlST V03.05 and later versions, the InputDiagEnab configuration bit can be set to disable all diagnostics for a specified input (AC1 or AC2), making parallel wiring unnecessary.

Output Diagnostic Management: If a switched output (e.g., JAC1) needs to be frequently turned on and off, and it is undesirable to trigger a nuisance diagnostic alarm when it's off, the corresponding FuseDiag parameter in the PPDA configuration can be changed from its default "Enabled" to "Disabled".