The CV213 velocity transducer is a high-performance vibration measurement device from VM Sensing Systems. It is specifically designed for low-frequency vibration monitoring. Suitable for various industrial environments, it excels particularly in monitoring vibrations on slow-speed rotating machinery. Its robust construction, wide operating temperature range, and self-generating nature make it an ideal choice for critical equipment such as hydroelectric and steam turbines.

Features & Benefits

1. Wide Frequency Response & High Sensitivity

The CV213 offers a broad frequency response range from 10 Hz to 1 kHz, making it particularly adept at capturing low-frequency vibration signals. Its nominal sensitivity is 20 mV/mm/s (508 mV/in/s), with a tolerance of ±5% at 22°C, ensuring accurate and stable vibration data even on slow-speed machines.

2. Self-Generating Operation (No Power Required)

Operating on the electromagnetic induction principle, this transducer requires no external power supply. It generates a voltage output signal proportional to vibration velocity. This feature makes it especially suitable for portable measurement systems or remote monitoring applications where power availability is limited or undesirable.

3. Exceptional Environmental Durability

The CV213 operates reliably in extreme temperatures from -29°C to 204°C (-20°F to 400°F). It boasts an IP64 protection rating, making it resistant to dust and moisture ingress, and is suitable for damp, corrosive, or dusty industrial environments.

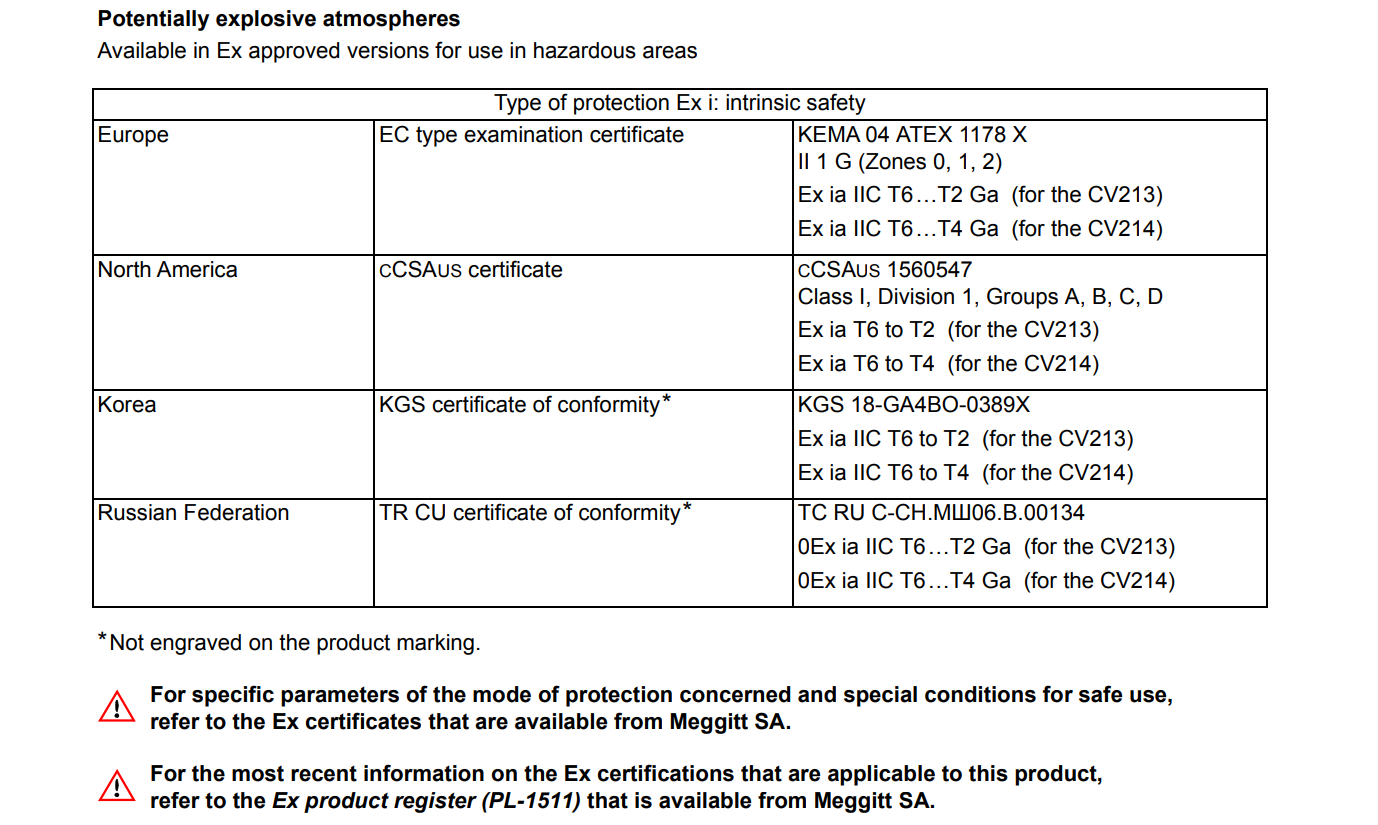

4. Certifications for Hazardous Areas

The transducer is certified for use in potentially explosive atmospheres by various international standards, including European ATEX, North American cCSAus, Korean KGS, and Russian TR CU. It is approved for safe operation in hazardous areas (e.g., Zone 0/1/2 or Division 1).

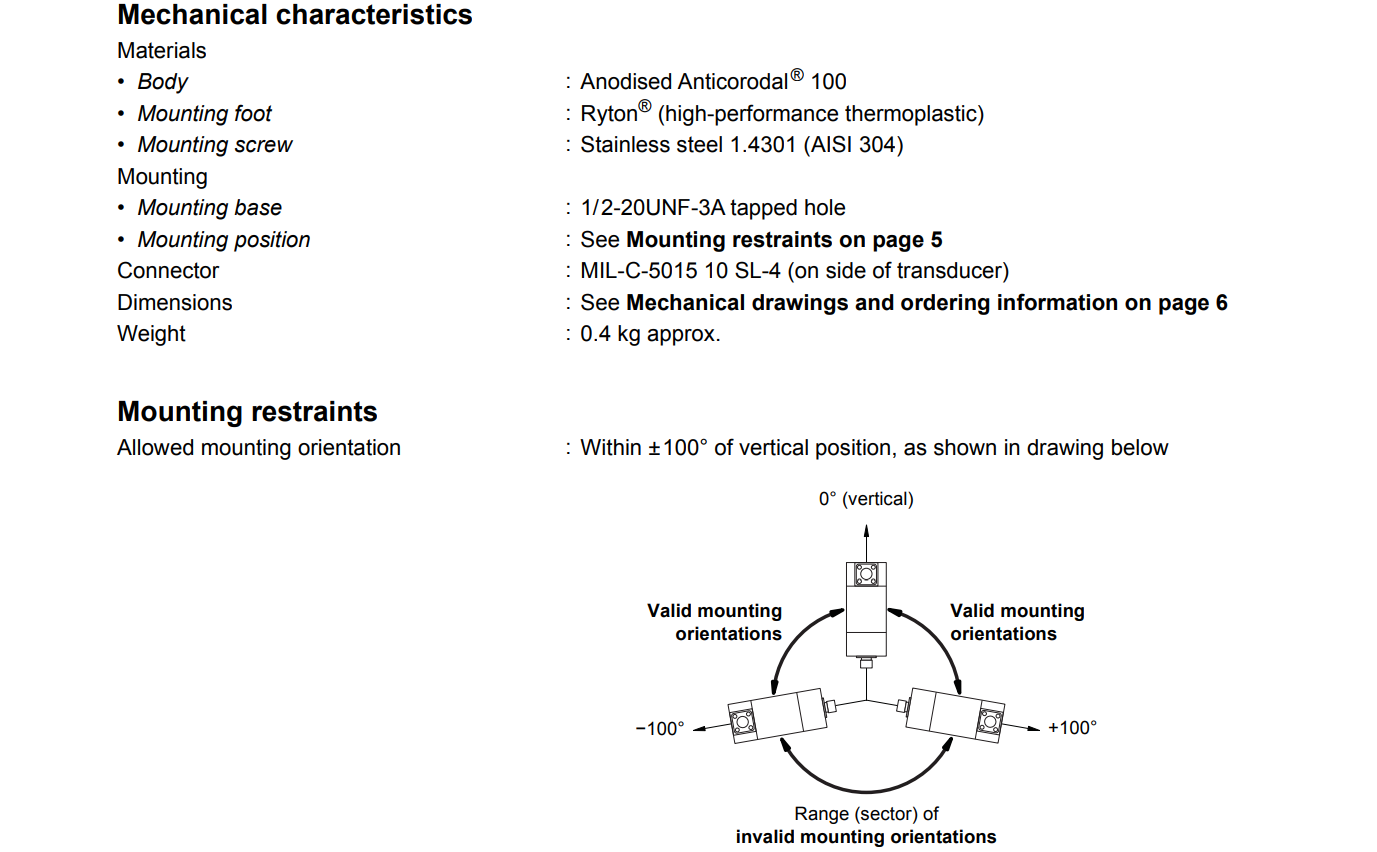

5. Rugged Mechanical Construction

The sensor housing is constructed from anodized Anticorodal® 100 aluminum alloy. The mounting foot is made of Rylon, a high-performance thermoplastic, and the mounting screw is stainless steel (AISI 304). This combination ensures overall durability and corrosion resistance.

6. Flexible Mounting Options

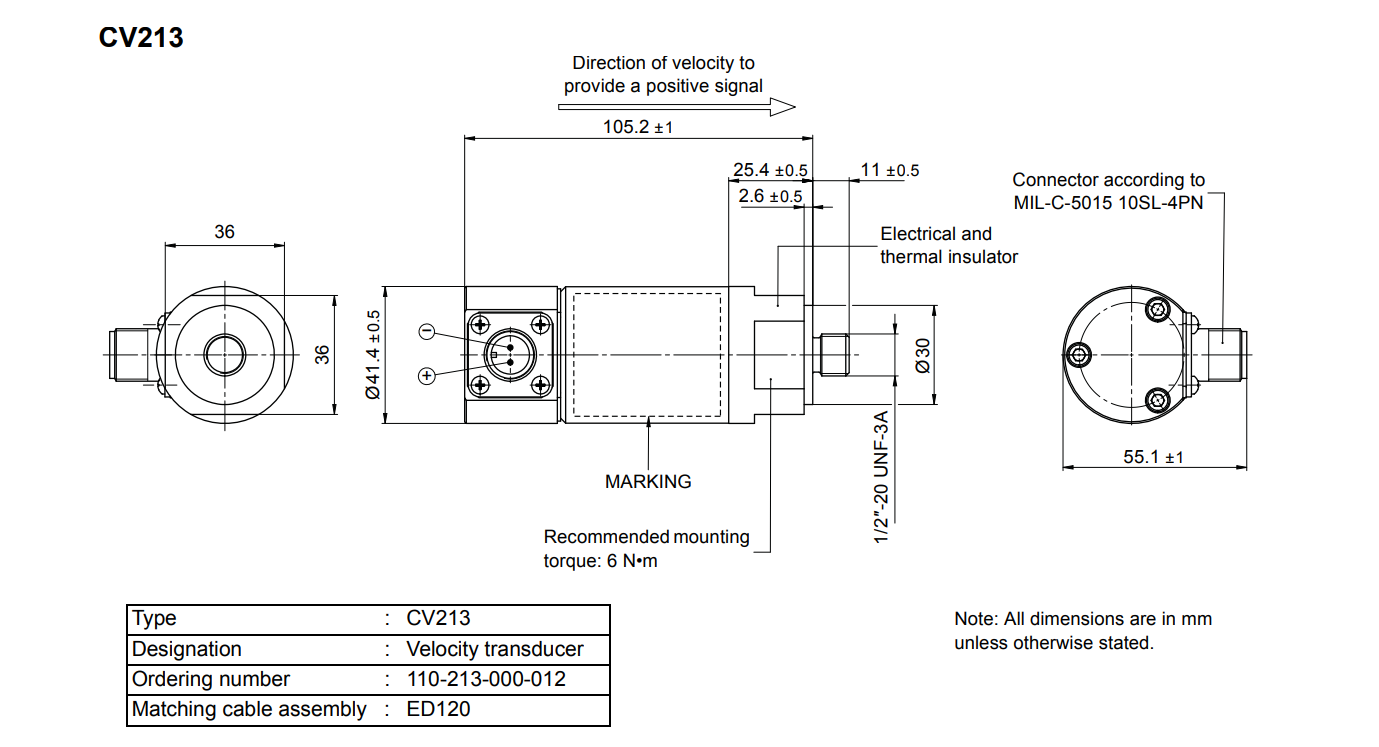

The CV213 can be mounted within ±100° of the vertical position, accommodating various mechanical layouts. The recommended mounting torque is 6 N·m, ensuring secure installation without damaging the equipment.

7. No Signal Conditioner Required

The transducer provides a voltage output signal that can be connected directly to monitoring electronics, eliminating the need for and cost associated with an additional signal conditioning module, thus simplifying system integration.

Working Principle

The CV213 velocity transducer operates based on the principle of electromagnetic induction. Its core sensing element consists of a moving coil surrounded by a permanent magnet. When the transducer is mounted on a vibrating structure, the vibration causes the coil to move relative to the magnet. According to Faraday's law of electromagnetic induction, this movement induces an electromotive force (voltage) in the coil, which is directly proportional to the vibration velocity.

Detailed Operational Mechanism:

Vibration Transfer: Vibration is transferred from the machine surface to the sensor's internal components via its mounting base.

Coil Movement: The relative motion between the coil and the magnet cuts the magnetic flux lines, generating an electromotive force.

Signal Output: The output voltage signal is transmitted to the monitoring equipment via a two-wire shielded cable. The signal amplitude directly corresponds to the vibration velocity.

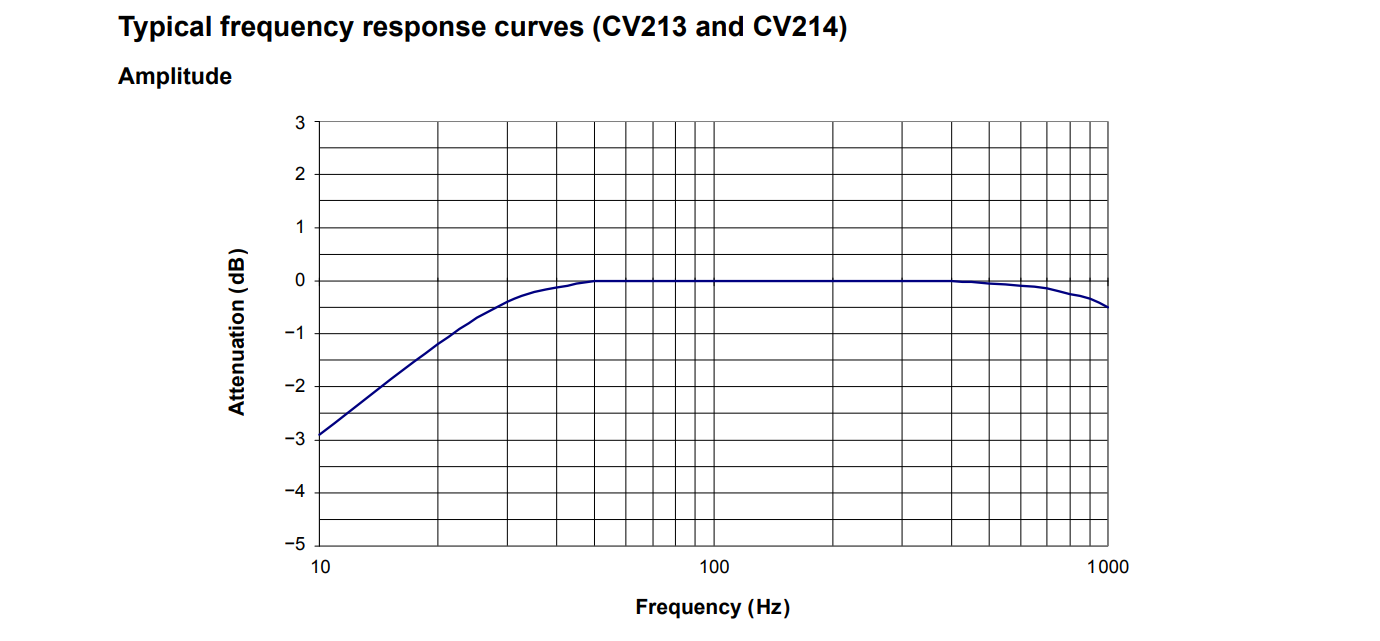

Frequency Response: The transducer offers excellent linear response within the 10 Hz to 1 kHz range. The low-frequency cutoff is 10 Hz (-3 dB). The response deviation is only ±0.5 dB within the 30–400 Hz range and ±1 dB within the 400 Hz–1 kHz range.

Advantages:

Self-Powered: Requires no external power supply, ideal for hazardous environments or remote locations.

High Signal-to-Noise Ratio: Low output impedance (<700 Ω) provides strong noise immunity.

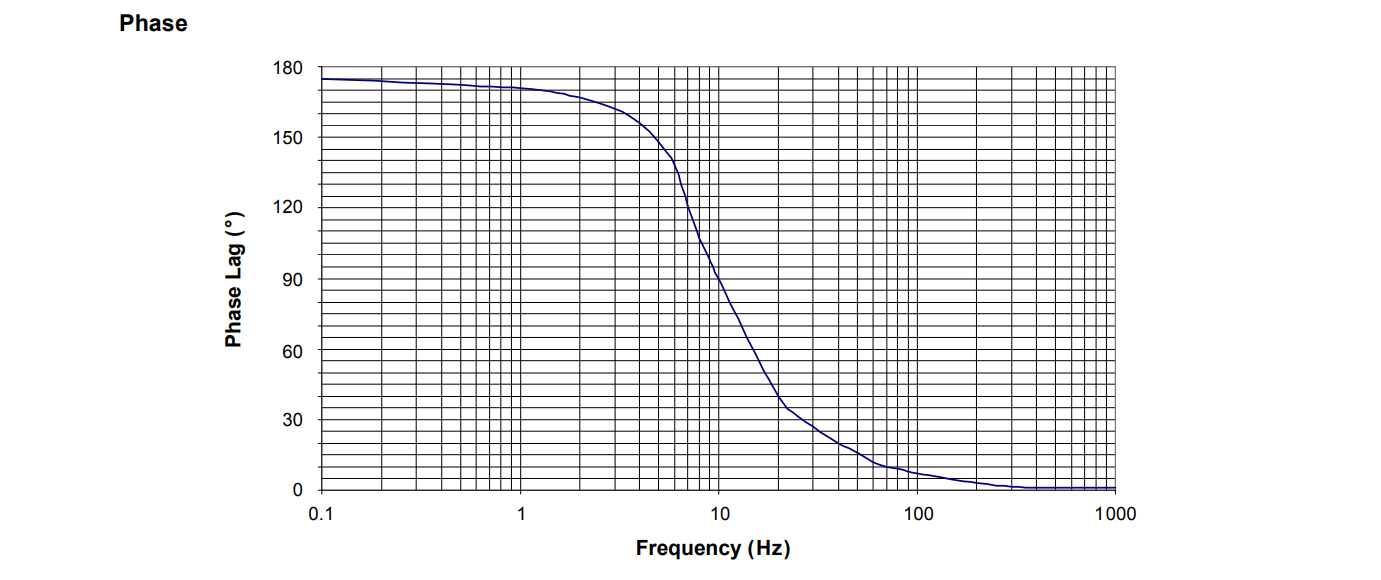

Stable Phase Response: Consistent phase response across the frequency band suits phase-sensitive diagnostic systems.

Applications

The CV213 is primarily used in the following fields:

Hydroelectric Generators: Monitoring vibration of turbines, generator bearings, and frames.

Steam Turbines: Suitable for vibration monitoring on critical components like high, intermediate, and low-pressure casings, and bearing housings.

Slow-Speed Industrial Machinery: Such as fans, pumps, compressors, and gearboxes.

Portable Vibration Measurement Systems: No power requirement facilitates easy temporary installation and spot checks on-site.

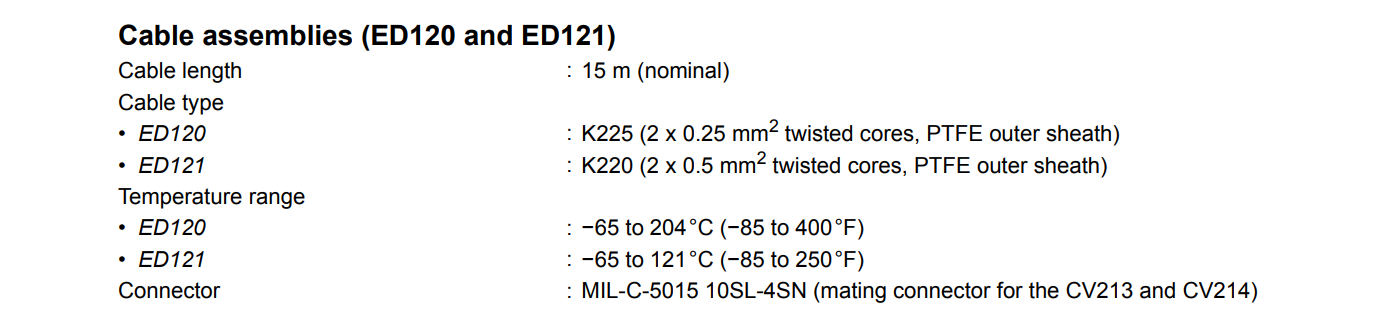

Matching Cable & Installation Advice

The CV213 is designed for use with the dedicated ED120 cable assembly. This cable has a nominal length of 15 meters, features twisted and shielded pairs (2 × 0.25 mm²), and has a PTFE outer sheath, supporting a temperature range from -65°C to 204°C. It is terminated with a MIL-C-5015 10SL-4SN connector, mating perfectly with the sensor's connector.

In extremely harsh industrial environments, it is recommended to protect the cable assembly further with a flexible metal conduit (sheath) for mechanical protection against damage or extreme heat.

Key Specifications Summary

Sensitivity: 20 mV/mm/s ±5%

Frequency Range: 10 Hz – 1 kHz

Operating Temperature: -29°C to 204°C (-20°F to 400°F)

Protection Rating: IP64 (IEC 60529)

Output Impedance: <700 Ω

Mounting Torque: 6 N·m

Weight: approx. 0.4 kg

Hazardous Area Certifications: ATEX, cCSAus, KGS, TR CU