The IS200AEPAH1A (Alternative Energy Pitch Axis) is a specialized I/O control module designed by General Electric (GE) for the Pitch Control System (PCS) of its 1.5 MW wind turbines. This module is a version of the Pitch Axis Controller (AEPA) and is compatible with the BPPB processor board. Its primary function is the precise angular control of individual wind turbine blades. The AEPAH1A module is installed in the Axis Box within the hub, with one AEPA module dedicated to each blade, working together to provide independent control of all three blades.

As the core execution unit of the pitch system, the IS200AEPAH1A module is responsible for receiving position commands from the central master controller, the AEPC (Alternative Energy Pitch Center). It converts these commands into a motor torque signal that drives the DC pitch motor, thereby adjusting the blade angle to achieve precise control of the turbine's rotor speed and torque.

System Architecture and Integration

1. System Composition

The Pitch Control System (PCS) consists of the following main components:

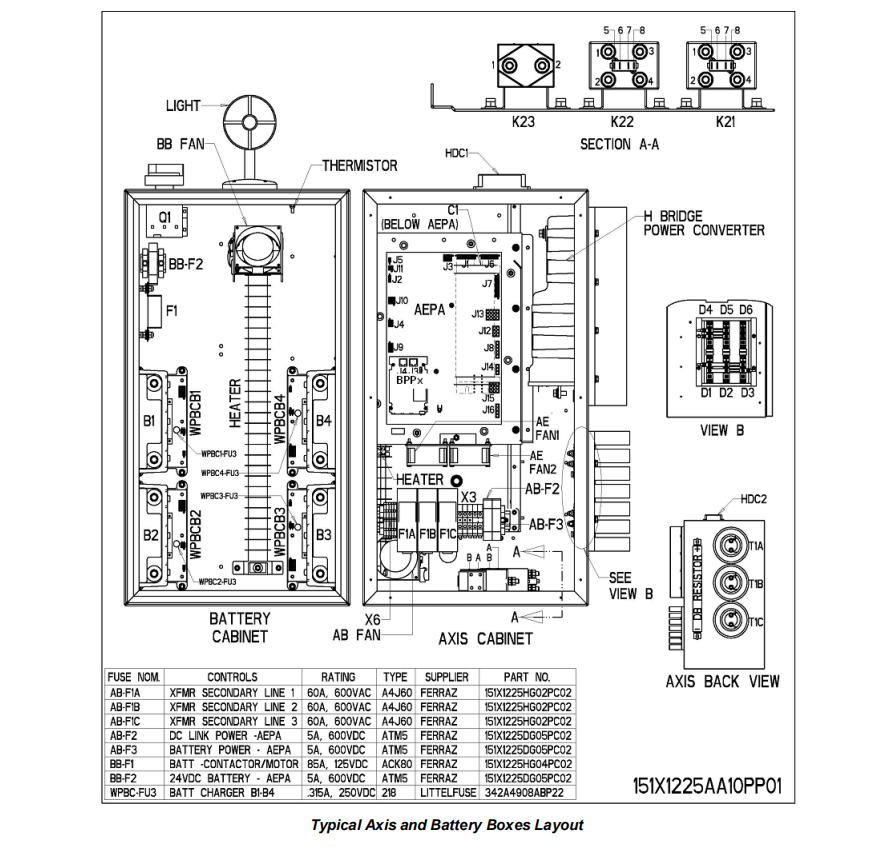

Center Box: Contains the AEPC module, responsible for power distribution, signal aggregation, and communication with the main turbine controller.

Axis Box: One per blade, housing the AEPA module (e.g., AEPAH1A), a 3-phase transformer, rectifier, power converter, and DC contactors.

Battery Box: Provides backup power for emergency feathering.

Pitch Motor: A DC motor with an integral brake and an incremental encoder.

The IS200AEPAH1A module, located in the Axis Box, is the critical link between control commands and motor execution.

2. Network Communication Structure

The IS200AEPAH1A communicates with the AEPC module via Ethernet, forming a star network topology:

The AEPC receives blade angle commands from the Bachmann® PLC via an RS-422 serial link.

The AEPC distributes these commands to the three AEPA modules (including AEPAH1A) over Ethernet.

The AEPA modules feed back current blade angle, motor status, fault information, etc., to the AEPC, which is then relayed to the main turbine controller.

This structure ensures low-latency transmission of control commands and efficient monitoring of system status.

Key Functions of the IS200AEPAH1A

1. Blade Position Control

The IS200AEPAH1A receives a position setpoint from the AEPC. Through an internal cascaded control loop (position-speed-torque), it drives the pitch motor to rotate the blade to the target angle. It offers high control precision and fast response, ensuring the turbine maintains optimal performance under varying wind conditions.

2. Speed and Torque Regulation

The module contains a built-in Speed Regulator and torque limiting functions. It can automatically adjust its output based on load changes to prevent motor overload or loss of control. The torque reference signal is output as a 4-20 mA analog signal to the motor power converter.

3. Motor Protection and Status Monitoring

The IS200AEPAH1A continuously monitors motor parameters such as current, voltage, and temperature. It includes protection functions against overcurrent, overtemperature, and stalling. Upon detecting an abnormality, it immediately triggers an alarm or shutdown to prevent equipment damage.

4. Encoder Feedback Processing

The pitch motor has a built-in incremental encoder. The IS200AEPAH1A receives the encoder signals to calculate the motor speed and the actual blade position in real-time, forming a closed-loop control system that ensures positional accuracy.

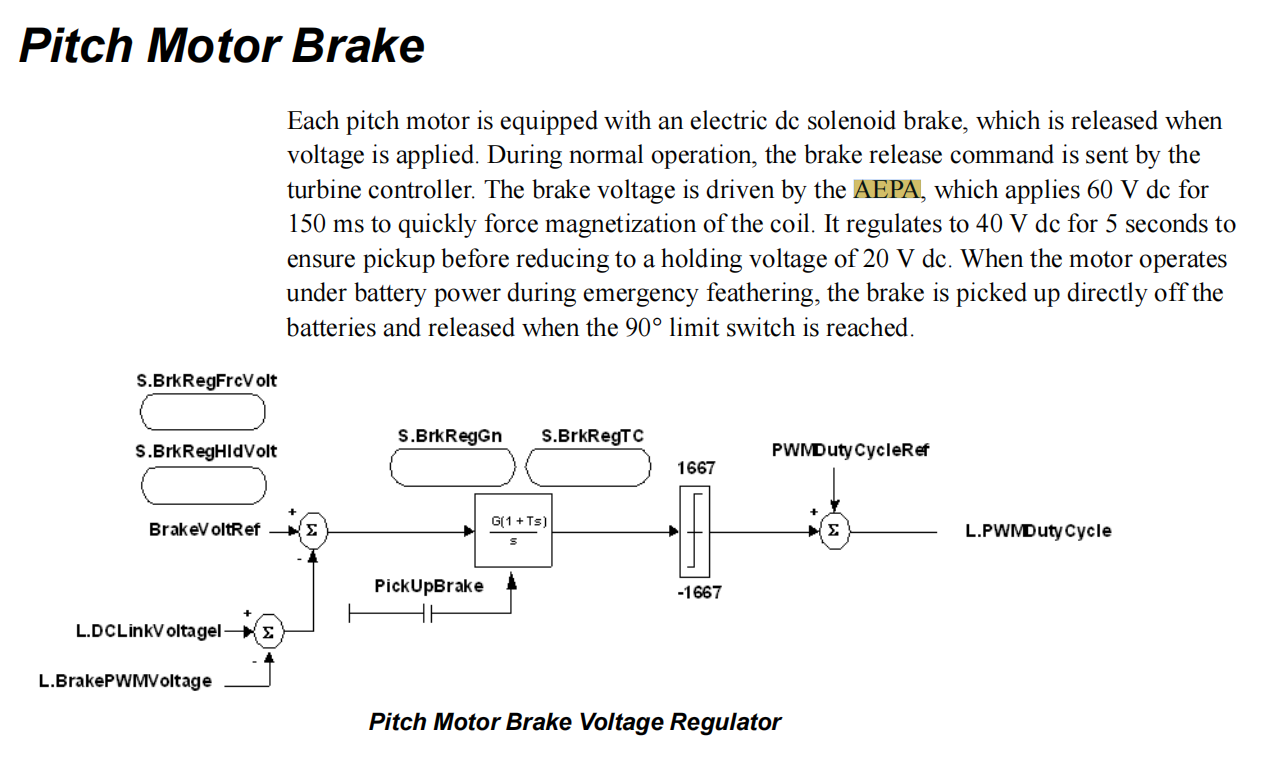

5. Brake Control

The module controls the pitch motor's electromagnetic brake using a multi-stage voltage strategy: it applies 60 Vdc for 150 ms for fast pickup, reduces to 40 Vdc for 5 seconds, and then maintains a holding voltage of 20 Vdc to keep the brake released during operation.

6. Emergency Feathering Function

In the event of a grid power loss or a safety loop break, the IS200AEPAH1A automatically switches to battery power and drives the blade to the 90° feather position, ensuring a safe turbine shutdown.

7. Battery Management and Self-Test

The IS200AEPAH1A communicates with the battery chargers via an RS-485 interface to monitor battery voltage, current, and charging status. It also initiates an automatic battery self-test every 30 minutes to verify the reliability of the backup power source.

Detailed Working Principles

1. Control Loop Structure

The control logic within the IS200AEPAH1A is structured in three cascaded layers:

Position Loop: Calculates the required speed based on the error between the setpoint and the feedback value.

Speed Loop: Calculates the required torque based on the speed command from the position loop.

Torque Loop: Outputs a PWM signal or analog current signal to the power converter to control the motor torque.

This cascaded structure ensures system stability and dynamic response.

2. Power Conversion and Motor Drive

The main power input is 400 Vac, 3-phase. This is stepped down to approximately 63 Vac by a transformer and then rectified to create an 80 Vdc link voltage. The pitch power converter, commanded by the IS200AEPAH1A, regulates the motor voltage and current using Pulse Width Modulation (PWM) techniques to achieve precise torque control.

3. Communication Protocol and Data Exchange

The IS200AEPAH1A uses GE's proprietary Ethernet Global Data (EGD) protocol to communicate with the AEPC. It transmits various signals, including angle, speed, torque, and fault codes. All signals can be monitored in real-time and recorded using the ToolboxST software.

4. Parameterization and Calibration

Each IS200AEPAH1A module has a unique set of parameters, including:

Parameters can be modified online via the Handheld HMI or the ToolboxST tool. Blade position calibration (referencing the 0° and 90° limit switches) is also performed through these interfaces.

Hardware Specifications and Compatibility

Model: IS200AEPAH1A (shipped as a single unit with the BPPB processor board).

Compatible Version: IS200AEPAH1C (compatible with the BPPC1 board, requires ControlST software suite V04.06 or later).

Operating Temperature: -30°C to +50°C (ambient inside hub).

Power Requirements: 24 Vdc control power; 80 Vdc maximum motor power.

Communication Interfaces: Ethernet (EGD), RS-485 (for charger/converter communication).

Installation: Plug-in module, requiring anti-static handling precautions.

Configuration and Maintenance Tools

1. ToolboxST Software

GE's ToolboxST application is the primary tool for configuring, monitoring, and diagnosing the IS200AEPAH1A module. Key features include:

Online monitoring of variables (position, speed, current, voltage, etc.)

Trend recording (Trender) for fault analysis

Dynamic Data Recorder (DDR) for capturing event data

Parameter modification and controller program download

Viewing fault alarms and diagnostics

2. Handheld HMI (Exor ePALM10)

Used for local manual operation, supporting the following functions:

Jogging the blade

Setting the gear ratio parameter

Executing blade position calibration

Viewing and setting IP addresses

Typical Application Scenarios

1. Normal Operation Mode

In Auto mode, the IS200AEPAH1A receives commands from the main turbine controller to continuously adjust the blade angle for optimal wind energy capture.

2. Maintenance Mode

In Manual mode, technicians use the Handheld HMI to directly control blade movement for installation, commissioning, or maintenance.

3. Emergency Feathering Mode

Upon detection of a safety loop break or mains power failure, the IS200AEPAH1A automatically switches to battery power to drive the blade to the safe 90° feather position.