The PA150 Probe Mounting Adaptor with Proximity Measurement Chain is a complete, self-contained non-contact displacement measurement system from VM product line. This integrated system combines a TQ912 eddy current proximity sensor and an IQS900 signal conditioner housed within a rugged, sealed enclosure, specifically designed for harsh industrial environments and hazardous areas (potentially explosive atmospheres). Its core function is to accurately measure relative shaft vibration and axial position in rotating machinery (such as steam turbines, gas turbines, hydraulic turbines, generators, turbo-compressors, and pumps). It is widely used for machinery protection, condition monitoring, overspeed detection systems (ODS), and safety-related applications, fully compliant with API 670 5th Edition standards.

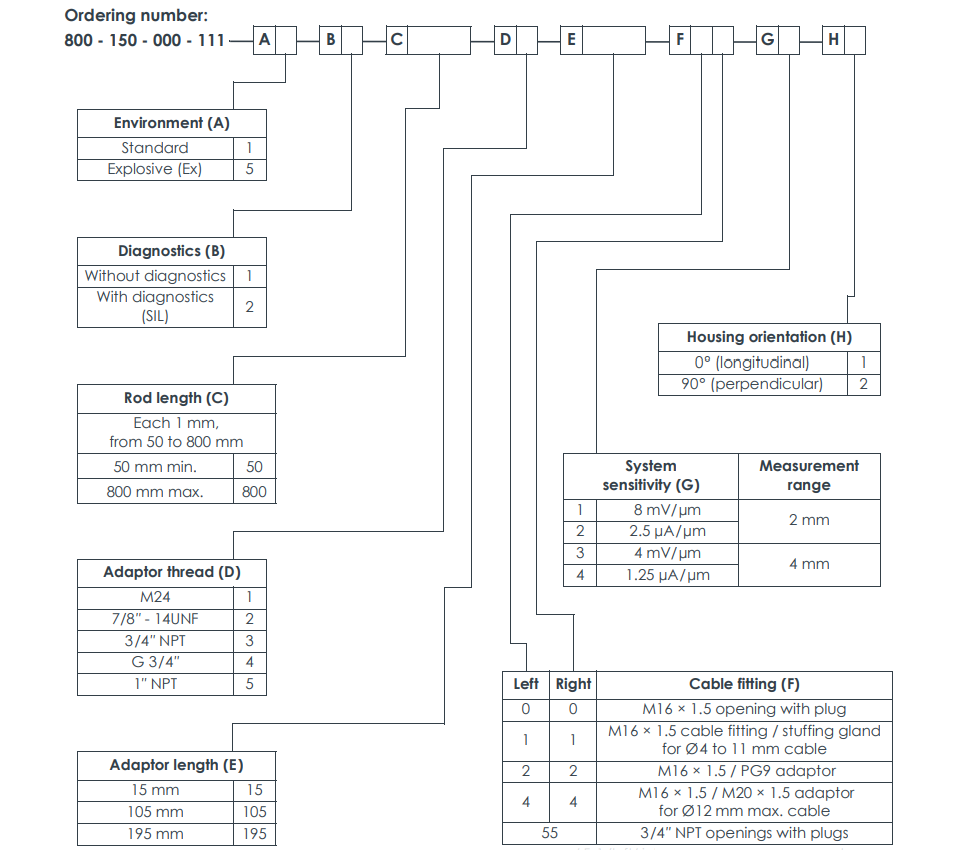

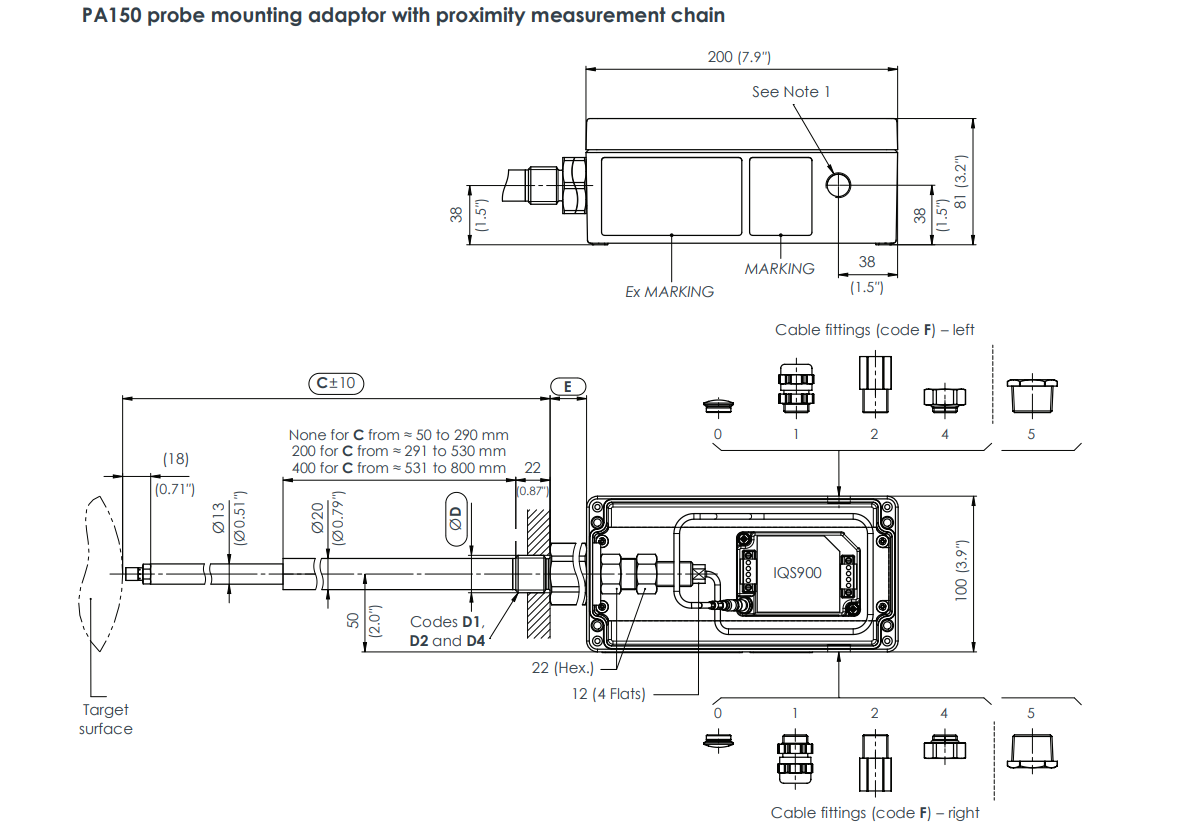

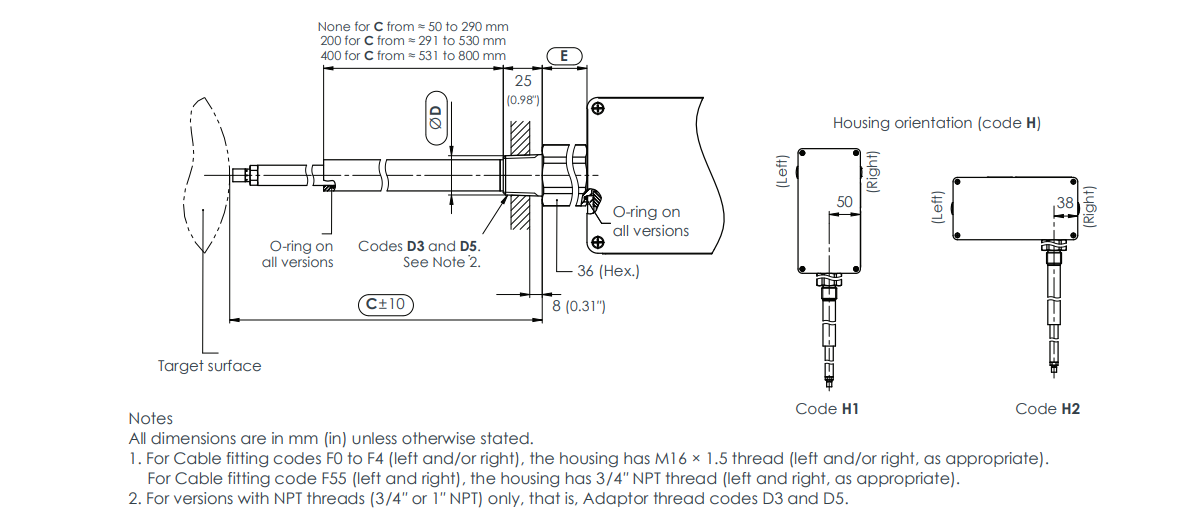

A key advantage of the PA150 is its highly integrated and modular design. It combines the sensor, a 1-meter integral cable, and the signal conditioner into a single unit, eliminating the need for a separate EA902 extension cable. Its unique removable housing with a U-shaped retainer facilitates exceptionally easy probe installation and gap adjustment, even while the machine is running. The adjustable stainless steel rod (available in lengths from 50 to 800 mm) and various adaptor thread and length options provide immense installation flexibility to adapt to complex machine structures and spatial constraints.

The system offers either voltage (3-wire) or current (2-wire) output, featuring short-circuit protection. Its frequency response extends up to DC to 20 kHz, enabling the capture of subtle vibration details in high-speed rotating machinery. The sensor end offers an extremely wide operating temperature range (-40°C to +180°C), allowing it to handle high-temperature environments. Furthermore, the PA150 is available in standard versions and explosion-proof (Ex) versions certified by various international standards (ATEX, IECEx, CSA, KGS, UKEX, EAC, etc.), meeting safety requirements for use in hazardous areas globally. The built-in IQS900 signal conditioner also supports optional built-in self-test (BIST) functionality, raw signal output, and test signal input, significantly simplifying system commissioning, field testing, and troubleshooting processes.

Working Principle

The PA150 system operates based on the Eddy Current Principle to achieve its high-precision, non-contact displacement measurement. Its working principle is a complex and precise process involving electromagnetic induction, high-frequency signal modulation and demodulation, signal linearization, temperature compensation, and built-in diagnostics. The process is elaborated step-by-step below.

1. Eddy Current Induction and Signal Generation

The core of the system is the TQ912 proximity sensor. Its head contains a probe consisting of a precision-wound coil, encapsulated in high-performance thermoplastic PPS (polyphenylene sulfide) and crimped into a stainless steel (AISI 316L) body. A high-frequency oscillator within the IQS900 signal conditioner generates an AC signal in the MHz range, which is transmitted to the sensor probe coil via a 70-ohm characteristic impedance coaxial cable.

When high-frequency current flows through the coil, it generates an alternating electromagnetic field at its front end. When this field approaches a conductive metal target (typically the machine's shaft), eddy currents are induced on the target surface according to Faraday's Law of Electromagnetic Induction. These eddy currents themselves generate a new magnetic field opposing the original field (Lenz's Law), causing a change in the effective impedance of the sensor coil. This change in impedance has a specific functional relationship (typically approximately a negative exponential relationship) with the gap distance between the probe tip and the target surface and is also influenced by the electromagnetic properties (conductivity, permeability) of the target material and the ambient temperature.

2. Signal Modulation, Transmission, and Demodulation

The change in the sensor coil's impedance amplitude-modulates the high-frequency carrier signal from the conditioner. That is, the amplitude of the return signal (carrying the distance information) contains the gap information. This modulated high-frequency signal is transmitted back to the IQS900 signal conditioner via the coaxial cable.

Inside the IQS900, the return signal is first pre-amplified. Subsequently, a precise demodulation circuit (often using phase-sensitive detection technology) is responsible for stripping away the high-frequency carrier, extracting a low-frequency voltage signal proportional to the change in coil impedance. This process is crucial; it must accurately restore the true amplitude of the impedance change while effectively suppressing noise introduced by power supply fluctuations, cable capacitance variations, and external electromagnetic interference (EMI), ensuring signal purity and reliability.

3. Linearization, Amplification, and Output Conversion

The raw voltage signal from the demodulator has a non-linear relationship with the gap distance. The internal processing circuit of the IQS900 includes a dedicated linearization module. This module processes the raw signal through complex algorithms (such as polynomial fitting or piecewise linear compensation) to convert it into a standard signal that has a highly linear proportional relationship with the mechanical gap.

Next, the linearized signal is sent to a precision amplification circuit for scaling and bias adjustment to precisely match the output range and sensitivity selected by the user through ordering options:

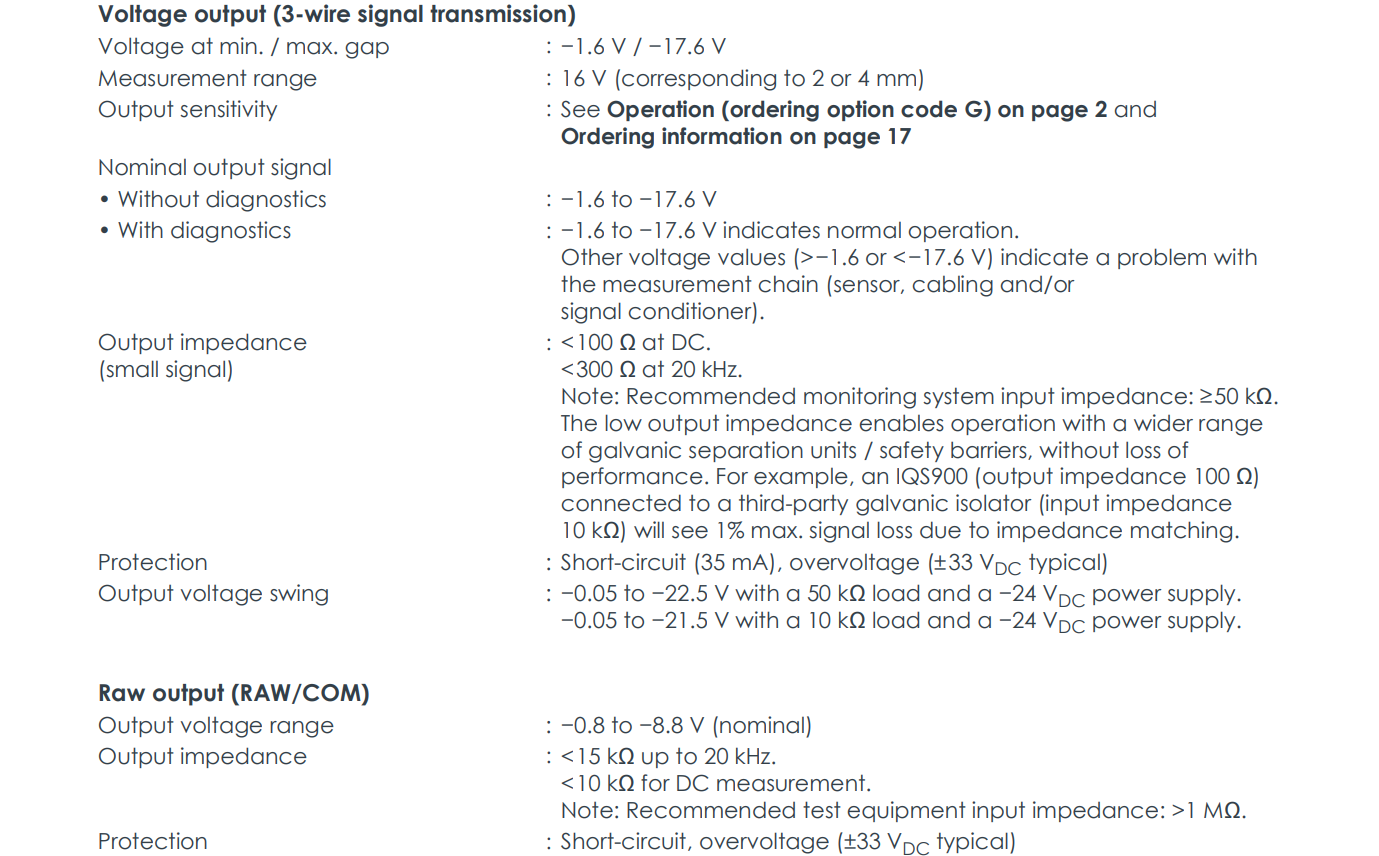

Voltage Output Mode (3-wire): Provides a linear voltage signal from -1.6 V (corresponding to minimum gap) to -17.6 V (corresponding to maximum gap). It features low output impedance (<100 Ω), a dynamic range of 16 V, and is suitable for short-distance transmission to data acquisition cards or PLCs, offering strong anti-interference capability.

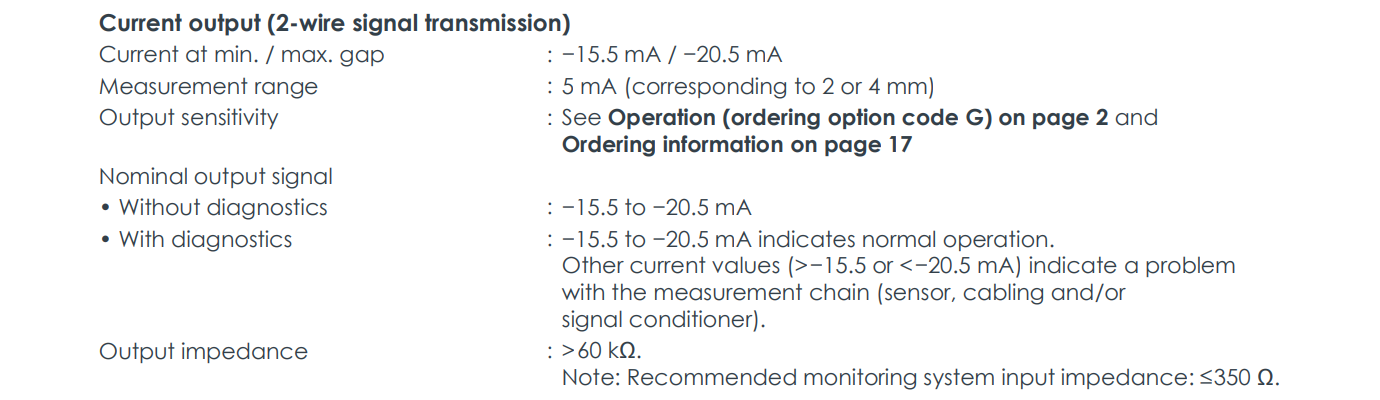

Current Output Mode (2-wire): Provides a current signal from -15.5 mA (min gap) to -20.5 mA (max gap). The dynamic range is 5 mA. Current output is immune to voltage drops and noise over long distances, making it ideal for long-distance transmission to control rooms or DCS systems, and inherently provides wire break detection.

Both outputs are designed with short-circuit protection and overvoltage protection.

4. Temperature Compensation and System Calibration

Temperature variations affect coil resistance, cable characteristics, and the electromagnetic properties of the target material. The PA150 system employs comprehensive temperature compensation design. An internal temperature sensor monitors the ambient temperature, and algorithms dynamically adjust the excitation signal amplitude or demodulation circuit parameters to maintain output signal stability and accuracy across the specified wide temperature range (Sensor: -40°C to +180°C; Conditioner: -40°C to +85°C), minimizing measurement drift (<5% @ -30 to 150°C).

The entire measurement chain (sensor + conditioner) is factory-calibrated using a standard VCL 140 steel (1.7225) target at 23°C ±5°C, ensuring complete interchangeability of components. This means the sensor or conditioner within the system can be replaced individually without recalibrating the entire system, greatly simplifying field maintenance and reducing spare parts inventory costs.

5. Built-in Diagnostics and Test Features (BIST)

The optional diagnostic functionality of the IQS900 signal conditioner is a standout feature. It supports Built-In Self-Test (BIST), which can continuously or on-demand automatically monitor the health of the measurement chain (including the sensor, cable, and conditioner itself). If a fault is detected (e.g., sensor open circuit, short circuit, cable damage, or internal conditioner fault), it alerts remotely by driving the output to a value outside the normal operating range (< -20.5 mA or > -15.5 mA; < -17.6 V or > -1.6 V), enabling predictive maintenance.

Furthermore, the IQS900 provides unique in-situ test support:

Raw Output (RAW/COM): Provides a "raw" voltage signal (-0.8 to -8.8 V) that directly reflects the internal signal received by the conditioner before final scaling processing. This is available even when the system is configured for current output. This function is used to verify the health of the link from the sensor to the front end of the signal conditioner.

Test Input (TEST/COM): Allows an AC test voltage signal to be injected into the conditioner's input. The conditioner processes this test signal as if it came from the real sensor and passes it to the main output. This is used to verify the integrity of the entire signal path from the signal conditioner to the subsequent monitoring system (including isolation barriers and wiring).

Together, these features enable efficient in-situ commissioning and troubleshooting without disconnecting wires or stopping the machine.

Key Features and Benefits

High Integration & Easy Installation: Integrates sensor, cable, and conditioner into one unit, eliminating external extension cables. Removable housing and U-shaped retainer allow for exceptionally easy probe installation and gap adjustment, supporting online adjustments while the machine is running.

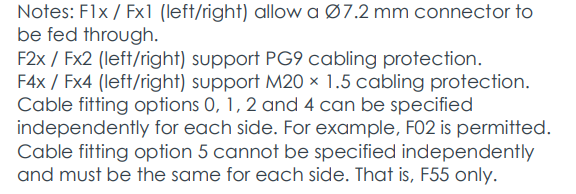

Excellent Mechanical Design & Adaptability: Features an adjustable stainless steel rod (50-800mm), various adaptor threads (M24, 7/8"-14UNF, 3/4"NPT, G3/4", 1"NPT) and lengths, and multiple cable fitting options (Option F), meeting almost all installation space and mechanical interface requirements.

Comprehensive Environmental & Safety Certifications: Sensor rated IP68, overall housing rated IP65. Available in explosion-proof (Ex) versions certified per ATEX, IECEx, CSA, KGS, UKEX, EAC, etc., for use in Zone 0/1/2 (Gas) and Zone 20/21/22 (Dust) hazardous areas. Complies with API 670 5th edition and functional safety standards SIL 2 (IEC 61508) / Cat 1 PL c (ISO 13849-1).

High-Performance Measurement Core: Based on the proven TQ912 & IQS900 measurement chain, offering 2mm or 4mm linear measurement range, with selectable sensitivity of 8 mV/μm, 4 mV/μm, 2.5 μA/μm, or 1.25 μA/μm. Wide frequency response (DC to 20 kHz) ensures capture of all relevant vibration components.

Advanced Diagnostics & Test Capabilities: Optional Built-In Self-Test (BIST) for real-time system health monitoring. Raw output and Test input interfaces support comprehensive in-situ commissioning and fault diagnosis, reducing downtime.

Robust Environmental Tolerance: Sensor withstands operating temperatures from -40°C to +180°C, pressure differentials up to 6 bar, vibration up to 5g, and shock up to 15g. Sealed aluminum housing (with Viton O-rings and NBR gasket) ensures the conditioner is protected in harsh industrial environments.

Flexible Electrical Output & Power Supply: Supports voltage and current output, compatible with most monitoring systems. Wide power supply range (-18 to -30 VDC), can be sourced from the monitoring system or an external safety power supply.

Applications

Machinery Protection Systems: For shaft relative vibration and axial position monitoring in large rotating machinery such as steam turbines, gas turbines, hydraulic turbines, compressors, pumps, and generators to prevent catastrophic failures.

Condition Monitoring & Predictive Maintenance: Provides high-precision vibration data for machine health analysis and fault diagnosis.

Overspeed Detection Systems (ODS): Serves as a speed (Keyphasor) sensor for critical overspeed protection functions.

Safety-Related Applications: With its SIL 2 certification, it can be used in machine protection loops requiring functional safety.

API 670 Applications: Fully compliant with the American Petroleum Institute's 5th Edition standard for machinery protection systems, making it ideal for the oil, gas, and petrochemical industries.

Hazardous Area Applications: Explosion-proof versions enable use in environments with explosive gases or dust, such as in oil & gas, chemical, and pharmaceutical industries.