The IQS452 is a high-performance signal conditioner developed by VM specifically designed to work with non-contact eddy current sensors such as the TQ422 and TQ432. This system is used for measuring shaft vibration and position changes in rotating machinery (e.g., turbines, pumps, compressors) and is widely applied in industries including energy, oil and gas, and hydropower, especially in high-pressure, high-temperature, or hazardous environments.

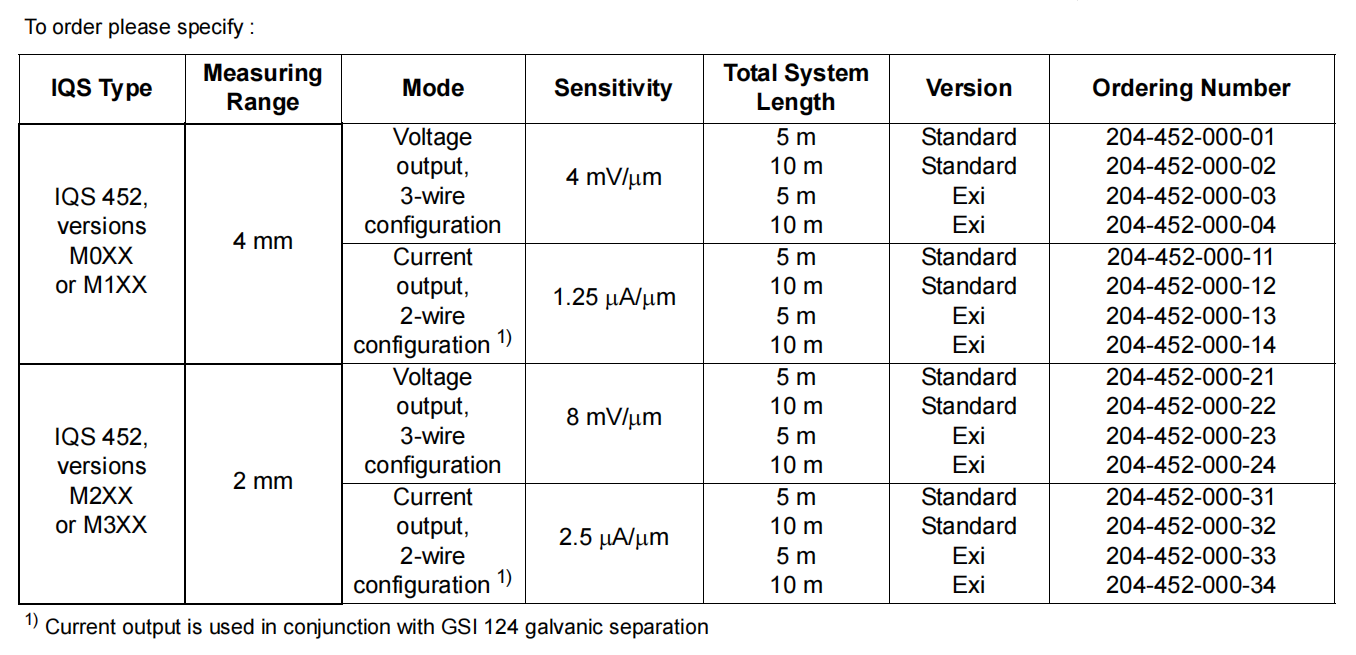

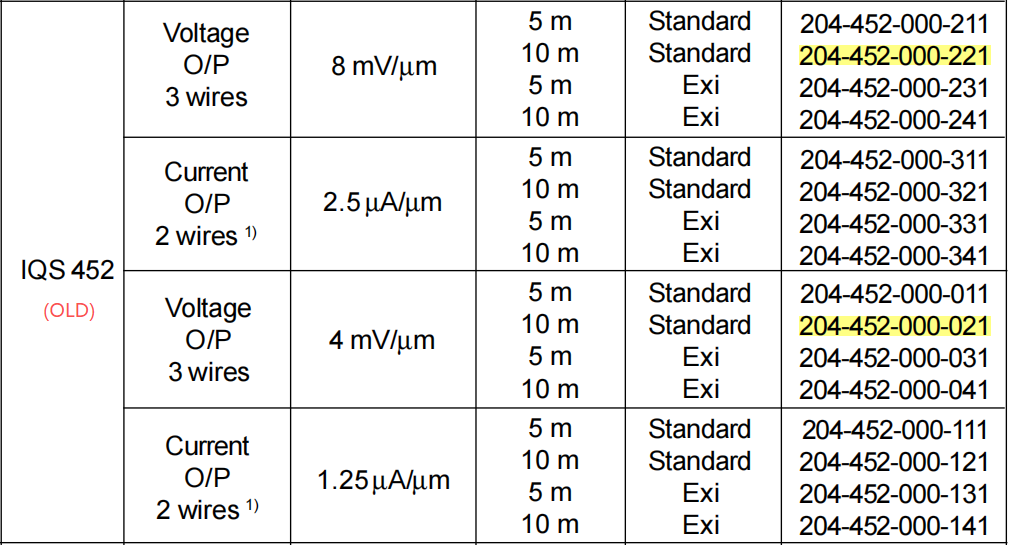

The IQS452 supports two output modes: voltage output (3-wire) and current output (2-wire). It offers excellent temperature stability and anti-interference capability, making it suitable for demanding industrial applications.

Comparison between IQS452 and IQS450

| Item |

IQS452 |

IQS450 |

| Measuring Range |

4 mm |

12 mm |

| Sensitivity |

4 mV/μm or 1.25 μA/μm |

1.33 mV/μm or 0.417 μA/μm |

| Pressure Resistance |

Up to 100 bar at sensor end |

High-pressure capability not explicitly stated |

| Temperature Range |

-30°C to +70°C (Conditioner) |

-35°C to +85°C (Conditioner) |

| Output Range |

Voltage: -2.4 V to -18.4 V

Current: 15.75–20.75 mA |

Voltage: -1.6 V to -17.6 V

Current: -15.5 to -20.5 mA |

| Application Scenario |

High-pressure environments (e.g., hydraulic turbines, submersible pumps) |

General industrial environments (e.g., steam turbines, compressors, generators) |

| Explosion-proof Certifications |

ATEX, IECEx, CSA |

ATEX, IECEx, CSA, KGS, EAC |

| Mechanical Interface |

Sensor with optional BOA armour protection |

Optional stainless steel hose or FEP sheath |

Working Principle

The IQS452 operates based on the Eddy Current Principle to achieve non-contact displacement measurement. Its working process involves multiple precision stages including electromagnetic induction, signal modulation and demodulation, linearization, and temperature compensation, each elaborated below.

1. Fundamentals of Eddy Current Sensors and Electromagnetic Induction

The core of an eddy current sensor is a coil driven by high-frequency alternating current. When brought near a conductive target (such as a metal shaft), eddy currents are induced on the target surface due to electromagnetic induction. According to Lenz's Law, these eddy currents generate an opposing magnetic field that reduces the effective impedance of the sensor coil. This change in impedance is highly correlated with the gap distance between the sensor and the target, although the relationship is inherently nonlinear and influenced by the electromagnetic properties of the target material (such as conductivity and permeability) and ambient temperature.

The IQS452 generates a high-frequency excitation signal (typically in the MHz range) via an internal oscillator. This signal is transmitted to the sensor coil through a high-quality coaxial cable. The high frequency is chosen to enhance the concentration of the eddy current effect on the surface (skin effect), thereby improving measurement sensitivity and resolution while reducing interference from the deeper structure of the target material.

2. Signal Modulation, Transmission, and Demodulation

The change in the sensor coil's impedance modulates (alters) the amplitude of the high-frequency carrier signal. This modulated signal travels back along the coaxial cable to the IQS452 signal conditioner. To minimize signal loss and noise interference during long-distance transmission, the system uses a coaxial structure with impedance matching (typically 70Ω).

Inside the IQS452, the returning high-frequency modulated signal is first pre-amplified. It then undergoes demodulation (typically using phase-sensitive or envelope detection techniques), a critical process that strips away the high-frequency carrier to extract the low-frequency voltage signal containing the distance information. This process must accurately restore the true amplitude of the impedance change while suppressing noise from power fluctuations, cable capacitance variations, and external electromagnetic interference.

3. Linearization, Amplification, and Output Conversion

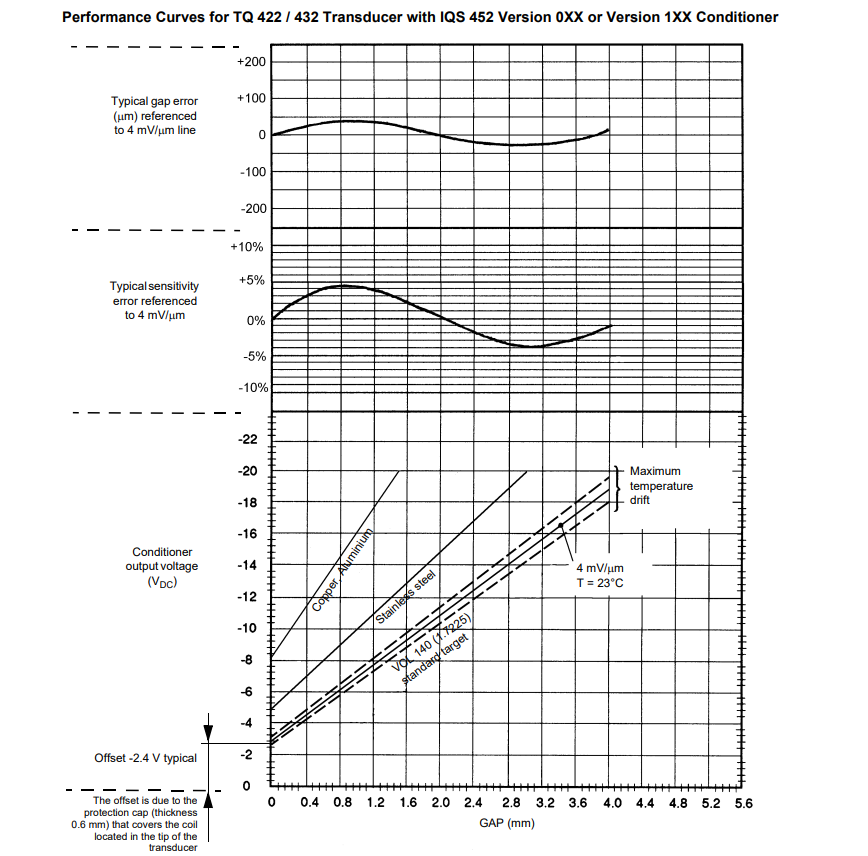

The raw voltage signal from the demodulator has a nonlinear relationship with distance (approximately a negative exponential function). The IQS452's internal processing circuit includes a dedicated linearization module that employs algorithms such as polynomial fitting or piecewise linear compensation to convert the nonlinear signal into a standard output that is highly linear with respect to the mechanical gap.

Subsequently, the linearized signal is sent to a precision amplification circuit for scaling and bias adjustment to match the user-selected output range:

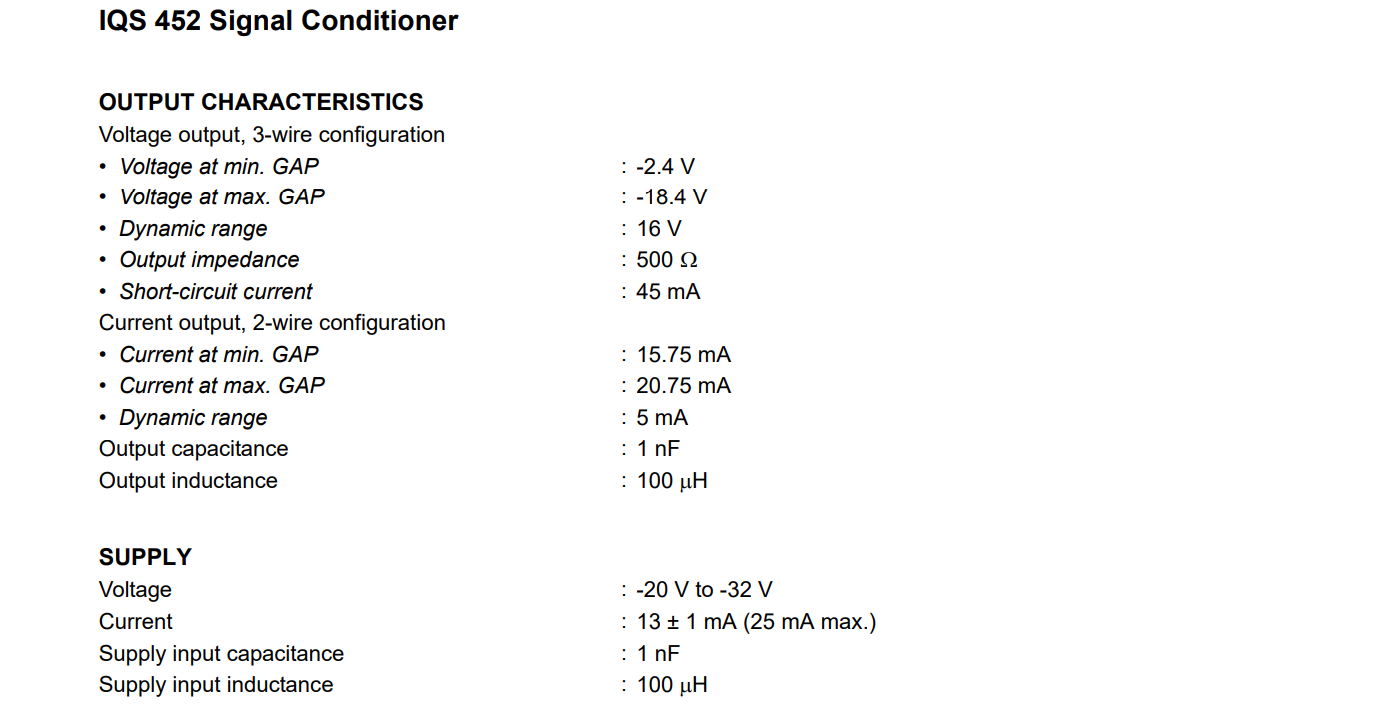

Voltage Output Mode (3-wire): Provides a linear voltage signal from -2.4 V (corresponding to the minimum gap of 0 mm) to -18.4 V (corresponding to the maximum gap of 4.0 mm). This mode features low output impedance (typically 500Ω) and strong anti-interference capability, making it suitable for short-distance transmission to data acquisition cards or PLCs.

Current Output Mode (2-wire): Provides a 4-20 mA loop current signal from 15.75 mA (0 mm) to 20.75 mA (4.0 mm). Current output is immune to voltage drops and noise over long distances, making it ideal for transmission to control rooms or DCS systems, and inherently provides wire break detection (zero current indicates a fault).

Both output circuits are designed with short-circuit protection to prevent damage from miswiring or faults.

4. Temperature Compensation and System Calibration

Temperature variations affect coil resistance, cable characteristics, and the electromagnetic properties of the target material. The IQS452 incorporates a temperature compensation design, using an internal temperature sensor to monitor ambient temperature and algorithms to dynamically adjust the amplitude of the excitation signal or the parameters of the demodulation circuit. This ensures stable output signals across the specified operating temperature range (-30°C to +70°C).

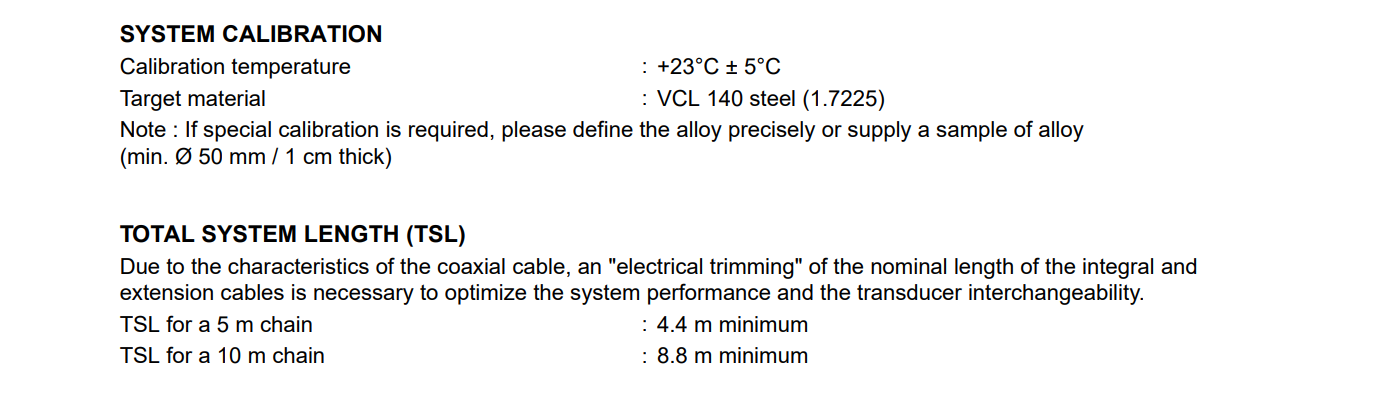

The entire system (sensor + cable + conditioner) is factory-calibrated using a standard VCL 140 steel (1.7225) target at 23°C ±5°C, ensuring interchangeability. This means any component within the system can be replaced individually without recalibrating the entire setup, greatly simplifying field maintenance.

Key Features and Benefits

The design of the IQS452 incorporates multiple advanced technologies to meet the stringent requirements for reliability, accuracy, and safety in industrial environments.

1. Superior High-Pressure and Environmental Adaptability

The TQ422/TQ432 sensors paired with the IQS452 are a core advantage. The sensor probe is made of robust PEEK (polyetheretherketone) material, which not only offers excellent mechanical strength and dimensional stability but can also directly withstand fluid pressures up to 100 bar (approximately 100 atmospheres). This makes it ideal for measuring shaft vibration and position in applications such as hydropower turbines (especially Francis and Kaplan types), deep-well submersible pumps, high-pressure compressors, and marine propulsion systems. The entire sensor body is constructed from stainless steel (1.4435) and potted with high-temperature epoxy resin, ensuring long-term durability in wet, high-pressure, and chemically corrosive environments.

2. Comprehensive Safety Certifications and Explosion Protection

The product design fully considers operational safety in hazardous environments, having obtained explosion-proof certifications from multiple global regions:

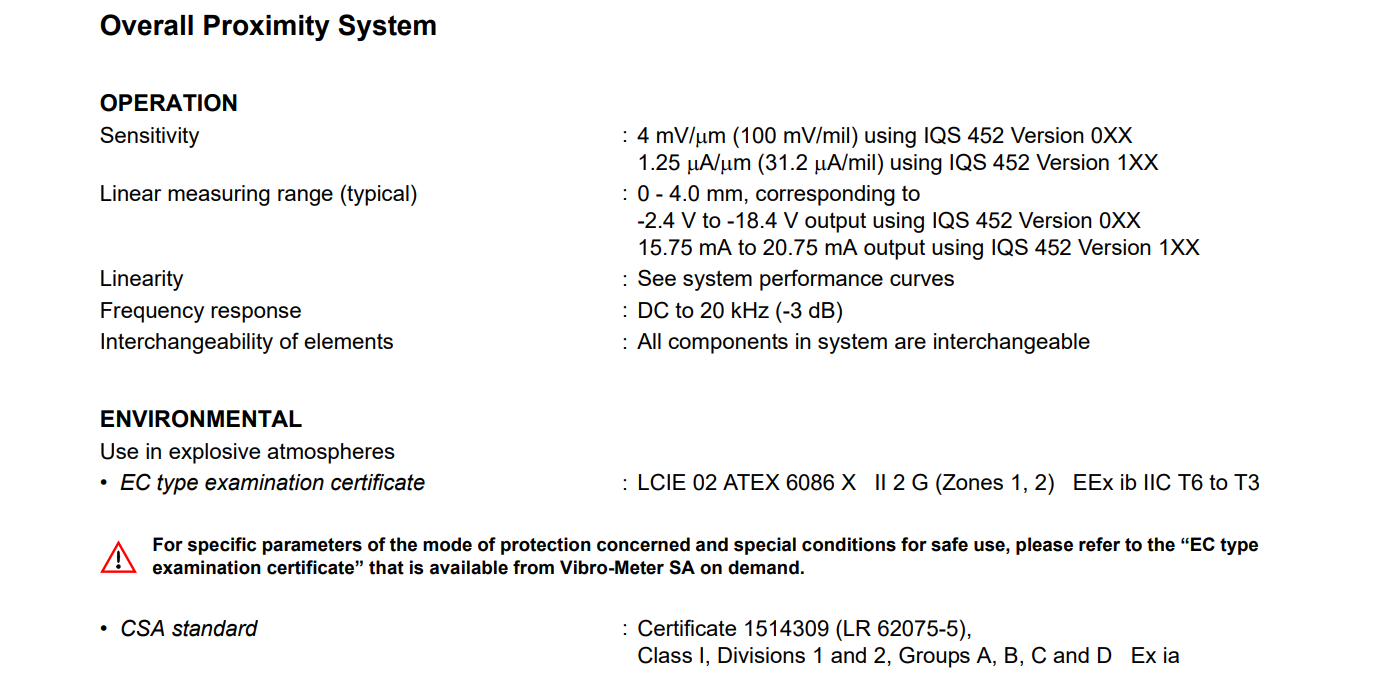

European ATEX Certification: LCIE 02 ATEX 6086 X, compliant with II 2G standards, suitable for Zone 1 & 2 explosive gas atmospheres (EEx ib IIC T6-T3).

North American CSA Certification: Certificate No. 1514309, compliant with Class I, Division 1 & 2, Groups A, B, C, D requirements, confirmed as Ex ia protection level.

International IECEx Certification: Provides globally recognized compliance proof.

These certifications mean that the IQS452 system (specific explosion-proof versions) has its circuit energy limited to extremely low levels, preventing ignition of surrounding explosive mixtures even in fault conditions, thus ensuring safety for critical industries like oil, gas, and chemicals.

3. High Accuracy, Wide Frequency Response, and Excellent Performance

High-Precision Measurement: The system provides high sensitivity of 4 mV/μm or 1.25 μA/μm, capable of detecting micron-level displacement changes accurately, delivering reliable data for predictive maintenance.

Wide Frequency Response: The frequency response ranges from DC to 20 kHz (-3 dB). This characteristic allows it to not only measure slow shaft displacements (like axial float) but also accurately capture high-frequency vibrations caused by imbalance, misalignment, gear meshing, etc., in high-speed rotating machinery (up to several hundred thousand RPM), providing rich spectral information for fault diagnosis.

Excellent Linearity and Temperature Stability: Internal linearization circuits and temperature compensation technology maintain highly linear output and stability across the full range and specified temperature range, minimizing measurement errors.

4. Robust Environmental Tolerance and Reliability

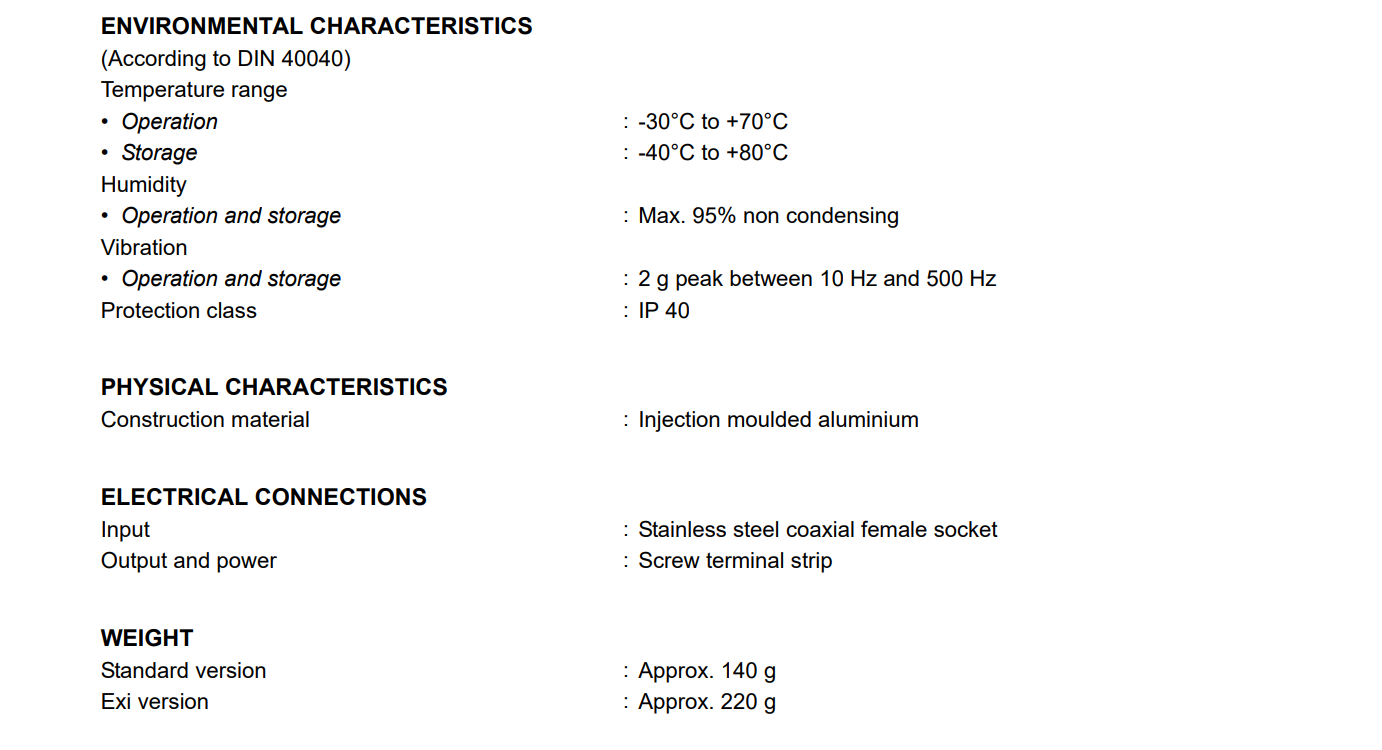

Wide Temperature Range: The signal conditioner operates reliably in ambient temperatures from -30°C to +70°C, while the sensor withstands temperatures from -25°C to +140°C.

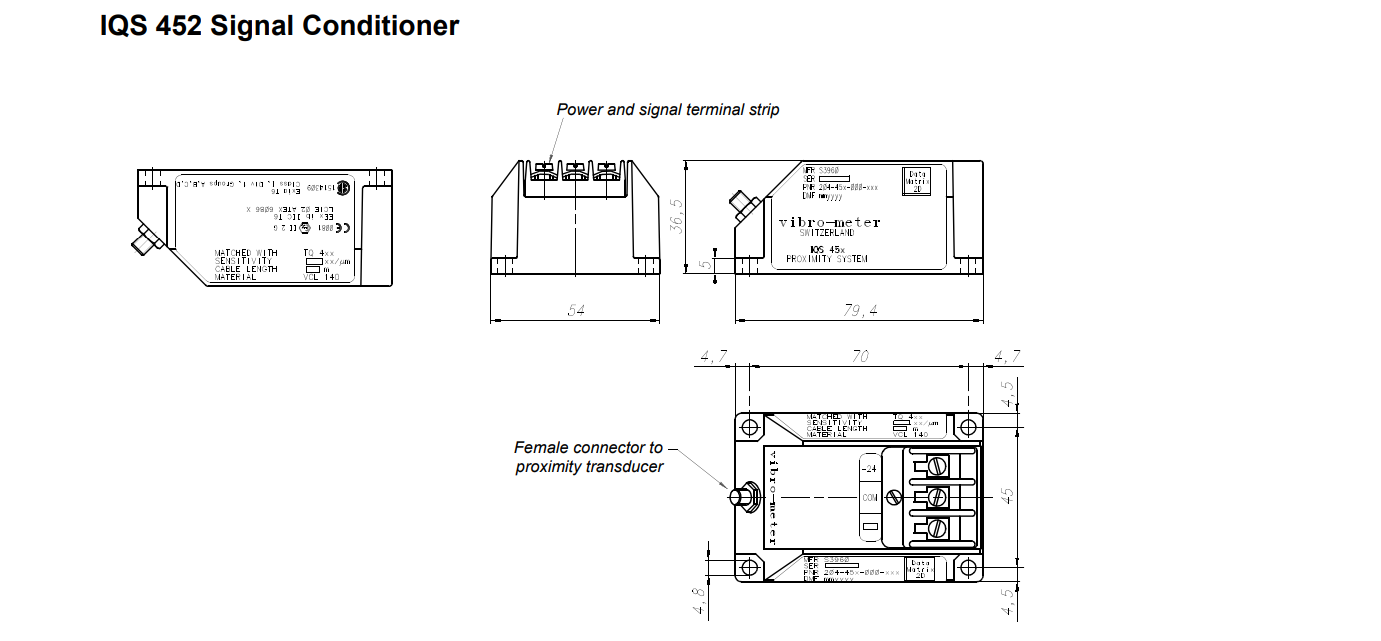

High Protection Rating: The sensor head achieves an IP68 protection rating (according to IEC 60529), allowing long-term submersion underwater; the signal conditioner is rated IP40, suitable for installation inside control cabinets.

Vibration and Shock Resistance: The conditioner withstands vibrations of 2g within 10-500 Hz, and the sensor endures vibrations of 5g and mechanical shocks of 15g (11ms half-sine wave), ensuring stable operation in highly vibrating mechanical environments.

5. System Flexibility and Ease of Use

Component Interchangeability: The sensor, extension cable, and conditioner form a pre-calibrated system where components can be replaced independently without recalibration, significantly reducing spare parts inventory and maintenance costs.

Multiple Output Options: Users can flexibly choose voltage or current output modes based on field wiring conditions and anti-interference needs.

Multiple Mounting Options: The signal conditioner can be mounted directly via screws or optionally fitted with an MA130 adapter for installation on standard DIN rails, facilitating integration.

Cable Protection Options: Optional stainless steel "BOA" armour sheathing and FEP outer sheath provide excellent mechanical abrasion protection and resistance to chemical corrosion.

Summary of Differences:

IQS452 is more suitable for high-pressure, high-reliability special environments, such as hydropower and deep-well pumps.

IQS450 is more versatile, with a larger measuring range (12 mm), suitable for vibration and position monitoring in most rotating machinery.

The two differ slightly in output characteristics, temperature range, and explosion-proof certifications, but share the same core working principle.