The IS420PPNGH1A (referred to as PPNG) is a PROFINET Gateway Module specifically designed for the GE Mark Vle control system. It acts as a critical bridge between the Mark Vle controller and third-party PROFINET I/O devices and smart sensors, enabling seamless data exchange between the PROFINET industrial Ethernet network and the core Mark Vle system's IONet. Certified as a PROFINET RT Version 2.2 I/O Controller and operating on 100 Mbps Ethernet interfaces, this module allows users to leverage the familiar ControlST* and ToolboxST* suites to integrate a wide range of PROFINET ecosystem products into a standard Mark Vle control architecture, significantly enhancing system flexibility and compatibility.

2. Core Functions & Detailed Principles

The core mission of the PPNG module is to enable reliable and efficient data interaction between different protocol networks. Its functions and principles are deeply integrated into the underlying architecture of the Mark Vle system and the communication mechanisms of PROFINET.

2.1 PROFINET and IONet Dual-Network Bridging

This is the PPNG's most fundamental function; it operates as an intelligent protocol converter and data router.

Technical Principle:

Network Role Definition: The PPNG module is equipped with three independent RJ-45 10/100 Mbps Ethernet ports. One port is dedicated to the PROFINET network, while the other two ports (ENET1, ENET2) are used to connect to the IONet network. This physical isolation ensures the independence and determinism of traffic for both networks, meeting the stringent real-time requirements of industrial control.

Data Mapping Mechanism: The PPNG is logically recognized by the Mark Vle controller as an I/O Pack. This means its communication behavior on the IONet is similar to other dedicated I/O cards within the system. The PPNG's internal firmware performs complex protocol conversion: it repackages input data (e.g., digital status, analog values) received from the PROFINET network from various slave devices and maps it into a process image area recognizable by the Mark Vle controller. Conversely, output data issued by the controller is also taken from the process image area by the PPNG, unpacked, and sent to the corresponding slave device according to the PROFINET protocol frame format.

Asynchronous Data Exchange: A key design feature is that the data exchange between the PPNG and PROFINET devices, and the data exchange between the PPNG and the Mark Vle controller, are asynchronous. The Data Update Cycle on the PROFINET side can be configured independently in ToolboxST (selectable from 1ms to 512ms), while the Mark Vle controller's Frame Scan Rate is another configurable parameter (e.g., 10ms, 20ms). The PPNG's internal data buffers smooth the transfer of information between the two networks with different cycles, ensuring data is not lost due to timing differences while also optimizing network load.

2.2 PROFINET I/O Controller Functionality

The PPNG acts as an I/O Controller on the PROFINET network, serving as the "master" that manages and controls all connected PROFINET slave devices.

Technical Principle:

Device Discovery and Configuration: Upon system startup or after configuration, the PPNG actively discovers and identifies all connected slave devices on the PROFINET network. This process relies on pre-configured GSDML (General Station Description Markup Language) files in ToolboxST. Provided by the device manufacturer, the GSDML file precisely describes the slave device's characteristics, supported modules, data length, and diagnostic information. ToolboxST uses these files to build the hardware configuration for the entire PROFINET network.

Establishment of Communication Relationships: A logical connection called a Communication Relationship (CR) is established between the PPNG and each slave device. This relationship consists of three types, collectively ensuring comprehensive communication:

Cyclic Data Exchange: Once all CRs are successfully established, the PPNG performs cyclic I/O data exchange with all slave devices according to the set update rate. This mechanism ensures the periodic refresh of process data, meeting the real-time requirements of industrial control.

Record Data CR: This is the first connection established, used for the transmission of non-real-time data, such as device power-up parameter configuration, firmware updates, detailed diagnostic information reading, and device identification queries. This communication is acyclic and occurs only when needed.

I/O Data CR: This is the core channel for real-time, cyclic data exchange. It is responsible for cyclically transferring input and output data between the PPNG and the slave at a fixed update rate, such as sensor readings and actuator control commands. This is the foundation for control logic execution.

Alarm CR: Used for the real-time, acyclic transmission of urgent events and alarms. If a slave device fails (e.g., short circuit, wire break, module missing), it immediately sends an alarm to the PPNG through this channel, ensuring the system can quickly respond to abnormal states.

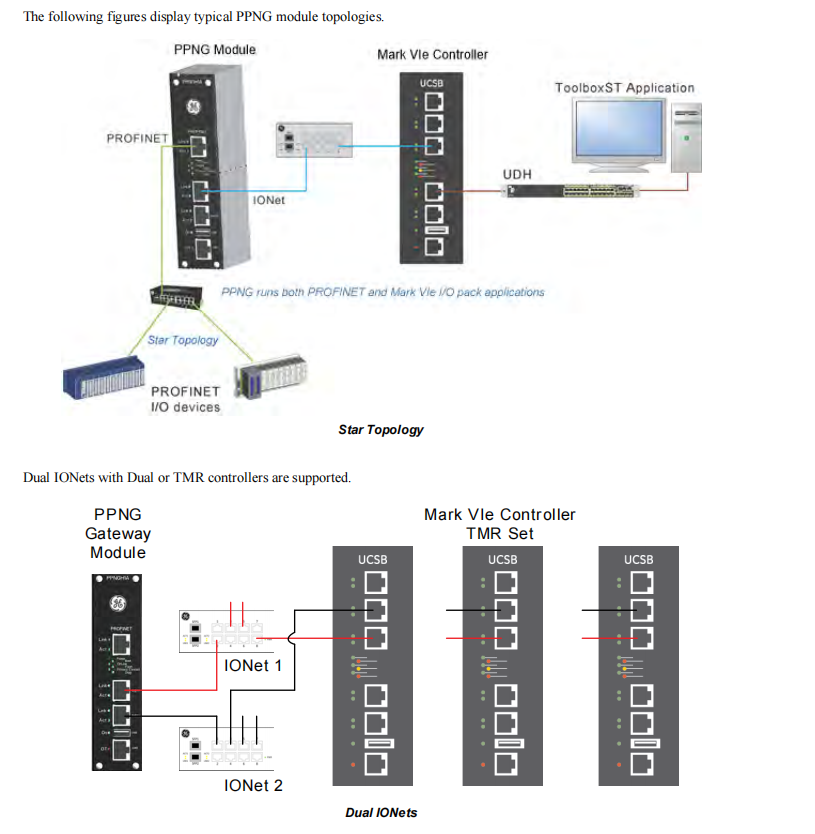

2.3 Flexible Network Topology Support

The PPNG offers multiple PROFINET network connection methods to suit different field layouts and cost considerations.

Technical Principle:

Star Topology: This is the most commonly used and recommended topology. The PPNG's PROFINET port connects to a GE-qualified unmanaged industrial Ethernet switch (e.g., ESWA 8-port or ESWB 16-port switch), and all PROFINET slave devices also connect to this switch. This topology is simple, easy to troubleshoot, and a fault in one slave does not affect the communication of others.

Line (Daisy-Chain) Topology: In this topology, the PPNG connects to the first slave, which then connects to the second, and so on, forming a chain. This topology saves switch costs and wiring. However, the documentation emphasizes that the PPNG must be at one end of the bus, and system performance may be limited because data from the end slave must pass through all intermediate slaves to reach the PPNG, imposing requirements on the switching performance of intermediate slaves.

Mixed Topology: The PPNG also supports a mix of star and line topologies. For example, a switch can be connected at a point within a daisy chain, extending a new star branch. This flexibility facilitates handling complex plant layouts.

2.4 High Performance and Scalability

The PPNG's design considers system performance boundaries to ensure stable operation in complex applications.

Technical Principle:

Performance Limits and Load Calculation: To prevent PPNG overload, there is an upper limit to the number of PROFINET devices it can connect. This limit is not a fixed value but is closely related to the Data Update Cycle of each device. The documentation introduces a "device equivalent" concept: a device with a 1ms update cycle is considered one standard load unit. The PPNG's maximum load capacity is 8 equivalent devices. If a device has a 2ms update cycle, its load is only 0.5 equivalent devices; a 4ms cycle equates to 0.25, and so on. Therefore, in practical configurations, by reasonably setting the update cycles, a single PPNG can connect up to 64 devices with an update cycle of 8ms or slower. The ToolboxST application enforces these limits during the build process.

System Expansion: Each Mark Vle controller can support up to 4 PPNG modules. This means the entire system can theoretically integrate hundreds of PROFINET slave devices, fully meeting the expansion needs of large, complex control systems.

2.5 Configuration and Integration

PPNG configuration is fully integrated into GE's ControlST engineering framework, providing a seamless user experience.

Technical Principle:

ToolboxST Configuration Workflow: Engineers use the ToolboxST "Component Editor" to add the PPNG hardware and use the "I/O Pack Setup Wizard" to transfer the base firmware from the Mark Vle controller to the PPNG. Subsequently, by importing the slave device's GSDML file, PROFINET devices are added via drag-and-drop in the graphical interface, and appropriate I/O data update rates are assigned.

Variable Connection: After configuration, every I/O point of a PROFINET slave device generates a corresponding variable in ToolboxST. These variables can be dragged and dropped, just like the controller's local I/O variables, and connected to the Mark Vle controller's application logic to implement complex control strategies. This design makes using PROFINET devices nearly indistinguishable from using native Mark Vle I/O devices in terms of programming experience.

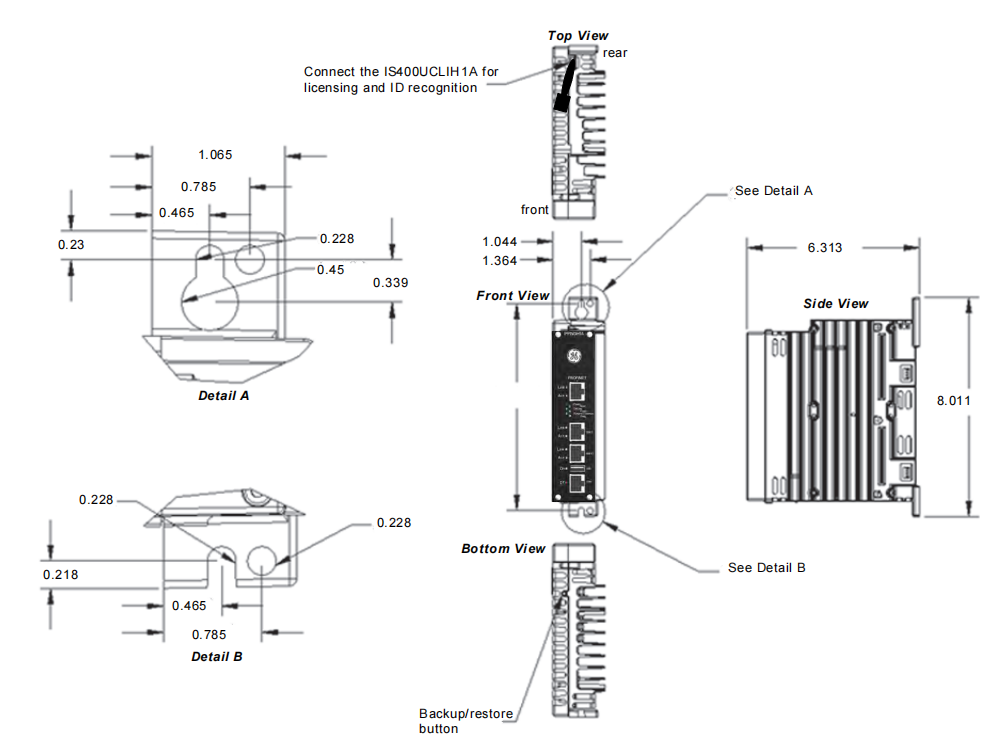

3. Hardware Specifications & Installation

Core Hardware: Utilizes an Intel EP80579 1066 MHz processor running the QNX Neutrino real-time operating system. Equipped with 256 MB DDR2 memory with ECC and 2 GB NAND flash.

Power Supply: Typical operating voltage is 28V DC, connected via a mandatory IS400UCLIH1A ID Assembly. This assembly not only transmits power but also provides license recognition and terminal board ID recognition for the PPNG module; without it, the PPNG will not function properly.

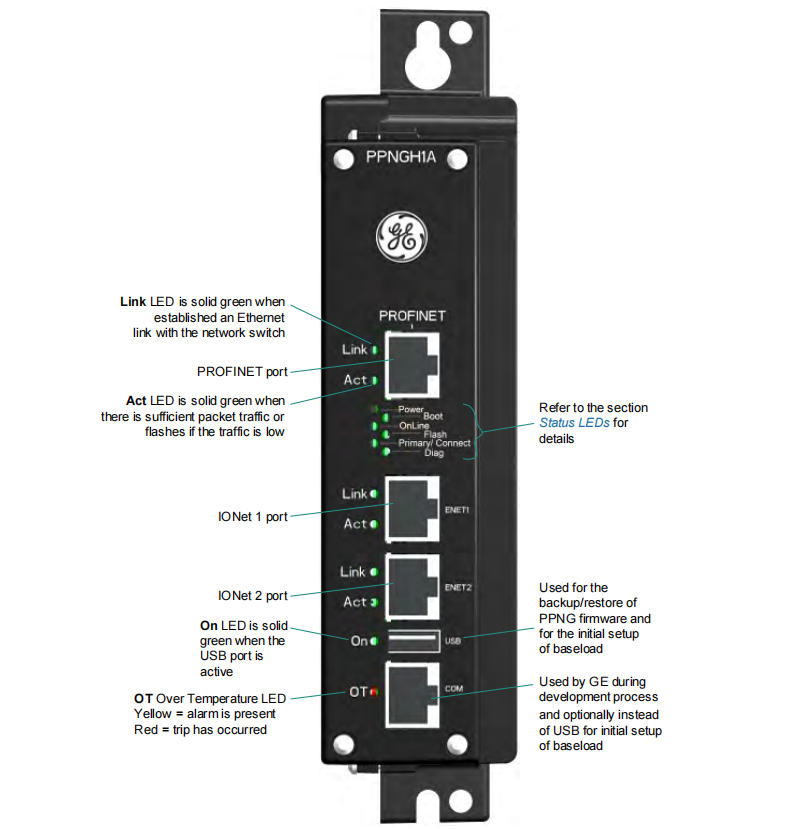

Interfaces:

PROFINET Port: 1 x RJ-45, for the PROFINET network.

IONet Ports: 2 x RJ-45 (ENET1, ENET2), supporting IONet network redundancy.

USB Port: For firmware backup/restore and initial base load setup.

COM Port: Used for development or as an alternative method for initial setup.

Installation: The module mounts directly onto panel sheet metal and must be installed vertically to ensure unobstructed airflow for cooling. Installation steps include mechanical fixing, connecting PROFINET and IONet network cables, connecting the ID assembly and power, and finally performing software configuration via ToolboxST.

4. Diagnostics & Maintenance

The PPNG provides multi-level, visual diagnostics, greatly facilitating system debugging and maintenance.

Front Panel LED Status Indicators: A rich set of LEDs provides real-time module status, including:

Power, Online: Indicate power and operational status.

Link/Act: Show link status and data activity for PROFINET and IONet ports.

Primary/Connect: Solid green indicates the PPNG is the primary and all devices are connected; flashing indicates one or more devices are disconnected.

Diag: Solid red indicates an active diagnostic alarm.

OT: Yellow indicates an over-temperature alarm; red indicates a temperature trip has occurred.

Boot: Indicates boot failures (e.g., memory test failure, firmware checksum error) via specific flashing codes during startup.

Software Diagnostics: Within ToolboxST, detailed diagnostic information for the PPNG itself, as well as diagnostic alarms reported by all PROFINET slave devices (e.g., module plug/unplug, short circuits, communication errors), can be viewed. These diagnostic messages can be acknowledged and reset.

Controller Variables: The PPNG provides a set of key status variables to the Mark Vle controller (e.g., L3DIAG_PPNG_R, LINK_OK_PPNG_R, CPU_HOT_PPNG_R, BoardTmpr_PPNG_R). This allows the control system logic and operator interface to monitor the PPNG's health in real-time and implement high-level and interlock protection.