The 330980 sensor is the core signal-processing unit of the 3300 XL NSv Proximity Transducer System, manufactured by Bently Nevada, a Baker Hughes business. This system is a high-precision, high-reliability solution designed for condition monitoring and protection of critical rotating machinery across modern industries. It excels in applications with challenging installation spaces and small measurement targets, such as in centrifugal air compressors, refrigeration compressors, and process gas compressors. As the system's brain, the 330980 Proximitor Sensor is responsible for powering the probe, processing the raw signal, and delivering a standardized, high-signal-to-noise measurement output. It is the critical component that enables the precise conversion of physical gap into a readable electrical signal.

The system forms a complete measurement chain, comprising three precisely matched components:

3300 NSv Probe: Acts as the "eyes" of the system, directly facing the target to generate the primary electromagnetic induction signal.

3300 NSv Extension Cable: Serves as the "nerves," tasked with transmitting the high-frequency signal between the probe and the sensor with minimal loss and distortion.

3300 XL NSv Proximitor Sensor (e.g., 330980): Functions as the "brain," providing power, processing the signal, and outputting a standard signal.

The system is engineered to address specific installation constraints, with typical application scenarios including:

Locations where counterbore, side-view, or rear-view access is restricted, preventing the use of standard 5 mm or 8 mm transducer systems.

Small-target applications, such as measuring radial vibration on shafts smaller than 51 mm (2 inches) in diameter or measuring axial (thrust) position on flat targets smaller than 15 mm (0.6 inches).

Precise measurement of radial vibration, radial position, axial position, speed, and Keyphasor signals on fluid-film bearing machines.

II. Detailed Core Functions

The 330980 sensor is more than a simple signal amplifier; it is an intelligent transmitter unit integrating multiple key functions:

Radial Vibration Measurement and Protection

This is one of the system's most fundamental and vital functions. Using two sensor systems with probes mounted orthogonally (typically in X and Y directions) on a bearing housing, perpendicular to the shaft, the 330980 sensor continuously monitors the dynamic movement of the rotating shaft within the bearing. It captures vibration signals caused by common faults like rotor unbalance, misalignment, shaft bend, component looseness, or oil whirl. The output voltage signal is proportional to the vibration displacement peak-to-peak. Monitoring systems use these signals to assess machine health in real-time, triggering alarms or shutdowns when vibration limits are exceeded, thereby preventing catastrophic failures.

Axial (Thrust) Position Monitoring

For machines with thrust collars (e.g., compressors, steam turbines), monitoring the rotor's axial movement is critical. The 330980 sensor, paired with a probe aimed at the thrust collar, accurately measures the rotor's minute axial shifts. This monitors thrust bearing wear and prevents the rotor from contacting stationary components. Accurate axial position measurement is decisive in avoiding severe machine damage caused by thrust bearing failure.

Speed and Zero Speed Detection

Via a dedicated probe known as a Keyphasor, the 330980 sensor generates a pulse signal for each revolution of the shaft. This pulse provides precise rotational speed information and serves as the phase reference for vibration analysis. Concurrently, this signal is used for zero-speed detection, confirming whether the rotor has completely stopped, which is essential for automation sequences like turning gear interlocking and start-up sequencing.

Phase Reference Signal Provision

The Keyphasor pulse is not just a speed signal; it is the phase reference for vibration analysis. By correlating the vibration waveform with the Keyphasor pulse in time, the high spot of the vibration can be determined. This is used for field balancing and fault diagnosis (e.g., identifying rotor cracks, blade pass frequency). The clean, stable Keyphasor signal output by the 330980 sensor is foundational for advanced vibration analysis and diagnostics.

System Compatibility and Upgrade Path

The 330980 sensor is designed with strong backward compatibility. It can directly replace the Proximitor module in earlier 3300 RAM Transducer Systems, utilizing existing probes and extension cables, offering users a low-cost upgrade path. For upgrading from older 3000-series or 7000-series I90 systems, the transition to the 3300 XL NSv system requires replacing the probe, cable, and sensor with NSv components, thereby gaining superior performance and enhanced chemical resistance.

III. In-Depth Working Principle: Eddy Current Sensing Technology

The 330980 sensor and its system operate on the well-established physical principle of the eddy current effect to achieve non-contact, high-precision displacement and vibration measurement. The detailed working process is as follows:

High-Frequency Oscillator and Magnetic Field Generation

Inside the 330980 sensor is a precise high-frequency oscillator circuit. This circuit generates a stable, high-frequency alternating current, typically in the 1 MHz to 2 MHz range, which is delivered to the coil of the probe via the extension cable. When this current flows through the probe's front-end coil, it generates a high-frequency alternating magnetic field around it. This field projects forward from the probe tip, with its strength decaying rapidly with increasing distance.

Eddy Current Generation in the Target Conductor

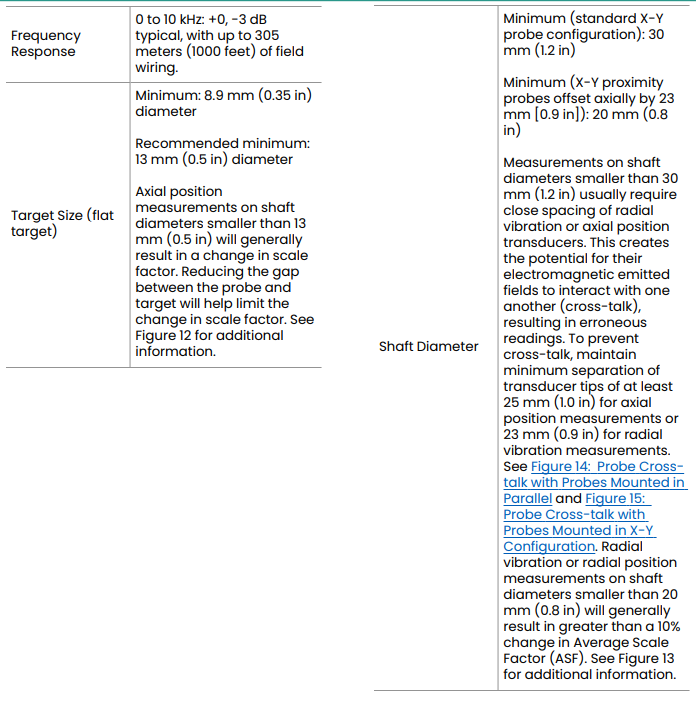

When this high-frequency alternating magnetic field approaches any electrically conductive surface (typically the machine's steel shaft or thrust collar), according to Faraday's Law of Electromagnetic Induction, the changing magnetic field induces closed-loop circulating currents, called eddy currents, on the conductor surface. The distribution and strength of these eddy currents depend on several factors, but most critically on the gap between the probe tip and the conductor surface.

Change in Probe Coil Impedance

The induced eddy currents themselves generate a secondary magnetic field, opposite in direction to the original field. According to Lenz's Law, this secondary field opposes the change in the primary field. This interaction causes a change in the effective electrical impedance of the probe coil. Specifically, as the gap decreases, the eddy current effect strengthens, causing a greater change in coil impedance. As the gap increases, the effect weakens, and the impedance change is smaller. Thus, the mechanical gap information is accurately "encoded" as a change in the electrical impedance of the probe coil.

Signal Detection, Demodulation, and Linearization

This is the core processing stage within the 330980 sensor. The sensor's internal circuitry continuously monitors these minute impedance changes in the probe coil. A demodulation circuit extracts the gap-modulated information from the high-frequency carrier signal. Subsequently, through amplification and linearization processes, this signal is converted into a DC voltage signal that has a highly linear relationship with the gap. The standard Average Scale Factor for the 3300 XL NSv system is 7.87 V/mm (200 mV/mil), meaning the output voltage changes by approximately 7.87 volts for every 1 mm of target movement.

Temperature Compensation and Stability Assurance

Variations in ambient temperature can affect the probe coil's resistance and the characteristics of the sensor's electronic components. The 330980 sensor incorporates internal temperature compensation circuits that automatically counteract output drift caused by temperature variations within the specified ambient range (0°C to +45°C), ensuring long-term measurement stability and accuracy.

Interference Immunity and Robustness

Industrial environments are rich with electromagnetic interference. The 330980 sensor employs enhanced Radio Frequency Interference/Electromagnetic Interference suppression design. Its metal housing provides excellent shielding, and internal circuit layout and filtering techniques are optimized, allowing it to pass stringent CE mark requirements and effectively resist interference from common sources like two-way radios and motor drives, ensuring a pure and reliable output signal.

IV. Key Performance and Technical Features

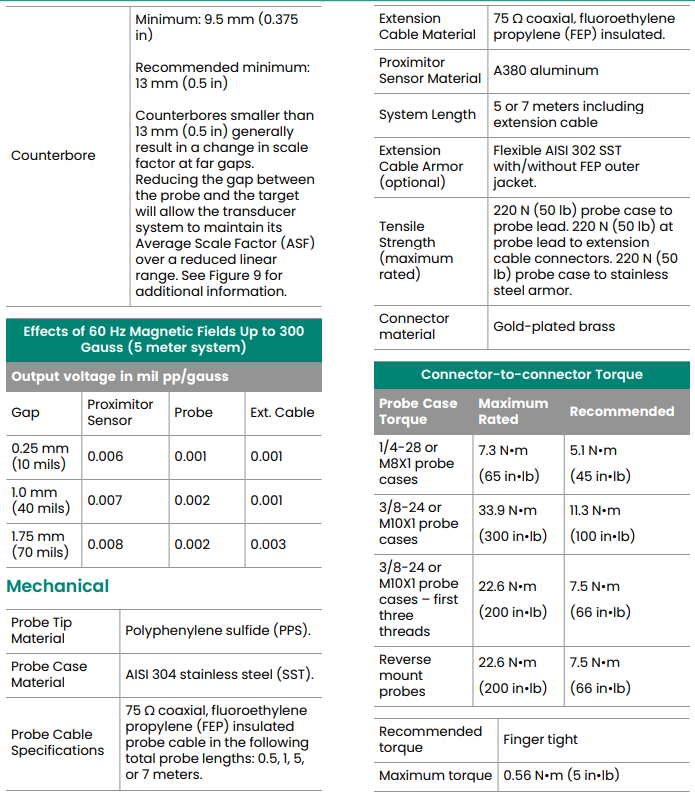

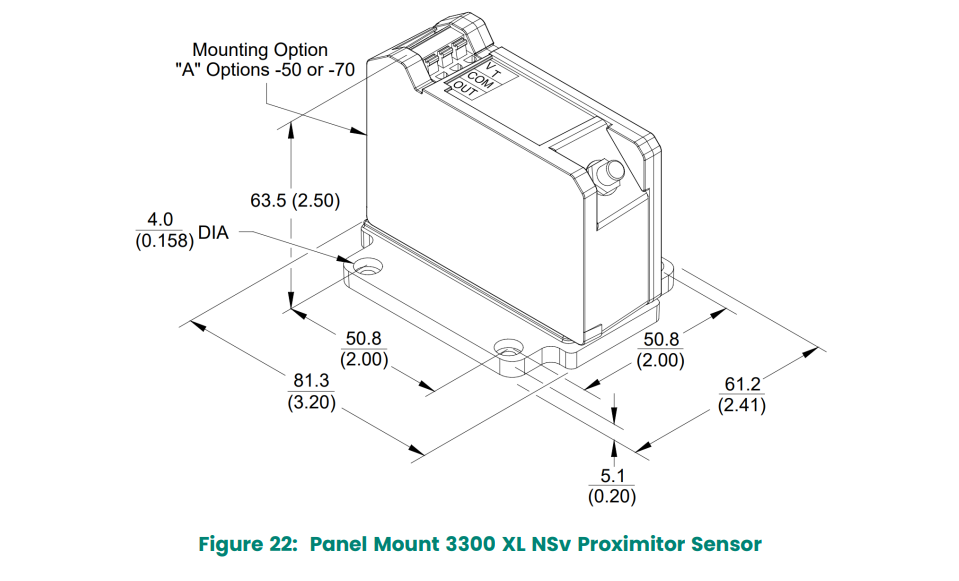

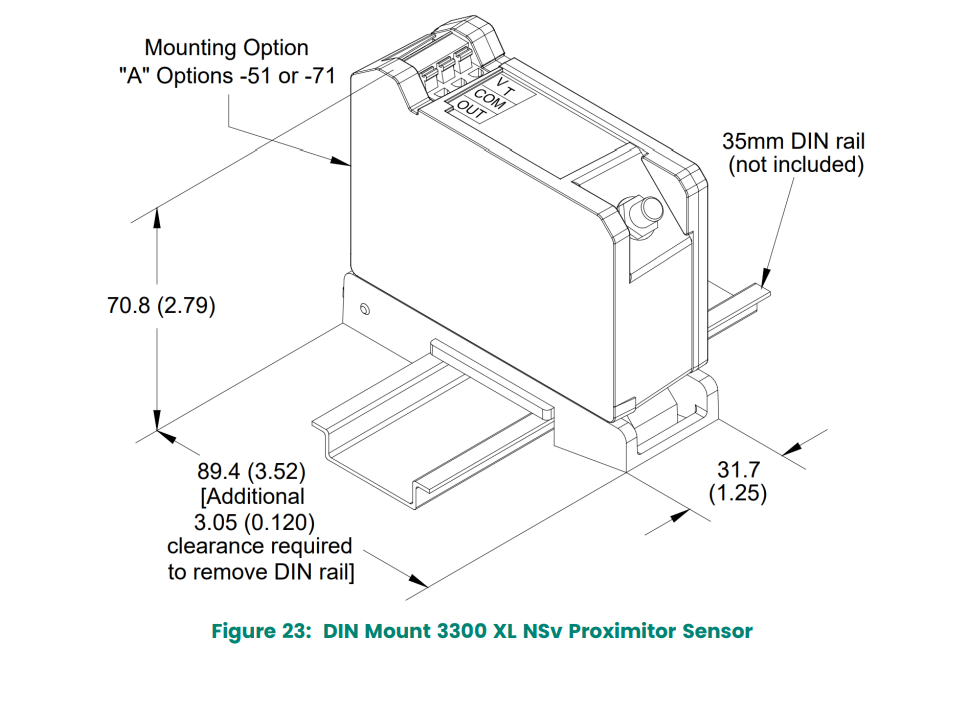

Compact Mechanical and Installation Design

The sensor features a thin profile, allowing for high-density DIN-rail installation within control panels, saving valuable space. It also supports traditional panel-mount configurations, adapting to various installation practices and cabinet layouts.

Exceptional Electrical Performance

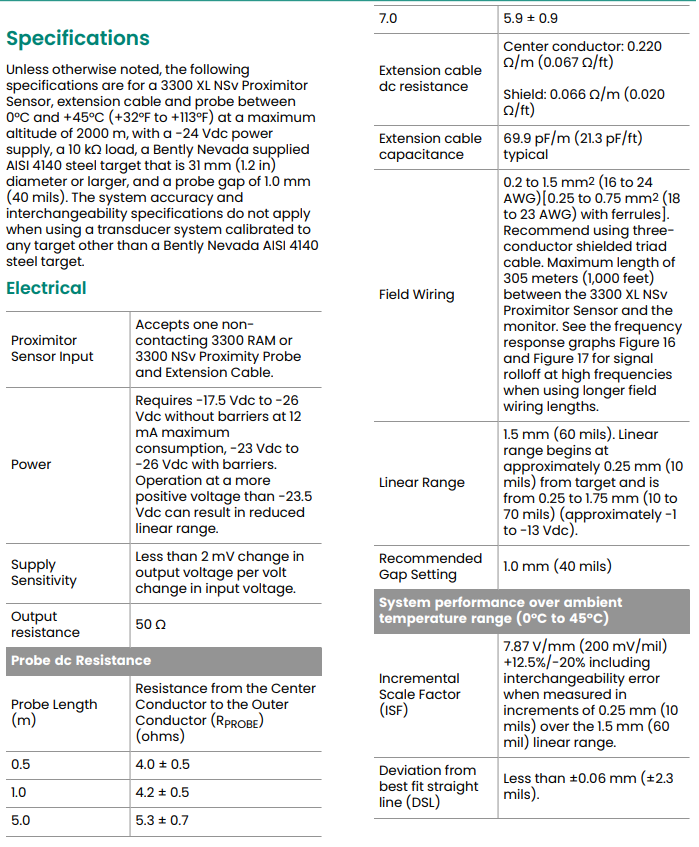

Linear Range: 1.5 mm, starting at approximately 0.25 mm, ensuring ample operating margin around the recommended 1.0 mm gap setting.

High Accuracy: Deviation from the Best Fit Straight Line is less than ±0.06 mm, guaranteeing measurement fidelity.

Frequency Response: 0 to 10 kHz, sufficient to capture most high-frequency vibration components found in industrial rotating machinery.

Output Drive Capability: 50-ohm output impedance enables driving field wiring up to 305 meters to the monitoring system.

Robust Environmental Adaptability

Wide Operating Temperature: The sensor operates reliably from -52°C to +100°C.

High Humidity Resistance: With protected connectors, it can withstand 100% condensing humidity.

Chemical Resistance: The NSv probe offers improved resistance to chemical corrosion compared to its predecessors, suitable for process industries with lubricating oils, refrigerants, and other chemicals.

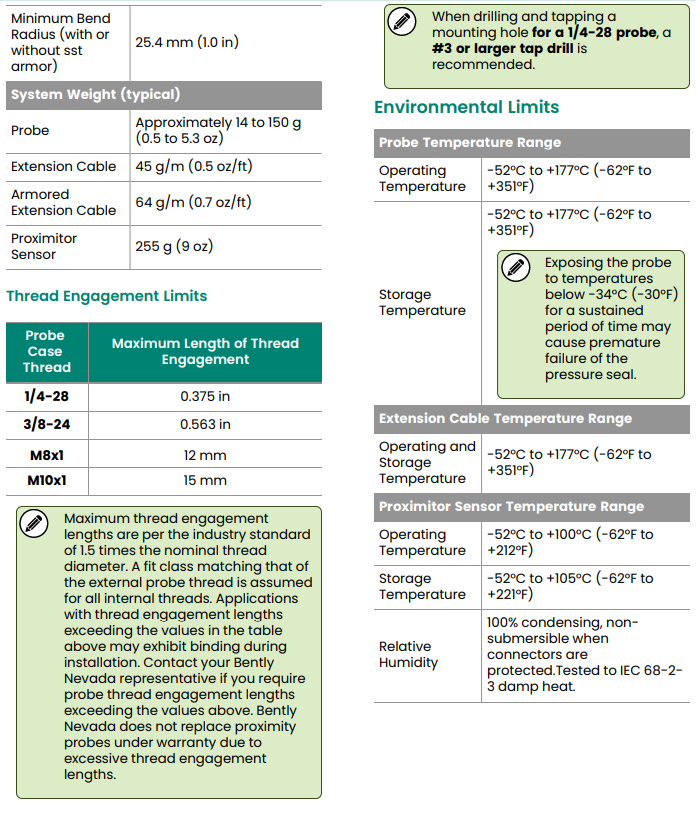

Safety and Certifications

Supports SIL 2 and SIL 3 Safety Integrity Levels for use in safety instrumented systems.

Holds multiple hazardous area certifications including ATEX, IECEx, and cNRTLus, permitting use in potentially explosive atmospheres (when installed with appropriate intrinsic safety barriers or isolators).