The IS200PDIOH1B is an advanced version of the PDIO series discrete input/output module, playing a critical role in industrial automation and control systems. As an upgraded version of the IS200PDIOH1A, it inherits all the superior functionalities of its predecessor while achieving significant improvements in processor performance and software compatibility. Specifically designed for industrial applications requiring higher processing power and more advanced features, the IS200PDIOH1B provides reliable signal interface functionality for precise acquisition of discrete signals and efficient output control.

Differences Between IS200PDIOH1B and IS200PDIOH1A

1. Processor Upgrade

The most significant difference lies in the processor board upgrade:

2. Software Compatibility

IS200PDIOH1A supports earlier versions of ControlST software

IS200PDIOH1B requires ControlST software suite V04.04 or later

BPPC processor provides better software compatibility and longer product lifecycle

3. Processing Performance

BPPC processor provides higher processing speed and larger storage capacity

Enhanced processing capability supports more complex application scenarios and faster response times

Improved architecture provides better foundation for future function expansion

4. Diagnostic Functions

IS200PDIOH1B provides more advanced diagnostic functions and more detailed status information

Enhanced self-monitoring capability improves system reliability and maintainability

More precise fault detection and localization functions

5. Configuration Flexibility

BPPC processor supports more complex configuration options

Provides more parameter adjustment and function customization capabilities

Better compatibility with future software updates and function enhancements

6. Upgrade Considerations

When upgrading from IS200PDIOH1A to IS200PDIOH1B, note:

Requires simultaneous upgrade of ControlST software to V04.04 or later

Check compatibility of existing configuration

Refer to relevant technical documentation (such as GHT-200051) for smooth upgrade

Pay attention to firmware version matching to avoid configuration errors

Key Features

1. Signal Interface Capability

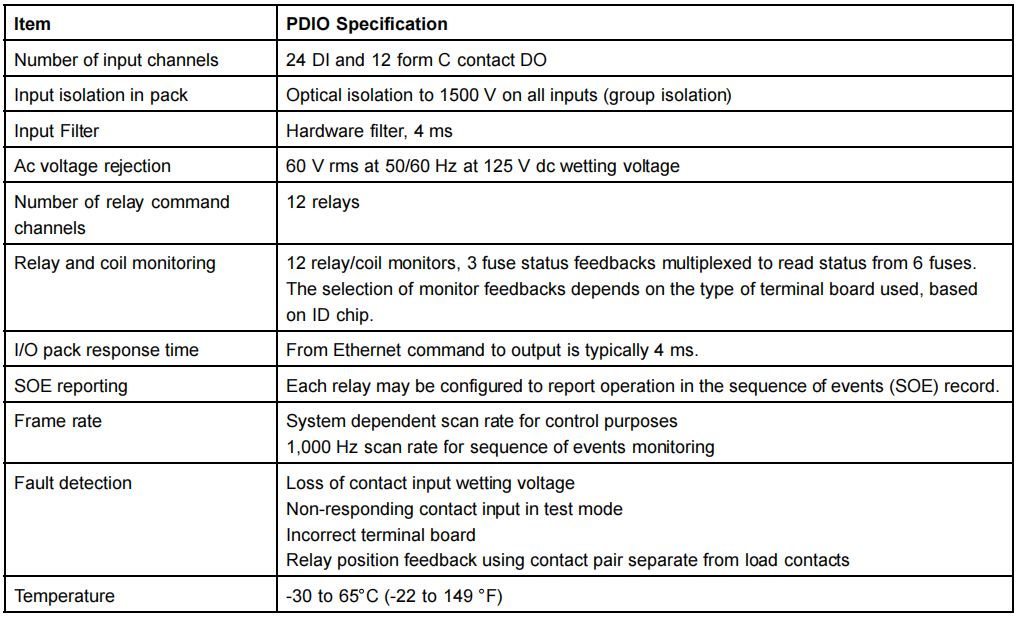

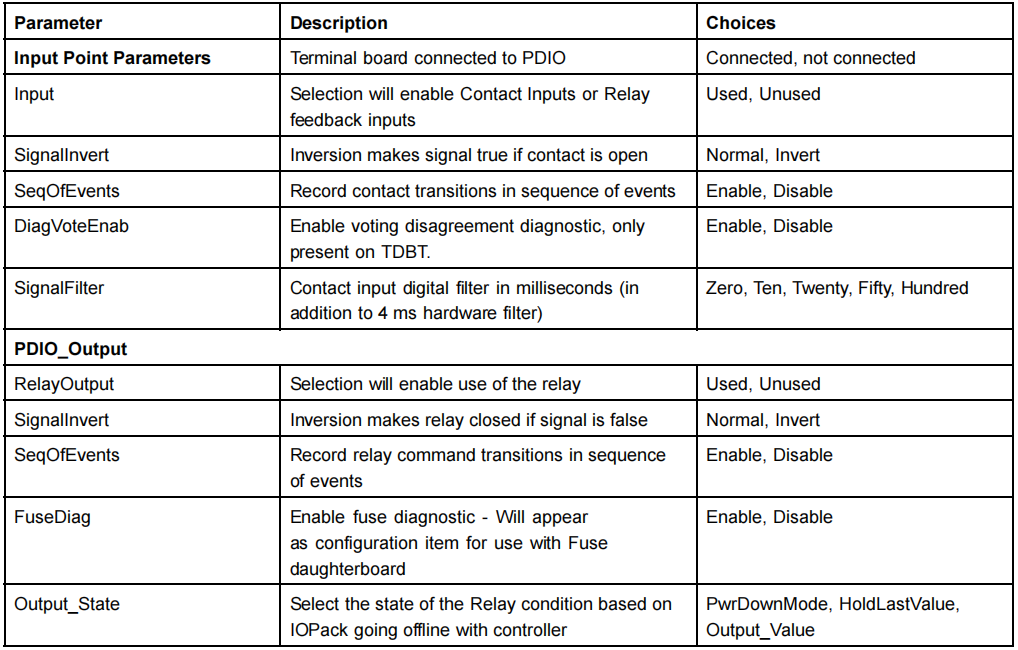

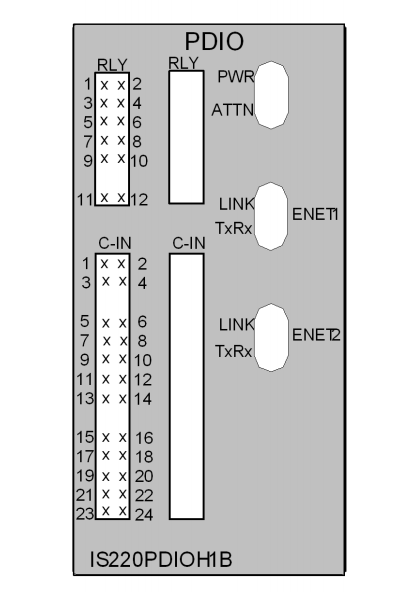

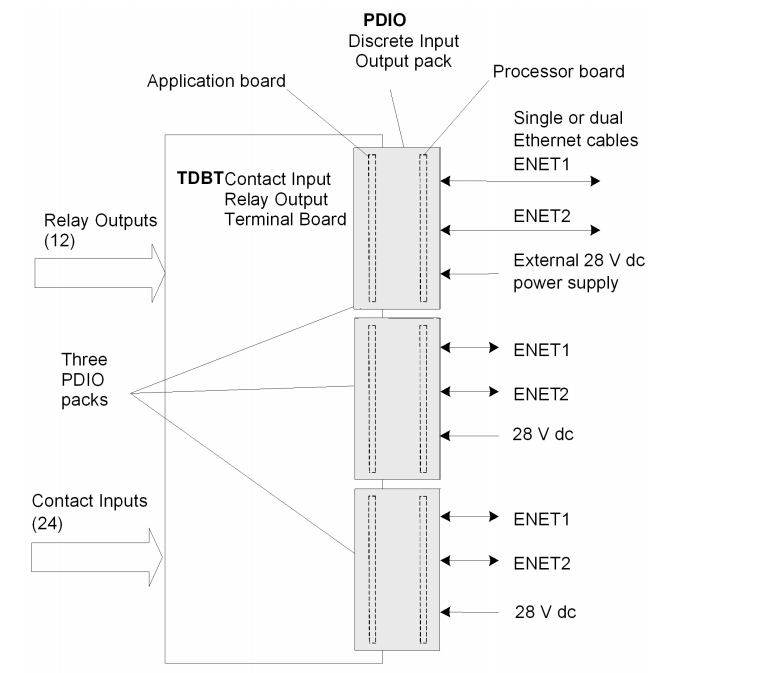

The IS200PDIOH1B provides 24 discrete input channels and 12 relay output channels, maintaining the same interface specifications as the PDIOH1A. The input channels support contact-type signal input with advanced signal conditioning capabilities, while the output channels support relay control with Form C contact output. The module connects directly to the terminal board through a DC-62 pin connector, ensuring stable and reliable signal transmission.

2. Network Communication

The module is equipped with dual RJ-45 Ethernet interfaces (ENET1 and ENET2), supporting redundant network configurations that enhance system communication reliability. ENET1 serves as the main communication interface typically connected to the main controller network, while ENET2 provides a backup communication path as a redundant interface, ensuring continuous system operation during network failures.

3. Power Management

The IS200PDIOH1B receives 28 V dc power through a three-pin power connector, supplying power to both the module and the connected terminal board. Inheriting the soft-start capability of the PDIO series, the module effectively controls inrush current during power-up, eliminating the need to disconnect power before plugging or unplugging, thereby improving operational convenience and system safety.

4. Visual Diagnostic System

The front of the module features multiple groups of high-brightness status indicator LEDs that display real-time input/output status, network communication status, power status, and system fault information. These visual diagnostic functions enable field technicians to quickly identify and resolve issues, significantly reducing system downtime.

5. Expanded Compatibility

The IS200PDIOH1B incorporates a BPPC processor board, which represents the most significant difference from the PDIOH1A. The BPPC processor provides enhanced processing power and more advanced functionalities, supporting ControlST software suite V04.04 and later versions. The module remains compatible with various terminal boards, including the TDBS series for simplex applications and the TDBT series for triple modular redundant (TMR) applications.

6. Advanced Configuration Features

Using GE's ToolboxST software, users can perform detailed configuration of the IS200PDIOH1B, including input/output parameter settings, signal filtering adjustments, sequence of events (SOE) recording, and diagnostic function enabling. The support for the BPPC processor enables the module to handle more complex configuration requirements, meeting the demands of advanced application scenarios.

Working Principle

1. Input Signal Processing Mechanism

The discrete input channels of the IS200PDIOH1B employ a two-stage signal conditioning system, maintaining the same processing architecture as the IS200PDIOH1A. The terminal board provides preliminary signal conditioning, including noise suppression and voltage adaptation, while the acquisition board inside the module performs secondary processing, completing level conversion and threshold judgment.

Each input channel is isolated from the control logic through opto-isolators, featuring independent filtering and hysteresis functions. The input threshold is automatically adjusted based on the wetting voltage provided by the terminal board, typically set to 50% of the nominal voltage and clamped to 13% in case of abnormal voltage to avoid indeterminate states. The module performs threshold pulse tests every four seconds to detect opto-coupler responses, ensuring input channel reliability.

2. Output Control Mechanism

The relay output channels utilize an open-collector transistor drive circuit, with each output featuring current monitoring capability to detect output status and load connection in real-time. The output enable signal remains disabled until all internal self-tests are completed, ensuring relays remain in a safe state during system power-up and initialization.

3. Monitoring and Feedback System

The module supports 15 inverting level-shifting monitoring inputs for receiving relay contact feedback and fuse status signals. Through multiplexing control technology, the module can receive two sets of 15 signals from the terminal board, achieving comprehensive monitoring of output status.

4. Sequence of Events Recording Function

All input and output channels can be configured to generate SOE records when signal states change. Input signals are scanned at a rate of 1000 Hz, and output commands are captured when received through the network, providing high-precision timestamp functionality that meets the high requirements for sequence of event analysis.

5. Diagnostic and Self-test System

The IS200PDIOH1B performs comprehensive self-test procedures during startup, including memory checks, port detection, and hardware verification. During operation, it continuously monitors internal power status, input voltage status, relay feedback status, and provides detailed diagnostic information through ToolboxST software. The BPPC processor enhances the precision and depth of diagnostic functions, providing more comprehensive system health status information.

Application Scenarios

IS200PDIOH1B is suitable for more demanding industrial automation and control scenarios:

Heavy-duty industrial control systems requiring higher processing power and more advanced functions

Applications with higher requirements for system reliability and diagnostic functions

Systems planned for long-term use requiring good software support

Projects requiring the latest technology and future expansion capabilities

Upgrade projects replacing PDIOH1A, pursuing better performance and functionality