| General Information | Product Model / Article Number | TB840A / 385E037760R1 |

| Communication Protocol | ModuleBus |

| Role | Slave |

| Redundancy Support | Line Redundancy: Yes; Module Redundancy: Yes |

| Hot Swap Support | Yes |

| Compatibility with High Integrity Controller | Yes |

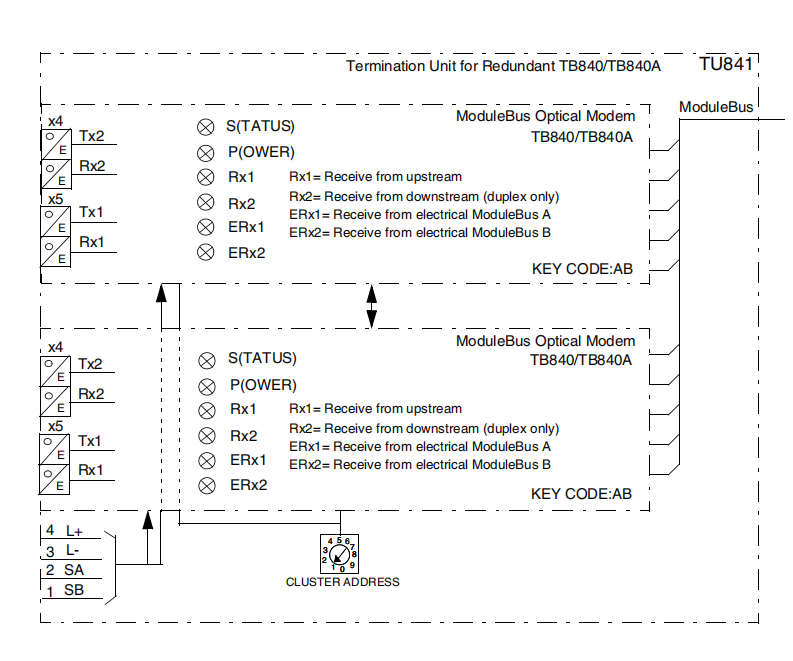

| Compatible Termination Units | TU807 (Single Module, Single Bus)

TU840/TU848 (Redundant Modules, Redundant Bus)

TU841/TU849 (Redundant Modules, Single Bus) |

| Electrical Characteristics | Input Power | 24 V DC (19.2 - 30 V) |

| Typical Power Consumption (@24V) | 120 mA |

| Input Fuse | 2 A Fast-Acting |

| Power Dissipation | 6 W |

| Power Supply Monitoring Inputs | High Level: ≥15V; Low Level: ≤8V; Maximum Voltage: 30V |

| ModuleBus Power Output | 24 V: Max. 1.4 A

5 V: Max. 1.5 A (Short-circuit protected) |

| Communication & Interfaces | Electrical ModuleBus | Max. 12 connected I/O modules |

| Optical ModuleBus | Max. 7 connected I/O clusters |

| Fiber Optic Interface | 2 transmitters, 2 receivers |

| Communication Rate | Up to 10 Mbit/s |

| Optical Wavelength | 650 nm |

| Supported Fiber Types & Distance | Plastic Optical Fiber (POF): Max. 15 meters

Hard Clad Silica (HCS) fiber: Max. 200 meters |

| Physical Characteristics | Width (excluding handle) | 54 mm (2.13 inches) |

| Height (including handle) | 119 mm (4.69 inches) |

| Depth | 96 mm (3.78 inches) |

| Weight | 0.2 kg (0.44 lbs) |

| Ingress Protection | IP20 (according to IEC 60529) |

| Environmental & Certifications | Operating Temperature | 0 to +55 °C (Certified range: +5 to +55 °C) |

| Storage Temperature | -40 to +70 °C |

| Relative Humidity | 5% to 95%, non-condensing |

| Pollution Degree | Degree 2 (IEC 60664-1) |

| Corrosion Protection | ISA-571.04: G3 |

| Electrical Safety Certification | EN 61010-1, UL 61010-1, EN 61010-2-201, UL 61010-2-201 |

| Hazardous Location Certification | Class I Div 2 cULus, Class I Zone 2 cULus, ATEX Zone 2 |

| Marine Certifications | ABS, BV, DNV-GL, LR |

| Environmental Compliance | RoHS: DIRECTIVE/2011/65/EU

WEEE: DIRECTIVE/2012/19/EU |

| LED Indicators | Status (S) | Green: Normal operation; Red: Fault condition (e.g., reset, electrical bus communication error) |

| Power (P) | Green: Internal DC/DC converter and electrical bus +5V supply are valid |

| Optical Receive (Rx1, Rx2) | Yellow blinking: Indicates data reception on the respective optical channel |

| Electrical Bus Receive (ERx1, ERx2) | Yellow blinking: Indicates data reception on Electrical ModuleBus A and B respectively |