The Bently Nevada® 3300/12 AC Power Supply is the core power delivery unit for the 3300 Machinery Protection and Condition Monitoring System, designed to provide highly stable, clean, and reliable DC power for up to 12 channels of monitoring modules and their associated sensors. This product embodies Bently Nevada's over-half-a-century philosophy of safety and reliability in rotating machinery monitoring. It aims to eliminate the risk of monitoring failure due to power quality issues, serving as the cornerstone for ensuring the continuous and safe operation of critical machinery.

Different from general-purpose industrial power supplies, the 3300/12 is specifically designed for industrial field environments with high electromagnetic interference. It features a built-in standard line noise filter and employs a modular, field-configurable architecture. Its most significant value proposition is that a single unit can meet the entire power demand of a standard monitoring rack, eliminating the need for parallel or redundant configurations. This simplifies system architecture, reduces the Total Cost of Ownership (TCO), and provides critical system health status indication via an independent "OK Relay," which serves as a key interface for predictive maintenance and safety interlocking.

This product holds multiple international hazardous area certifications, including CSA and ATEX, making it suitable for Class I Division 2 and Zone 2 potentially explosive atmospheres, demonstrating its design commitment to meeting the highest global safety standards.

2. Core Technology & Design Features

2.1 High-Reliability Power Conversion

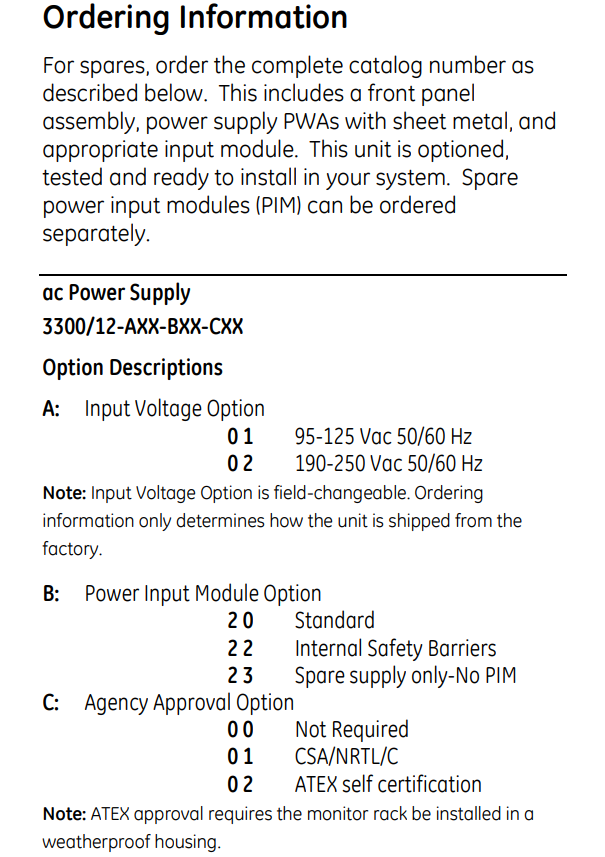

Wide-Range Adaptive Input: Supports 95-125 Vac or 190-250 Vac single-phase AC input (field-switchable via jumper), compatible with mainstream global industrial grid standards and tolerant of voltage fluctuations.

Clean Output: Utilizes multi-stage filtering and precision voltage regulation technology, delivering DC output with extremely low ripple. This provides an ideal operating baseline for high-precision vibration, phase, Keyphasor®, and other sensor signal conditioning circuits, ensuring measurement data accuracy.

Multi-Layer Protection:

Overload Protection: Sensor power channels feature independent overload protection at the individual monitor board level, ensuring fault isolation and preventing a single sensor fault from affecting the entire system.

Fuse Protection: The input stage is equipped with slow-blow fuses capable of withstanding inrush currents (26A peak) such as those from motor starts, while providing reliable over-current protection.

Surge Immunity: Possesses primary surge suppression capability, enhancing resistance to transient spikes on industrial power grids.

2.2 Modularity & Configurability

Field-Programmable Output: Users can flexibly select the sensor excitation voltage as -24 Vdc (for mainstream 3300/7200 series sensors) or -18 Vdc (compatible with legacy 3000 series sensors) via plug-in jumpers, facilitating system upgrades and mixed use of different generations of sensors.

Optional Input Modules: Offers a Standard Power Input Module (PIM) and a PIM with Internal Safety Barriers. The latter converts the power output to an intrinsically safe (Ex i) limited-energy output for directly driving IS sensors installed in hazardous areas (Zone 0/1 or Division 1), forming the core of a complete intrinsic safety monitoring loop.

Certification Selectable: Can be configured ex-factory to versions compliant with CSA/NRTL/C or ATEX certifications based on target market regulatory requirements, ensuring global compliance.

2.3 Integrated System Health Diagnostics (OK Relay)

Hermetically Sealed Contacts: A Single-Pole, Double-Throw (SPDT) sealed relay located at the rear of the power supply remains energized during normal power supply operation.

Critical Safety Function: The relay changes state if the power supply itself fails, or if the monitoring system loses its protective function for any reason (e.g., loss of primary power, critical monitor failure). It is strongly recommended to connect these contacts to the plant DCS or an independent annunciator as the ultimate safety indication of the machinery protection system's integrity, serving as the last line of defense against "silent failures."

3. Application Scenarios & Installation Guidelines

3.1 Typical Applications

Critical Rotating Machinery Protection Systems: Provides primary power for vibration, displacement, and speed monitoring systems of turbines, gas turbines, compressors, large pumps, and fans.

Mixed Sensor Systems: Simplifies power architecture in modernization projects requiring simultaneous use of 3300 series (-24Vdc) and legacy 3000 series (-18Vdc) sensors through a single power supply.

Potentially Explosive Atmospheres: Use certified versions in Division 2/Zone 2 areas of industries like Oil & Gas, Petrochemical, and Pharmaceutical. To monitor IS sensors in Division 1/Zone 1 areas, the PIM with Internal Safety Barriers option (B=22) is mandatory.

3.2 Key Installation Steps

Mandatory Location: Must be installed in Position 1 (leftmost slot) of the 3300 Monitoring Rack. This position is dedicated to the power supply, ensuring optimal heat dissipation and backplane power distribution.

Primary Power Wiring:

Refer to the field wiring diagram in the documentation.

Connect Line, Neutral, and Ground strictly according to the selected voltage rating (A Option) and use the specified fuse rating.

Use COPPER CONDUCTORS ONLY for all wiring.

Safety Warning: When installing or servicing in atmospheres with explosive gases (certified areas), relevant safety procedures must be followed, ensuring work is performed under de-energized and verified safe conditions.

System Diagnostics Wiring: CRITICAL – Connect the output contacts (NO/NC) of the OK Relay to the plant's central alarm system or an independent annunciator to enable remote monitoring of the monitoring system's power health status.

4. Brand Differentiation & Conclusion

The Bently Nevada® 3300/12 AC Power Supply is far more than a simple power converter; it is the intelligent power core integrated into a world-leading machinery protection system. Its design is permeated with the philosophy of "Safety, Reliability, Simplicity":

Founded on Safety: From the mandatory OK Relay alarm output to multiple international certifications for hazardous areas, safety considerations are integrated into every design detail.

Engineered for Reliability: Wide-range input, stringent output regulation, and independent channel protection ensure uninterrupted, clean power delivery in the harshest industrial environments.

Ultimate Engineering Flexibility: Field-adjustable input/output voltages, modular PIM selection, and global certification options allow the same platform to flexibly adapt to the specific needs of customers worldwide.

Choosing the 3300/12 Power Supply means choosing a solid, trustworthy power foundation for your critical asset monitoring system. It ensures the integrity of every byte of data from sensor to monitoring system and is a strategic component in implementing predictive maintenance, avoiding unplanned downtime, and safeguarding personnel and equipment.