The VM600 IOCR2 is a critical component of the VM600 series rack monitoring system from VM product line. It serves as the matching input/output and communication interface card for the CPUR2 rack controller card. Together, the IOCR2 and CPUR2 form a complete card pair that provides rack control, communication gateway, and signal interface functions for the VM600 system. Designed for industrial environments, this card is used in rotating machinery protection and condition monitoring systems, widely applied in power generation, oil and gas, and other industries.

The IOCR2 card is installed in the rear of the VM600 ABE04x system rack and connects to the front-mounted CPUR2 card via the backplane. Together, they enable configuration management, data communication, and signal processing for various monitoring cards in the VM600 system (such as MPC4, XMX16, etc.). Its design supports hot-swapping and offers excellent electromagnetic compatibility (EMC) and electrical isolation, making it suitable for demanding industrial environments.

Key Features

1. Communication Interface Functionality

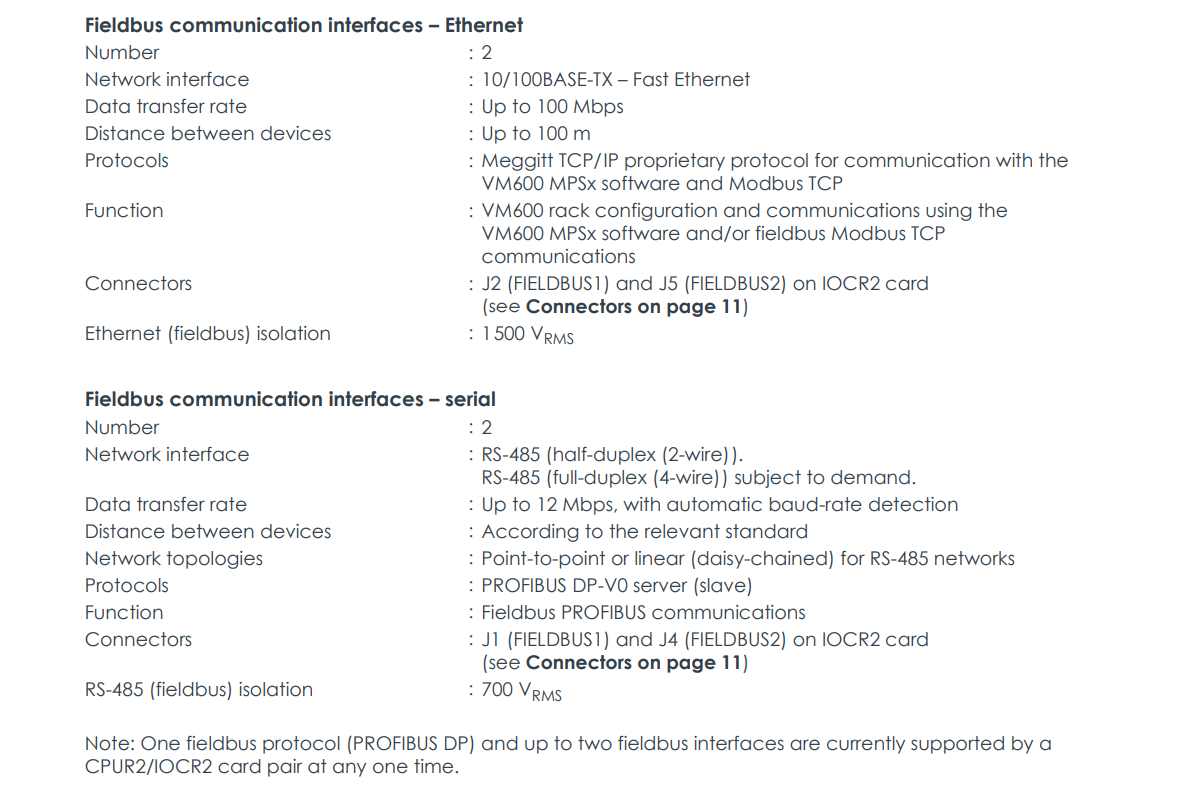

The IOCR2 card provides multiple communication interfaces, supporting system Ethernet and fieldbus communication, including:

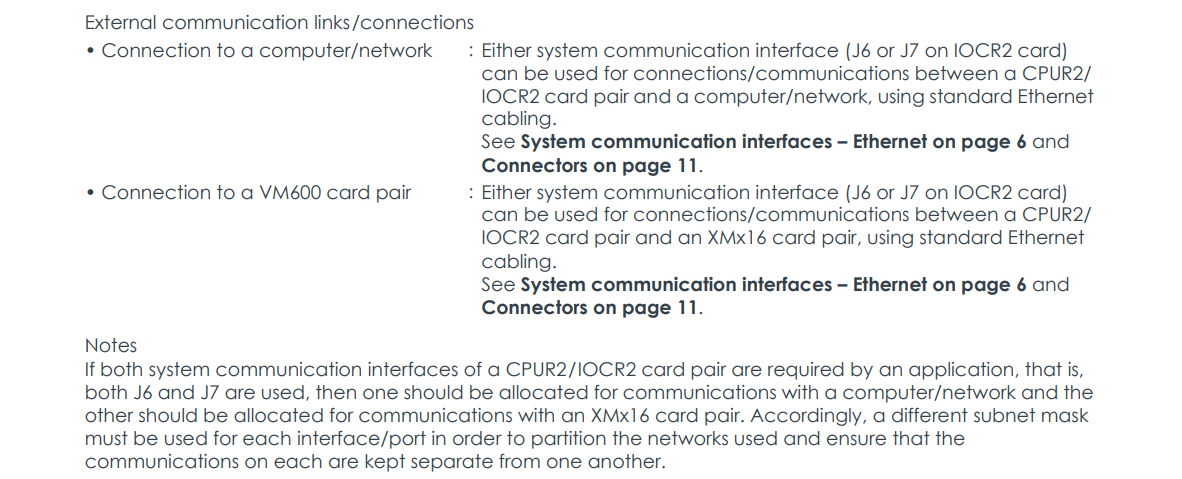

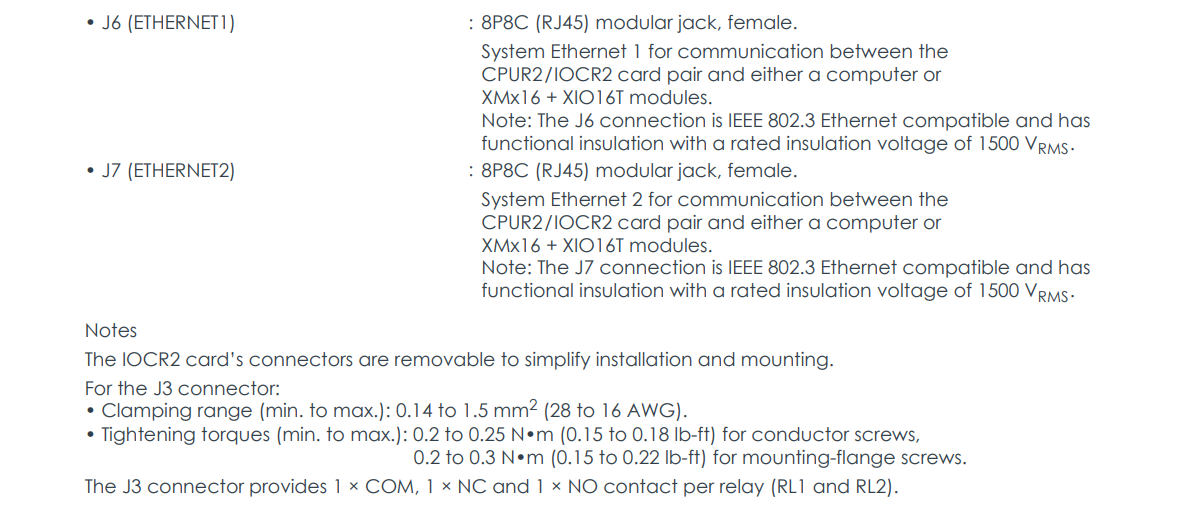

System Ethernet Interfaces: Two 10/100/1000BASE-T(X) Ethernet ports (ETHERNET1 and ETHERNET2) for:

Communication with computers running VM600 MPSx or VibroSight software;

Communication with XMX16/XIO16T monitoring card pairs;

Support for Modbus TCP protocol for data exchange with third-party systems (e.g., DCS, PLC).

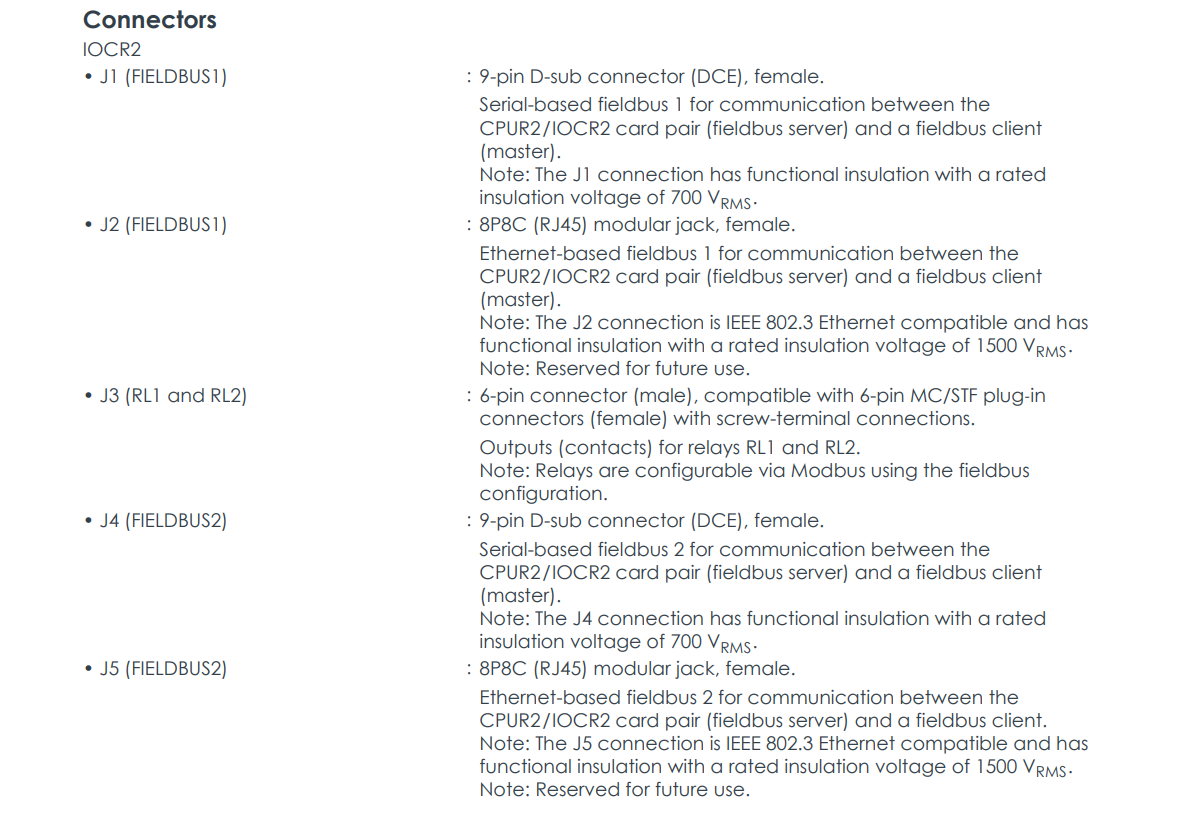

Fieldbus Interfaces: Two independent fieldbus ports (FIELDBUS1 and FIELDBUS2), each containing:

One RS-485 serial interface (supporting PROFIBUS DP) for communication with fieldbus master devices;

One Ethernet interface (supporting Modbus TCP) for high-speed data exchange;

Support for simultaneous operation of dual fieldbuses, enabling communication redundancy.

2. Relay Output Functionality

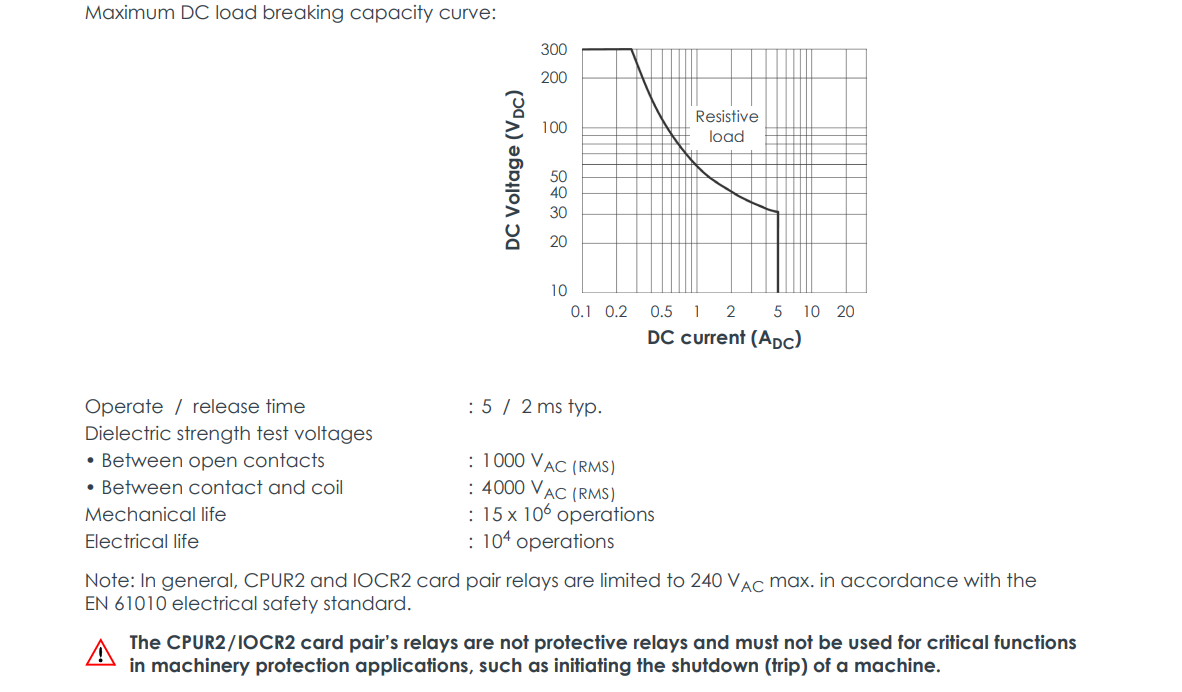

The IOCR2 card provides two user-configurable relays (RL1 and RL2), each of the single-pole double-throw (SPDT / Form C) type, with the following characteristics:

Rated voltage: 240 VAC;

Rated current: 5 A;

Maximum breaking capacity: 1250 VA (without contact protection);

Can be mapped via Modbus bit variables for remote indication of system status, communication status, or general alarm information.

3. Electrical Isolation and Electromagnetic Compatibility (EMC)

The IOCR2 card provides electromagnetic interference (EMI) and surge protection for all input signals, complying with the following standards:

Serial fieldbus interface (RS-485) isolation voltage: 700 V₍RMS₎;

Ethernet fieldbus interface isolation voltage: 1500 V₍RMS₎;

Complies with EMC standards such as EN 61000-6-2 and EN 61000-6-4.

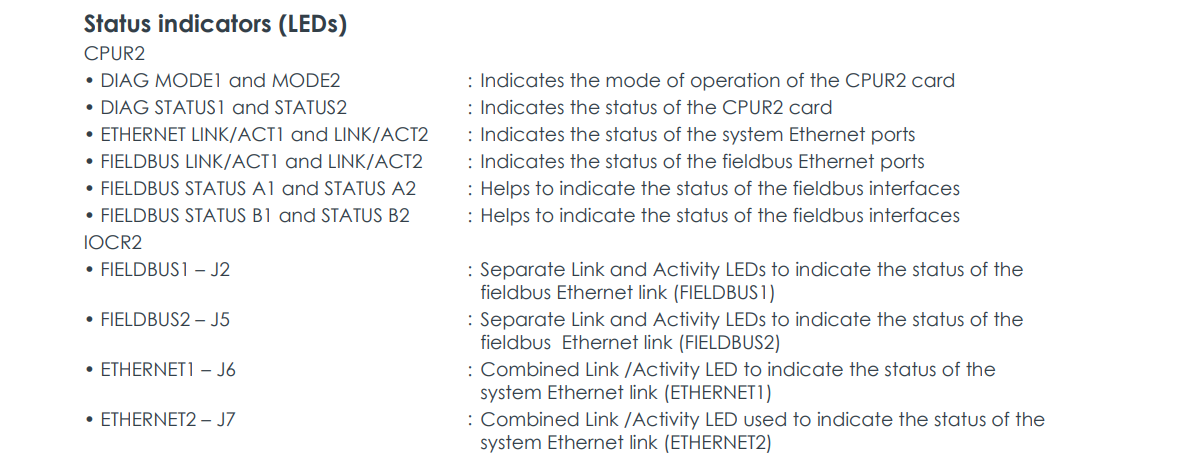

4. Status Indication and Diagnostics

The IOCR2 card front panel is equipped with multiple LED indicators for real-time display of communication status:

Link/Activity indicators for FIELDBUS1 and FIELDBUS2;

Link/Activity indicators for ETHERNET1 and ETHERNET2;

Supports downloading diagnostic logs via VibroSight software for easy system maintenance and troubleshooting.

5. Hot-Swapping and Automatic Configuration

The IOCR2 and CPUR2 card pair supports hot-swapping, allowing card replacement without powering down the system. The system automatically recognizes and reconfigures the cards, significantly improving system availability and maintenance efficiency.

Working Principle

1. System Architecture and Data Flow

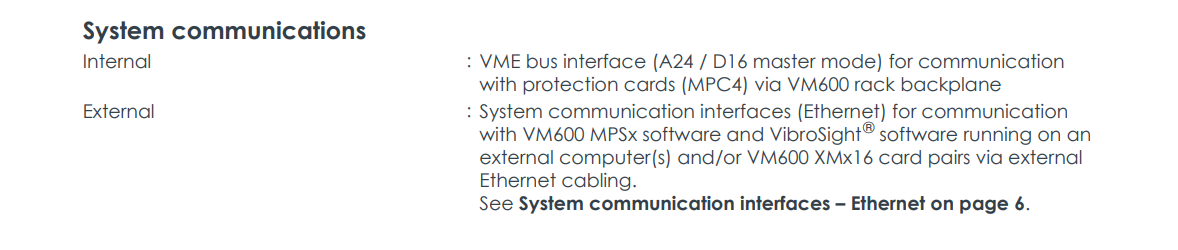

The IOCR2 card acts as a communication and signal interface extension for the CPUR2, exchanging data with the CPUR2 via the VM600 rack backplane. Its workflow is as follows:

Data Acquisition: The CPUR2 acquires data from protection cards like MPC4 via the VME bus, or from monitoring cards like XMX16 via the system Ethernet;

Data Processing: The CPUR2 performs mathematical processing on the acquired data (e.g., arithmetic operations, logical judgments, scaling, extreme value detection);

Data Output: The processed data is sent to third-party systems (e.g., DCS, PLC) via the IOCR2's fieldbus interfaces (Modbus TCP or PROFIBUS DP);

Status Feedback: The relays on the IOCR2 can trigger based on system status or alarm information, outputting dry contact signals.

2. Communication Protocols and Network Topology

Modbus TCP: The IOCR2 acts as a slave device, responding to read/write requests from master devices, supporting up to 131,072 registers and coils;

PROFIBUS DP: The IOCR2 acts as a DP-V0 slave, each interface supporting up to 244 input and output bytes;

Network Topology: Supports point-to-point or linear (daisy-chain) connection methods, suitable for complex industrial network environments.

3. Electrical Isolation and Signal Protection

All external interfaces of the IOCR2 card feature electrical isolation, effectively preventing ground loop interference, surges, and electromagnetic interference, ensuring stable system operation in harsh industrial environments.

4. Configuration and Management

The IOCR2 card itself does not require independent configuration. Its functionality is entirely configured by the CPUR2 card using VibroSight software. Users can upload fieldbus configuration files via VibroSight Configurator to define data processing logic, relay mapping, and communication parameters.

Technical Specifications Summary

Power Requirements: Powered by the VM600 RPS6U rack power supply, 5 VDC, max. power consumption 7.5 W;

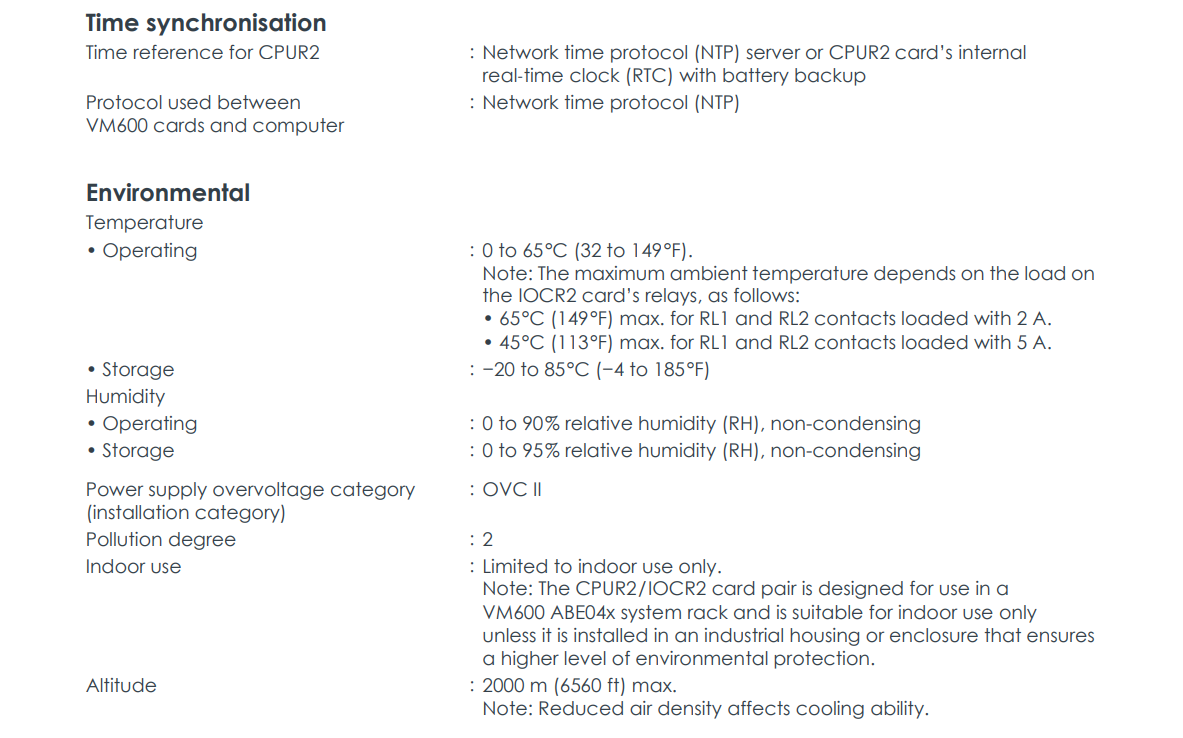

Operating Temperature: 0°C to 65°C (depending on relay load);

Communication Interfaces:

Relays: 2x SPDT, 5 A / 240 VAC;

Connectors: Include D-sub, RJ45, and screw terminal types, supporting quick installation;

Compliance: CE, EN 61010-1, EN 61326-3-1, RoHS, etc.

Application Scenarios

The IOCR2 card is widely used in the following scenarios:

Vibration protection and condition monitoring for steam turbines, gas turbines, and hydro turbines in power plants;

Monitoring of rotating machinery such as compressors, pumps, and fans in the oil and gas industry;

Centralized monitoring and data integration for balance-of-plant (BOP) equipment;

Integration with control systems like DCS and PLC for data sharing and linked control.