The IS220YDIAS1A is an important discrete input processing module within GE's Mark VIeS control system, belonging to the YDIA series I/O components. This module undertakes the critical task of collecting field device status signals, specifically designed to handle binary switch signals such as limit switches, relay contacts, pushbutton statuses, and more. Serving as a bridge between the control system and field devices, the IS220YDIAS1A converts physical world switch statuses into digital signals, providing reliable input basis for control logic.

In modern industrial automation systems, the reliability and real-time performance of discrete input modules directly impact the response speed and safety performance of the entire control system. The IS220YDIAS1A design incorporates advanced signal processing technology and comprehensive diagnostic mechanisms, ensuring stable performance even in harsh industrial environments. The module supports multiple system configuration methods, providing corresponding solutions from basic simplex systems to demanding Triple Modular Redundant (TMR) systems.

The model designation IS220YDIAS1A specifically indicates it is equipped with a BPPB processor board, enabling high performance while maintaining excellent system compatibility. In various industrial applications including gas turbines, steam turbines, and water treatment systems, the YDIAS1A plays an irreplaceable role, providing fundamental data support for equipment status monitoring, safety interlock protection, and sequential control functions.

2. Hardware Architecture and Interface Design

The hardware design of the IS220YDIAS1A module reflects the high reliability and modular concept of industrial-grade products, with its architecture primarily consisting of two core components:

Processor Board (BPPB): Serving as the intelligent core of the module, the BPPB processor manages communication with the control network, processes input signals, executes diagnostic programs, and coordinates the work of various hardware components. This processor uses industrial-grade chips with powerful data processing capabilities and excellent environmental adaptability.

Dedicated Discrete Input Acquisition Board: This is the signal processing core of the module, specifically optimized for the characteristics of discrete input signals. The acquisition board contains 24 independent input channels, each equipped with a complete signal conditioning circuit.

The physical interface design of the module fully considers the practicality of industrial applications:

3. Core Functions and Working Principles

The functional implementation of IS220YDIAS1A is based on precise hardware design and intelligent signal processing algorithms, with its working principles involving multiple technical aspects.

3.1 Multi-stage Signal Conditioning and Isolation

Discrete input signals in industrial environments are often accompanied by various interferences. IS220YDIAS1A employs a multi-stage processing mechanism to ensure signal quality:

Primary Signal Conditioning: Completed at the terminal board level, including basic processing such as surge protection and filtering to eliminate most field interference.

Secondary Signal Conditioning: Implemented at the module acquisition board level, using comparator circuits for level detection. Each input channel is equipped with an independent hardware filter providing 4ms filtering time constant, effectively suppressing spike pulses and high-frequency interference.

Electrical Isolation Protection: All 24 input channels utilize optical coupler isolation technology with isolation strength up to 1500V. This design not only prevents field interference from entering the control system but also avoids measurement errors caused by ground potential differences. Each channel uses an independent isolated power supply, ensuring channel independence so that single channel failure does not affect other channels.

3.2 Intelligent Threshold Detection Mechanism

The core technical feature of IS220YDIAS1A is its variable threshold detection system, significantly improving signal identification reliability:

Dynamic Threshold Calculation: The detection threshold for input signals is not fixed but dynamically adjusted based on contact wetting voltage. The system samples the wetting voltage through a precision resistor network, typically setting 50% of the wetting voltage as the judgment threshold. This design enables the module to adapt to different field voltage levels, maintaining consistent detection performance from 24VDC to 125VDC.

Threshold Clamping Protection: To prevent system misjudgment due to abnormal wetting voltage drop, the module has a 13% lower threshold clamp. Even if the wetting voltage drops to zero, the threshold will not fall below 13%, ensuring signal status does not exhibit uncertain oscillation.

Undervoltage Detection Alarm: When detecting that the wetting voltage is below 40% of the rated value, the module activates an undervoltage alarm mechanism, reporting abnormal status to the controller through the diagnostic system, alerting maintenance personnel to address power issues promptly.

3.3 Advanced Diagnostics and Test Functions

IS220YDIAS1A incorporates comprehensive self-diagnostic systems to ensure operational reliability:

Power-on Self-test: The module executes comprehensive hardware checks during startup, including RAM, Flash memory, Ethernet interface, and processor core function verification.

Periodic Functional Testing: Every 4 seconds, the module automatically executes an input channel test sequence. During testing, the threshold voltage undergoes high-low pulse changes while monitoring optocoupler response status. Any abnormally responding channels are flagged and generate diagnostic alarms.

Real-time Status Monitoring: The module continuously monitors key parameters including internal power status (18V and 28V power supplies), processor temperature, network connection quality, etc., providing detailed diagnostic information through ToolboxST software.

Electronic ID Verification: The module, terminal board, and acquisition board perform identity verification through electronic ID information, ensuring hardware combination compatibility and integrity.

3.4 Flexible System Configuration Capability

IS220YDIAS1A supports various system architectures to meet reliability requirements of different application scenarios:

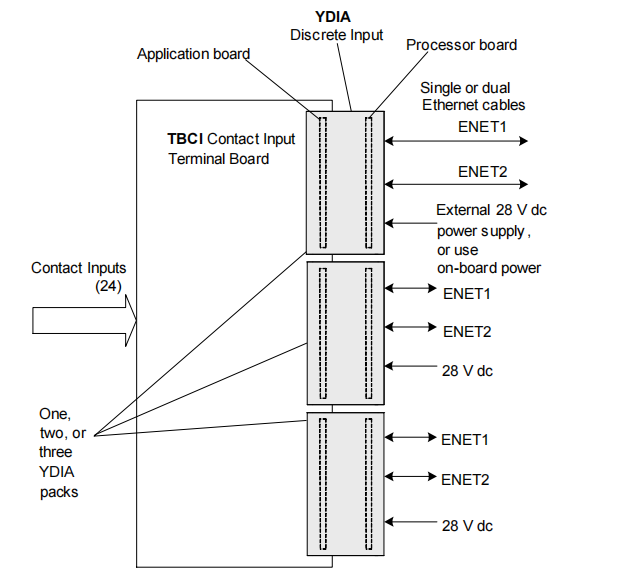

Simplex Configuration: Uses a single module to process 24 discrete inputs, suitable for general control applications. On STCI series terminal boards, a single module can complete all input processing.

Dual Redundant Configuration: Uses two YDIAS1A modules on TBCI terminal boards, achieving redundant input signal acquisition through JR1 and JS1 connectors, improving system availability.

Triple Modular Redundancy (TMR): In safety-critical applications, uses three YDIAS1A modules connected through JR1, JS1, and JT1 connectors respectively. Three modules independently acquire the same set of input signals, with the controller determining the final status through two-out-of-three voting logic, providing the highest reliability assurance.

3.5 Sequence of Events Recording Function

For application scenarios requiring precise time tagging, IS220YDIAS1A supports Sequence of Events (SOE) recording function:

High-precision Timestamp: The module can record the timing of input status changes with 1ms resolution, providing accurate time basis for fault analysis and event tracing.

Configurable Filter Parameters: Users can select different filter time constants (0, 10, 20, 50, 100ms) based on input signal characteristics, achieving optimal balance between anti-interference and response speed.

Flexible Function Enablement: Through ToolboxST software, the SOE function can be configured independently per channel, optimizing system resource utilization.

4. System Configuration and Data Management

IS220YDIAS1A is fully configured through ToolboxST software:

5. Diagnostic Mechanism and Maintenance Support

IS220YDIAS1A provides multi-level diagnostic information, supporting preventive maintenance and rapid fault localization:

Channel-level Diagnostics: Includes input response test failures, signal quality abnormalities, etc.

Module-level Diagnostics: Covers power abnormalities, communication faults, processor status, etc.

System-level Diagnostics: Provides vote difference alarms in TMR configurations, timely detecting potential faults

The module's alarm system provides clear fault guidance, from wiring checks and power verification to module replacement, with corresponding handling suggestions. Combined with detailed diagnostic information from ToolboxST software, maintenance personnel can quickly locate problems, minimizing system downtime.