The IS215UCCCM04 is a high-performance single-board controller module from the UCCC series in GE's Mark VIe control system. This module is a complete computing unit, specifically designed for demanding industrial control environments and widely used in gas turbines, steam turbines, hydro turbines, and various balance-of-plant (BOP) controls. As the core brain of the control system, it is responsible for executing complex control algorithms, processing massive I/O data, and ensuring the stable, real-time, and reliable operation of the entire control system.

The IS215UCCCM04 module assembly includes the core component IS215UCCCH4 single-board controller, integrated with 128 MB of flash memory, 256 MB of DDR SDRAM, and the critical IS200EPMC functional daughterboard. The module adopts a CompactPCI (CPCI) form factor, installed in the backplane slot of a CPCI chassis. Through its powerful processing capabilities and extensive communication interfaces, it builds bridges between operator interfaces, engineering tools, subordinate control systems, and field I/O modules.

2. Key Features

High-Performance Processing Core: Equipped with an Intel Pentium M processor, running at up to 1.6 GHz, providing powerful computing capability for executing complex control logic and mathematical operations.

Large-Capacity Memory Configuration: Features 256 MB of DDR SDRAM, ensuring smooth operation of the multi-tasking real-time operating system and fast response of control applications; 128 MB CompactFlash is used for storing the operating system, application, and firmware.

Integrated IS200EPMC Daughterboard: This daughterboard provides critical system functions, including power supply monitoring, Flash-backed SRAM, three IONet Ethernet interfaces, and Ethernet physical layer packet snooping for precision time synchronization.

Extensive Communication Interfaces:

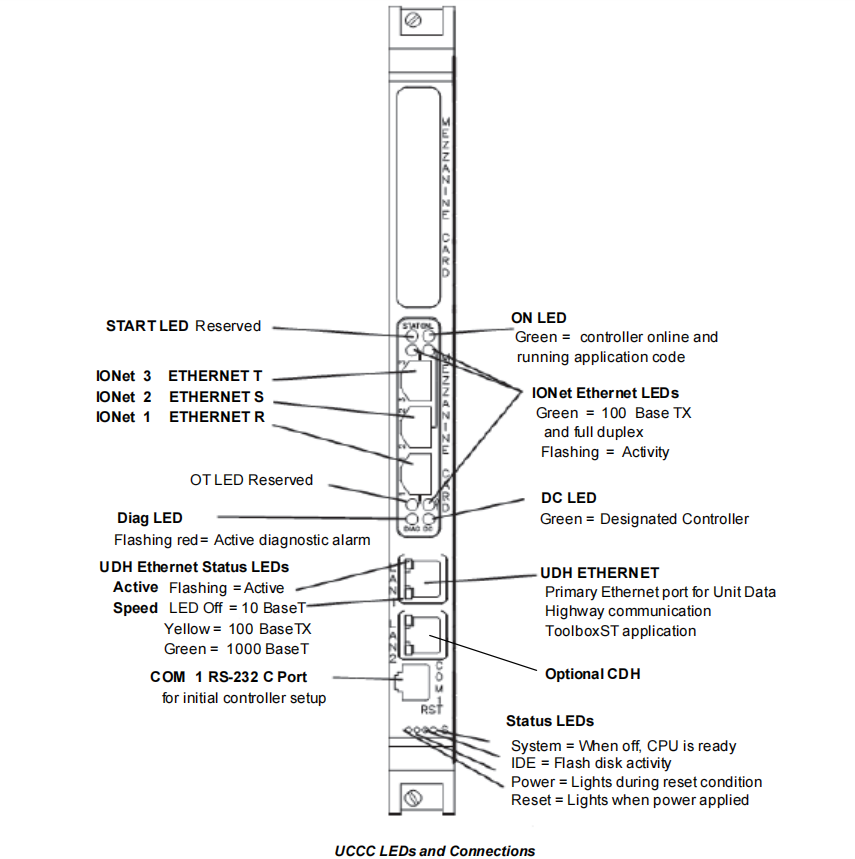

2 Front Ethernet Ports: For connecting to the Unit Data Highway (UDH) and the optional Control Data Highway (CDH), supporting 10/100/1000Base-TX auto-negotiation, used for communication with the ToolboxST engineering tool, HMI interfaces, and other control equipment.

3 IONet Ethernet Ports via EPMC (labeled R, S, T): These are dedicated, private Ethernet networks specifically designed for high-speed, real-time data exchange between the controller and various I/O packs.

1 Front RS-232C Serial Port (COM1): Used for initial controller setup and diagnostics.

High-Reliability Design: Utilizes the industrial-grade QNX Neutrino Real-Time Operating System (RTOS), features a watchdog timer, supports redundant power supplies (in dual-power supply chassis), and comprehensive status diagnostic LEDs.

Precision Clock Synchronization: Supports the IEEE 1588 Precision Time Protocol (PTP), synchronizing the clocks of the controller and all I/O modules via the IONet to within ±100 microseconds, which is crucial for sequence of events (SOE) recording and coordinated control.

Non-Volatile Storage: Supports a large number of non-volatile program variables, forces, and totalizers, ensuring critical data is retained during power loss.

3. Detailed Functionality and Principles

The operational principle of the IS215UCCCM04 is a complex process integrating high-speed computation, real-time communication, reliable management, and precise coordination. Its design fully embodies the pursuit of determinism, reliability, and real-time performance in industrial control.

1. System Architecture and Core Processing Principle

The core of this module is a single-board computer system built around the Intel Pentium M 1.6 GHz processor. The processor connects to memory, flash, and the EPMC daughterboard via high-speed buses (such as the front-side bus and PCI bus). The 256 MB of DDR SDRAM provides high-speed operational space for the executing real-time operating system (QNX) and control application code. All control logic—whether based on function block diagrams, ladder logic, or other custom algorithms—is compiled and executed here. The 128 MB CompactFlash acts as the "hard drive," persistently storing the operating system kernel, device drivers, control application, and default BIOS settings. This separation of storage and execution ensures fast system boot and application loading while guaranteeing that the system image and application code are not lost during unexpected power outages.

Its soul is the QNX Neutrino Real-Time Operating System (RTOS). Unlike general-purpose operating systems, the core characteristic of an RTOS is the "deterministic" scheduling of tasks. This means the system can guarantee that high-priority tasks (such as emergency shutdown logic, critical protection algorithms) are processed within a predetermined, very short time frame under any circumstances, without being blocked by lower-priority tasks or system background activities. This hard real-time capability is the lifeline of industrial control systems, ensuring the timeliness and precision of control responses.

2. Multi-Layer Network Communication and Data Exchange Principle

The network interfaces of the IS215UCCCM04 are clearly divided into the "information layer" oriented UDH/CDH and the "control layer" oriented IONet, reflecting a typical layered design philosophy.

Unit Data Highway (UDH) and Control Data Highway (CDH): These two front Ethernet ports are the system's interface with the "outside world." The UDH is the main channel, used by the ToolboxST engineering station for program downloads, parameter configuration, real-time monitoring, and fault diagnosis. Simultaneously, it exchanges data with upper-level HMIs (like CIMPLICITY), DCS distributed control systems, or other PLCs using industrial protocols such as Ethernet Global Data (EGD) or Modbus TCP. The CDH is an optional high-speed redundant data channel, used in multi-controller systems for more efficient data synchronization between controllers or for isolated communication with higher-level networks. These two networks typically operate on standard TCP/IP protocol stacks, handling monitoring and management information with relatively longer cycles and larger data volumes.

I/O Networks (IONet: R, S, T): These three Ethernet ports provided by the EPMC daughterboard are the link between the system and the "field world." They are dedicated, private Ethernet networks. Physically, they are standard Ethernet, but the protocols are often optimized solely for communication between the controller and the various I/O packs distributed in the field (responsible for acquiring analog/discrete signals and outputting control commands). Their communication characteristics are high real-time performance, high determinism, and small data packets. The controller periodically polls all I/O modules via the IONet, collecting the latest process data (like temperature, pressure, valve position) into its internal process image area, while simultaneously sending the computed control outputs (like valve commands, start signals) to the corresponding output modules. This periodic scanning mechanism ensures that the control logic processes the most recent data and that outputs act on the process promptly.

3. Data Synchronization Principle in Redundant and Fault-Tolerant Systems

In systems requiring high availability, such as Dual or Triple Modular Redundant (TMR) configurations, two or three IS215UCCCM04 controllers are deployed. In these configurations, collaboration between controllers is crucial.

In Dual Systems, both controllers execute the same control program simultaneously. They communicate with each other via dedicated network links (possibly utilizing the CDH or direct IONet communication), exchanging internal state values, initialization information, and synchronization status. One controller is designated as the Designated Controller (DC), and its outputs are typically prioritized. If the primary controller fails, the backup controller can take over seamlessly because it possesses a system state almost identical to the primary controller.

In TMR Systems, three controllers run simultaneously and exchange data via a dedicated communication network. Critical inputs and control variables are subject to "two-out-of-three" voting among the three controllers. If one controller produces an output that differs from the other two, its result is ignored, and the system continues normal operation based on the consistent outputs of the other two. The powerful processing capability and high-speed network interfaces of the IS215UCCCM04 make this complex, millisecond-level data synchronization and voting mechanism possible, significantly enhancing the system's fault tolerance.

4. Precision Time Synchronization (IEEE 1588) Principle

In distributed control systems, having a unified, precise clock across all controllers and I/O modules is vital, especially for Sequence of Events (SOE) recording, which requires accurately recording the sequence of discrete actions for incident analysis. The IS215UCCCM04 achieves this through the IEEE 1588 PTP protocol. The hardware on the EPMC daughterboard supports Ethernet physical layer packet snooping, which can precisely capture timestamps of 1588 synchronization messages on the network, unaffected by operating system protocol stack processing delays. The controller, acting as a master or slave clock, continuously adjusts its local clock by exchanging synchronization messages with other devices and calculating network transmission delays. Ultimately, the clocks of the entire control network—including all controllers and I/O modules—are synchronized to within a very high accuracy of ±100 microseconds, providing a unified time reference for the entire control system.

5. Power Management and Hardware Monitoring Principle

Reliability design is evident in the details. The module's IS200EPMC daughterboard integrates power supply monitoring functionality, continuously monitoring the various DC voltages supplied to the controller (+5V, +3.3V, ±12V) to ensure they are within normal ranges. If a power anomaly is detected, it can report it to the processor, triggering appropriate safety handling routines. The Flash-backed SRAM is a special type of memory that behaves like ordinary RAM during normal operation but can retain its contents via a backup capacitor or battery during a system power loss, or be promptly transferred to non-volatile Flash, used for preserving critical intermediate data or status flags that must be maintained during a power outage and are frequently written.

The watchdog timer on the module is the last line of software defense. The control application must regularly "feed the watchdog." If the application fails to do so due to a program crash or deadlock, the watchdog circuit will force a controller reset, allowing it to recover from the fault. The extensive LED indicators on the front panel (e.g., ON, DC, Diag, network status lights) provide maintenance personnel with an intuitive hardware status diagnosis interface, allowing quick assessment of whether the controller is running, if it is the designated controller, if there are any diagnostic alarms, and the network link status without connecting software.

6. Installation, Maintenance, and Thermal Management Principle

The module uses the CPCI standard size and receives power and ground through the chassis backplane. Its unique injector/ejector lever design not only facilitates insertion and removal but, more importantly, ensures a secure and reliable connection between the module and the backplane. The step of tightening the screws on the injector/ejectors is crucial, as it not only prevents the module from loosening in vibrational environments but, most importantly, provides a reliable chassis ground path for the module, which is essential for immunity to electromagnetic interference and electrostatic discharge.

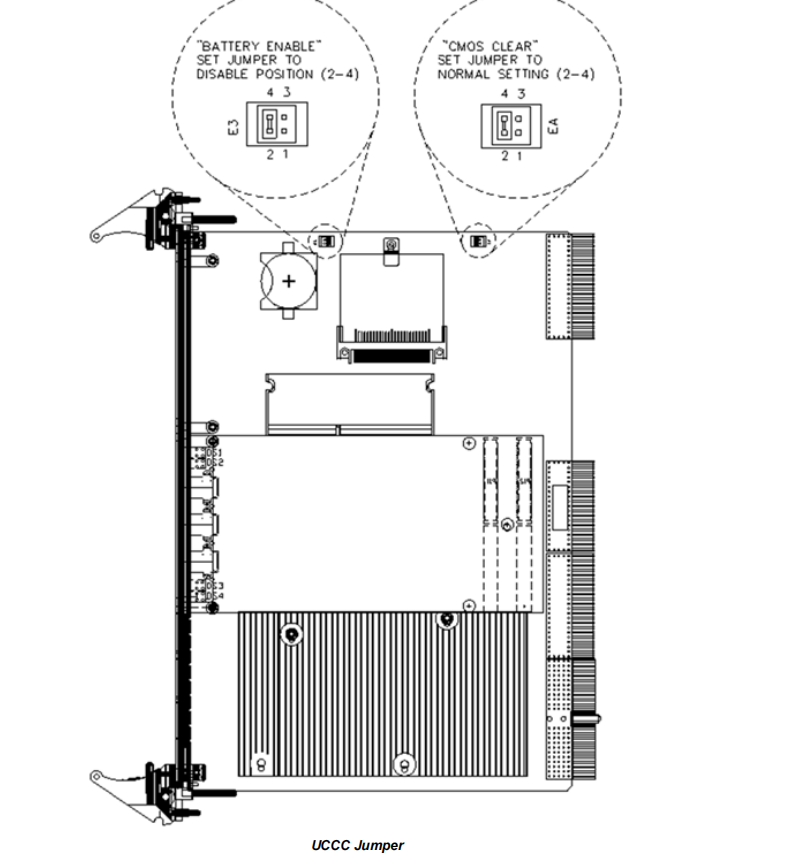

For heat dissipation, the processor is equipped with a heat sink, relying on the forced airflow generated by the system cooling fan in the CPCI chassis. The documentation explicitly states that the airflow velocity measured at the output side of the heat sink must be greater than 300 LFM to ensure the processor core temperature is kept within a safe range. The controller's internal firmware can monitor the CPU core temperature and can trigger alarms or enter a low-power protection state in case of overtemperature, preventing hardware damage. The field-replaceable cooling fan and the replaceable CMOS battery with a 10-year service life both reflect the design's maintainability.