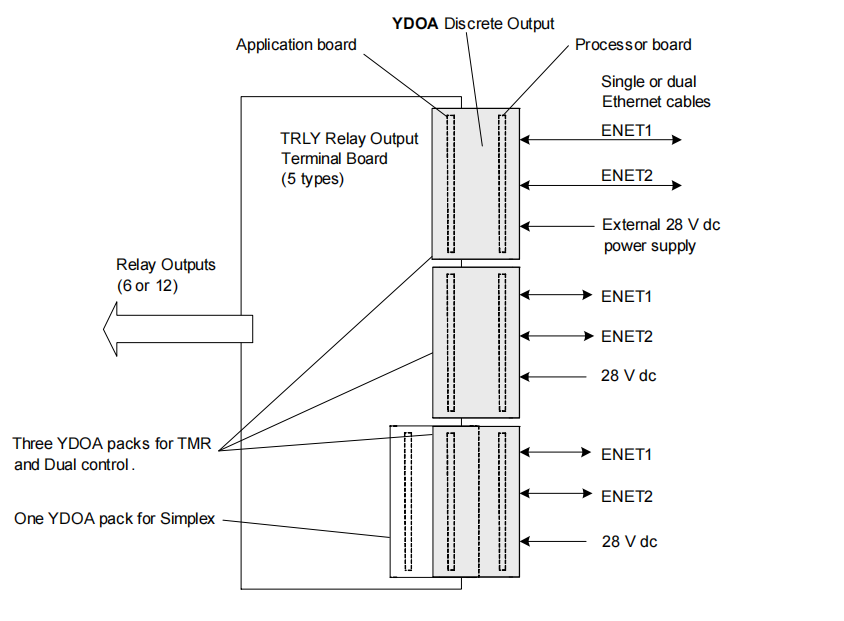

The IS420YDOAS1B is a Safety Discrete Output Module part of GE's Mark VIeS series, belonging to the YDOA family. This module is primarily used in industrial automation and control systems to provide highly reliable control of relay outputs, suitable for critical industrial applications such as power generation, power transmission and distribution, and process control. The YDOA module is designed with a strong emphasis on safety and redundancy, supporting Simplex, Dual, and Triple Modular Redundant (TMR) configurations to meet the reliability requirements of different application scenarios.

The IS420YDOAS1B module communicates with the control system via Ethernet interfaces and features comprehensive diagnostics and status feedback capabilities. It can monitor output status, relay coils, fuse status, etc., in real-time, ensuring the system can alarm promptly and take safety measures in case of a fault.

2. Key Features

1. Relay Control Capability

The IS420YDOAS1B module can control up to 12 relay output channels; the specific type depends on the connected Terminal Board.

Supports control of electromagnetic relays (e.g., TRLYS1B, TRLYS1D, TRLYS1F).

Each output features an open-collector transistor driver circuit and includes integrated current monitoring to detect whether the output successfully drives the load.

2. Status Feedback and Diagnostics

The module provides 12 channels of relay driver status feedback (Relay#Fdbk), reflecting in real-time whether the output command is executed effectively.

Supports Relay Contact Status Feedback (Relay#ContactFdbk) for terminal boards with contact sensing capability (e.g., TRLY#C, TRLY#E, SRLY).

Provides Fuse Status Feedback (Fuse#Fdbk), monitoring the status of up to 6 fuses through multiplexing technology.

For TRLY#D terminal boards, it also provides Solenoid Resistance Sense (Solenoid#Status) to determine if the load impedance is within the allowable range.

3. Communication Interface and Network Redundancy

The module is equipped with dual RJ-45 Ethernet interfaces (ENET1 and ENET2), supporting network redundancy.

ENET1 is typically connected to the network associated with the main (R) controller, while ENET2 serves as the redundant interface.

The module can operate normally on either port, ensuring communication is maintained even if one network fails.

4. Power Management and Soft-Start

The module receives external 28 V DC power via a 3-pin power connector, supplying power to both the module and the terminal board.

Features soft-start capability, effectively suppressing inrush current during power-up, allowing hot-plugging of the power connector without requiring power removal.

5. Sequence of Events (SOE) Recording

Each relay channel can be configured to generate an SOE record upon a state change, used for fault analysis and system tracing.

It is recommended to prioritize the use of output feedback signals (e.g., relay contact feedback) for SOE recording to improve event accuracy.

6. Safety and Self-Diagnostics

The module performs comprehensive self-tests upon power-up, including:

RAM and Flash memory checks

Ethernet port diagnostics

Processor board hardware verification

Continuously monitors internal power supply status, consistency between output commands and feedback signals, terminal board electronic ID, and other information.

Supports latching and resetting of diagnostic signals (via the RSTDIAG signal).

3. Working Principle

1. Signal Flow

The IS420YDOAS1B module acts as the interface between the control logic and field devices, performing signal conditioning and level shifting:

2. Output Enable Mechanism

During power-up or module initialization, all outputs are disabled until the self-test sequence is completed.

An Enable signal operates independently of the control command, ensuring relays remain de-energized while the system is not ready, preventing maloperation.

3. Feedback Multiplexing

The module has 15 inverting level-shifting monitor input circuits, of which:

Via a multiplexing control signal, the module can receive two sets totaling 30 status signals, enabling comprehensive monitoring of complex terminal boards.

4. Collaboration with the Terminal Board

The IS420YDOAS1B connects directly to the terminal board via a DC-37 pin connector.

The terminal board provides fuse protection and power distribution; power is applied directly to the terminal board, not through the module.

The module and terminal board perform hardware matching verification via an electronic ID, ensuring system compatibility and safety.

4. System Integration and Configuration

1. Compatibility

2. Installation Steps

Securely mount the terminal board in the cabinet.

Plug the IS420YDOAS1B module directly into the DC-37 interface of the terminal board.

Secure the module to the mounting bracket using the threaded studs, avoiding side force on the connector.

Connect one or two Ethernet cables; it is recommended to connect ENET1 to the primary network.

Connect the 28 V DC power supply.

Use the ToolboxST software to configure the module and download parameters.

3. Software Configuration Parameters

Input Parameters:

Contactinput: Enables relay feedback.

Signallnvert: Signal inversion.

SeqOfEvents: Enables SOE recording.

DiagVoteEnab: Enables voting diagnostics.

Output Parameters:

RelayOutput: Enables relay output.

FuseDiag: Enables fuse diagnostics.

Output_State: Sets the output state when the module goes offline (Hold Last Value or Predefined Value).

5. Diagnostics and Alarm Handling

The IS420YDOAS1B module provides extensive diagnostic functions, with specific alarm details available in the ToolboxST software, including:

| Alarm Code | Description | Recommended Action |

| 33-129 | Signal Voting Mismatch | Check R/S/T module configuration, power, and network connections. |

| 130-141 | Fuse(s) Blown | Check terminal board fuses, power, and configuration. |

| 142 | All Fuses Blown or No Terminal Board Excitation | Check terminal board power and connections. |

| 143-154 | Relay Output Coil does not match commanded state | Check terminal board connection, power, and load. |

| 155-166 | NO contact voltage disagreement with command | Check load voltage and configuration. |

| 167-178 | Relay Driver does not match commanded state | Check module-to-terminal board connection. |

| 179-184 | Connected field device impedance outside acceptable range | Check load impedance and power. |

| 191 | TRLY_F terminal board configured for SIMPLEX redundancy | Change redundancy configuration to TMR. |

| 192-195 | PGEN Communication Failure | Check network, firmware version, and configuration. |