| Product Identification Information | Product Model | CA202 (Ex ia Intrinsically Safe) | Meggitt vibro-meter Product Series |

| Order Number | 144-202-000-135 | Intrinsically Safe Explosion-Proof Version, 20m Cable Length |

| Explosion Protection Type | Intrinsically Safe Type "ia" Protection Level | Compliant with IEC 60079-11 Standard |

| Equipment Protection Level | Ga (for Gas Environments) | Provides Highest Level of Protection |

| Electrical Output Characteristics | Charge Output, Differential Mode | Two-Wire System, Electrically Insulated from Housing |

| Performance Parameters | Sensitivity (Nominal Value) | 100 pC/g | @23±5°C, 120Hz, 5g Peak Condition |

| Sensitivity Tolerance | ±5% |

|

| Dynamic Measurement Range | 0.01-400 g (Peak) | Linear Operating Range |

| Overload Protection Capability | 500 g (Peak) | Transient Impact Tolerance Capability |

| Linearity Error | ±1% (0.01-20g Peak)

±2% (20-400g Peak) | Expressed as Percentage of Full Scale |

| Transverse Sensitivity Ratio | ≤3% |

|

| Mounted Resonant Frequency | >22 kHz (Typical Value) | Actual Value Depends on Mounting Stiffness |

| Frequency Response Range | 0.5 Hz-6 kHz (±5%) | Flat Response Bandwidth |

| 8kHz Frequency Response Deviation | +10% (Typical Value) | Deviation Relative to Flat Response |

| Insulation Resistance | ≥1×10⁹ Ω | Signal Terminal to Housing, Minimum Value |

| Capacitance Parameters | Sensor Body Capacitance (Ci) | Inter-Pole Capacitance: ~5000 pF

Pole-Housing Capacitance: ~10 pF | Critical Parameter for Intrinsic Safety Loop Calculation |

| Cable Distributed Capacitance (per meter) | Inter-Pole Capacitance: ~105 pF/m

Pole-Housing Capacitance: ~210 pF/m | 20m Cable Total Capacitance Must Be Precisely Included in Loop Calculation |

| 20m Cable Total Capacitance | Inter-Pole Capacitance: ~2100 pF

Pole-Housing Capacitance: ~4200 pF | Calculated Value for 20m Total Cable Length |

| Environmental Parameters | Operating Temperature Range | Sensor Head: -55°C to +260°C

Integrated Cable: -55°C to +200°C | Continuous Operating Temperature Range |

| Short-Term Survival Temperature | Sensor Head: -70°C to +280°C

Integrated Cable: -62°C to +250°C | Non-Operating Storage Temperature |

| Temperature Coefficient Characteristics | -55°C to +23°C: 0.25%/°C

+23°C to +260°C: 0.1%/°C | Sensitivity Change Rate Relative to 23°C Reference Temperature |

| Temperature Class Range | T6 to T2 | Specific Class Determined Based on Ambient Temperature Ta |

| Mechanical Structure | Material Construction | Housing: Austenitic Stainless Steel 1.4441

Hose: Heat-Resistant Stainless Steel 1.4541 | Full-Path Hermetically Welded Structure |

| Protection Level | IP68 Equivalent | Dustproof, Waterproof, Corrosion Resistant |

| Shock Resistance | ≤1000 g (Peak) | Half-Sine Wave, 1ms Duration |

| Base Strain Sensitivity | 0.15×10⁻³ g/με | @250 με Peak-to-Peak Condition |

| Total Weight (Estimation) | Sensor: Approximately 250 grams

20m Cable: Approximately 2700 grams

Total: Approximately 2950 grams |

|

| Explosion-Proof Certifications | Explosion-Proof Marking | Ex ia IIC T6...T2 Ga |

|

| Equipment Category | II 1G (Gas Environment) | Suitable for Zone 0,1,2 Areas |

| Gas Group | IIC | Includes Hydrogen, Acetylene, etc. |

| Main Certification Numbers | ATEX: LCIE 02 ATEX 6179 X

IECEx: IECEx LCI 10.0018X

cCSAus: 70004630

UKEX: CML 22 UKEX 2746 X | All Carry "X" Special Conditions for Use Marking |

| Safety Parameters | Maximum Input Voltage (Ui) | According to Specific Values in Explosion-Proof Certificate | Maximum Voltage Allowed for Intrinsic Safety Loop |

| Maximum Input Current (Ii) | According to Specific Values in Explosion-Proof Certificate | Maximum Current Allowed for Intrinsic Safety Loop |

| Maximum Input Power (Pi) | According to Specific Values in Explosion-Proof Certificate | Maximum Power Allowed for Intrinsic Safety Loop |

| Internal Capacitance (Ci) | See Capacitance Parameter Column |

|

| Internal Inductance (Li) | Negligible (≤1 µH) |

|

| Maximum Allowed External Capacitance (Co) | According to Matched Safety Barrier Parameters | Includes Total Capacitance of Cable and Sensor |

| Maximum Allowed External Inductance (Lo) | According to Matched Safety Barrier Parameters | Includes Total Inductance of Cable and Sensor |

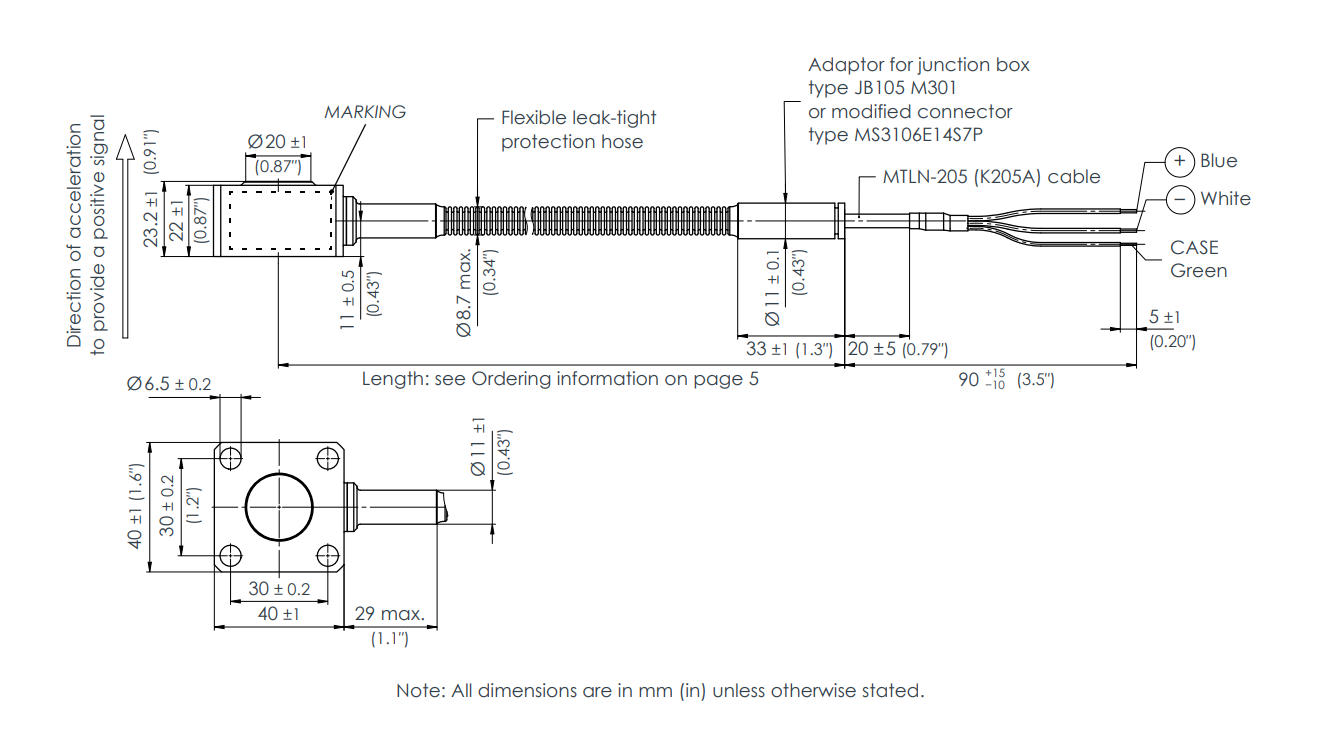

| Physical Characteristics | Cable Length | 20 meters | Integrated Stainless Steel Hose Cable |

| Cable Construction | Twisted-Pair Shielded Low-Noise Cable, Sheathed in Stainless Steel Flexible Braided Hose | Specially Designed Ultra-Long Cable Structure |

| Minimum Bend Radius | Static: 50mm

Dynamic: 75mm |

|

| Mounting Method | 4×M6×35 Socket Head Cap Screws

4×M6 Spring Lock Washers

Mounting Torque: 15 N·m | No Electrical Insulation Required on Mounting Surface |

| Electrical Interface | Flying Lead Terminals at Cable End | Red/White Signal Wires and Shield Layer |

| Compliance Certifications | Electromagnetic Compatibility | EN 61000-6-2:2005

EN 61000-6-4:2007+A1:2011 |

|

| Electrical Safety | EN 61010-1:2010 |

|

| Environmental Compliance | RoHS Directive (2011/65/EU) | Restriction of Hazardous Substances Directive |

| Factory Calibration | Dynamic Calibration @5g Peak, 120Hz, 23°C | Provides Calibration Certificate, No Field Calibration Required Under Normal Use |