The 3500/40M Proximitor Monitor is a high-performance, four-channel machinery protection and condition monitoring module developed by Baker Hughes under the Bently Nevada brand, specifically designed for the 3500 Series Machinery Monitoring System. Its core function is to accept raw signals from Bently Nevada proximity transducers (such as eddy current sensors), perform precise signal conditioning, calculation, and analysis, and ultimately convert them into key parameters reflecting machine health, which are continuously compared against user-programmable alarm setpoints to achieve continuous protection and early fault diagnosis for critical machinery.

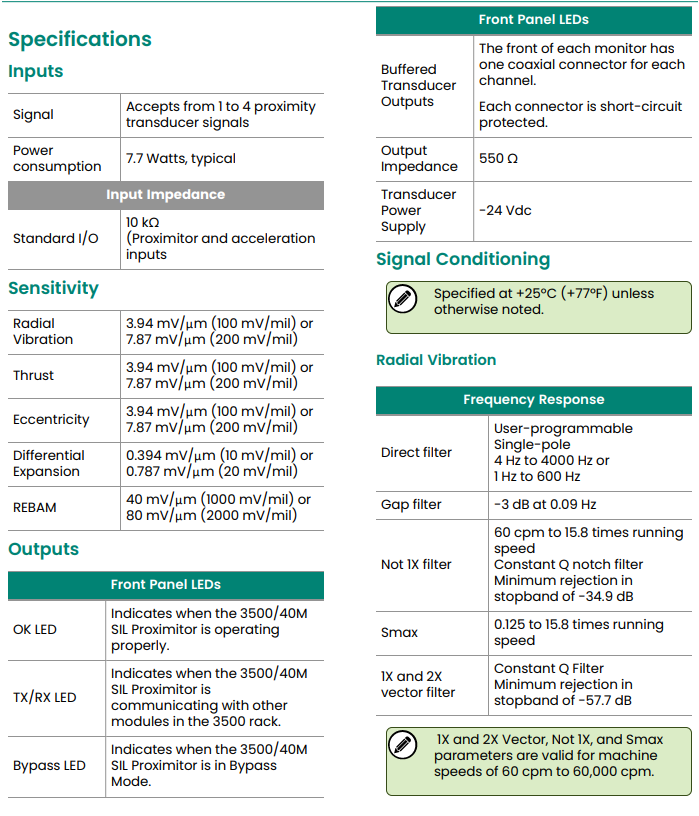

The monitor is renowned for its flexibility, high precision, and high reliability. Users can configure each channel independently via the 3500 Rack Configuration Software to perform different monitoring functions, including Radial Vibration, Eccentricity, REBAM (Rolling Element Bearing Activity Monitoring), Thrust Position, and Differential Expansion. The module is configured and managed in Channel Pairs; Channels 1 and 2 form one pair, and Channels 3 and 4 form another pair. Each channel pair can perform one monitoring function, enabling a single 3500/40M module to support two different monitoring applications simultaneously.

2. Core Features and Detailed Functional Principles

2.1 Core Function: Signal Conditioning and Parameter Generation

The 3500/40M is not merely a signal repeater; it is a sophisticated signal processing center. Its core workflow is as follows:

Signal Input and Power Supply: The module accepts raw analog voltage signals from up to four proximity transducers. Simultaneously, the front panel provides a Buffered Transducer Output coaxial connector for each channel, which is short-circuit protected, and can supply approximately ~24 Vac Transducer Power to directly power the proximitors, simplifying system wiring.

Signal Conditioning and Filtering: The input raw signal contains rich machine dynamic information but is also mixed with various noises. The 3500/40M incorporates a powerful Digital Signal Processor and user-programmable filter banks to precisely condition the signal.

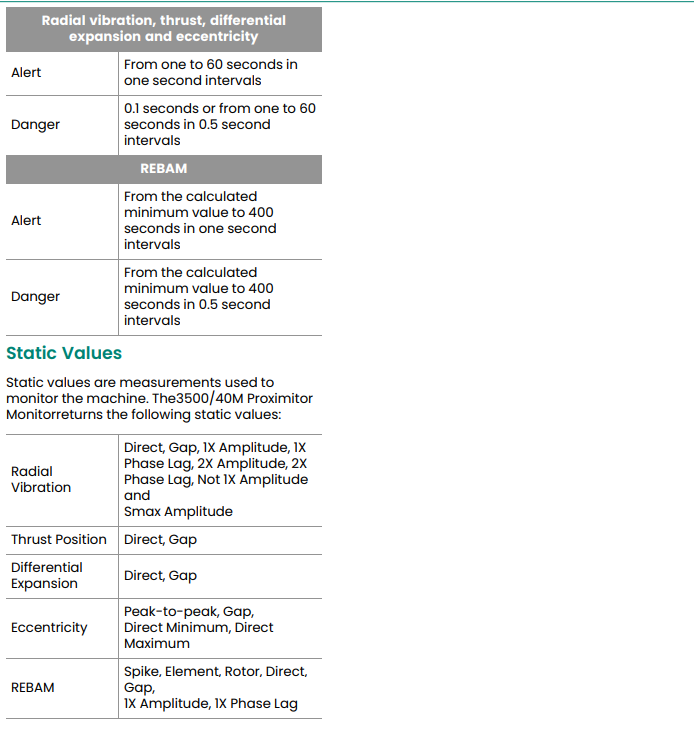

Static Values Calculation: The conditioned signals are used to calculate various parameters known as Static Values. These values are the measurements reflecting the machine's state and form the basis for alarm decisions. Depending on the channel configuration, different static values are generated. For example, a channel configured for Radial Vibration can generate multiple static values including Direct (Gap), 1X Amplitude, 1X Phase, 2X Amplitude, 2X Phase, Not 1X Amplitude, and Smax Amplitude, describing the rotor's vibration condition from different dimensions.

Alarm Decision and Output: Users can set Alert setpoints for each active static value and can select any two of the most critical static values to set Danger setpoints. The monitor continuously compares the real-time calculated static values against these setpoints. Upon an exceedance, the module, based on the configured alarm delay logic, triggers the corresponding alarm outputs, driving external alarm or shutdown systems via relay modules, thereby achieving machinery protection.

2.2 Detailed Working Principles for Each Monitoring Function

a) Radial Vibration

Principle: Measures the vibration displacement of the shaft relative to the bearing housing using two eddy current sensors mounted 90 degrees apart. This is a key parameter for assessing rotor balance, alignment, and early-stage rubbing faults.

Signal Processing:

Direct Filter: User-programmable, providing a wideband frequency response from 4 Hz to 4000 Hz or 1 Hz to 600 Hz, capturing the overall vibration level.

Gap Filter: A high-pass filter (~3 dB at 0.09 Hz) used to extract and monitor the average gap voltage (DC Gap) of the transducer. This voltage is directly related to the average position of the shaft within the bearing and can be used to monitor slow processes like changes in oil film thickness.

1X and 2X Vector Filters: Utilize high-Q (Quality Factor) constant Q band-pass filters to accurately extract vibration components synchronous with running speed (1X) and twice running speed (2X). Their stopband rejection is as high as ~57.7 dB, effectively isolating interference from other frequencies, allowing precise calculation of amplitude and phase for dynamic balancing and alignment analysis.

Not 1X Filter: A constant Q notch filter used to reject the 1X component, thereby extracting non-synchronous vibration components (e.g., subsynchronous oscillations, oil whirl).

Smax Filter: Identifies the frequency component with the maximum amplitude within a frequency range of 0.125 to 15.8 times running speed, helping to identify prominent non-synchronous vibration issues.

b) Thrust Position

Principle: Uses one or more proximity transducers to measure the position of the thrust collar, monitoring the axial movement of the rotor in rotating machinery (e.g., steam turbines, centrifugal compressors) to prevent contact between impellers and stationary components.

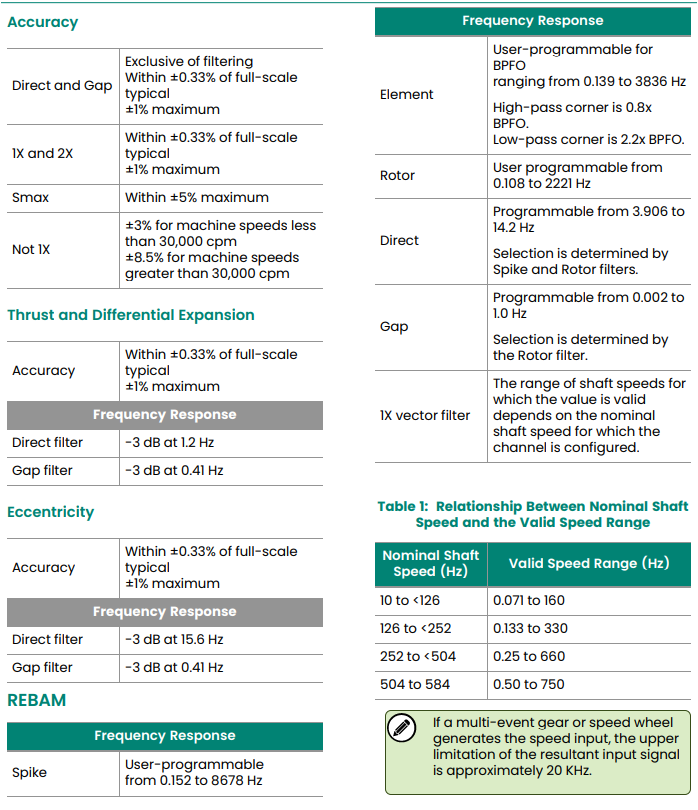

Signal Processing: Primarily uses the Direct Filter (~3 dB at 1.2 Hz) and Gap Filter (~3 dB at 0.41 Hz), focusing on slowly changing axial displacement and the average gap voltage.

c) Differential Expansion

Principle: Measures the difference in thermal expansion between the machine rotor and the casing (stationary part). Critical for large turbines and other equipment with slow startup/shutdown processes to prevent internal collisions due to differential expansion.

Signal Processing: Similar to Thrust Position, uses low-frequency Direct and Gap Filters to track the slow expansion process. Its input sensitivity is typically lower (0.394 mV/μm) to accommodate large-range displacement measurement.

d) Eccentricity

Principle: Measures shaft bow (mechanical eccentricity) or temporary bending due to uneven heating (thermal eccentricity) at low speeds, especially during turning gear operation.

Signal Processing: Uses the Direct Filter (~3 dB at 15.6 Hz) and Gap Filter (~3 dB at 0.41 Hz) to capture static or slow dynamic shaft bow at low speeds.

e) REBAM (Rolling Element Bearing Activity Monitoring)

Principle: Specifically designed for monitoring early-stage damage in rolling element bearings. It detects bearing defects by analyzing vibration energy around the characteristic fault frequencies (e.g., Ball Pass Frequency Outer race (BPFO), Ball Pass Frequency Inner race (BPFI), Ball Spin Frequency (BSF)).

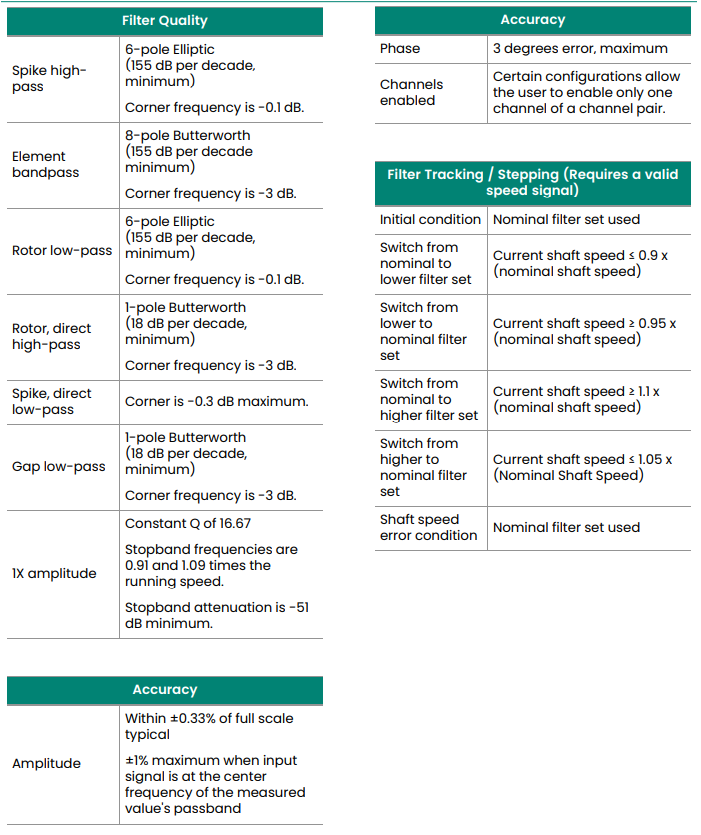

Signal Processing: This is one of the most complex processing modes, involving a dedicated set of filters:

Spike Filter: A programmable high-pass filter (0.152 to 8678 Hz) used to extract high-frequency impact signals.

Element Filter: A programmable band-pass filter whose center frequency is calculated based on user-input bearing parameters (e.g., BPFO), used to directly monitor the fault frequency of specific bearing components.

Rotor Filter: A programmable low-pass filter (0.108 to 2221 Hz).

The combined use of these filters effectively isolates characteristic bearing fault information from complex vibration signals, generating various static values including Spike, Element, Rotor, Direct, Gap, 1X Amplitude, and 1X Phase for a comprehensive assessment of bearing health.

2.3 Filter Tracking and Stepping Function

For filters that are dependent on running speed (e.g., 1X, 2X Vector Filters), the 3500/40M features an advanced Filter Tracking/Stepping function. When the module receives a valid Keyphasor speed signal, the filters can automatically switch between predefined filter sets based on changes in the actual shaft speed. For example:

Initial Condition: Uses the Nominal Filter Set configured for the rated speed.

Speed Decrease: Switches to the Lower Filter Set optimized for low speeds when the current shaft speed ≤ 0.9 x (Nominal Shaft Speed).

Speed Increase (from low): Switches back to the Nominal Filter Set when the current shaft speed ≥ 0.95 x (Nominal Shaft Speed).

Speed Increase (from nominal): Switches to the Higher Filter Set optimized for high speeds when the current shaft speed ≥ 1.1 x (Nominal Shaft Speed).

Speed Decrease (from high): Switches back to the Nominal Filter Set when the current shaft speed ≤ 1.05 x (Nominal Shaft Speed).

Speed Signal Error: In case of a lost valid speed signal, the module automatically uses the Nominal Filter Set, ensuring monitoring continuity.

This function ensures that during machine startup, coastdown, or speed fluctuations, the filters are always operating within their optimal frequency response range, guaranteeing accurate measurement of vibration components.

2.4 Accuracy and Performance

The 3500/40M delivers exceptional measurement accuracy. At +25°C, for most Direct, Gap, 1X, and 2X measurements, the typical accuracy is within ±0.33% of full scale, with a maximum of ±1% of full scale. The phase accuracy for the 1X Vector filter is as high as 3 degrees error maximum. This high level of accuracy provides a reliable data foundation for precise fault diagnosis and dependable protection decisions.

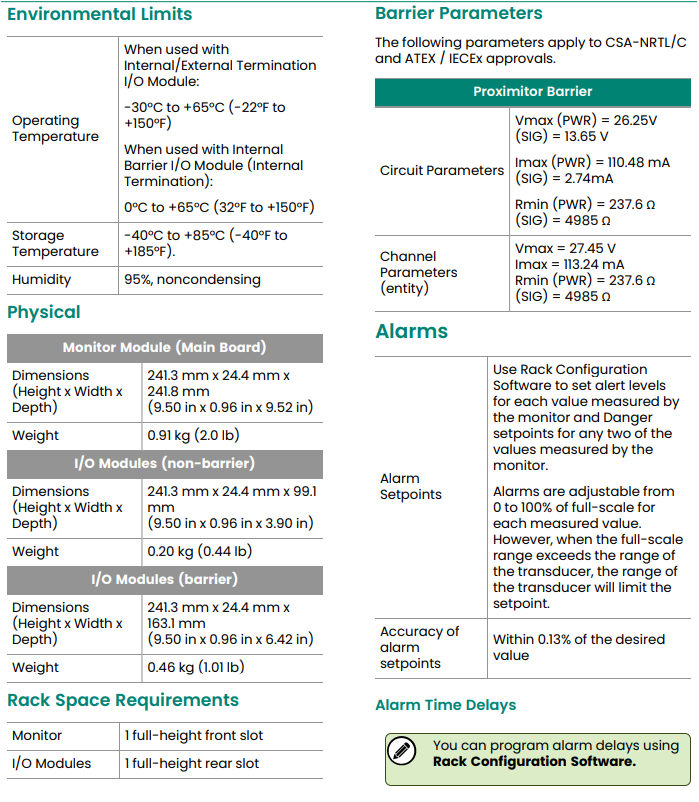

2.5 Alarms and Delays

Alarm Setpoints: Alert and Danger setpoints for each static value can be adjusted via software from 0 to 100% of full scale. The accuracy of the alarm setpoints themselves is within ±0.13% of the desired value.

Alarm Delays: To prevent false alarms, users can program alarm time delays.

For parameters like Radial Vibration and Thrust, Alert delays can be set from 1 to 60 seconds (in 1-second intervals), and Danger delays can be 0.1 seconds or from 1 to 60 seconds (in 0.5-second intervals).

For REBAM, the delay range is wider, from a calculated minimum value up to 400 seconds, accommodating the potentially intermittent nature of bearing fault signals.

3. Hardware Characteristics and Configuration Options

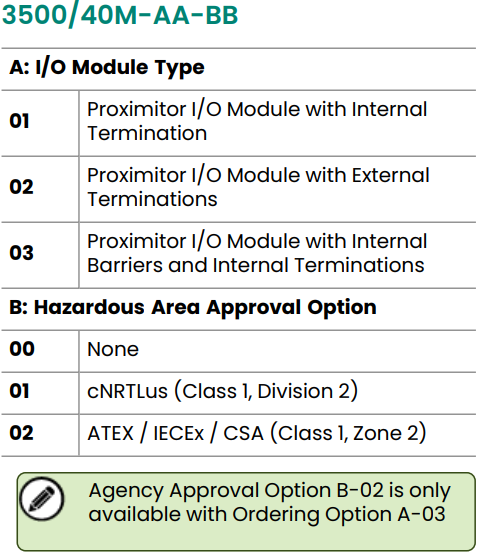

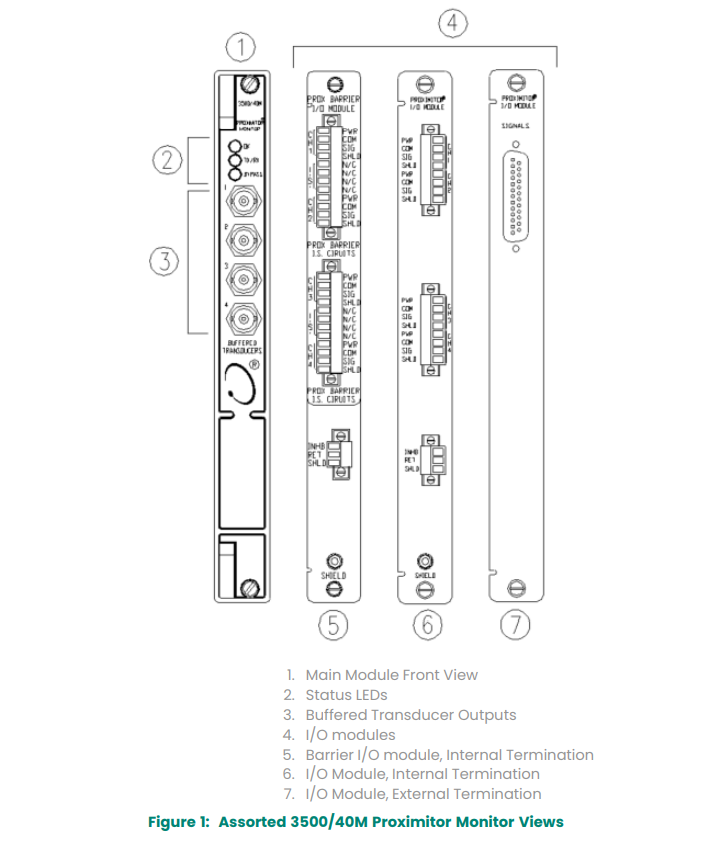

Module Structure: Follows the standard 3500 module architecture, consisting of a full-height Main Monitor Module (installed in the front of the rack) and a matching I/O Module (installed in the rear of the rack).

I/O Module Types: Three key I/O module options are available to meet different installation and environmental needs:

I/O Module with Internal Termination: All wiring is done via the module's built-in terminal blocks, offering a compact structure.

I/O Module with External Terminations: Connects via cables to separate external termination blocks, facilitating maintenance and isolation in harsh environments.

I/O Module with Internal Barriers: Integrates intrinsic safety barriers, allowing the monitor to be used in Hazardous Areas (e.g., Class I, Division 2 / Zone 2) without external discrete barriers. This is key for obtaining hazardous area certifications like ATEX, IECEx, and cNRTLus.

Status Indication: The front panel provides multiple LED indicators, including OK (operating normally), TX/RX (inter-module communication), and Bypass (Bypass Mode active), enabling quick field diagnostics of the module's status.

4. Environmental Suitability, Certifications, and Applications

Environmental Limits: Wide operating temperature range, from -30°C to +65°C when used with Internal/External Termination I/O Modules, and 0°C to +65°C when used with the Internal Barrier I/O Module.

Compliance Certifications: The module complies with numerous international standards, including FCC, EMC Directive, Low Voltage Directive, RoHS Directive, and holds marine certifications from DNV GL and ABS, as well as hazardous area certifications like ATEX, IECEx, and cNRTLus.

Application Scenarios: The 3500/40M is a cornerstone for protecting critical rotating equipment across industries, widely used in:

Power Generation: Steam turbines, gas turbines, generators, hydro turbines.

Oil & Gas: Pipeline compressors, gas turbines, pump sets.

Chemical and Process Industries: Various large compressors, turbomachinery.

Marine Propulsion Systems.