The 3500/61 Temperature Monitor Module is a high-performance, industrial-grade temperature monitoring device with recorder outputs, operating under the 3500 Machinery Protection System. It is a critical component of the 3500 series, specifically designed for continuous and reliable temperature monitoring and protection of essential mechanical equipment.

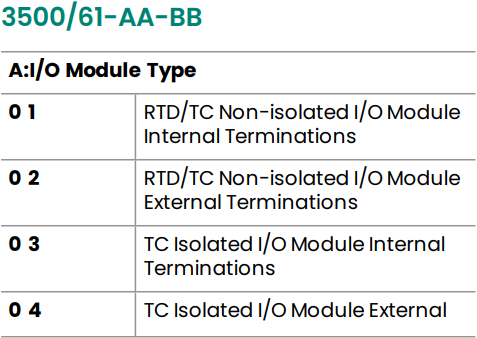

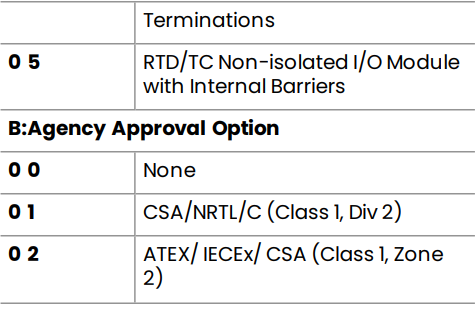

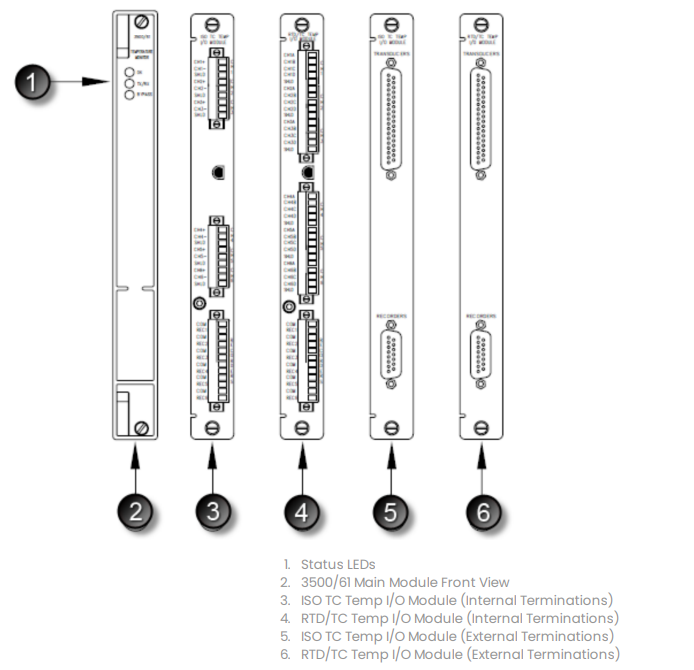

The 3500/61 consists of a fixed front module (P/N 163179-02) and five different types of rear I/O modules (refer to the Ordering page for details). The 163179-02 can form a complete system when combined with any of the rear I/O modules.

The 3500/61 module provides six channels of temperature monitoring, capable of simultaneously accepting inputs from various temperature sensors, including Resistance Temperature Detectors (RTDs) and Thermocouples (TCs). Users can independently and flexibly configure each channel using the dedicated 3500 Rack Configuration Software, even allowing the mixing of different sensor types on the same module. Its core functionalities include high-precision signal conditioning, user-programmable alarm settings, comprehensive front-panel status indication, backplane communication, and unique six-channel analog recorder outputs.

Compared to the 3500/60 module, which lacks recorder outputs, the 3500/61 provides an independent 4-20 mA analog output signal for each channel. These outputs are used to connect to Distributed Control Systems (DCS), recorders, or other data acquisition devices, enabling trend recording and process monitoring. This makes it the ideal choice for building complete, integrated monitoring and protection systems.

Features & Functions

1. Multi-Channel Flexible Input

Number of Channels: Provides 6 completely independent temperature monitoring channels.

Sensor Compatibility: Supports all mainstream types of temperature sensors.

100Ω Platinum RTD (Pt100), alpha = 0.00385 (Global industrial standard, recommended)

100Ω Platinum RTD (Pt100), alpha = 0.00392

120Ω Nickel RTD (Ni120)

100Ω Copper RTD (Cu100)

Thermocouples (TC): Types E, J, K, T.

Resistance Temperature Detectors (RTD): Supports 2-wire, 3-wire, and 4-wire configurations. Types include:

Mixed Configuration: Users can individually configure the sensor type for each channel via software, allowing RTD and TC inputs to be mixed on the same module, offering significant configuration flexibility.

2. High-Precision Signal Conditioning and Measurement

High-Performance Analog Front End: The module incorporates a high-precision signal conditioning circuit capable of amplifying, filtering, and linearizing the weak resistance changes from RTDs and the microvolt-level voltage signals from TCs.

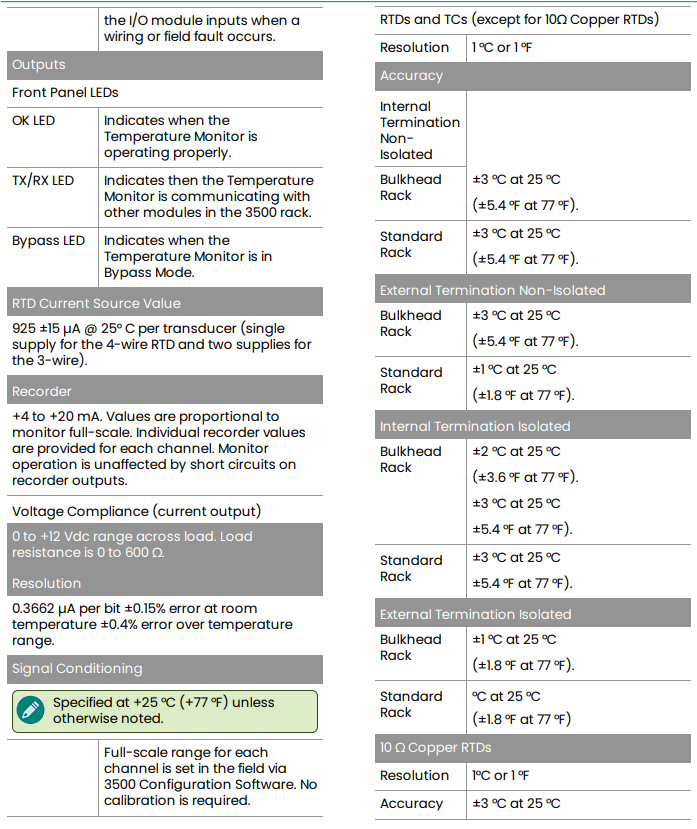

High Resolution: Temperature measurement resolution reaches 1°C or 1°F, meeting the precise reading requirements of industrial applications.

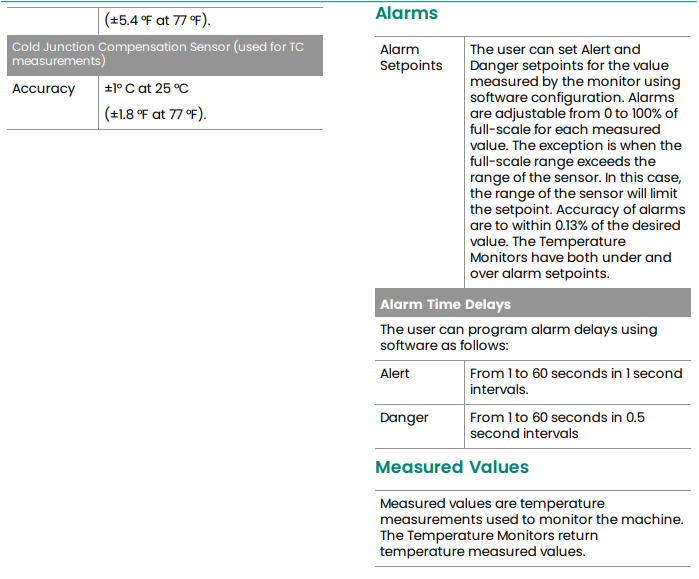

Cold Junction Compensation (CJC): For thermocouple measurements, the module integrates a high-precision CJC sensor, ensuring accurate temperature readings even when the rack ambient temperature changes, with a compensation accuracy of ±1°C at 25°C.

RTD Excitation Current: Provides a high-precision constant current source excitation of 925 µA ±15 µA for RTD sensors (a single source for 4-wire RTDs, two sources for 3-wire RTDs), ensuring measurement stability.

3. Programmable Alarm Function

Dual Alarm Setpoints: Each channel can independently set two alarm thresholds: "Alert" and "Danger". Supports both over-temperature and under-temperature alarms.

High Setpoint Accuracy: Alarm setpoints can be arbitrarily set from 0% to 100% of the range with high accuracy up to 0.13%, ensuring precise alarm triggering.

Adjustable Alarm Delay: To prevent false alarms caused by transient interference, users can configure a delay time for each alarm setpoint individually:

Alert Delay: 1 to 60 seconds, in 1-second increments.

Danger Delay: 1 to 60 seconds, in 0.5-second increments (provides faster emergency response capability).

4. Status Indication and Communication

Front Panel LED Indicators: Provides clear module status indication:

OK (Green): Module operating normally.

TX/RX (Green): Module is communicating with other modules in the 3500 rack.

Bypass (Yellow): Module is in Bypass Mode.

Backplane Communication: Exchanges real-time data with other system modules, such as the Framework Interface Module (FIM) and monitors, via the 3500 backplane. Uploads temperature values, alarm statuses, and module health information, offering high integration.

5. Recorder Output Function (Unique to 3500/61)

Output Signal: Provides independent +4 to +20 mA analog output signals for all 6 channels.

Proportional Output: The output current value is proportional to the monitor's full-scale range, facilitating connection to DCS, recorders, or PLCs.

High Load Capacity: Voltage compliance of 0 to +12 Vdc, capable of driving load resistances up to 600 Ω.

High Resolution: Output resolution reaches 0.3662 µA/bit, enabling precise reflection of temperature changes.

Short-Circuit Protection: Short circuits on the recorder outputs do not affect the normal operation of the monitor, ensuring high system reliability.

6. Support for Triple Modular Redundant (TMR) Configuration

High Availability Architecture: When used in a TMR configuration, three 3500/61 modules are installed side-by-side, monitoring the same set of signals.

Voting Mechanism: The system uses a "two-out-of-three" voting logic to process alarms and outputs. A failure of any single module will not cause system false trips or false alarms, greatly enhancing the safety and availability of critical applications.

7. Multiple I/O Module Options

Users can choose different types of rear I/O modules based on the application environment and safety requirements:

Non-Isolated I/O Modules: Suitable for general industrial environments, support mixed RTD/TC input, cost-effective.

Isolated I/O Modules: Provide 250 Vdc channel-to-channel and 500 Vdc system-to-ground electrical isolation, effectively suppressing ground loop interference and external noise, suitable for complex electrical environments.

I/O Modules with Internal Barriers: Designed for hazardous areas, feature internal safety barriers, and meet explosion-proof certification requirements such as ATEX, IECEx, CSA, suitable for Class I Division 2 / Zone 2 areas.

Working Principle

1. Signal Input and Conditioning

Signal Acquisition: Signals from temperature sensors (RTD or TC) are accessed through the rear I/O module.

RTD Measurement Principle: The module applies a precise constant current (925 µA) to the RTD and measures the voltage drop across it via a high-precision ADC. The resistance value is calculated using Ohm's law and then converted to a temperature value via a standard curve (e.g., IEC 60751). The 3-wire configuration compensates for lead resistance using the additional wire.

TC Measurement Principle: The module directly measures the microvolt-level thermoelectric potential (emf) generated by the thermocouple. The temperature at the terminal block (cold junction) is measured by the built-in CJC sensor. This cold junction temperature is used to convert the measured emf to the absolute temperature at the hot junction using the reference table (e.g., Type E/J/K/T) corresponding to the thermocouple type.

Signal Processing: The converted digital signal is further processed by the module's internal processor (e.g., DSP or FPGA) for linearization, digital filtering, and engineering unit conversion, ultimately yielding a high-precision digital temperature value.

2. Alarm Logic Processing

Value Comparison: The real-time temperature value calculated for each channel is continuously compared against the user-defined Alert and Danger setpoints configured via software.

Delay Judgment: When the temperature value exceeds a setpoint, the corresponding delay timer starts. The alarm state is only confirmed if the out-of-limit condition persists beyond the set delay time.

Alarm Output: The confirmed alarm state is output in the following ways:

Reported to the 3500 system framework via backplane communication, triggering rack alarm relays and system event records.

Indicated on the front panel via LEDs or a display (if applicable).

3. Recorder Output Generation

D/A Conversion: A function unique to the 3500/61 module. The processor converts the digital temperature value for each channel into a corresponding analog current value proportionally.

Current Output: A high-precision Digital-to-Analog Converter (DAC) and Voltage-to-Current (V/I) conversion circuit generate a 4-20 mA current signal precisely proportional to the temperature value. This signal is sent from the dedicated recorder output terminals for use by external devices.

4. Communication and Data Interaction

Backplane Integration: The module acts as an intelligent node in the 3500 system, continuously communicating with the Framework Interface Module (FIM) via a high-speed backplane bus.

Data Upload: Uploads real-time data for all channels, including temperature values, alarm statuses, delay statuses, and sensor health status (e.g., open circuit, short circuit).

Remote Configuration: Supports remote configuration, diagnosis, and monitoring via the 3500 Configuration Software (or via the FIM through protocols like Modbus, Ethernet).

5. Redundancy and Fault Tolerance Mechanism (TMR Mode)

Synchronous Monitoring: In a TMR configuration, three modules simultaneously monitor the same sensor signals.

Voting: A dedicated voter module (or software algorithm) collects output data from the three modules. A "two-out-of-three" voting logic is applied to the alarm status of each channel. This means an alarm is only ultimately validated and acted upon (e.g., shutdown) if at least two modules agree on the alarm condition. This ensures a failure of any single module does not affect the overall system's decision-making.

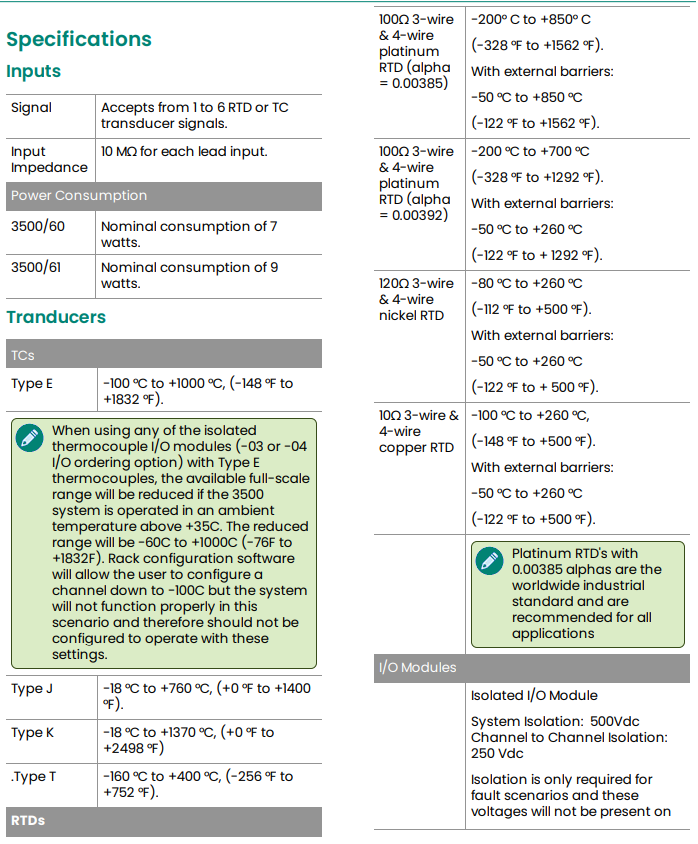

Technical Specifications

| Item | Specification Description |

| Input Channels | 6 channels, fully independent |

| Sensor Types | RTD (Pt100, Ni120, Cu100, etc.; 2/3/4-wire), Thermocouple (Type E, J, K, T) |

| Input Impedance | 10 MΩ per lead input |

| Power Consumption | 9 W typical |

| Measurement Accuracy | ±1°C to ±3°C (Depends on I/O module type, rack type, and sensor) |

| Resolution | 1°C or 1°F |

| Recorder Output | 6 channels, +4 to +20 mA, Load capability 0-600 Ω, Resolution 0.3662 µA/bit |

| Alarm Delay | Alert: 1–60 sec (1-sec increments), Danger: 1–60 sec (0.5-sec increments) |

| Alarm Accuracy | Within 0.13% of setpoint value |

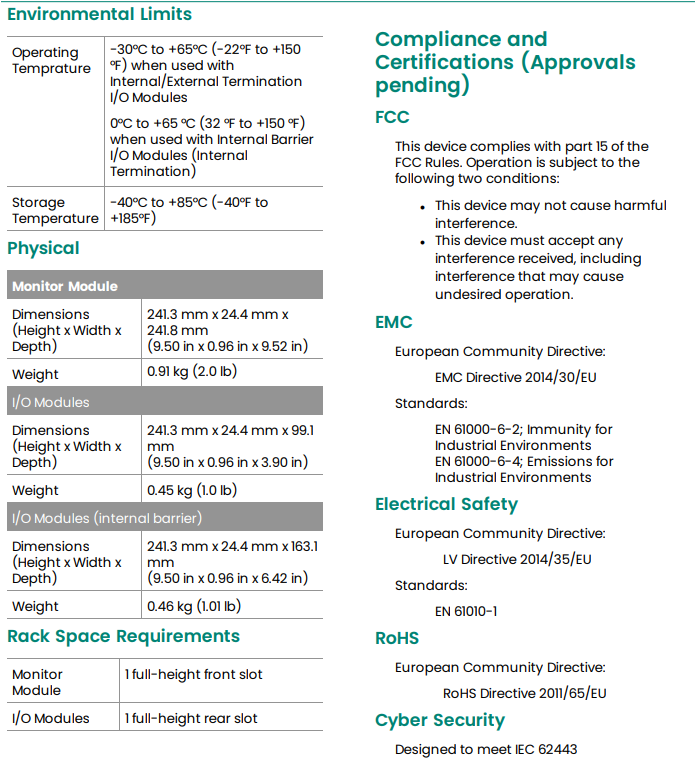

| Operating Temperature | -30°C to +65°C (when used with Internal/External Termination I/O Modules) |

| Storage Temperature | -40°C to +85°C |

| Rack Space | 1 front slot (Monitor Module) + 1 rear slot (I/O Module) |

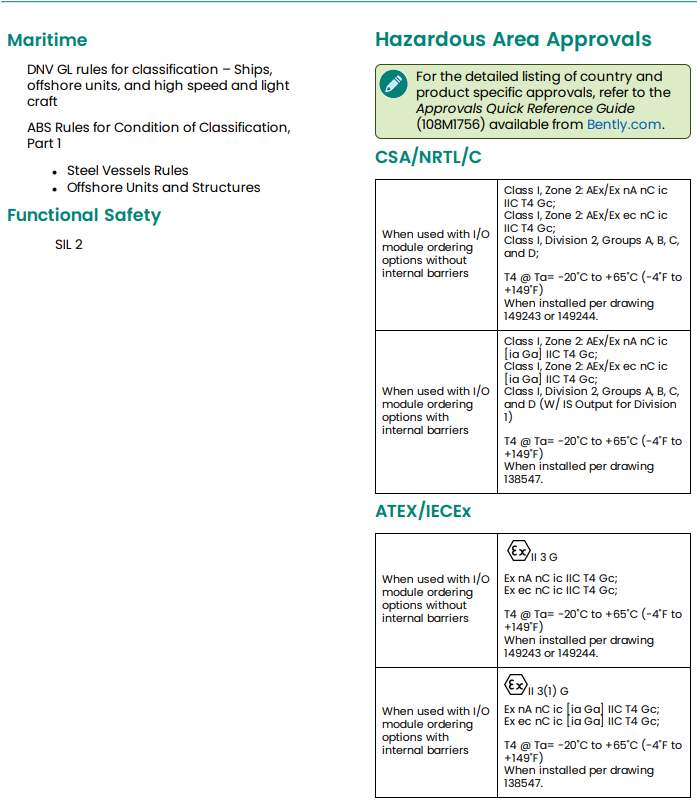

| Safety Certifications | Functional Safety: SIL 2

Explosion Proof: CSA, ATEX, IECEx (Class I Div 2 / Zone 2)

Others: FCC, CE (EMC, LVD), RoHS, DNV GL, ABS, IEC 62443 (Cybersecurity) |

Detailed Comparison: 3500/61 vs. 3500/60

While the 3500/61 and 3500/60 modules share the same technical foundation and architecture for core temperature monitoring and protection, they differ fundamentally in functional completeness, application positioning, and system integration capabilities. These differences dictate their respective suitable scenarios.

The most critical distinction lies in the presence or absence of analog recorder outputs. The 3500/61 is a fully-featured "All-in-One" solution with built-in analog output circuitry serving all six channels. This means it can simultaneously perform the dual roles of "equipment guardian" and "data provider." Users can directly and reliably interface temperature signals into the plant's recording and control systems without any additional external devices. This integrated design simplifies the overall monitoring system architecture, reduces potential failure points and wiring errors associated with using external transmitters, and enhances the reliability and data consistency of the entire signal chain.

In contrast, the 3500/60 is a "pure" monitoring module focused on core protection functions. It does not provide any analog recorder outputs. If the application requires temperature signals for recording or process display, engineers must separately configure and install external signal transmitters for each temperature sensor in the field. This not only increases equipment procurement costs but also makes the system structure more complex, adding to the installation, wiring, and ongoing maintenance workload and cost.

This fundamental difference leads to other consequential variations. Because the 3500/61 contains additional analog output circuitry, its power consumption (typically 9 watts) is slightly higher than that of the protection-focused 3500/60 (typically 7 watts). This slight difference should be considered during rack power planning. In terms of hardware identification, the two are distinctly different. The 3500/61 main module and its corresponding I/O modules have their own specific part numbers (often ending in "-02") and are not interchangeable with the 3500/60 modules (which end in "-01"). Furthermore, a 3500/61 system requires dedicated Recorder External Termination Blocks for connecting the recorder output cables, an additional component not needed in a 3500/60 system.

Consequently, their application positioning is clearly distinct. The 3500/61 is positioned for high-end, fully integrated applications where there is a mandatory requirement for data recording, trend analysis, and process control integration. It is the ideal choice for new projects or major upgrades pursuing system simplicity and data integrity. The 3500/60, on the other hand, is better suited for core protection applications where the primary need is reliable alarm and shutdown protection, with no requirement for continuous recording, or where recording functionality is intended to be obtained through other independent channels. It offers users a more economical foundational solution.

Application Scenarios

The 3500/61 Temperature Module is highly suitable for the following industrial scenarios due to its high reliability, precision, and recorder outputs:

Rotating Machinery Protection: Continuous monitoring and protection of bearing temperature, winding temperature, and exhaust temperature for gas turbines, steam turbines, compressors, water pumps, and fans.

Process Monitoring & Recording: Trend recording and over-temperature alarm for key processes in chemical reactors, industrial furnaces, pipelines, heat exchangers, etc.

Power Industry: Temperature monitoring for power generation unit transformers, generator stators/rotors, and motor bearings.

Marine & Offshore: Temperature monitoring for ship main engines, auxiliary engines, and gearboxes, meeting requirements of classification societies (e.g., DNV GL, ABS).

Any system requiring highly reliable temperature signals for both local protection and high-precision remote recording.