| Microprocessor | Intel EP80579, 1066 MHz |

| Memory | 256 MB DDR2 SDRAM with Error-Correcting Code (ECC) |

| Flash Memory | 2 GB NAND Flash |

| Non-Volatile Memory | 8 KB Flash-backed SRAM (allocated as NVRAM for controller functions) |

| Operating System | QNX Neutrino (real-time multitasking OS) |

| Programming Support | Control block language (analog and discrete blocks); relay ladder diagram logic |

| Data Types | Boolean, 16/32-bit signed/unsigned integers, 32/64-bit floating point |

| Ethernet Interfaces | 2 × RJ-45 ports (10/100Base-TX) for UDH and optional CDH |

| IONet Interfaces | 3 × RJ-45 ports (10/100Base-TX) for I/O module communication |

| Serial Port | 1 × RS-232C (via RJ-45 connector), used for initial setup |

| USB Port | 1 × front USB 2.0 port for system backup and restore |

| Input Voltage | 28 V DC (range: 18–36 V DC) |

| Typical Power | 15.6 W |

| Peak Power | 26.7 W |

| Operating Temp. | -30°C to 65°C (-22°F to 149°F) |

| Storage Temp. | -40°C to 85°C (-40°F to 185°F) |

| Humidity | 5% to 95% non-condensing |

| Cooling | Fanless, convection cooling |

| Dimensions | Standard module form factor (exact dimensions not specified in document) |

| Weight | 2.4 lbs (1.09 kg) |

| Mounting | Panel mount or DIN-rail mount |

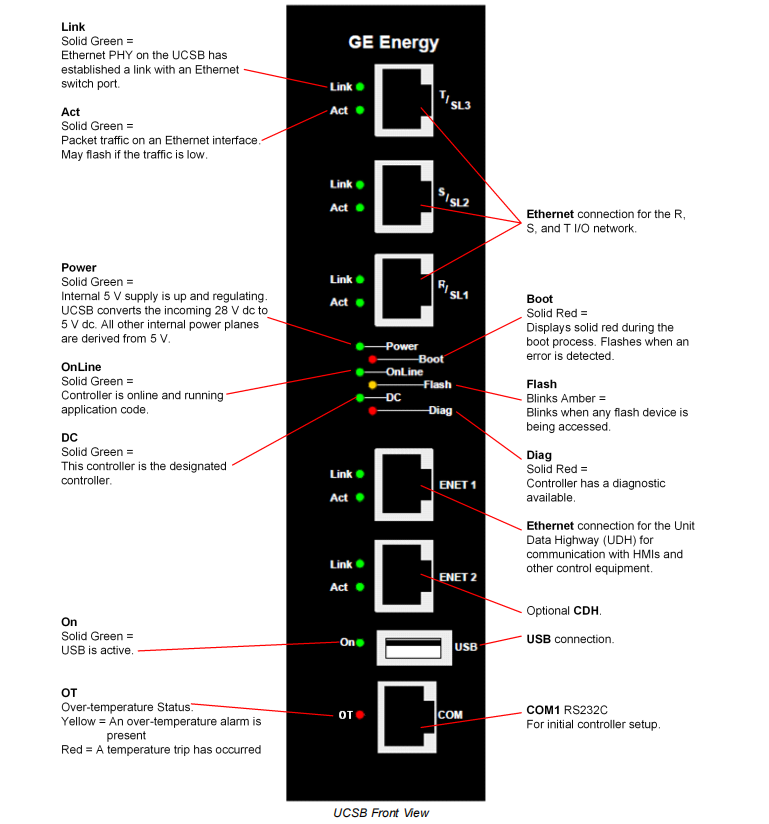

| LED Indicators | Link, Act, Power, Online, Flash, Diag, Boot |

| USB Recovery | Supports backup/restore via FAT32 USB drive (min. 4 GB) |

| Recovery Button | Located on rear of controller |

| Network Protocol | TCP/IP, Ethernet Global Data (EGD), Modbus TCP |

| Time Sync | IEEE 1588 Precision Time Protocol (PTP) for I/O pack synchronization |

| Redundancy Support | Simplex, Dual, or TMR architectures |

| Certifications | Complies with industrial standards for vibration, shock, and EMC (see Chapter 28) |