The IS200SRLYH2A is a high-performance, high-density Simplex Relay Output Terminal Board, designed for use with PDOA or YDOA I/O packs in the Mark VIe control system. As a member of the S-type terminal board family, it provides 12 independent Form C (changeover) relay output channels connected via 48 customer terminals, capable of directly driving various field actuators such as valves, motor starters, and indicator lights.

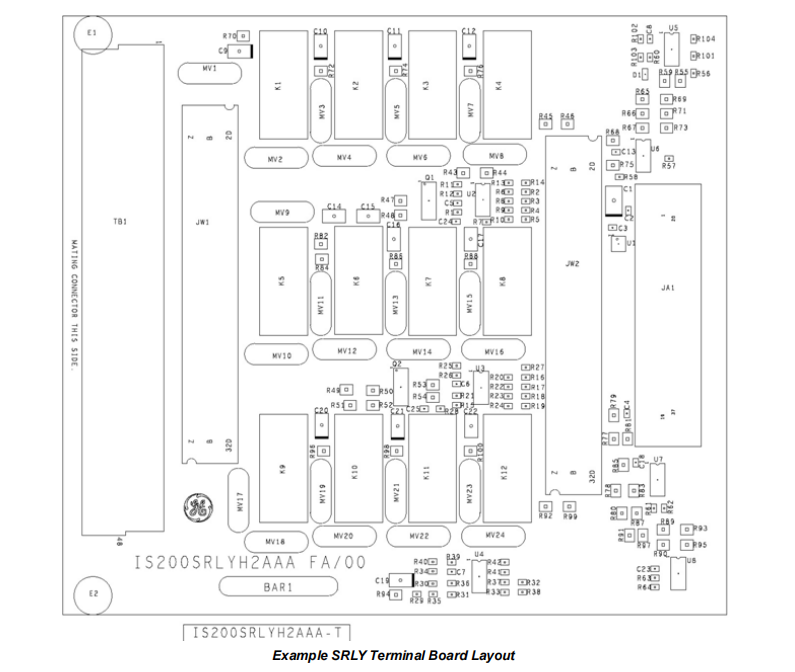

The core feature of this terminal board is its modularity and scalability. The IS200SRLYH2A itself is equipped with pluggable Euro-style terminal blocks, greatly facilitating field wiring and maintenance. More importantly, it reserves two connectors (JW1, JW2) that can host a variety of optional daughterboards with different functions. This allows the generic relay output functionality to be flexibly adapted to various complex power distribution and fault diagnosis application scenarios, achieving a high degree of customization.

II. Key Features & Functions

1. Basic Relay Output Function

Number of Channels: 12 independent channels.

Contact Type: Each relay is Form C type, providing one Common (COM), one Normally Open (NO), and one Normally Closed (NC) contact, offering maximum wiring flexibility.

Load Capacity: Relay contacts use silver cadmium oxide material, offering long electrical life (100,000 operations) and mechanical life (10,000,000 operations). Load capacity varies with voltage:

24 V DC operation: Max load current 3.15 A.

120/240 V AC operation: Max load current 3.15 A.

48 V DC operation: Max load current 1.2 A.

125 V DC operation: Max load current 0.6 A.

Response Time: Typical switch response time is 25 ms, meeting the demands of rapid control.

2. Position Feedback Diagnostics

Each relay on the IS200SRLYH2A includes a set of auxiliary contacts, fully isolated from the load contacts, dedicated to relay status feedback. This feedback signal is sent to the associated PDOA or YDOA I/O pack. By comparing the control command with the actual state of the feedback contacts, the system can diagnose in real-time whether the relay has successfully pulled in or dropped out, thereby detecting relay coil drive faults or mechanical failures of the relay itself, significantly enhancing system reliability.

3. Optional Daughterboard Expansion (Core Advantage)

The true power of the IS200SRLYH2A lies in its ability to expand functionality by hosting different optional daughterboards. These daughterboards plug directly into the terminal board's connectors, requiring no additional wiring.

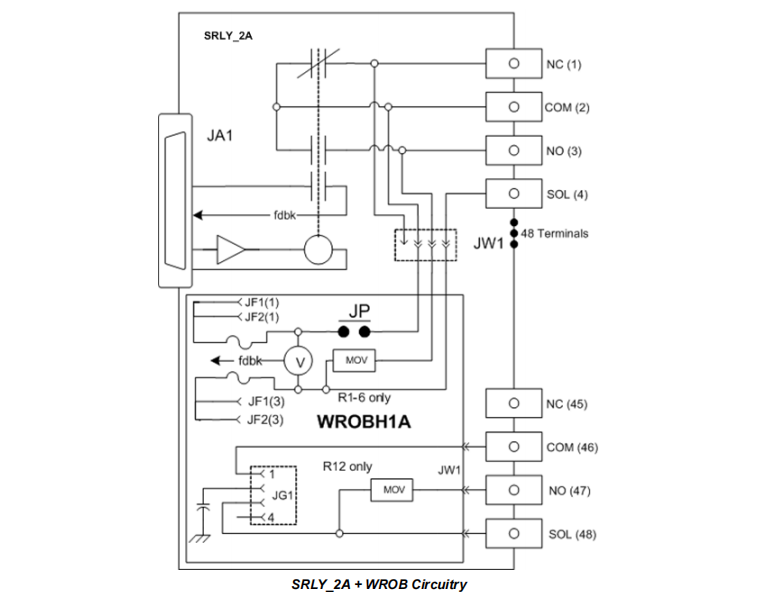

a) IS200WROB Daughterboard

This board converts the IS200SRLYH2A into a functional equivalent of the TRLY_1B terminal board, providing power distribution and comprehensive diagnostics.

Power Distribution: Provides dual-fused and monitored power distribution for the first six relays (Relays 1-6) (i.e., both the positive supply and return paths are fused). This design is particularly suitable for DC power systems floating with respect to ground, capable of detecting a blown fuse on either side.

Dedicated Power: Provides one unfused dedicated power input for the 12th relay (Relay 12) via the JG1 connector.

Diagnostics: Monitors the solenoid excitation voltage downstream of the fuses using isolated voltage sensing circuits. A diagnostic alarm is generated if the voltage falls below 9 V DC.

b) IS200WROF Daughterboard

This daughterboard adds a series fuse and voltage detection capability to each relay.

Series Fusing: Converts the original SOL terminal for each relay into a fused common point. Users can choose to connect the external power to the original unfused COM terminal or to the fused COM terminal, enabling flexible switching on the power side or ground side.

Isolated Voltage Detection: Each fuse is equipped with an isolated voltage sensor that is not polarity-sensitive. Even if the fuse is removed, this voltage detection circuit remains operational, used to detect the voltage status on the load side contacts (e.g., to confirm if a contactor is indeed energized), enabling isolated contact voltage feedback.

c) IS200WROG Daughterboard

This daughterboard provides single-ended fused power distribution for all 12 relays.

Power Distribution: Distributes power from a common input point (JF1) to the load circuit of each relay, with an independent fuse on the power side for each circuit. The power return path is not fused.

Diagnostics: Also includes fuse status monitoring; a diagnostic alarm is triggered if voltage is present but the fuse is open.

d) IS400WROH Daughterboard

This is the most comprehensive power distribution daughterboard, providing advanced power distribution and integrated diagnostics for all 12 relays.

Dual-End Fusing: Provides dual-end fused power distribution for all 12 relays (both positive and return paths fused), offering the highest level of protection.

Comprehensive Diagnostics: Provides isolated voltage sensing on both the positive and negative power supply sides, allowing precise diagnosis of a fuse failure on either side.

Flexible Power Supply: Relay 12 can be powered independently using the JG1 connector by removing jumpers JP12 and JP13, meeting special application needs.

Version Selection: Two versions are available to accommodate different feedback voltage ranges: WROHH1 (14–60 V DC) and WROHH2 (60–145 V DC or 90–265 V AC).

III. Detailed Working Principle

The operation of the IS200SRLYH2A and its ecosystem is a collaborative process integrating control driving, power management, status monitoring, and intelligent diagnostics.

1. Control Signal Flow & Relay Driving

Command Issuance: The Mark VIe controller sends output commands resulting from control logic via IONet Ethernet to the connected PDOA (or YDOA) I/O pack.

Signal Conversion & Driving: The PDOA pack receives the digital command and, through its internal output circuits, generates a signal level sufficient to drive the relay coil. This signal is sent via the connector on the back of the terminal board (e.g., JA1) to the coil of the specified relay on the IS200SRLYH2A.

Relay Action: The relay coil energizes, generating a magnetic field that drives the internal armature movement, changing the state of the load contacts (COM, NO, NC) (e.g., COM connects to NO, disconnects from NC), thereby connecting or disconnecting the power circuit of the connected external field device (e.g., motor, light, solenoid valve).

2. Position Feedback Monitoring Mechanism

This is the key link ensuring output reliability. Simultaneously with the relay action:

Feedback Contact State Change: The auxiliary feedback contacts, which are mechanically linked but electrically isolated from the load contacts, change state synchronously.

Status Signal Readback: The PDOA pack continuously scans the status of these feedback contacts and reads them back.

Comparison & Diagnosis: The I/O pack or controller firmware compares the readback feedback status with the previously issued control command in real-time.

Match: Indicates the relay has correctly executed the command; the system is normal.

Mismatch: For example, the command is "ON", but the feedback shows the contact is still "OFF". The system immediately generates a "Relay Fault" or "Position Mismatch" diagnostic alarm, notifying the operator of a hardware fault.

3. Enhanced Working Principle with Optional Daughterboards

Power Distribution Daughterboards (WROB, WROG, WROH) Working Principle

These daughterboards add controlled power distribution and protection to the basic relay function.

Power Introduction: External wetting power (can be AC or DC) is introduced through dedicated connectors on the daughterboard (e.g., JF1, J1, JG1).

Power Distribution & Protection: Power is distributed to individual relay circuits via the printed wiring on the daughterboard. Fuses (typically default 3.15A) are connected in series in the circuit as overcurrent protection elements. WROB and WROH use dual-end fusing, capable of handling more complex ground fault scenarios.

Load Connection: When the relay energizes, the fused power from the daughterboard is provided to the field device through the relay's load contacts (typically COM and NO).

Diagnostic Daughterboards (WROB, WROF, WROG, WROH) Monitoring Principle

These daughterboards utilize high-impedance voltage sensing circuits for non-intrusive monitoring.

Fuse Monitoring: The voltage sensor is connected across the load side of the fuse. Its working principle is to detect the presence or absence of voltage at that point.

Normal Condition: The fuse is intact. If power is normal and the circuit is closed, the sensor detects voltage and reports "Normal".

Fuse Blown: After the fuse opens, even if the supply side is powered, voltage cannot be established on the load side. The sensor detects no voltage, thus reporting "Fuse Fault".

Power Monitoring: WROB and WROH can also monitor the solenoid excitation voltage, ensuring the voltage reaching the device is within the operable range (e.g., not below 9 V DC), thereby diagnosing issues like power sags or excessive line voltage drop.

Isolated Contact Voltage Feedback (WROF Special Application): When the fuse on the WROF daughterboard is removed, its voltage detection circuit can be used independently as a universal voltage detector. For example, the VSENSE terminal can be connected to the auxiliary contact of a field contactor to confirm whether that contactor has pulled in for other reasons (not controlled by this relay), enabling monitoring of third-party device status.

4. Electronic Identification & System Integration

The IS200SRLYH2A terminal board and all its optional daughterboards integrate a read-only electronic ID chip. This chip stores device information such as serial number, board type, revision number, and connection location. When the PDOA pack powers up, it reads this ID information and compares it with the hardware configuration in the control system. Any mismatch immediately triggers a "Hardware Incompatibility" fault, preventing incorrect hardware from being used in the system and ensuring configuration accuracy.

IV. Installation

1. Mechanical Installation

Prepare Components: Assemble the IS200SRLYH2A terminal board with the accompanying plastic insulator.

Mount on Carrier: Mount the assembled unit onto the dedicated metal carrier.

Cabinet Mounting: Securely mount the entire assembly (terminal board + insulator + carrier) inside the control cabinet onto a backplate or rail using screws. Its physical dimensions are consistent with other S-type terminal boards for neat alignment. After installation, ensure no components (including subsequently installed I/O packs) exceed the allowable height to support potential double-stacking of terminal boards, saving space.

2. Electrical Connection

Customer Wiring: All field device wiring is done through the 48 customer terminals on the board. Each relay corresponds to 4 terminals:

NC: Normally Closed contact

COM: Common point

NO: Normally Open contact

SOL: The function of this terminal depends on whether and which optional daughterboard is used. When using the IS200SRLYH2A alone, this terminal is typically unconnected.

Connect I/O Pack: Plug the PDOA I/O pack directly into the corresponding connector on the back of the SRLYH2A terminal board (e.g., JA1), ensuring a firm connection.

Install Optional Daughterboard: If using an optional daughterboard (e.g., WROB, WROF, etc.), align it with the connectors on the IS200SRLYH2A (JW1, JW2) and insert it vertically. It is held in place by the connector's insertion force, usually requiring no additional tools or fasteners.

Power Connection (if using power distribution daughterboards): If using power distribution daughterboards like WROB, WROG, or WROH, connect the external wetting power supply to the specified input connectors on the daughterboard (e.g., JF1, J1, JG1) according to the daughterboard's requirements.

3. Jumper Configuration (If Applicable)

IS200SRLYH2A Main Board: No jumpers to configure.

WROB Daughterboard: Includes 6 jumpers (JP1-JP6) for connecting power to Relays 1-6. All jumpers are in place from the factory. If a relay is used as a dry contact (not powered via the daughterboard), remove the corresponding jumper.

WROH Daughterboard: Includes 13 jumpers (JP1-JP13) for connecting power to all 12 relays. All jumpers are in place from the factory. If a relay is used as a dry contact, remove the corresponding jumper. To provide independent power to Relay 12, remove JP12 and JP13.

WROF & WROG Daughterboards: No user-configurable jumpers.

4. System Power-Up and Identification

After completing all mechanical and electrical installation, power up the system. The PDOA I/O pack will automatically read the electronic ID information of the IS200SRLYH2A terminal board and any installed optional daughterboards, verifying them against the control system configuration to ensure the correctness of the hardware combination.