The TQ902 is a high-performance, non-contact proximity sensor based on the eddy-current principle from the VM product line. It serves as the core front-end component of a complete Proximity Measurement Chain, which typically consists of the TQ902 sensor, an optional EA902 extension cable, and an IQS900 signal conditioner.

The TQ902 sensor is specifically designed for condition monitoring and protection systems of rotating machinery. Its core function is to accurately measure the relative displacement (gap) between the sensor probe and a metal target (typically the shaft of rotating machinery). Utilizing a non-contact method, it converts minute changes in mechanical gap into variations in electrical parameters, providing raw data for subsequent signal conditioning and system decision-making.

The TQ902 is a form, fit, and functionally equivalent replacement for the TQ4xx series sensors, with optimizations in materials and design, matching or even exceeding their performance.

This system is widely used in critical equipment such as steam turbines, gas turbines, hydraulic turbines, turbo-compressors, large pumps, fans, generators, and motors to monitor shaft radial vibration, axial displacement (thrust position), and rotational speed (Keyphasor). It is an indispensable sensing unit for achieving machinery protection, predictive maintenance, and functional safety (e.g., Overspeed Detection Systems - ODS). The entire measurement chain complies with the requirements of API 670 5th Edition.

Core Features and Benefits

The design of the TQ902 sensor aims to provide reliable, stable, and precise measurement in extreme industrial environments. Its core features include:

Non-Contact Eddy-Current Measurement Principle:

Utilizes mature eddy-current effect for measurement, completely avoiding contact with the high-speed rotating target, eliminating wear and tear, and providing an extremely long service life and high reliability.

Capable of measuring targets made of various metallic materials, offering a wide range of application.

High-Temperature and Environmental Resilience:

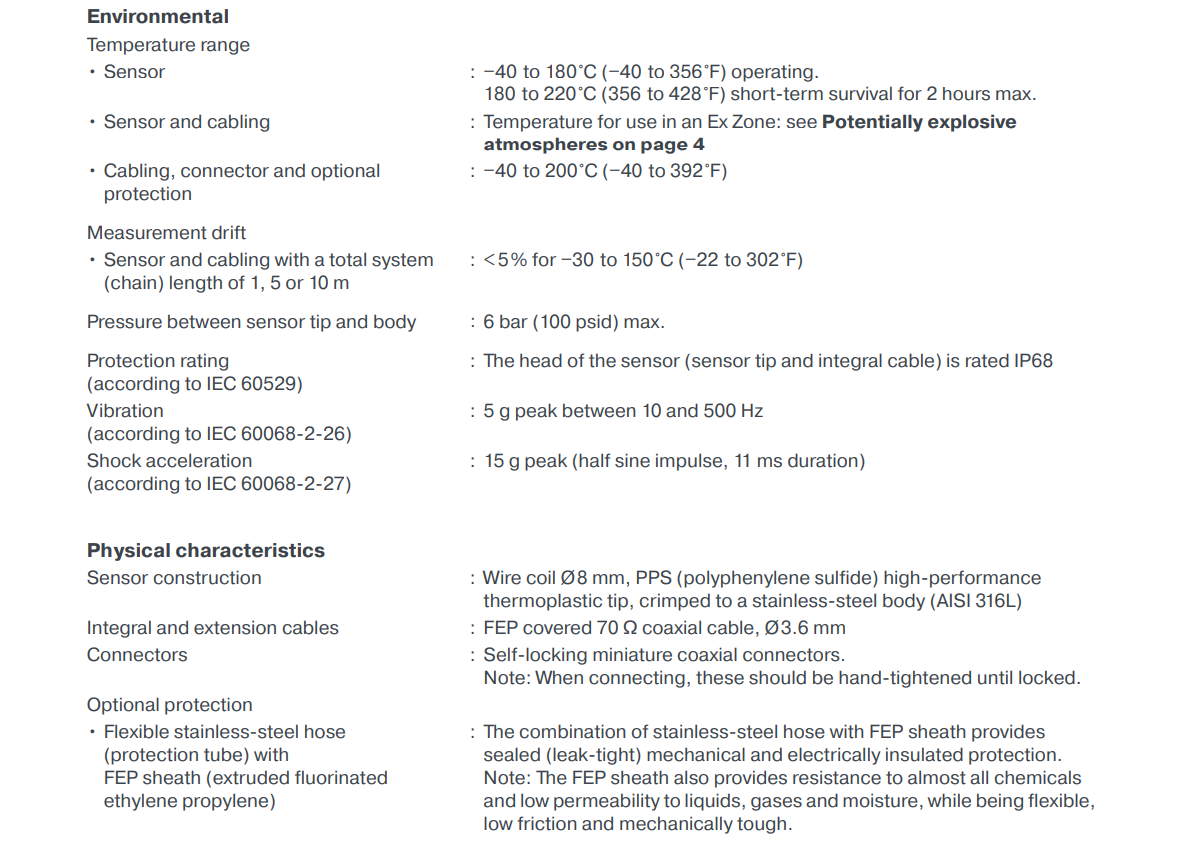

Wide Operating Temperature Range: The sensor body can operate continuously at ambient temperatures from -40°C to +180°C and withstand short-term survival temperatures up to +220°C (for a maximum of 2 hours), suitable for various high-temperature industrial environments, such as locations near turbine bearing housings.

Exceptional Protection Rating: The sensor head (probe and integral cable) boasts an IP68 protection rating, offering complete protection against dust ingress and continuous immersion, ensuring stable operation in harsh, wet, oily, and dusty environments.

Robust Mechanical Construction:

Probe Material: The sensor's sensitive coil is precisely encapsulated within the probe tip made of PPS (Polyphenylene Sulfide), a high-performance, high-temperature engineering thermoplastic. PPS material offers excellent resistance to high temperatures, chemicals, and mechanical strength.

Body Material: The sensor body is manufactured from AISI 316L stainless steel and is securely crimped to the probe section, ensuring overall structural integrity and corrosion resistance.

Pressure Resistance Design: The sensor can withstand a maximum pressure differential of 6 bar (100 psid) between the probe tip and the body, suitable for installation environments with pressure gradients.

Flexible Configuration and Installation:

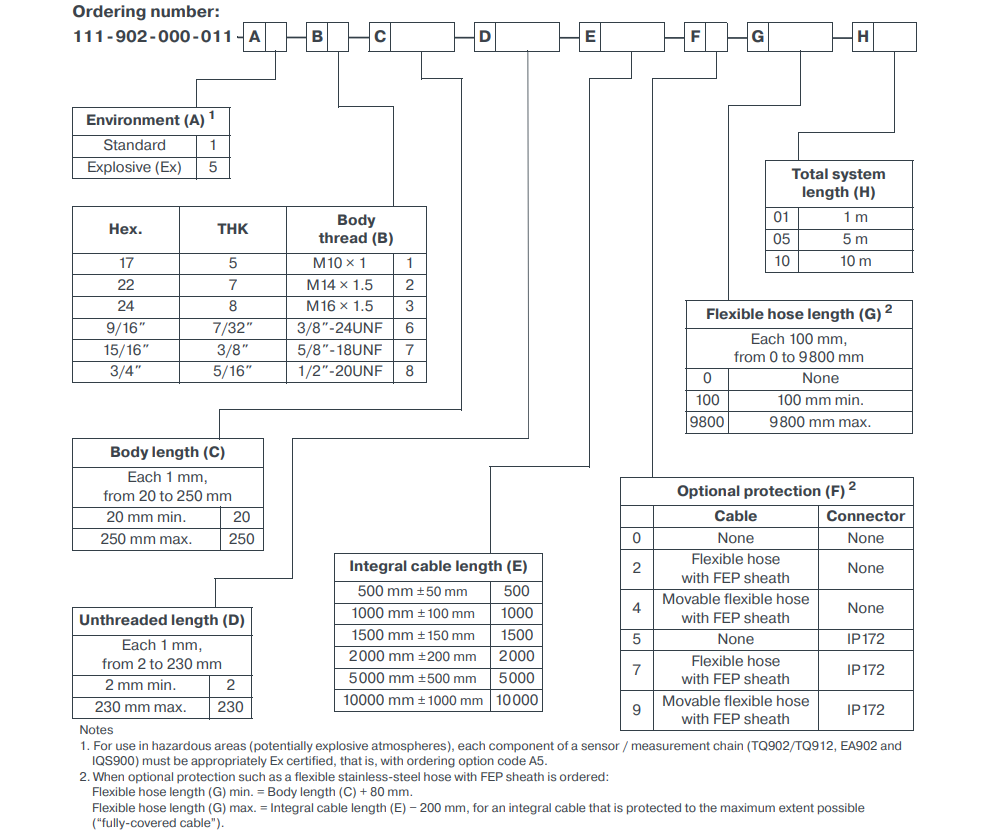

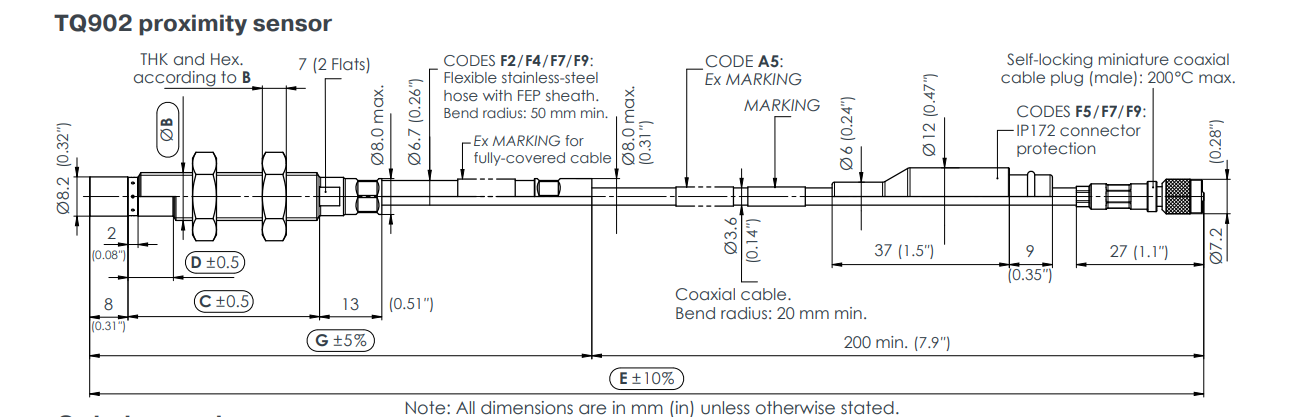

Multiple Thread Types: Offers both metric (M10×1, M14×1.5, M16×1.5) and imperial (3/8"-24UNF, 5/8"-18UNF, 1/2"-20UNF) thread options to meet installation requirements for different regions and equipment globally.

Customizable Dimensions: Body length (C) and unthreaded length (D) can be customized in 1 mm increments within a specified range (e.g., 20mm to 250mm) to adapt to different mounting hole depths and mechanical structures.

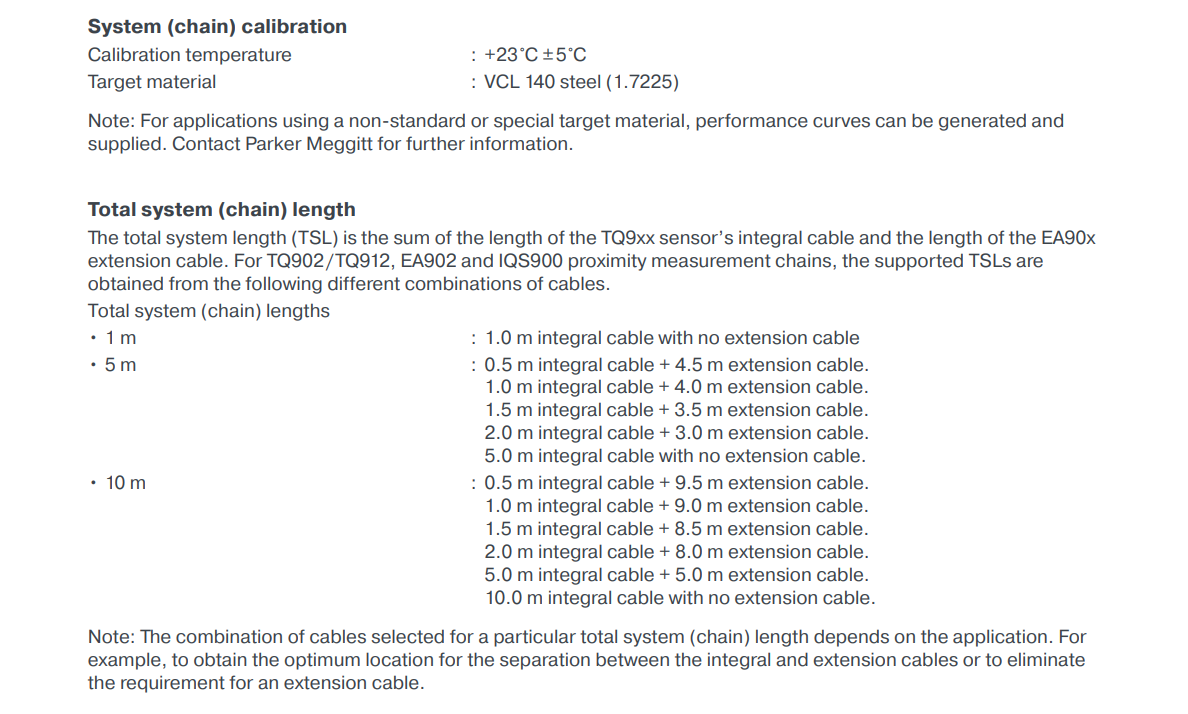

Multiple Cable Lengths: Provides various integral cable lengths (E) (e.g., 0.5m, 1.0m, 1.5m, 2.0m, 5.0m, 10.0m), which can be combined with EA902 extension cables to achieve Total System Lengths (TSL) of 1m, 5m, or 10m, meeting on-site wiring distance requirements.

Comprehensive Explosion Protection Certifications:

Available in certified explosion-proof versions (Ordering Option Code A5) for use in hazardous areas (potentially explosive atmospheres).

In "Ex ec" protection mode, the TQ902 itself acts as a "Simple Apparatus" and, when used with an IQS900 signal conditioner certified for "Ex ec", can be applied in Zone 2 gas environments.

In "Ex ia" intrinsic safety protection mode, the TQ902 also acts as a "Simple Apparatus" and, when used with an IQS900 certified for "Ex ia", can be applied in Zone 0, 1, 2 gas environments and Zone 20, 21, 22 dust environments.

Holds certifications from multiple global regions, including European ATEX, International IECEx, North American cCSAus, Korean KGS, UK UKEX, and Kazakhstani EAEU.

Optional Protection Kits:

Flexible Stainless-Steel Hose with FEP Sheath: Optional flexible stainless-steel hose with an FEP (Fluorinated Ethylene Propylene) sheath provides sealed (leak-tight), mechanical protection, and electrical insulation for the sensor cable. The FEP sheath also offers resistance to almost all chemicals, low permeability (against liquids, gases, moisture), flexibility, low friction, and high mechanical toughness, effectively protecting the cable from damage in demanding operating conditions.

Excellent Vibration and Shock Resistance:

Capable of withstanding vibration of 5 g peak between 10 Hz and 500 Hz, and shock acceleration of 15 g peak (half-sine pulse, 11 ms duration), ensuring stable signal provision even next to vigorously vibrating machinery.

Component Interchangeability:

Forms a calibrated measurement chain with the EA902 extension cable and IQS900 signal conditioner, wherein all components are interchangeable. This means any component can be replaced without recalibrating the entire system, significantly reducing maintenance costs and inventory complexity.

In-Depth Working Principle Explanation

The TQ902 sensor is the signal initiator for the entire measurement chain. Its working principle is based on electromagnetic induction and the eddy-current effect. This is a physical process that converts mechanical gap changes into inductance changes, detailed in the following steps:

Establishment of High-Frequency Electromagnetic Field:

The sensor requires drive from a downstream IQS900 signal conditioner. A high-frequency oscillator inside the IQS900 generates a stable, high-frequency (typically MHz range) AC sinusoidal current.

This high-frequency current is transmitted via coaxial cable to the precision coil inside the TQ902 sensor. This coil is made of wound wire and encapsulated within the PPS material probe tip.

Eddy Current Generation and Energy Dissipation:

When high-frequency current flows through the coil, it generates a high-frequency alternating electromagnetic field in the surrounding space. This field penetrates the PPS material at the top of the sensor probe and extends into the space ahead.

When the sensor probe approaches a metal target (e.g., a shaft), the alternating electromagnetic field induces closed-loop currents, called eddy currents, on the target surface.

According to Lenz's Law, these eddy currents generate a new induced magnetic field opposite in direction to the original field, always attempting to oppose the change in the field that created them.

Sensor Impedance Modulation:

As eddy currents flow within the target, they generate heat due to the material's resistive properties, dissipating energy. This energy comes from the source (IQS900) driving the coil.

This energy dissipation manifests as a change in the effective impedance of the sensor coil. Specifically, both the coil's inductance (L) and effective resistance (R) decrease.

Key Point: The gap (distance) between the sensor probe and the metal target directly determines the strength of the eddy-current effect, thereby governing the degree of coil impedance change. A smaller gap results in stronger electromagnetic field coupling, stronger induced eddy currents, greater energy loss, and more significant coil impedance change. Conversely, a larger gap results in less impedance change.

Signal Transmission:

The change in coil impedance modulates (alters) the amplitude of the high-frequency signal reflected back from the IQS900. Essentially, the gap information is encoded in the amplitude variation of this high-frequency signal.

This modulated high-frequency signal is returned via the coaxial cable to the IQS900 signal conditioner for subsequent processing.

Workflow: IQS900 supplies high-frequency current → TQ902 coil generates alternating magnetic field → Induces eddy currents in metal target → Eddy currents cause energy dissipation → Coil impedance changes → Impedance change modulates the amplitude of the return signal → Modulated signal returns to IQS900.

The TQ902 itself does not directly output a voltage or current signal proportional to the gap. It accomplishes the first step of "electromechanical conversion," transforming changes in mechanical gap into changes in electrical parameters (impedance/inductance). Subsequent complex signal processing tasks—demodulation (extracting amplitude variation from the high-frequency signal), amplification, linearization, temperature compensation, and standardized output (conversion to 4-20mA or -1~-17V DC signals)—are all performed by the downstream IQS900 signal conditioner. The performance and accuracy of the TQ902 are the foundation and guarantee for the high-precision measurement of the entire system.

Application and Importance in the Complete Measurement Chain

As the sensing unit, the TQ902 plays a vital role in the complete measurement chain composed of "Sensor - Cable - Signal Conditioner":

Front End for Machinery Protection Systems: It continuously monitoring shaft vibration and position and when vibration amplitude or displacement exceeds safety thresholds, the system triggers alarms or shutdowns to prevent catastrophic equipment damage.

Foundation for Condition Monitoring and Diagnostics: The raw signal it provides contains rich machine state information. Analyzing vibration spectra and trends can diagnose early faults such as rotor unbalance, misalignment, and bearing wear, enabling predictive maintenance.

Key Component in Functional Safety Applications: When paired with an IQS900 featuring diagnostics (SIL 2 certified), the entire measurement chain can be used in Safety Instrumented Systems (SIS), such as Overspeed Protection Systems (ODS), providing protection for plant safety operations that complies with international safety standards (IEC 61508, ISO 13849).

Starting Point for Long-Distance Transmission: When its signal is converted to a current signal (2-wire) by the IQS900 and transmitted via isolation units like the GSI127, signal transmission over distances up to 1 kilometer can be achieved, suitable for distributed monitoring in large plants.