The 3500/44M Aero-Derivative Gas Turbine Vibration Monitor is a high-performance, four-channel monitoring module within the Bently Nevada 3500 Series Machinery Condition Monitoring System, specifically designed for aero-derivative gas turbine applications. These gas turbines are widely used in power generation, oil and gas pipeline drives, and marine propulsion, characterized by high rotational speeds, frequent operational changes, and complex vibration characteristics. The 3500/44M was developed precisely to meet these demanding monitoring requirements.

The monitor's core mission is to provide continuous, reliable machinery protection by constantly comparing monitored parameters against user-programmable alarm setpoints to drive alarms, while simultaneously communicating critical machine information to operations and maintenance personnel. It connects to Bently Nevada's Velomitor velocity sensors, accelerometers, and corresponding interface modules via dedicated Aero GT I/O modules or Prox/Velom I/O modules, forming a complete and reliable vibration monitoring chain.

A standout feature of the 3500/44M is its exceptional adaptability and advanced signal processing capabilities. It supports various filter options including signal integration, 1X vibration tracking filtration, and bandpass vibration, and can accept two independent Keyphasor signals, allowing each channel pair to use a different tracking filter source, providing great flexibility for monitoring complex multi-rotor systems.

2. Core Features and Detailed Functional Principles

2.1 Core Function: Intelligent Monitoring for Dynamic Operating Conditions

The core value of the 3500/44M lies in its ability to adapt to the rapidly changing operating modes of aero-derivative gas turbines and provide precise vibration measurement and protection. Its workflow and advanced functions are as follows:

Multi-Sensor Signal Input: The module can accept signals from 1 to 4 channels, originating from:

Velomitor velocity sensors and accelerometers connected via interface modules.

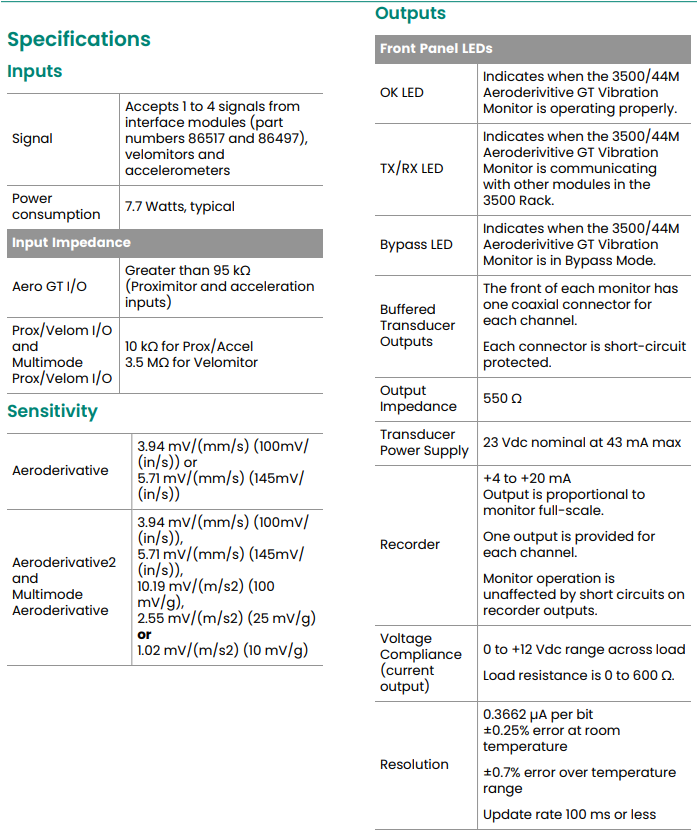

Its input impedance is optimized for different I/O modules: greater than 95 kΩ for Aero GT I/O modules, and 10 kΩ for Proximitor/Acceleration inputs / 3.5 MΩ for Velomitor on Prox/Velom I/O modules, ensuring signal acquisition accuracy.

Front Panel Interfaces and Outputs:

Each channel provides a Buffered Transducer Output coaxial connector, with short-circuit protection and an output impedance of 550 Ω, usable for connecting diagnostic equipment for in-depth analysis.

The module provides 23 Vdc nominal excitation power for sensors.

Each channel provides an independent 4-20 mA Recorder Output for connection to DCS or recorders, proportional to the monitor's full scale, and output shorts do not affect normal monitor operation.

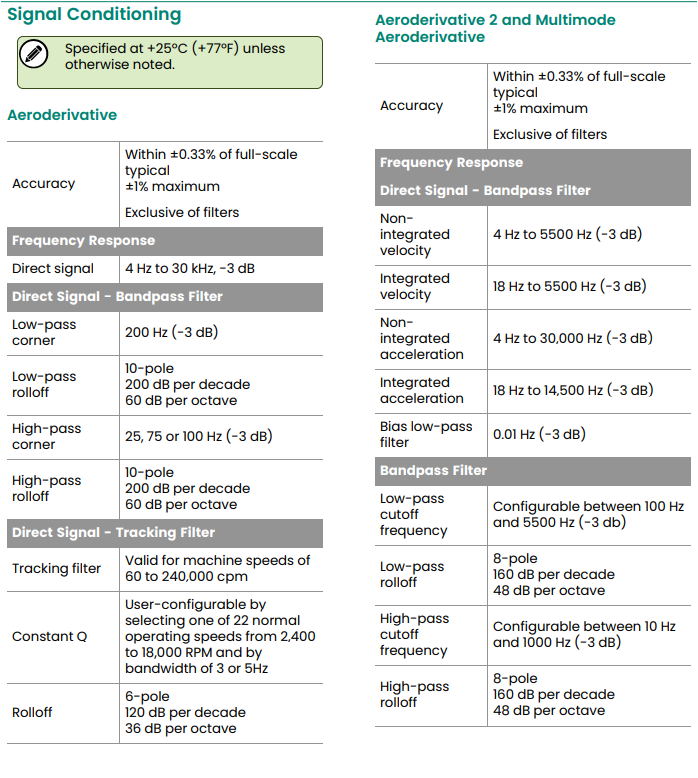

High-Precision Signal Conditioning: The module's typical power consumption is 7.7 Watts. At +25°C, its measurement accuracy is typically ±0.33% of full scale, with a maximum of ±1% of full scale, providing data assurance for precise diagnostics of high-speed equipment.

2.2 Key Monitoring Functions: Working Principles and Technological Innovations

a) Multi-Mode Channels and Alarm Management

This is the core technology of the 3500/44M for coping with the various operating conditions of gas turbines (e.g., ignition, acceleration, full load, deceleration).

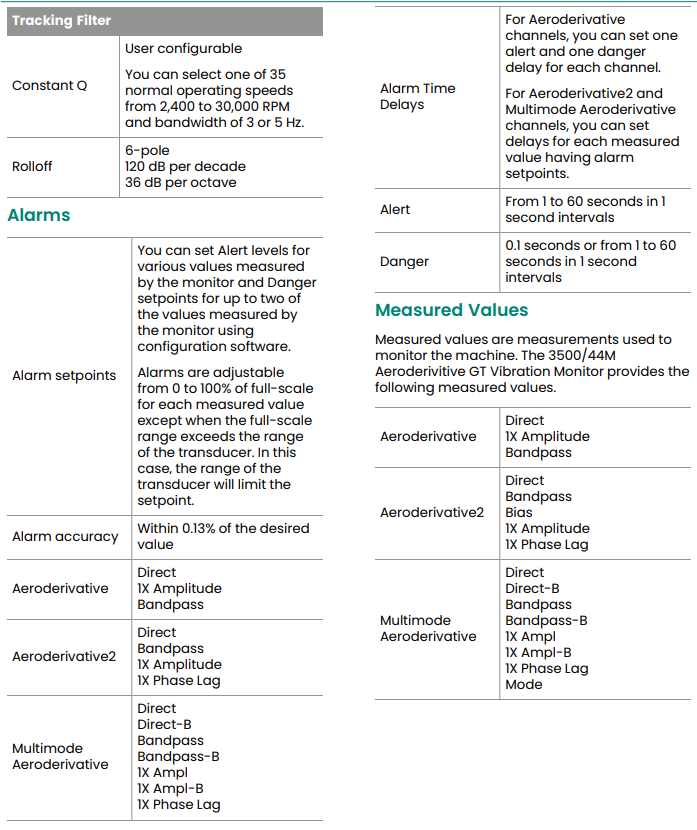

Principle: Users can configure up to eight independent sets of alarm parameters for each channel. Each parameter set includes Alert and Danger setpoints and alarm time delays. Each set can be associated with a specific machine operating mode (e.g., "Idle", "Full Speed").

Dynamic Switching: When the machine's operating condition changes, the monitor can automatically switch to the corresponding alarm parameter set in two ways:

Via external dry contact signals on the Multimode I/O modules.

Via software commands issued through a communication gateway (e.g., 3500/22M TDI).

Value: This function ensures that alarm thresholds always match the current operating state throughout startup/shutdown processes and under different loads. For example, when the machine passes through a critical speed, alarm delays can be temporarily increased or thresholds relaxed to prevent false trips; while under stable operation, stricter protection settings can be applied. This significantly enhances the intelligence and reliability of protection.

b) Dual Keyphasor Input and Tracking Filters

Principle: The 3500/44M allows the connection of two independent Keyphasor signals. This enables Channels 1 and 2 to track the speed of one rotor (e.g., high-pressure rotor), while Channels 3 and 4 track the speed of another rotor (e.g., low-pressure rotor). This is crucial for dual-spool aero-derivative gas turbines.

Tracking Filter: The monitor provides a high-performance tracking filter with an extremely wide operating speed range of 60 to 240,000 cpm, fully covering the entire range of the gas turbine from startup to maximum speed.

Users can select one from 22 predefined normal operating speeds (2400 to 18,000 RPM) and choose a bandwidth of 3 Hz or 5 Hz via configuration software.

The filter uses a 6-pole design, providing a steep roll-off of 120 dB/decade, enabling extremely precise isolation of the running speed (1X) vibration component, effectively suppressing noise and non-synchronous vibration interference.

This precise extraction of the 1X component is essential for monitoring faults like rotor unbalance, misalignment, and thermal bow.

c) Advanced Filter Options and Signal Processing

The 3500/44M supports multiple signal processing modes; users can configure channels as Aeroderivative, Aeroderivative2, or Multimode Aeroderivative types.

Bandpass Filters:

In Aeroderivative mode, it provides a fixed high-pass (25, 75, or 100 Hz) and low-pass (200 Hz) bandpass filter, using a 10-pole design with a roll-off rate as high as 200 dB/decade, creating a very sharp passband for isolating vibrations in specific frequency bands (e.g., related to structural resonances or gear meshing).

In Aeroderivative2 and Multimode modes, the high-pass and low-pass cutoff frequencies of the bandpass filter can be flexibly configured by the user within a certain range (High-pass: 10-1000 Hz, Low-pass: 100-5500 Hz), using an 8-pole design (160 dB/decade), offering greater adaptability.

Signal Integration Processing: The module can digitally integrate acceleration signals to convert them to velocity, or integrate/differentiate velocity signals to obtain displacement. This allows users to select the most appropriate vibration parameter (acceleration, velocity, or displacement) for monitoring and alarming based on need, meeting different diagnostic standards and engineer preferences.

Bias Filter: In Aeroderivative2 and Multimode modes, a bias filter with a cutoff frequency of 0.01 Hz is provided to remove very low-frequency DC components from the signal, ensuring accurate AC vibration signal measurement.

2.3 Measured Values and Alarm Mechanism

Depending on the channel configuration, the monitor can provide various Measured Values:

Aeroderivative: Direct, 1X Amplitude, Bandpass.

Aeroderivative2: Direct, Bandpass, 1X Amplitude, 1X Phase Lag.

Multimode Aeroderivative: In addition to the above values, it provides a second set of parameters (e.g., Direct-B, Bandpass-B, 1X Ampl-B) for comparative monitoring across modes.

Users can set Alert alarms for each active measured value and select any two of them for Danger alarms. The accuracy of alarm setpoints is within ±0.13% of the desired value. Alarm delays can be flexibly set: Alert delay from 1 to 60 seconds (in 1-second intervals), Danger delay can be 0.1 seconds or from 1 to 60 seconds (in 1-second intervals), effectively preventing false triggers due to transient disturbances.

3. Hardware Architecture and Configuration Options

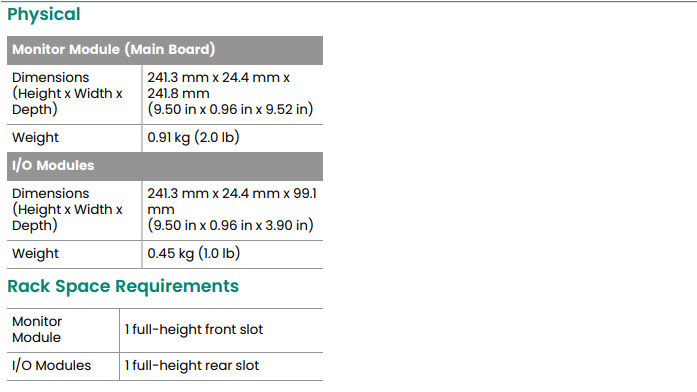

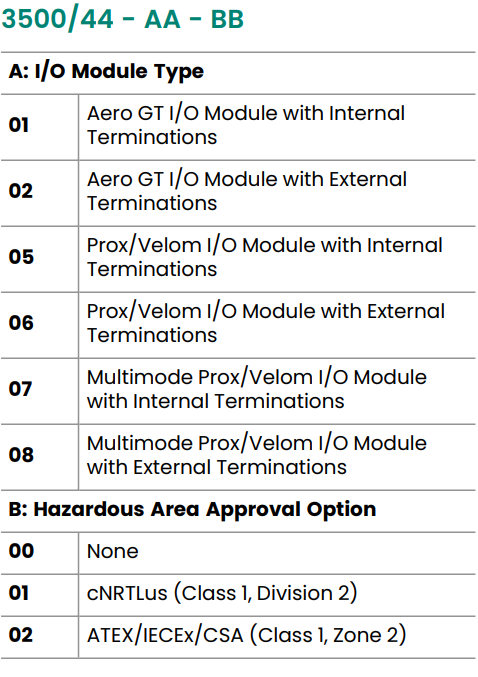

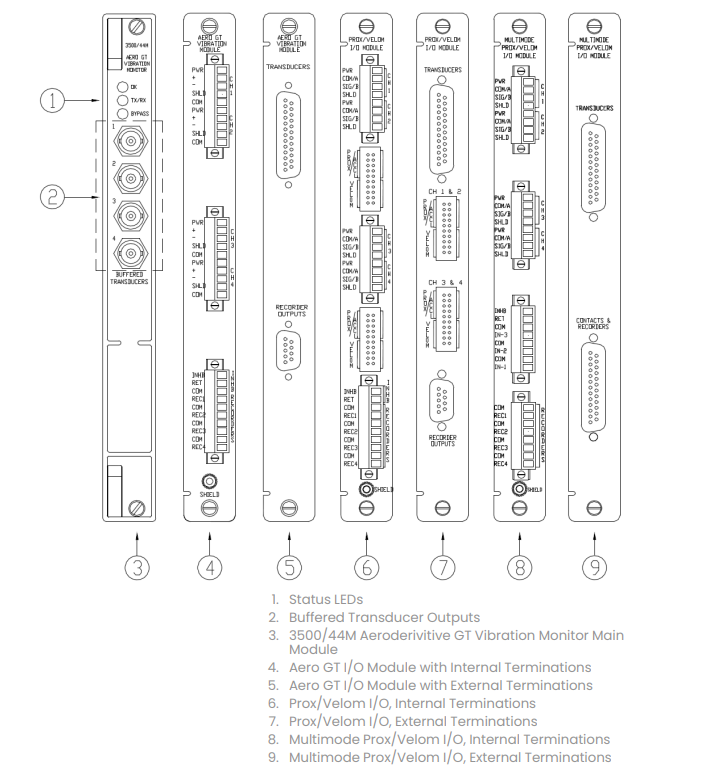

Modular Structure: Uses the standard 3500 architecture, consisting of a full-height Main Monitor Module (241.3 mm x 24.4 mm x 241.8 mm) and a matching I/O Module.

Flexible I/O Module Selection:

Aero GT I/O Module: Specifically designed for connection with Velomitor and accelerometer interface modules.

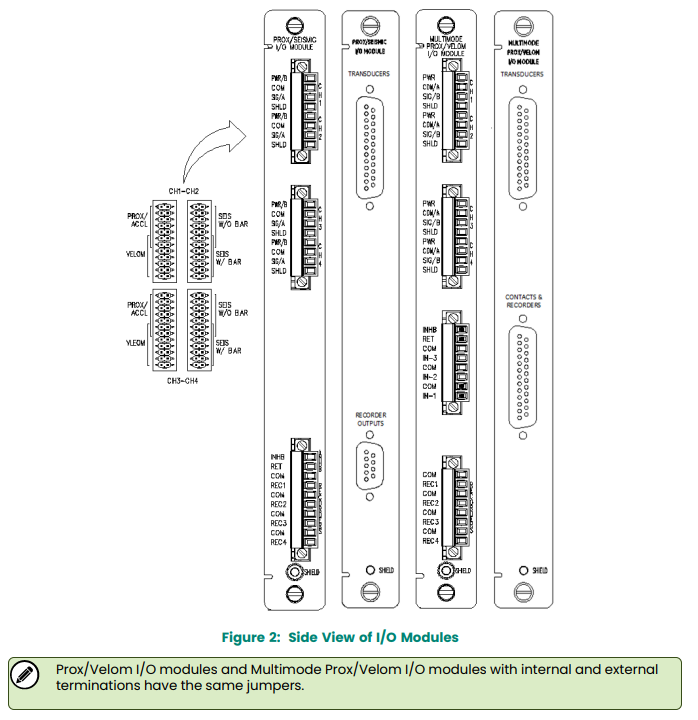

Prox/Velom I/O Module: Supports direct connection of proximity transducers and Velomitor velocity sensors.

Multimode Prox/Velom I/O Module: Adds external contact inputs for multi-mode switching to the Prox/Velom functionality.

Each type of I/O module is available in both Internal Termination and External Termination versions to suit different cabinet layouts and maintenance practices.

4. Compliance and Environmental Suitability

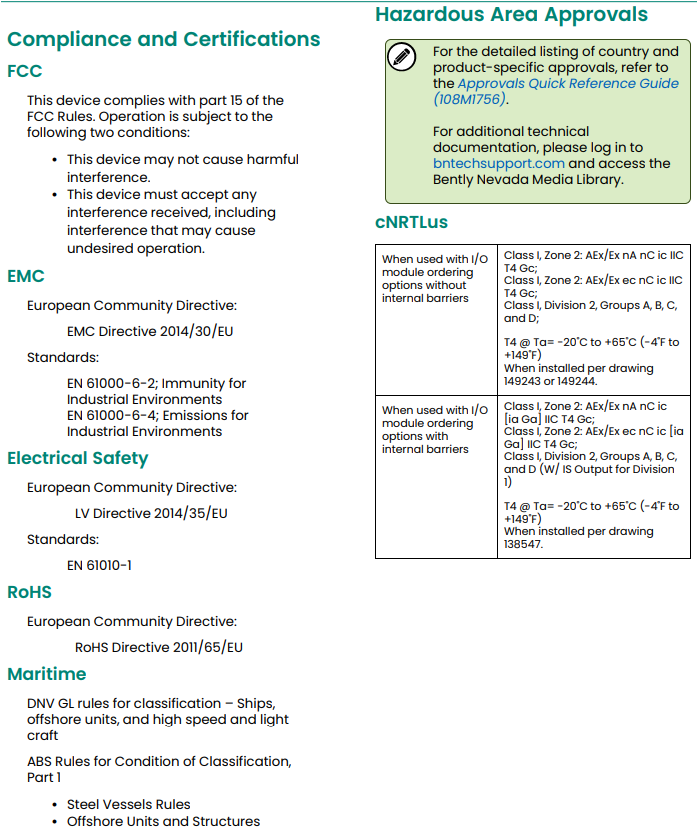

The 3500/44M complies with numerous international standards, ensuring its usability and safety worldwide:

Electromagnetic Compatibility: Complies with FCC Part 15 and EMC Directive (EN 61000-6-2, EN 61000-6-4).

Electrical Safety: Complies with the Low Voltage Directive (EN 61010-1).

Environmental: Complies with the RoHS Directive.

Maritime Certifications: Holds DNV GL and ABS classification society certifications, suitable for ships and offshore installations.

Hazardous Area Approvals: When used with I/O Modules with Internal Barriers, it can obtain cNRTLus, ATEX, IECEx, etc., certifications for use in Class I, Division 2 / Zone 2 hazardous areas.

Environmental Limits: Wide operating temperature range: -30°C to +65°C with standard I/O modules, and 0°C to +65°C when used with Internal Barrier I/O modules.

5. Application Scenarios

The 3500/44M is the ideal choice for the following applications:

Power Generation: Aero-derivative gas turbines driving generators (e.g., models like LM2500, LM6000, Trent).

Oil & Gas: Gas turbine units for pipeline compression and pump drives.

Marine Propulsion: Gas turbines used as main propulsion or auxiliary power.

Any demanding industrial environment requiring high-speed, multi-condition vibration monitoring.