The 330704 Probe is a core sensing component within the Baker Hughes Bently Nevada 3300 XL 11 mm Proximity Transducer System. This specific probe model refers to the version with M14 x 1.5 metric threading and stainless steel armor. As the "eyes" of the entire measurement system, it is positioned directly facing the target, responsible for detecting the dynamic changes of mechanical components in harsh industrial environments.

The 3300 XL 11 mm system is a high-performance solution designed to meet the needs of long-range displacement measurement. Compared to standard 5 mm or 8 mm probe systems, its larger 11 mm probe tip design delivers a significantly extended linear range, making it an indispensable choice for applications requiring large displacement monitoring. The system forms a complete measurement chain, consisting of three precisely matched parts:

3300 XL 11 mm Probe: Such as the 330704, the system's front-end sensor.

3300 XL 11 mm Extension Cable: Connects the probe to the proximitor sensor.

3300 XL 11 mm Proximitor Sensor: The signal processing hub of the system.

The 330704 probe and its system are primarily used in the following scenarios requiring a long linear range:

Axial (Thrust) Position Measurement: Monitoring the axial movement of rotors in large compressors and steam turbines.

Ramp Differential Expansion Measurement on Steam Turbines: Precisely measuring the relative thermal expansion between the rotor and the casing.

Rod Position or Rod Drop Measurement on Reciprocating Compressors.

Speed (Keyphasor) and Zero Speed Detection.

The system is designed to replace the older 7200-series 11 mm and 14 mm transducer systems. When upgrading, the probe, cable, and sensor must all be replaced with 3300 XL 11 mm components, and the monitoring system must be verified to support this new model.

II. Detailed Core Functions

As the sensing terminal, the core function of the 330704 probe is to enable precise non-contact measurement, providing the most primary gap data for the plant's condition monitoring and machinery protection systems.

Long-Range Axial Position Measurement

This is the signature function of the 11 mm probe system. In fluid-film bearing machines, the axial displacement of the rotor must be strictly monitored to prevent catastrophic failure caused by thrust bearing issues. With its 4.0 mm linear range, the 330704 probe can reliably track substantial axial movement of the rotor, providing operators with ample warning time. Its standard scale factor of 3.94 V/mm output allows the monitoring system to accurately calculate the actual displacement value.

Differential Expansion Measurement

During steam turbine startup, shutdown, or load changes, the rotor and casing expand at different rates due to their differing masses and heat transfer conditions, resulting in differential expansion. Excessive differential expansion can lead to internal rubbing between rotating and stationary parts. The 3300 XL 11 mm system, paired with the 330704 probe, is the ideal tool for this critical measurement, as its long linear range can accommodate the entire expansion curve during startup and shutdown procedures.

Piston Rod Position Monitoring

In large reciprocating compressors, real-time monitoring of the piston rod position is crucial for detecting connecting rod bearing wear, crosshead problems, or piston rod fatigue fractures. The 330704 probe provides sufficient measurement range to capture the full dynamic travel of the piston rod.

Keyphasor (Phase Reference) and Speed Measurement

Although more common with smaller probes, the 11 mm probe can also be used for Keyphasor measurements, particularly in applications requiring larger installation gaps or with uneven target surfaces. It provides a precise once-per-revolution pulse, serving as a benchmark for vibration phase analysis and speed calculation.

Reliable Operation in Harsh Environments

The 330704 probe comes with stainless steel armor, which provides additional mechanical protection for the probe cable against cutting, abrasion, crushing, and other physical damage. Its robust AISI 304 stainless steel case and comprehensive sealing design enable it to withstand harsh operating conditions involving high temperatures, high pressure, and chemically corrosive media.

III. In-Depth Working Principle: Eddy Current Sensing Technology

The 330704 probe operates based on the eddy current effect to achieve non-contact displacement measurement. Its physical principle is consistent with all eddy current probes, but the 11 mm diameter gives it unique performance characteristics. The detailed working process is as follows:

Establishment and Emission of High-Frequency Magnetic Field

The system's operation begins with the 3300 XL 11 mm Proximitor Sensor. A high-frequency oscillator circuit within the sensor generates a high-frequency alternating current in the 1-2 MHz range. This current is transmitted via the extension cable to the flat coil at the front of the 330704 probe. When the current flows through this coil, it establishes a high-frequency alternating magnetic field in front of the probe tip. The strength of this magnetic field decays exponentially with increasing distance from the probe face.

Eddy Current Generation in the Target Conductor

When the 330704 probe is installed and its tip is brought near a conductive target (typically the machine's steel shaft or thrust collar), this high-frequency alternating magnetic field penetrates the conductor surface. According to Faraday's Law of Electromagnetic Induction, the changing magnetic field induces closed-loop circulating currents, known as eddy currents, within the conductor. The flow path and density of these eddy currents are closely related to the air gap between the probe tip and the conductor surface. A smaller gap results in stronger magnetic field coupling and induces stronger eddy currents.

Modulation of Probe Coil Impedance

According to Lenz's Law, these induced eddy currents generate a secondary magnetic field that opposes the original field. This opposing magnetic field resists the change in the primary field, and the net effect is a change in the effective AC impedance of the 330704 probe's coil. Specifically, as the gap decreases, the eddy current effect strengthens, causing a greater change in the coil's impedance. As the gap increases, the effect weakens, and the impedance change is smaller. Thus, the physical information of the mechanical gap is accurately "encoded" as a change in the electrical parameters (impedance) of the probe coil.

Signal Conditioning and Standardized Output

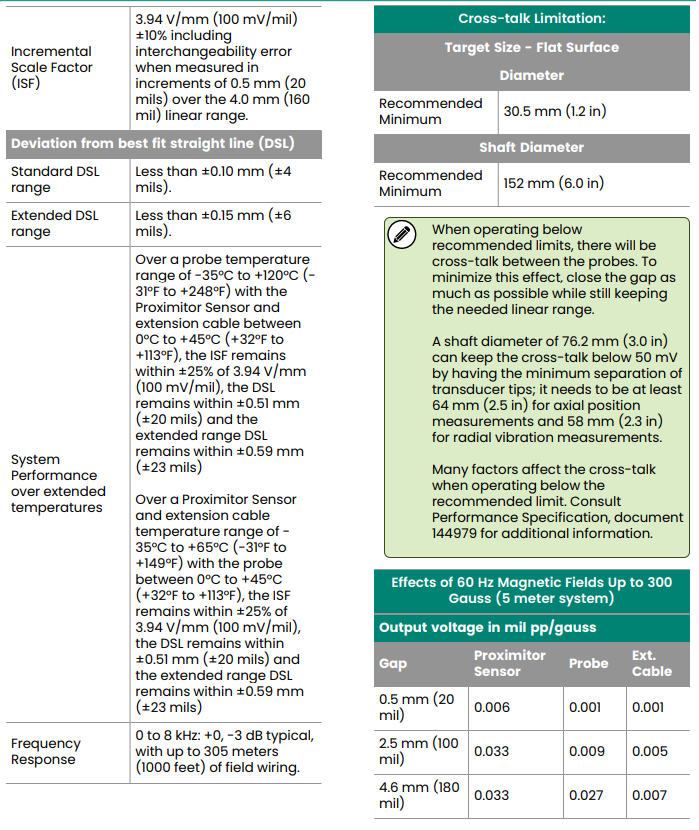

The minute change in the probe coil's impedance is transmitted back to the Proximitor Sensor via the extension cable. Precision circuitry inside the sensor (typically containing a bridge and demodulator circuit) is responsible for detecting and extracting this impedance change. The signal is then amplified, linearized, and temperature-compensated, ultimately being converted into a DC voltage signal that has a highly linear relationship with the gap. For the 3300 XL 11 mm system, the standard Incremental Scale Factor (ISF) is 3.94 V/mm (100 mV/mil). This means that for every 1 mm the target moves closer or farther away, the system's output voltage changes by approximately 3.94 volts. Its linear range starts at 0.5 mm and extends to 4.5 mm, providing a usable linear interval of 4.0 mm.

Unique Performance Advantages of the 11 mm Probe

Extended Linear Range: Compared to 5 mm or 8 mm probes, the 11 mm probe, due to its larger sensing area, has a wider and deeper magnetic field distribution, resulting in a significantly longer linear range (4.0 mm vs. typically around 2.0 mm for an 8 mm probe). This is the fundamental reason it is capable of large displacement measurements.

Reduced Sensitivity to Edge Effects: For uneven or irregularly shaped targets, the larger probe tip helps to average the magnetic field effects, providing more stable measurements.

Recommended for Large Shafts: The technical datasheet explicitly states that for radial vibration measurements, the recommended minimum shaft diameter is 152 mm (6.0 in). This ensures the magnetic field can fully form on the shaft surface, guaranteeing the accuracy of the scale factor.

Environmental Immunity Design

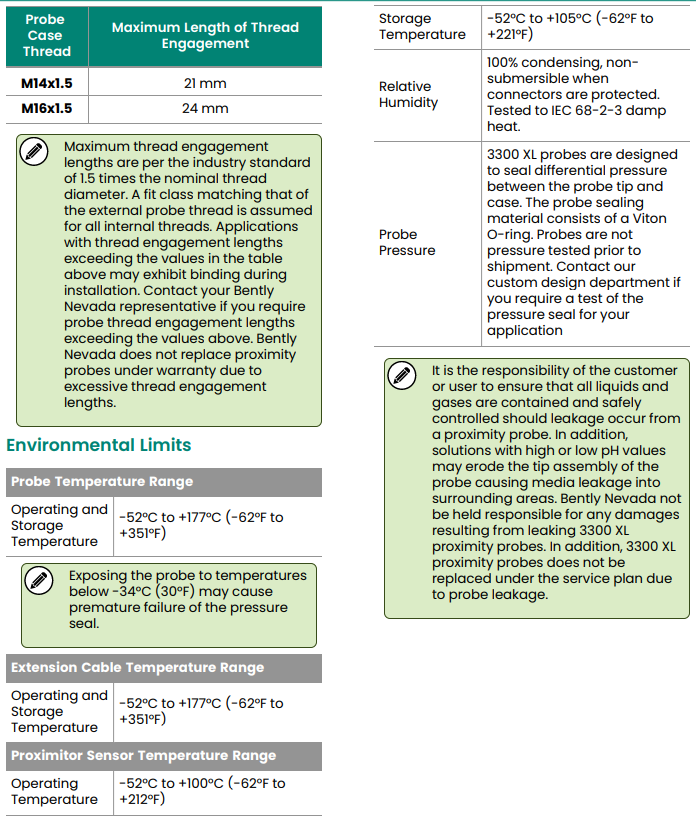

Temperature Stability: The materials and structural design of the probe allow it to operate and be stored in extreme temperatures from -52°C to +177°C. The temperature compensation circuitry inside the Proximitor Sensor ensures the output signal remains stable within an ambient temperature range of 0°C to +45°C.

Electromagnetic Interference Immunity: The entire system features enhanced RFI/EMI immunity, effectively resisting high-frequency radio interference from sources like two-way radios and motor drives on-site, complying with CE marking requirements.

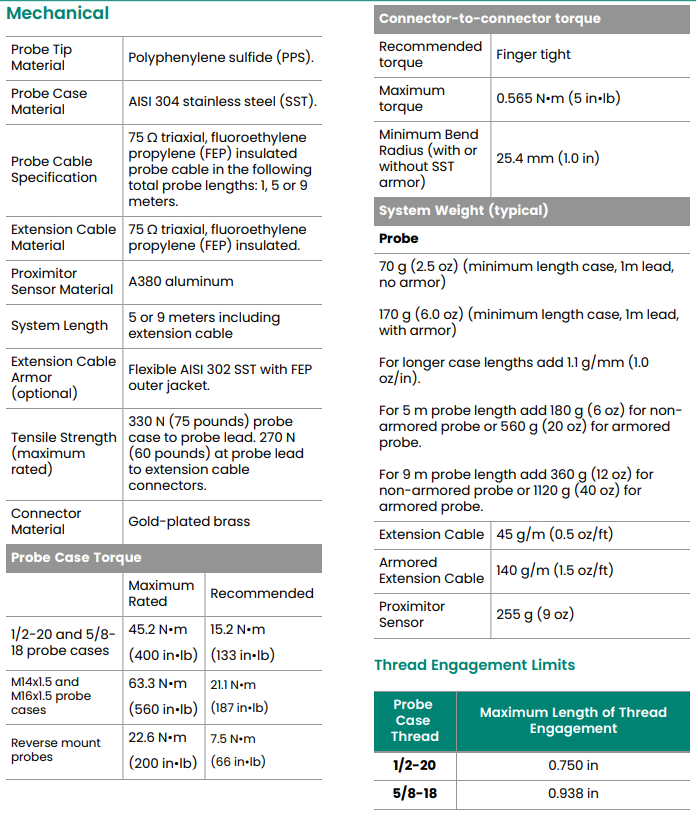

Mechanical Robustness: The patented CableLoc design ensures the probe cable can withstand a pull force of up to 330 N (75 lb) at the connection to the probe tip. The TipLoc molding process guarantees a robust bond between the probe tip and the body. The ClickLoc connectors, with their gold-plated brass interfaces and locking mechanism, provide an electrically stable and mechanically secure connection resistant to loosening.

IV. Key Performance and Technical Characteristics

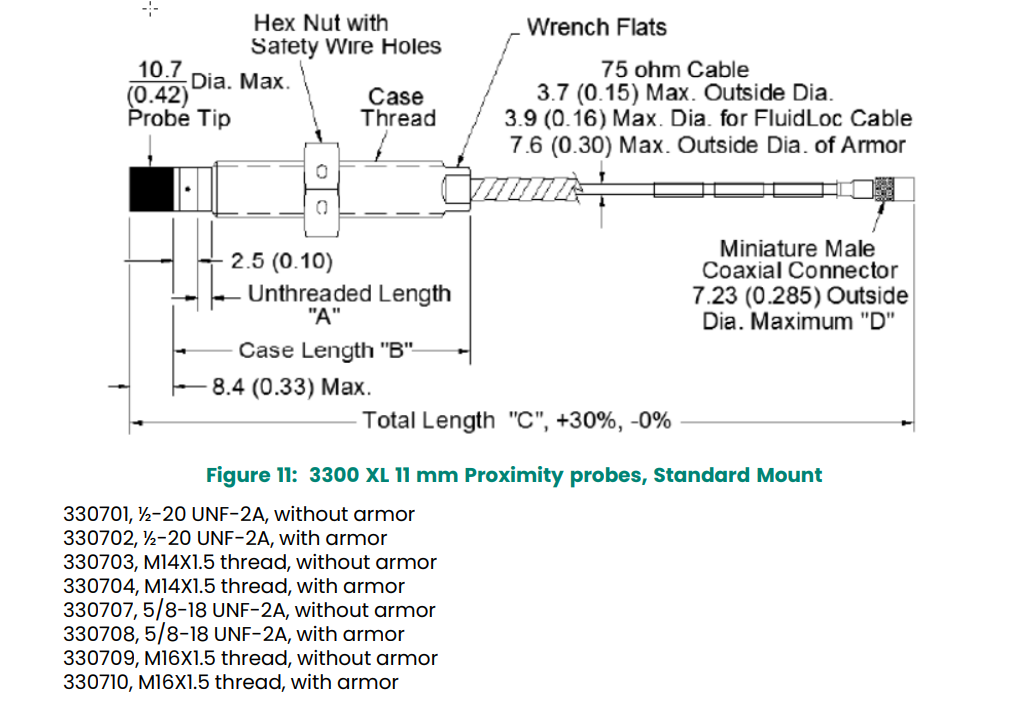

Mechanical Structure and Installation

Thread Specification: M14 x 1.5 metric thread for corresponding mounting holes.

Armor Protection: Flexible AISI 302 stainless steel armor, optionally with an FEP outer jacket, provides superior mechanical protection.

Secure Locking: Standard equipped with a locknut with pre-drilled safety wire holes to prevent loosening in vibrating environments.

Connector: Gold-plated brass miniature coaxial ClickLoc connector. Connector protectors or the supplied silicone tape can be used for additional protection in humid environments.

Cable Options: The FluidLoc cable option is available, designed to prevent oil or other liquids from inside the machine from leaking to the outside through the cable's interior.

Excellent Electrical and Measurement Performance

Linear Range: 4.0 mm, from 0.5 mm to 4.5 mm.

Recommended Gap Setting: 2.5 mm, where the system exhibits optimal performance.

Scale Factor: 3.94 V/mm ±10%, including interchangeability error.

Deviation from Best Fit Straight Line (DSL): Less than ±0.10 mm (±4 mils) over the standard DSL range.

Frequency Response: 0 to 8 kHz, suitable for monitoring the vast majority of vibrations in large rotating machinery.

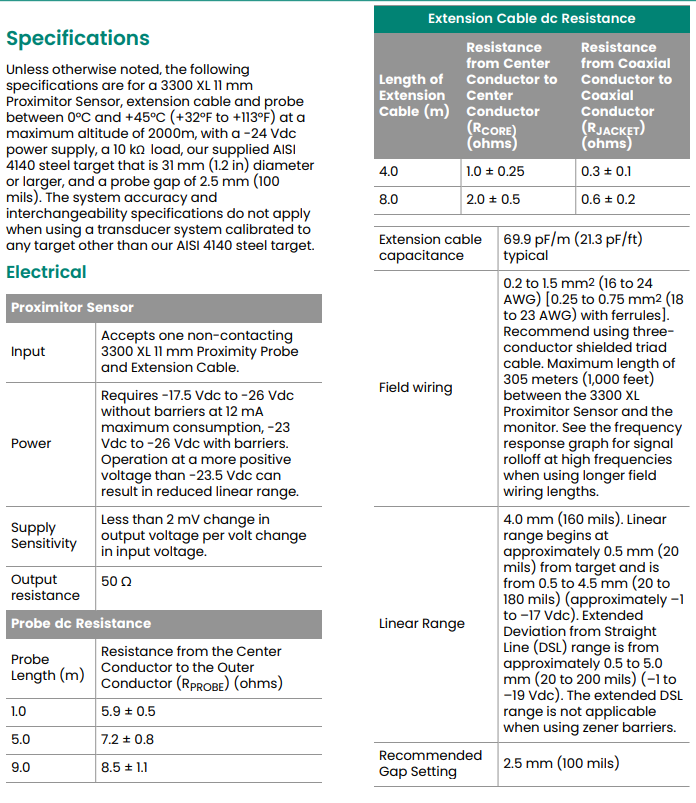

Probe DC Resistance: For a 5.0-meter probe, the resistance between the center conductor and outer conductor is 7.2 ± 0.8 Ω.

Robust Environmental Adaptability

Wide Operating Temperature: Probe operating and storage temperature range is -52°C to +177°C (-62°F to +351°F).

Pressure Seal: The probe is designed to seal differential pressure between the probe tip and the case, using a Viton O-ring as the sealing material.

Chemical Resistance: The probe tip material is Polyphenylene Sulfide (PPS), which offers good chemical inertness and resistance to various oils and chemicals.