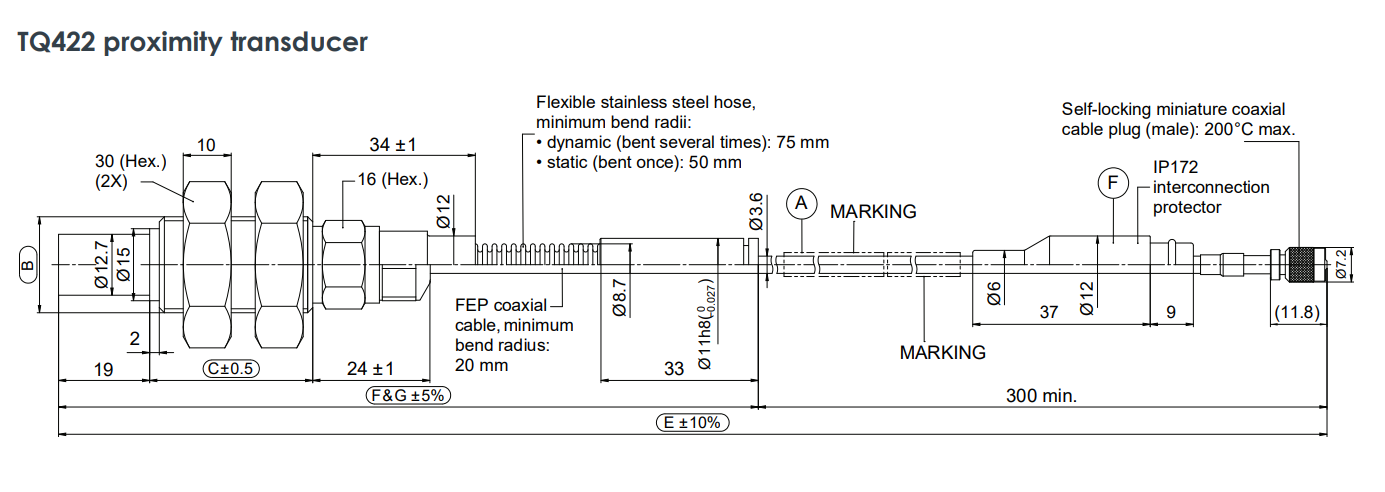

The TQ422 is a pressure-proof proximity transducer manufactured by Vibro-Meter, designed specifically for high-pressure environments. It serves as the core component of the TQ 422 & TQ 432 / EA 402 / IQS 452 proximity measurement system. Operating on the eddy current principle, this sensor enables non-contact measurement of relative displacement or vibration of moving machinery components. Its unique design allows it to withstand pressures up to 100 bar, making it particularly suitable for measurement applications in submerged environments such as submersible pumps, hydraulic turbines (e.g., Kaplan and Francis turbines), and other high-pressure conditions.

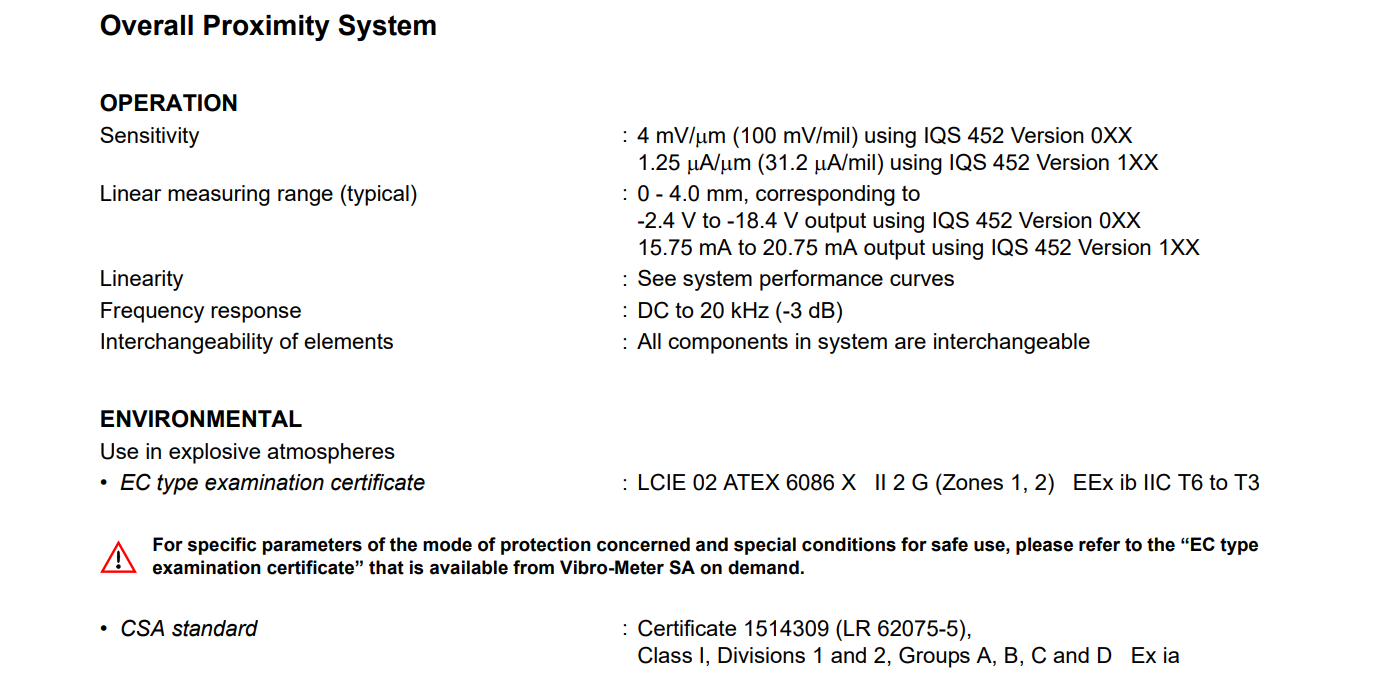

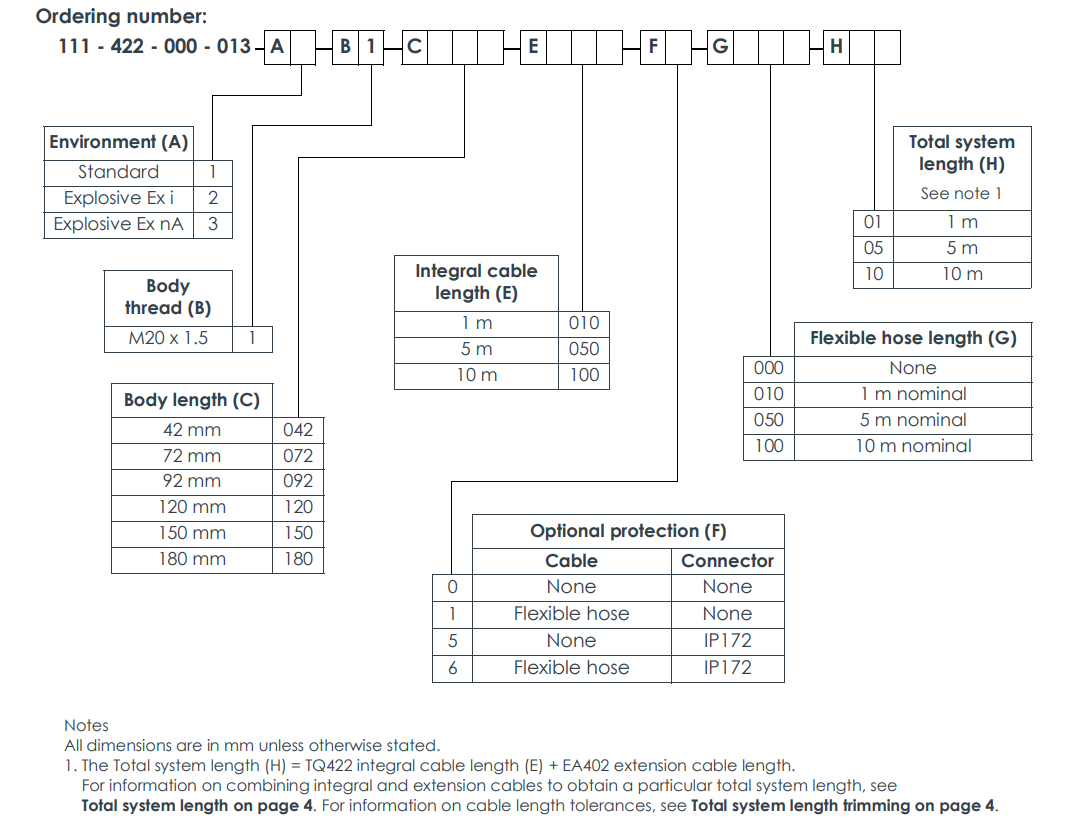

The TQ422 transducer forms a complete, calibrated proximity measurement system when paired with a matching IQS 452 signal conditioner and optional EA 402 extension cable. All components within this system are interchangeable, ensuring operational flexibility and maintenance convenience.

The TQ422 and TQ432 are functionally identical proximity transducers. The core difference lies in their mounting:

TQ422: Designed for forward mounting. Its probe features a BOA protection cap (approximately 0.6mm thick) at the front, which is also the cause of the inherent offset (-2.4V) in the voltage output. It is directly exposed to the high-pressure medium, providing the first line of defense.

TQ432: Designed for reverse mounting. It is typically installed from the opposite side of the pressure vessel, meaning the probe tip is not directly exposed to the high-pressure medium, and therefore does not require a BOA protection cap.

Key Features and Characteristics

1. High-Pressure Application Design

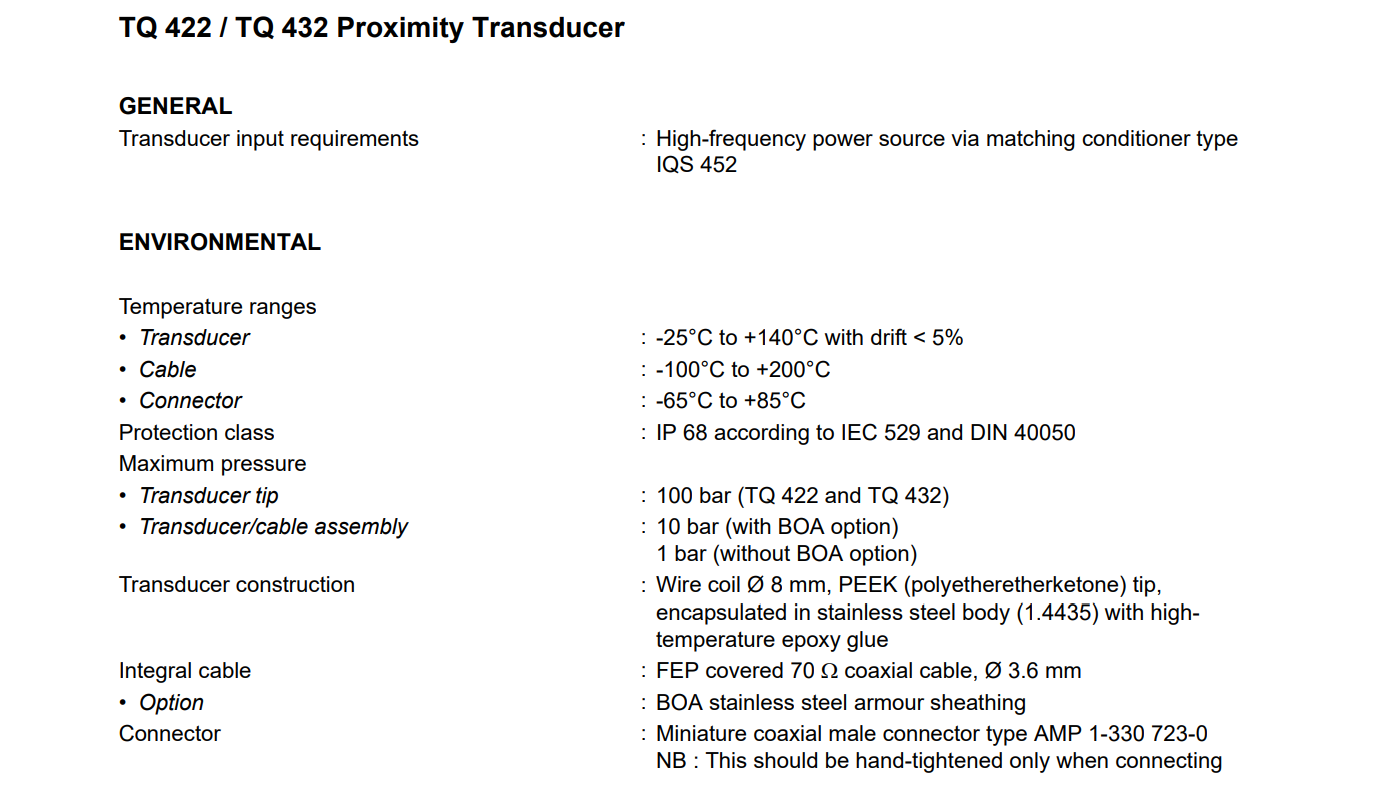

The sensor probe is manufactured from PEEK (polyetheretherketone) material, capable of directly withstanding fluid pressures up to 100 bar.

The transducer body is constructed from stainless steel (1.4435), offering excellent mechanical strength and corrosion resistance.

2. Non-Contact Measurement

Operates based on the eddy current principle, requiring no physical contact with the target (typically a metal shaft), thereby avoiding wear and enabling reliable long-term measurement without friction.

3. suitability for Explosive Atmospheres

4. Complete System Solution

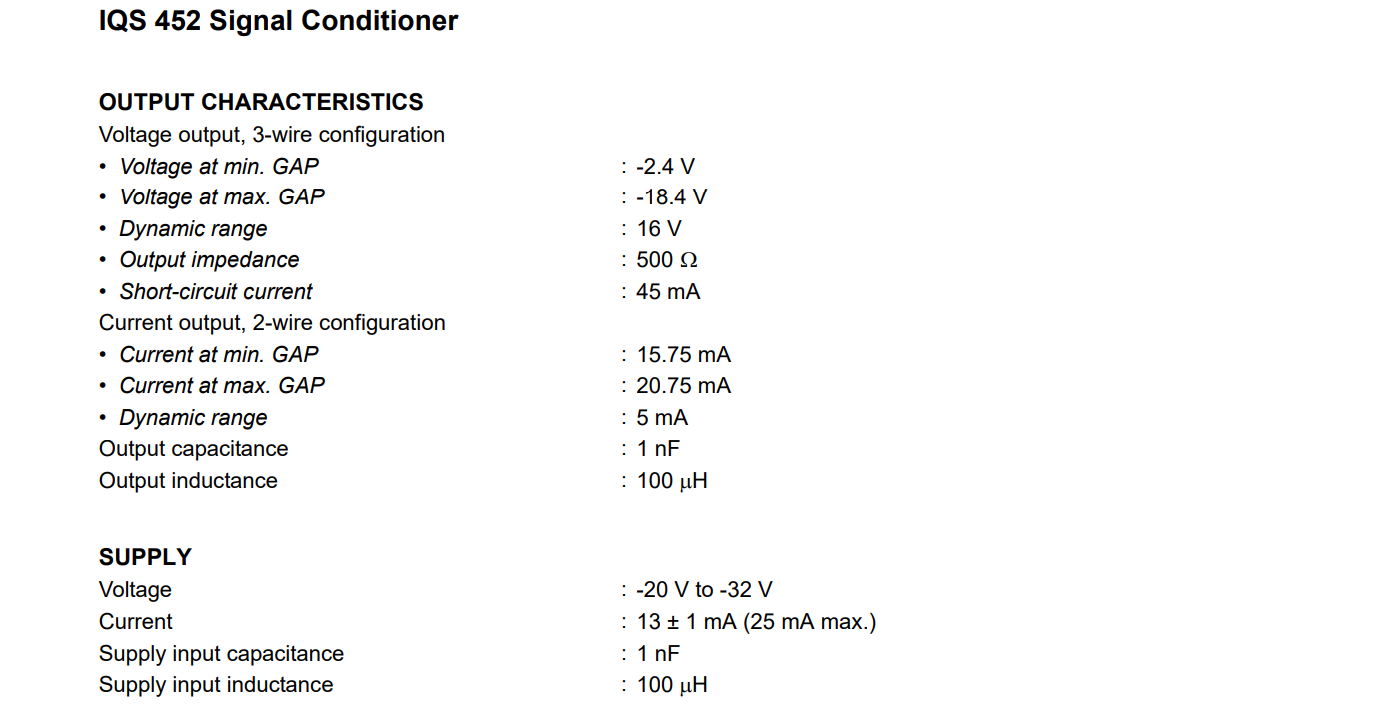

Paired with the IQS 452 signal conditioner to provide voltage or current output:

Voltage Output (3-wire): Sensitivity 4 mV/μm, dynamic range -2.4 V to -18.4 V.

Current Output (2-wire): Sensitivity 1.25 μA/μm, dynamic range 15.75 mA to 20.75 mA (typically used with GSI 124 galvanic separation unit).

Can be used with EA 402 extension cables to extend measurement distance, forming a complete 5-meter or 10-meter system.

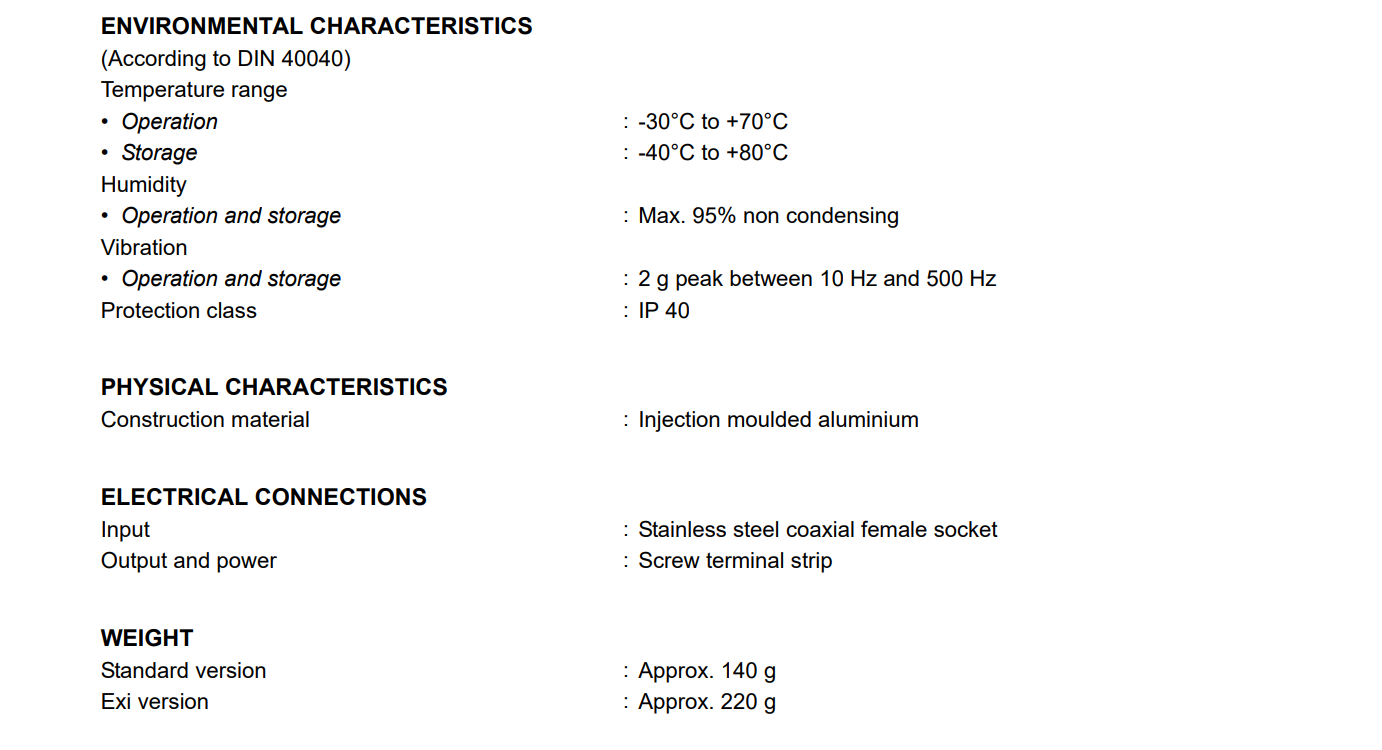

5. Environmental Adaptability

Wide operating temperature range: Transducer body from -25°C to +140°C (drift <5%); cable can withstand -100°C to +200°C.

High protection rating: IP68 (IEC 529 / DIN 40050), providing complete dust protection and capability for long-term submerged operation.

Excellent vibration resistance: Can withstand vibrations of 2 g within the frequency range of 10 Hz to 500 Hz.

6. Optional Protection Configuration

Offers BOA (Braided Outer Armour) stainless steel braided sheath option, providing additional mechanical protection for the transducer's integral coaxial cable, enhancing crush and abrasion resistance.

With BOA sheath, the pressure resistance of the transducer/cable assembly increases to 10 bar (1 bar without BOA).

Detailed Working Principle

The TQ422 proximity transducer operates based on the eddy current principle, an electromagnetic induction technology widely used for non-contact displacement and vibration measurement. The following sections elaborate on its working mechanism, system composition, and signal flow.

1. Core Physical Principle: Eddy Current Effect

When a metal conductor is placed in a changing magnetic field or moves relative to a magnetic field, according to Faraday's law of electromagnetic induction, closed-loop currents, known as eddy currents, are induced within the conductor. The strength, distribution, and phase of these eddy currents depend on several factors:

The gap between the coil and the conductor: This is the target parameter for measurement.

The electrical conductivity (σ) and magnetic permeability (μ) of the conductor.

The frequency (f) of the exciting magnetic field.

The geometric shape of the conductor.

The core of the TQ422 sensor is a precision-wound coil encapsulated within the PEEK material at the probe tip. PEEK is a high-performance engineering plastic known for its excellent mechanical strength, chemical resistance, and low moisture absorption. Crucially, it exhibits very low dielectric loss and good wave transmission properties in high-frequency electromagnetic fields, ensuring it does not interfere with the magnetic field generated by the coil.

2. System Workflow

The operational workflow of the entire proximity measurement system is a closed-loop process of "transmission-induction-demodulation-output":

High-Frequency Signal Generation and Transmission:

The paired IQS 452 signal conditioner contains a high-frequency (HF) oscillator and modulation/demodulation circuitry.

The conditioner supplies a high-frequency AC excitation current to the coil of the TQ422 transducer via a coaxial cable.

Electromagnetic Field Generation and Eddy Current Induction:

The alternating current passing through the coil generates a high-frequency alternating magnetic field around it.

When this magnetic field penetrates the PEEK probe tip and acts on the surface of a nearby metal target (e.g., a machine shaft), eddy currents are induced in the surface layer of the target.

Impedance Change Detection:

The induced eddy currents themselves generate a magnetic field. According to Lenz's law, this magnetic field opposes the original coil field, thereby weakening the original coil's magnetic field.

This "weakening" effect manifests as a change in the equivalent impedance of the sensor coil. The coil's impedance (Z), a combination of resistance (R) and inductive reactance (ωL), changes sensitively and regularly with variations in the gap between the coil and the target.

Decreasing Gap -> Stronger eddy current effect -> Greater change in coil impedance.

Increasing Gap -> Weaker eddy current effect -> Smaller change in coil impedance.

Signal Demodulation and Processing:

The IQS 452 signal conditioner continuously monitors the changes in the sensor coil's impedance.

The internal demodulation circuit converts (demodulates) this high-frequency impedance change into a linear DC voltage or current signal proportional to the gap.

The conditioner utilizes high-quality components to ensure signal stability and accuracy, and provides short-circuit protection.

Output and Calibration:

The system is factory-calibrated at +23°C ±5°C using a specific target material (VCL 140 steel, 1.7225).

The final output is a signal highly linear to the distance:

3. System Characteristics and Compensation

Temperature Compensation: The system incorporates temperature compensation to minimize the impact of ambient temperature variations on measurement accuracy, ensuring drift remains below 5% across the wide temperature range of -25°C to +140°C.

Cable Length Tuning (Electrical Trimming): Due to the distributed parameters (capacitance, inductance) of the coaxial cable affecting high-frequency signal transmission, the system has minimum requirements for the total cable length (TSL - Total System Length, i.e., transducer integral cable + EA402 extension cable length) (5m system ≥4.4m, 10m system ≥8.8m) to ensure optimal system performance and transducer interchangeability.

Target Material Requirements: The sensor's sensitivity and linearity are related to the electrical conductivity and magnetic permeability of the target material. Standard calibration is based on VCL 140 steel. If the target material differs, a sample must be provided for special calibration.

Application Areas

Hydroelectric Generator Sets: Measurement of relative displacement, vibration, and runout of shafts in various hydraulic turbines like Francis and Kaplan.

Submersible Pumps: Monitoring the dynamic operating conditions of pump shafts in underwater high-pressure environments.

Industrial Rotating Machinery: Shaft displacement and vibration monitoring for critical equipment such as compressors, gas turbines, and steam turbines.

Any application requiring non-contact displacement measurement in high-pressure, hazardous (explosive), or liquid-immersed environments.