The AE119 Casing Expansion Probe is a high-performance absolute displacement measurement device from VM product line, specifically designed for monitoring thermal expansion of machinery casings during temperature variations. Based on the eddy current measurement principle, this non-contact measuring device incorporates advanced signal processing electronics to deliver accurate and reliable mechanical expansion data.

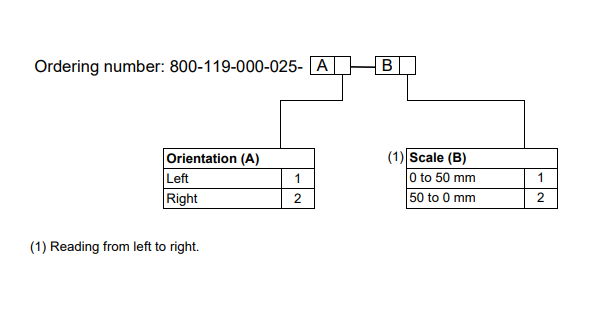

The AE119 probe is designed for medium and large gas turbines and steam turbines, capable of measuring absolute expansion up to 50 mm or 100 mm. Its robust mechanical construction and excellent environmental adaptability ensure long-term stable operation in harsh industrial environments. The device employs two-wire current transmission technology, outputting standardized 4-20 mA signals that can be directly integrated with various control systems.

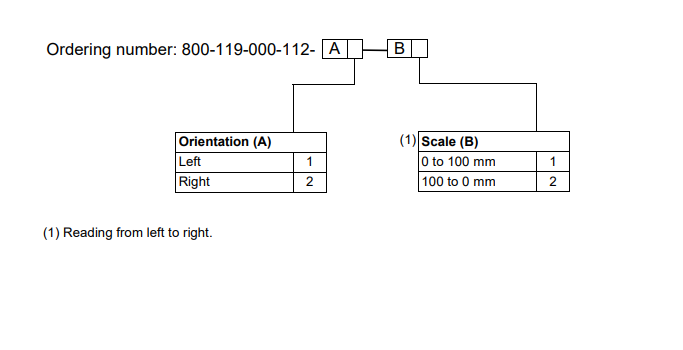

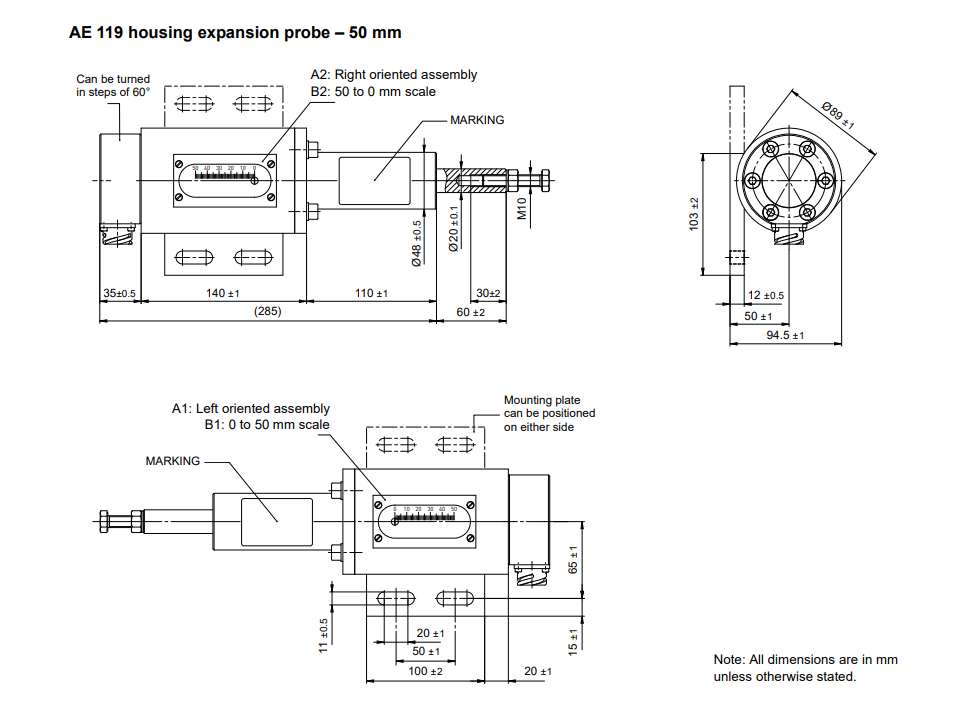

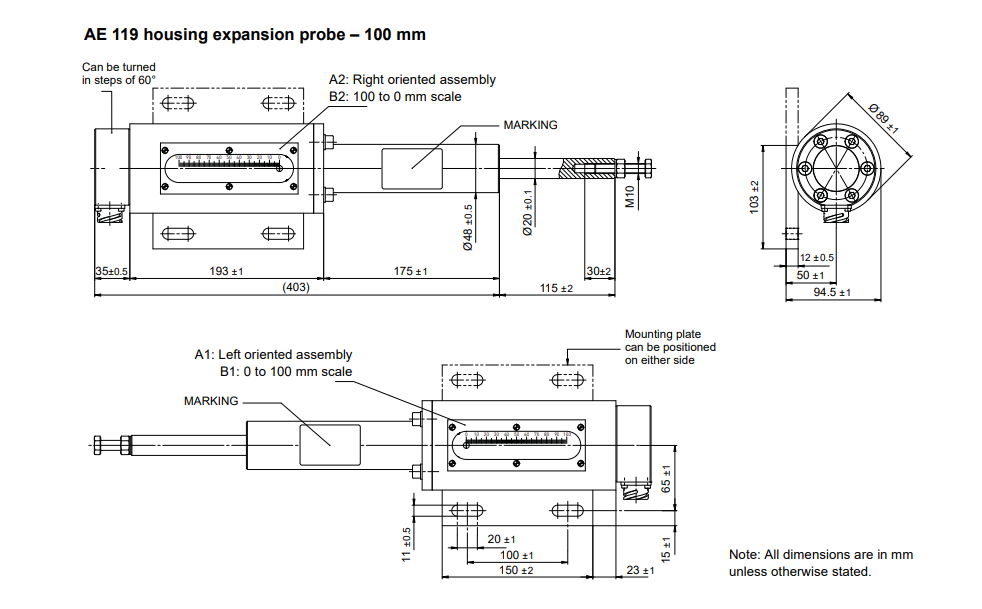

Featuring IP54 protection rating, the probe effectively prevents dust ingress and water splashes, ensuring reliable operation in humid or dusty environments. Its simple installation method and flexible orientation options (left or right assembly) enable adaptation to various installation space requirements.

Working Principle

The AE119 Casing Expansion Probe operates based on the eddy current effect principle, utilizing precision electronic circuits for displacement signal detection and processing. The working mechanism can be elaborated as follows:

1. Eddy Current Effect Sensing Mechanism

The probe contains a high-frequency oscillating circuit that generates a stable electromagnetic field. When the probe's measuring rod approaches the metal target surface, eddy currents are induced on the target surface according to electromagnetic induction laws. These eddy currents generate a secondary magnetic field opposite to the original magnetic field, thereby changing the equivalent impedance of the probe coil. The impedance change is proportional to the distance between the probe and the target, enabling precise displacement determination through accurate measurement of this impedance variation.

2. Signal Processing and Conversion

The probe incorporates complete signal processing electronic circuits, including modulators/demodulators, amplifiers, and signal conditioning circuits. The original distance signal is precisely demodulated and converted into a standard electrical signal. The device employs advanced temperature compensation algorithms to automatically correct the effects of environmental temperature changes on measurement accuracy, ensuring stable performance throughout the operating temperature range.

3. Current Output Transmission

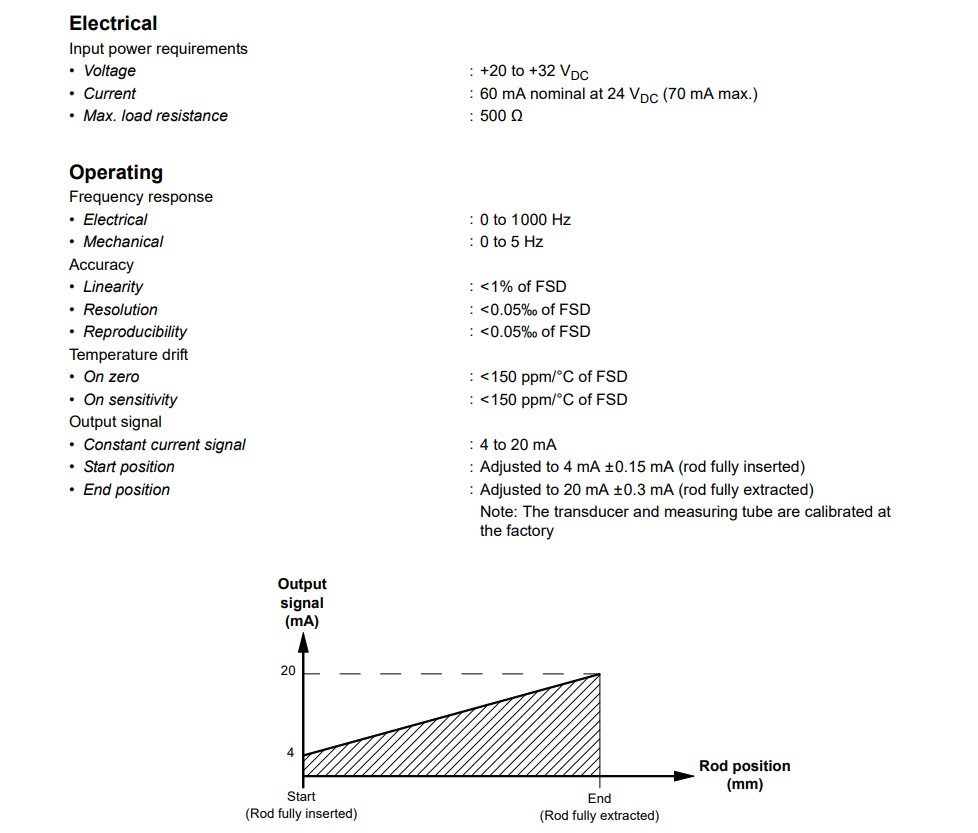

The AE119 uses two-wire current transmission technology, outputting standard 4-20 mA industrial signals. When the measuring rod is fully retracted (initial position), the output current is 4 mA ±0.15 mA; when the measuring rod is fully extended (maximum range), the output current is 20 mA ±0.3 mA. This current signal transmission method offers strong anti-interference capability and long transmission distance, making it particularly suitable for industrial environments.

4. Mechanical Transmission System

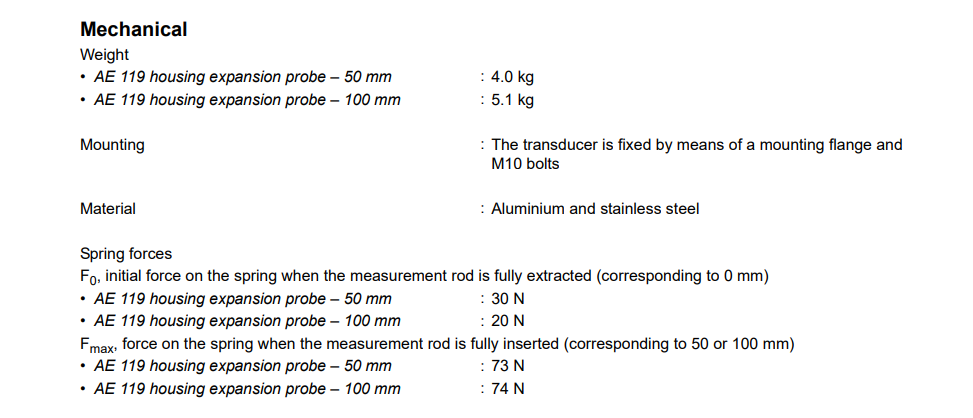

The probe employs precision mechanical guidance structures to ensure linear motion accuracy of the measuring rod. Custom springs provide appropriate contact pressure: for the 50 mm range model, the initial spring force is 30 N, maximum spring force is 73 N; for the 100 mm range model, the initial spring force is 20 N, maximum spring force is 74 N. These optimized spring parameters ensure reliable contact with the measurement surface while avoiding excessive mechanical loads.

5. Temperature Compensation Mechanism

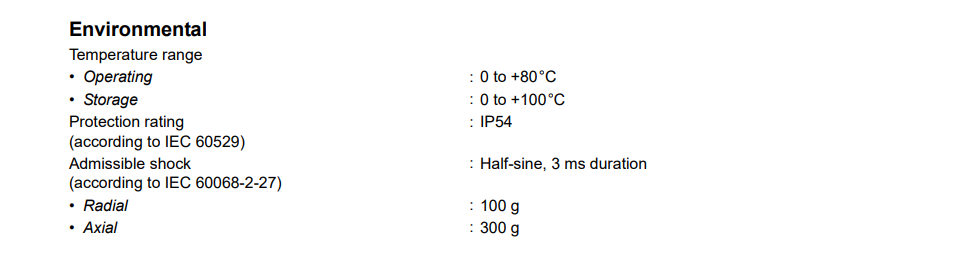

The device incorporates built-in temperature sensors and advanced compensation algorithms to monitor environmental temperature changes in real time and automatically compensate measurement results. Excellent temperature drift specifications: zero temperature drift less than 150 ppm/°C of FSD, sensitivity temperature drift also less than 150 ppm/°C of FSD. This precise temperature compensation ensures high-precision measurements throughout the operating temperature range of 0 to +80°C.

6. Power Management Circuit

The AE119 requires 20-32 VDC power supply voltage, with normal operating current of 60 mA (at 24 VDC), maximum current not exceeding 70 mA. The device includes efficient power management circuits that can operate stably with load resistance up to 500 Ω. The power circuit also features overvoltage protection and reverse connection protection functions, ensuring device safety under electrical abnormal conditions.

7. Signal Conditioning and Filtering

The internal electronic circuits include multi-stage filtering and signal conditioning. Electrical frequency response is 0-1000 Hz, enabling capture of rapid mechanical changes; mechanical frequency response is 0-5 Hz, suitable for monitoring relatively slow casing expansion processes. This dual frequency response characteristic allows the probe to track both rapid changes and ensure steady-state measurement accuracy.

Features

The AE119 Casing Expansion Probe offers multiple advanced features to meet the stringent requirements of industrial measurement systems:

1. High-Precision Measurement Performance

The device provides excellent measurement accuracy with linearity better than 1% of FSD, resolution better than 0.05‰ of FSD, and repeatability also better than 0.05‰ of FSD. This high precision enables reliable detection of minute casing expansion changes, providing accurate data for equipment condition monitoring.

2. Wide Range Measurement Capability

The AE119 offers two measurement range versions: 50 mm and 100 mm, meeting the measurement needs of different scale units. The large measurement range combined with high precision enables accurate monitoring of various expansion changes from minute to significant.

3. Strong Environmental Adaptability

The device operates normally in ambient temperatures from 0 to +80°C, with storage temperature range up to 0 to +100°C. IP54 protection rating ensures resistance to dust ingress and water splash effects, suitable for various harsh industrial environments.

4. Excellent Mechanical Durability

The probe is manufactured from aluminum alloy and stainless steel materials, featuring robust and durable construction. Capable of withstanding severe mechanical shocks: radial shock up to 100 g, axial shock up to 300 g (half-sine wave, 3 ms duration). This rugged design ensures long-term reliable operation in vibrating environments.

5. Flexible Installation Options

The device offers both left and right assembly orientation options, with mounting flange rotatable in 60° increments, providing great installation flexibility. Standard M10 bolt mounting method facilitates field installation and adjustment.

6. Plug-and-Play Integration

Standard two-wire connection method simplifies system integration, with 4-20 mA output signals directly compatible with most control systems. The device is factory calibrated, eliminating the need for complex field calibration procedures.

7. Comprehensive Protection Functions

The probe features short-circuit protection, overload protection, and reverse polarity protection functions, ensuring device safety under electrical fault conditions. Robust mechanical structure provides overtravel protection, preventing damage from accidental impacts.

8. Multiple Accessory Support

Dedicated accessories including EH 140 cable assemblies are available, with options for straight or 90° angled connectors, stainless steel flexible protection tubes, etc., meeting various installation environment requirements.

Technical Specifications Summary

| Item | Specification |

| Measurement Principle | Eddy Current Effect |

| Measurement Range | 50 mm or 100 mm |

| Output Signal | 4-20 mA Two-wire |

| Power Supply | 20-32 VDC |

| Operating Current | 60 mA nominal (at 24 VDC) |

| Load Resistance | Maximum 500 Ω |

| Linearity | <1% of FSD |

| Resolution | <0.05‰ of FSD |

| Operating Temperature | 0 to +80°C |

| Protection Rating | IP54 |

| Weight | 4.0 kg (50 mm) / 5.1 kg (100 mm) |

Application Areas

The AE119 Casing Expansion Probe is widely used in the following fields:

Power Generation Industry: Casing expansion monitoring for gas turbines and steam turbines

Petrochemical Industry: Thermal expansion monitoring of large compressors and pump units

Heavy Industry: Thermal deformation monitoring of rolling equipment and large machinery

Aerospace: Thermal expansion measurement of engine test benches

Research Field: Thermal expansion coefficient determination of materials and structural thermal deformation research