The IS200ESELH3A represents the pinnacle of control density and system integration within the GE EX2100 Exciter Selector Board family. Engineered for maximum-power excitation systems, the H3 variant functions as the ultimate command consolidation and distribution hub, capable of managing gate trigger pulses for up to six parallel Power Conversion Modules (PCMs). Its design addresses the critical control challenges in high-current applications, such as those found in large steam turbine generators or specialized industrial drives, where forcing requirements and operational reliability are paramount. The "H3" designation signifies its top-tier capacity, establishing it as the central nervous system for the largest EX2100 configurations, responsible for unifying control logic and ensuring absolute synchronization across a complex network of power conversion components.

II. Advanced Functional Capabilities

1. High-Density Pulse Distribution and System Synchronization

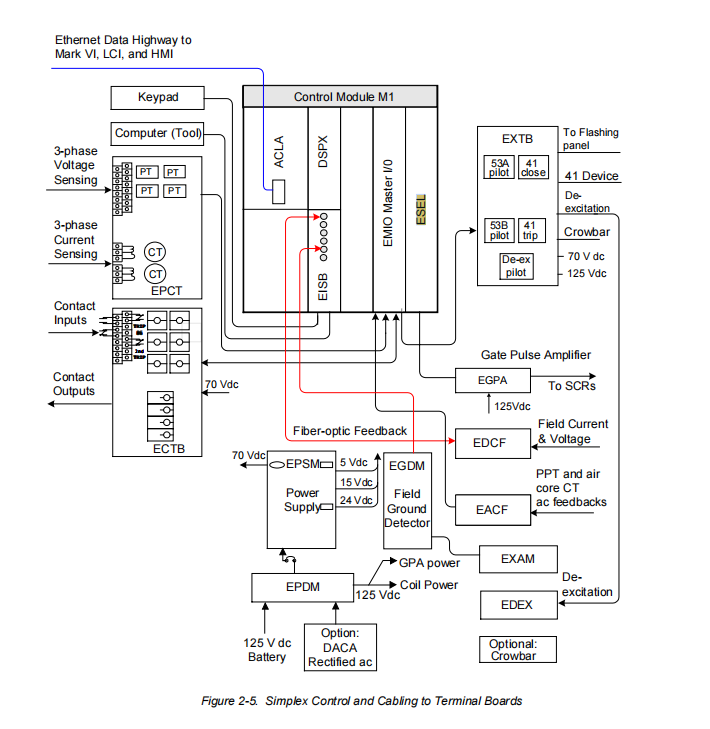

The core mandate of the IS200ESELH3A is to orchestrate the simultaneous operation of multiple power bridges from a single control point.

Command Consolidation: The board accepts the fundamental six-pulse command set from its paired EMIO board, which contains the firing solution computed by the DSPX.

Large-Scale Signal Fan-Out: The H3's advanced circuitry replicates this single input command into six perfectly synchronized output streams. Each stream consists of six pulses, directing a total of 36 individual gate commands to their respective EGPA boards. This massive fan-out capability is what enables a single control rack to govern an entire high-power excitation system.

Ensured Synchronization: Maintaining precise timing across all six outputs is non-negotiable. Any phase shift or delay between the pulse trains driving different PCMs would lead to severe current imbalance, potential circulating currents, and excessive stress on the power components. The H3 is designed with this precision in mind, ensuring all bridges operate as a single, cohesive power unit.

2. System-Level Redundancy Management for Maximum Availability

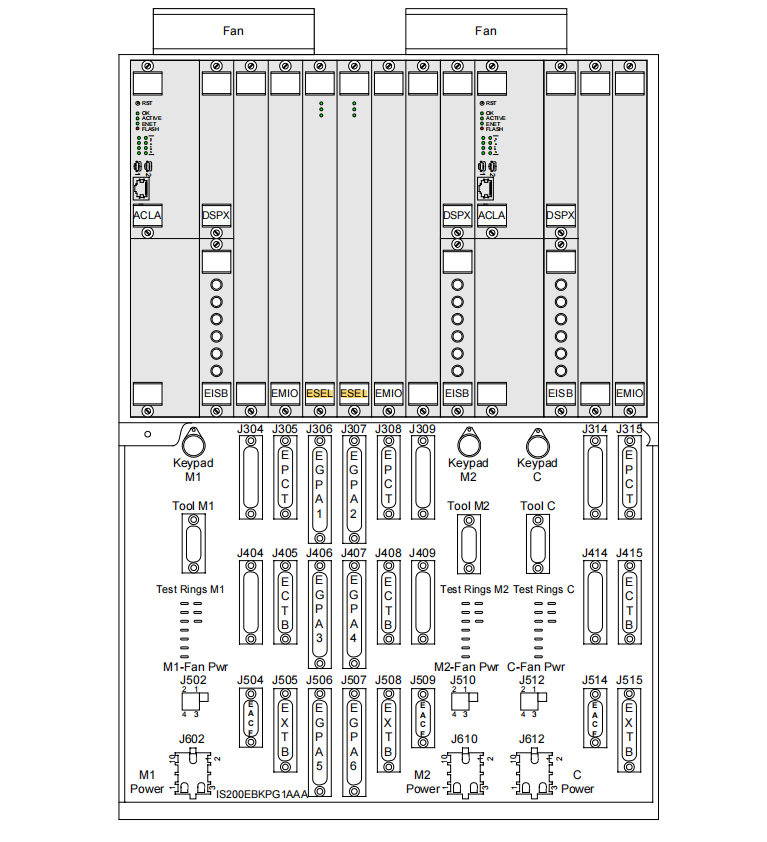

In a Triple Modular Redundant (TMR) system, the role of the IS200ESELH3A in failover scenarios is a system-wide event.

Unified Control Path Arbitration: Two H3 boards operate in lockstep with the M1 and M2 controllers. The Coordinator (C) controller performs its health-checking and voting logic, ultimately designating one master control path as active.

Comprehensive Output Gating: The arbitration signal from controller C does not enable or disable individual bridges; it switches the entire output suite of the active H3 board. When a failover occurs, control of all six PCMs is transferred instantaneously and simultaneously from the faulty master's H3 board to the standby master's H3 board. This guarantees that the entire excitation system fails over as a single entity, preserving system stability and preventing hazardous control conflicts.

3. Enabling Ultra-High Power and N+1 Redundancy Schemes

The capacity of the H3 model facilitates advanced reliability configurations that are not feasible with lower-density selector boards.

N+1 / N+2 Redundancy: With six bridges available, system designers can implement robust redundancy schemes. For example, a system might be designed with five bridges (N) required to carry the full load, with the sixth bridge being a hot or warm standby (N+1). The H3 seamlessly integrates this spare bridge into the control scheme, ready to be activated as part of the coordinated set without requiring additional control hardware.

Load Sharing and Thermal Management: By ensuring all bridges are fired identically, the H3 promotes natural current sharing. This is critical for the thermal management of the power conversion cabinet, as it prevents any single bridge from being overloaded, thereby extending the service life of the SCRs and associated cooling systems.

III. Operational Principles of a Multi-Bridge Controller

The operational paradigm of the IS200ESELH3A is that of a high-fidelity signal amplifier and distributor on a system scale.

1. Integrated Signal Flow for Maximum Power Output

Step 1: Centralized Computation: The DSPX in the active controller calculates the required firing angle based on the AVR or FCR algorithms. It outputs one set of six pulses, representing the command for the total desired field current.

Step 2: Signal Amplification and Replication: The EMIO board passes this command set to the IS200ESELH3A. The H3 board does not alter the command but performs critical signal integrity and driving functions. It buffers the input and uses its internal architecture to generate six identical, high-integrity copies of the original pulse train.

Step 3: Mass Distribution: The activated H3 board dispatches these six identical command sets through multiple, dedicated output connectors to six individual EGPA boards spread across one or more power conversion cabinets.

Step 4: Unified Power Generation: All six PCMs receive the gate pulses at the same instant. Their combined DC output, a product of this synchronized operation, is fed to the generator field, providing the immense excitation power required for the largest machines.

2. Failover Dynamics in a Complex System

The redundancy switchover process in an H3-controlled system is a testament to the EX2100's design for high availability.

System Fault Detection: Controller C continuously monitors the performance of the M1 and M2 control channels. Upon identifying a fault condition in the active master, it initiates a system-level transfer.

Coordinated Control Transfer: The "disable" command is issued to the active H3 board (e.g., M1), which immediately ceases all pulse transmission to its six assigned PCMs. In the same moment, the standby H3 board (M2) is enabled.

Instantaneous and Total Takeover: The M2-ESELH3 board, which has been internally replicating the tracking pulses from its DSPX, begins outputting its six sets of gate commands. All six power bridges transition their control allegiance from the failed controller to the healthy one without a single missed firing pulse, ensuring the generator remains in a perfectly regulated state throughout the fault recovery process.

IV. Detailed Comparison: IS200ESELH3A vs. IS200ESELH1A

The IS200ESELH3A and IS200ESELH1A serve fundamentally different market segments and system architectures, defined by their scale of operation.

| Parameter | IS200ESELH3A | IS200ESELH1A |

| Primary Application | Maximum-power excitation systems for large utility-grade generators. | Standard or base redundant systems for smaller generators or industrial applications. |

| System Scale | Enterprise-Level. Designed for the most demanding applications where current requirements are extreme. | Unit-Level. Designed for discrete, self-contained control of a single power stream. |

| Number of Bridges Driven | Six (6). This represents the maximum capacity within the EX2100 system. | One (1). This is the base-level, fundamental building block. |

| Architectural Role | System-Level Integrator / Master Controller. It consolidates control for an entire high-power exciter lineup. | Component-Level Controller / Dedicated Interface. It manages a single, discrete component within the exciter. |

| Core Operational Principle | Mass Synchronization and System-Wide Coordination. Its primary challenge is maintaining perfect harmony across a large array of power devices. | Precision Gating and Path Selection. Its primary focus is on the reliability of a single, critical signal path. |

| Impact on System Capability | Enables the highest possible power output of the EX2100 platform. Directly facilitates advanced N+1 redundancy within a compact control footprint. | Defines the basic unit of control. System expansion requires adding more of these basic units, increasing rack space and complexity. |

| Implementation Complexity | Manages a highly complex multi-bridge synchronization and current sharing paradigm. A failure or switchover affects the entire excitation system. | Manages a relatively simple binary switching operation. A failure or switchover is localized and isolated to a single power bridge. |

| Model Differentiation | The "H3" suffix identifies the maximum-capacity, system-level controller. | The "H1" suffix identifies the foundational, single-path controller. |