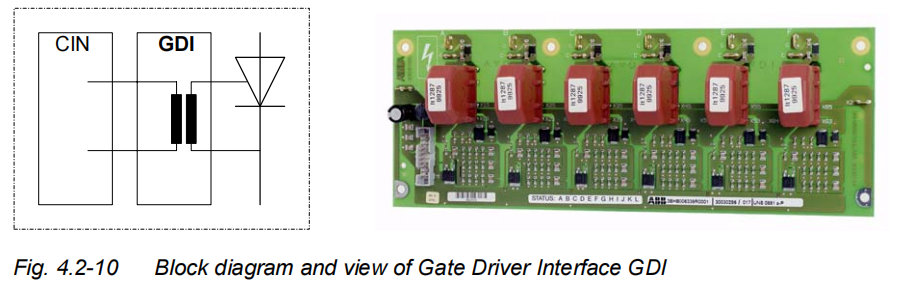

The UNS 0881a-P (abbreviated as GDI, Gate Driver Interface) is a core interface component in the ABB UNITROL® 5000 excitation system that connects the control unit to the power thyristor bridge. This device plays a vital role in the excitation system, primarily responsible for converting, amplifying, and isolating the low-power logic control signals from the control board (COB via CIN) into the high-power, high-reliability gate trigger pulses required to directly drive high-power thyristors. The GDI board is a key link in achieving safe, reliable, and efficient energy transfer between the control system and the power system, and its design quality directly affects the triggering accuracy, noise immunity, and operational stability of the entire excitation system. Designed specifically as a drive interface for high-power thyristors, the UNS 0881a-P supports disk-type thyristors, covering various specifications from 1.5 inches to 4 inches, and is suitable for a wide range of demanding industrial and power application environments, especially in synchronous generator excitation systems with high voltage, high current, and requiring high electrical isolation.

II. Key Functions

1. Power Amplification and Pulse Shaping

One of the core functions of the GDI board is power amplification. The trigger pulse signals received from the CIN (Converter Interface) are low-power logic level signals and cannot directly drive power thyristors that require significant trigger current and voltage. The power amplifiers integrated inside the GDI boost these weak signals in current and voltage, forming trigger pulses with sufficient energy and steep edges to ensure the thyristors turn on quickly and reliably.

2. Electrical Isolation

In excitation systems, there is a very high potential difference between the control circuit (low-voltage electronics) and the power circuit (high-voltage main circuit). The GDI board provides electrical isolation (Galvanic Isolation) of up to several kilovolts through its built-in pulse transformers. This function is crucial as it:

Protects Low-Voltage Control Equipment: Prevents high voltage from the power side from entering the control side, damaging sensitive electronic boards like the COB and CIN.

Suppresses Common-Mode Noise: Breaks ground loops, effectively suppressing high-frequency noise generated during power circuit switching from interfering with control signals, ensuring stable operation of the control system.

Enhances System Safety: Provides safety protection for both equipment and personnel.

3. Pulse Train Transmission

The GDI employs advanced high-frequency pulse train (62 kHz Pulse Train) technology to transmit trigger signals, instead of traditional wide pulses or DC signals. This method offers multiple advantages:

High Efficiency: Allows pulse transformers to be smaller, lighter, and have lower power consumption.

High Reliability: Enables easy monitoring and diagnostics of the trigger pulses by detecting the presence or absence of the pulse train.

Strong Noise Immunity: High-frequency AC signals are less susceptible to low-frequency noise, ensuring more reliable transmission.

4. Interface Adaptation and Flexibility

The GDI board is designed to drive one complete 6-pulse thyristor bridge. It connects to the CIN board via a ribbon cable to receive control signals; simultaneously, it connects to the gate-cathode terminals of each thyristor via twisted pair cables to output the trigger pulses. This design provides clear interface definitions, facilitating on-site wiring and maintenance. Furthermore, the board also supports control of a 2-pulse bridge, demonstrating its configuration flexibility.

5. Support for Multiple Thyristor Voltage Levels

To adapt to different system voltage requirements, the GDI offers two variants:

V1 Variant: Integrates a pulse transformer with 5 kV isolation capability, suitable for medium-voltage excitation applications.

V2 Variant: Designed for connection to an external 8 kV pulse transformer, suitable for higher voltage levels (such as those mentioned in UNITROL 5000 related to the 3800V Crowbar system) or applications with extreme isolation requirements. This modular design allows the system to be flexibly configured according to actual voltage levels, optimizing cost while ensuring safety.

III. Working Principle

1. System Integration and Signal Flow

The GDI's position in the UNITROL 5000 system is between the CIN (Converter Interface) and the power thyristors. Its operation begins with signal reception: the CIN board, based on commands from the COB (Control Board), generates logic pulse sequences containing firing angle information, which are transmitted to the GDI board via a shielded ribbon cable. Acting as a signal "relay station" and "amplifier," the GDI board receives these signals and proceeds to its core processing stage.

2. Internal Pulse Processing Mechanism

The core components inside the GDI board are the pulse forming and amplification circuit and the pulse transformer.

Signal Conditioning and Driving: The digital pulse signals from the CIN first enter the input stage circuit of the GDI board. This circuit shapes and pre-processes the signal, eliminating potential glitches and distortion to ensure signal purity. The processed signal then drives a power switching circuit (typically composed of high-power semiconductor devices).

High-Frequency Pulse Train Generation: The power switching circuit chops a DC power supply at a fixed high frequency (62 kHz), thereby modulating the original pulse command onto a 62 kHz carrier wave to form a high-frequency pulse train. When the CIN issues a "trigger" command, the GDI outputs this pulse train; when the command ceases, the pulse train stops.

Pulse Transformer Operation: The generated high-frequency pulse train is fed into the primary winding of the pulse transformer. The pulse transformer is the key component for GDI's isolation and energy transfer. Due to its high operating frequency, the transformer core can use high-frequency magnetic materials (e.g., ferrite), resulting in a compact and efficient transformer. The transformer transfers energy from the primary side to the secondary side via magnetic coupling, simultaneously achieving kilovolts of electrical isolation between the primary (control side) and secondary (power side).

3. Trigger Energy Transfer and Thyristor Turn-On

The secondary winding of the pulse transformer outputs the high-frequency pulse train. This signal is delivered to the connected thyristor gate. The thyristor's gate-cathode structure acts like a PN junction. When the high-frequency pulse train is applied, its positive voltage component generates a gate current. This current establishes sufficient carrier injection within the thyristor's gate region. When the anode-cathode voltage is positive, the thyristor is rapidly triggered into conduction. Using a pulse train instead of DC triggering offers the benefit that the continuous pulse energy ensures the thyristor maintains a stable conduction state throughout the entire conduction period (especially when carrying high current), which is particularly important for inductive loads, avoiding conduction failures due to insufficient gate current.

4. Working Principle Differences Between Variants (V1/V2)

V1 Variant (Integrated 5 kV Transformer): All functions, including power amplification, pulse train generation, and high-voltage isolation, are integrated onto a single board. Its compact structure suits most standard application scenarios. The board directly outputs the isolated trigger pulses to the thyristors.

V2 Variant (External 8 kV Transformer): The GDI V2 board itself performs signal conditioning, high-frequency pulse train generation, and primary driving. It then outputs the non-isolated high-frequency pulse train to an external, specially designed high-voltage pulse transformer (rated isolation voltage 8 kV). This external transformer is responsible for the final isolation and energy transfer. This design separates the heat-generating power components (external transformer) from the sensitive electronic circuits (GDI board), benefiting heat dissipation and maintenance, and enables higher isolation voltage levels to meet ultra-high voltage application requirements.

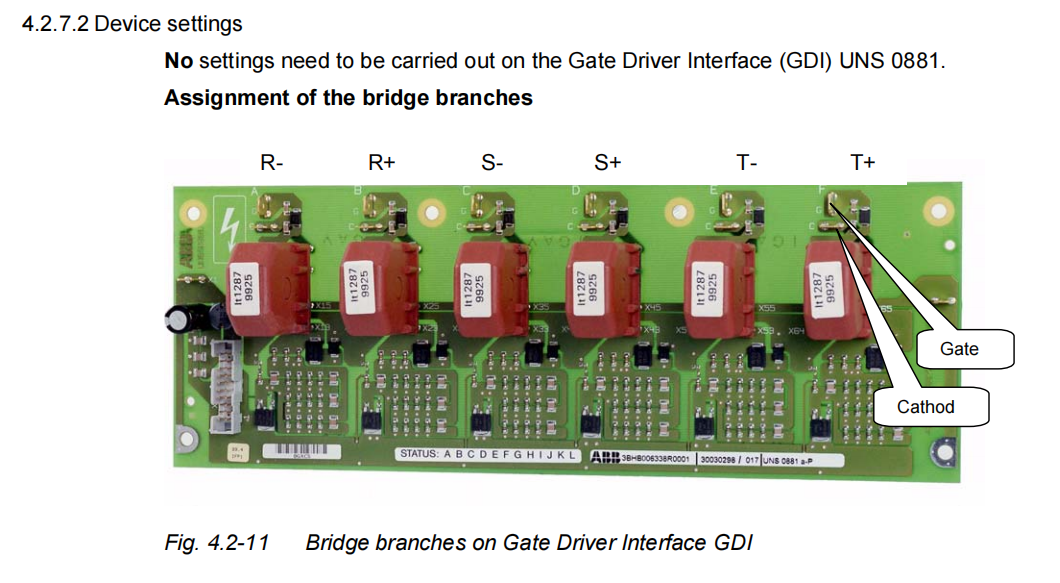

5. Bridge Arm Assignment and Synchronous Triggering

One GDI board is responsible for driving all six thyristors of one three-phase full-control bridge (6-pulse). The board has clear terminal markings (e.g., R+, R-, S+, S-, T+, T-), corresponding to the positive (common cathode group) and negative (common anode group) arms of the R, S, T AC input phases, respectively. The GDI ensures that the synchronous trigger pulses from the CIN are accurately distributed to the corresponding bridge arm thyristors, thereby achieving the precise phase control required for active inverter or rectifier functions.

6. Safety and Reliability Design

Passive Design and Energy Derivation: The trigger energy for the GDI board primarily comes from its own auxiliary power supply (typically provided by the system 24VDC), but its high-voltage isolation capability is its key safety feature. For trigger units in applications like Crowbar, the trigger energy is sometimes even derived directly from the anode-cathode voltage of the thyristor being triggered, reflecting a design philosophy focused on reliable operation even under extreme conditions.

No User On-Site Settings: As stated in the document, the GDI board itself requires no on-site settings. Its reliability is guaranteed by design and manufacturing. Once installed and connected correctly, it is ready for operation. This significantly reduces the risk of failure due to setting errors and simplifies the installation and maintenance process.

IV. Technical Features

High Isolation Strength: Provides 5 kV (V1) or supports external 8 kV (V2) electrical isolation, ensuring absolute safety for the control system.

High-Frequency Pulse Train Technology: Uses 62 kHz pulse transmission for high efficiency, strong noise immunity, and high reliability.

Strong Driving Capability: Capable of delivering the gate current and voltage required to reliably trigger 1.5-inch to 4-inch high-power thyristors.

Standardized Interfaces: Connects to CIN via ribbon cable and to thyristors via twisted pair, with clear interfaces for easy installation and maintenance.

Flexible Configuration: Supports control of a full 6-pulse bridge or a 2-pulse bridge, with V1/V2 variants for different voltage levels.

High Reliability and Maintenance-Free Operation: Solid-state design with no mechanical wear parts, requires no field commissioning, offers stable operation and long service life.

Compact Design: Optimized layout adapts to the confined installation space within excitation cabinets.

V. Application Scenarios

The UNS 0881a-P GDI Gate Driver Interface Board is an ideal choice for the following fields:

Excitation Systems for Large Synchronous Generators (Thermal power, hydropower, nuclear power plants)

Excitation Systems for Synchronous Motors in Industrial Drives (Compressors, pumps, mills)

Auxiliary Systems in High-Voltage Direct Current (HVDC) Converter Stations

Large-scale Frequency Converters and Power Quality Management Devices

Any Industrial Power Control Application requiring high-reliability, high-isolation strength thyristor driving