The IS220PSCAH1A is a crucial interface component designed by General Electric (GE) for the Mark VIe and Mark VIeS distributed control systems, known as the PSCA Serial Communication I/O pack. This module plays a vital role in industrial automation and control systems, serving as a protocol conversion hub and electrical interface bridge between the upper-layer Ethernet control network and various lower-layer serial communication devices.

By integrating traditional, widely-used serial communication protocols (such as RS-232, RS-422, RS-485) into the modern Ethernet-based Mark VIe IONet, the PSCA module effectively resolves compatibility issues between old and new equipment, protects user investments, and enables unified data acquisition and management for numerous serial devices. It is particularly suited for industrial applications requiring communication with smart transmitters, variable frequency drives, drive systems, and other devices supporting Modbus or proprietary serial protocols.

The model number IS220PSCAH1A specifically indicates that it incorporates a BPPB model processor board, which acts as the module's "brain," responsible for executing communication protocols, managing data, and performing self-diagnostics.

2. Hardware Architecture and Physical Interfaces

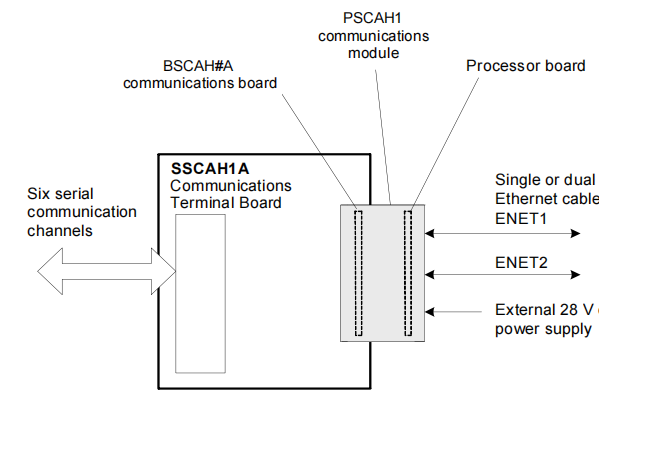

The hardware design of the PSCA module reflects a highly integrated and modular approach, consisting primarily of two parts:

Common Processor Board (BPPx): This is the common foundation for all Mark VIe distributed I/O packs. In the IS220PSCAH1A, it is specifically the BPPB processor board. It executes control logic, handles network communication, manages module power, and runs embedded diagnostic firmware. This processor board is the core for data exchange between the module and the Mark VIe controller.

Dedicated Serial Communication Board: This is the unique part of the PSCA module. This board integrates six independent serial communication channel transceivers, each configurable individually via software to adapt to different communication standards.

The module's physical interface design is compact and practical, primarily including:

3. Core Functions and Detailed Working Principles

The functionality of the PSCA module goes beyond simple signal conversion; it implements complex, configurable communication services. Its working principles can be understood in depth from three aspects: data flow, protocol support, and specific services.

3.1 Multi-Protocol Serial Communication Channels

This is the core function of the PSCA module. Its six serial channels are independent communication entities, each flexibly configurable:

Supported Standards:

RS-232: A common point-to-point, full-duplex standard for short distances (max 15 m), with a maximum rate of 115.2 kbps. Suitable for connecting to PCs, local display units, etc.

RS-422: A differential signaling standard supporting point-to-multipoint communication, with strong noise immunity, a transmission distance up to 305 m, and a high maximum rate of 375 kbps. Ideal for applications requiring longer distances and higher speeds.

RS-485 (Half-Duplex only): A widely used multipoint communication standard also using differential transmission, offering excellent noise immunity, a distance of 305 m, and a rate of 115.2 kbps. Each RS-485 channel can support up to 8 drop devices, with a maximum of 18 devices per PSCA board. Ideal for building small device networks.

Configuration Flexibility: The physical layer characteristics of each channel can be independently configured via the ToolboxST engineering software, including:

Implementation Mechanism: The actual electrical characteristics and termination are set not on the PSCA pack itself, but on its matching SSCA Terminal Board. Jumpers on the terminal board configure the termination resistors and line configuration required for the selected communication mode (RS-232/422/485). The PSCA pack sends signals to the terminal board via the DC-62 pin connector, which then connects to the field serial devices.

3.2 Dataflow Processing and Controller Interaction

Data flow from the PSCA to the controller is handled in two distinct types, reflecting its hierarchical processing capability:

3.3 Serial Modbus Master Service

The PSCA module supports operating as a Modbus Master on all six serial ports. This means it can actively poll Modbus slave devices on the serial network to request (read) or send (write) data.

Configurable Parameters (Port Level): In addition to basic serial parameters (baud rate, etc.), this includes:

Station Address List.

Time-out (milliseconds) per device.

32-bit Data Word Ordering (e.g., LSW or MSW first), crucial for handling floats or long integers.

Device Response Delay Time.

Configurable Parameters (Signal Level): In ToolboxST, for each Modbus data point:

Signal Type (e.g., Coil, Input Register, Holding Register).

Register Number.

Read/Write Access.

Transfer Rate (0.5, 1, 2, 4 Hz).

Scaling: Raw min/max, Engineering min/max.

Supported Function Codes: Covers common Modbus operations like Read Coils (01), Read Input Registers (04), Write Single Register (06), Write Multiple Registers (16), etc.

Fault Tolerance: The module periodically (every 10 sec) attempts to re-establish communications with a non-responding slave.

3.4 Ethernet Modbus Master Service

Besides serial Modbus, the PSCA module can use one of its two Ethernet ports specifically for Ethernet Modbus TCP/IP Master service. This function is restricted to use on a Simplex network topology.

Network Configuration: The Modbus TCP IP address must be outside the IONet subnet range. All Ethernet Modbus stations are configured via "Port 7" in ToolboxST.

Scale and Performance: A single PSCA module can support up to 18 Ethernet Modbus stations. CPU load per station varies based on the number of registers requested and the update rate. Data throughput must be validated during system test when multiple stations and/or large data volumes are involved.

Communication Mechanism: Follows the Open Modbus/TCP specification. The module employs a retry mechanism: if a response times out (default 1s), it retries reception up to 6 times, resulting in a total effective timeout of 6 times the single timeout setting. After three consecutive "No Response" events, the module closes the connection and periodically attempts to re-establish it.

3.5 Comprehensive Signal Processing

For both Fixed I/O and Modbus I/O, the PSCA module and ToolboxST application support type casting and scaling of all I/O signals to/from engineering units. This allows raw device data to be seamlessly converted into meaningful engineering values readily usable by control logic.

4. Diagnostics and Maintenance

The PSCA module features comprehensive self-diagnostics to ensure system reliability:

Power-up Self-test: Includes checks of RAM, flash memory, Ethernet ports, and most processor board hardware.

Continuous Monitoring: Monitors internal power supplies for correct operation.

Hardware/Software Validation: Checks electronic ID from terminal board, acquisition board, and processor board for hardware set match, and verifies application code compatibility.

Advanced Diagnostics: Analog inputs support configurable system limit checking. All diagnostic signals can be individually latched and reset via the RESET_DIA signal when healthy. Detailed diagnostics are available in ToolboxST for rapid troubleshooting.