The IS200STAIH1A is a member of the STAI (Simplex Analog Input) family of terminal boards used in GE's Mark VIe Control Systems. It is a compact, high-performance interface component specifically designed to provide high-precision, highly reliable signal interfacing for analog sensors and actuators in industrial automation and control systems.

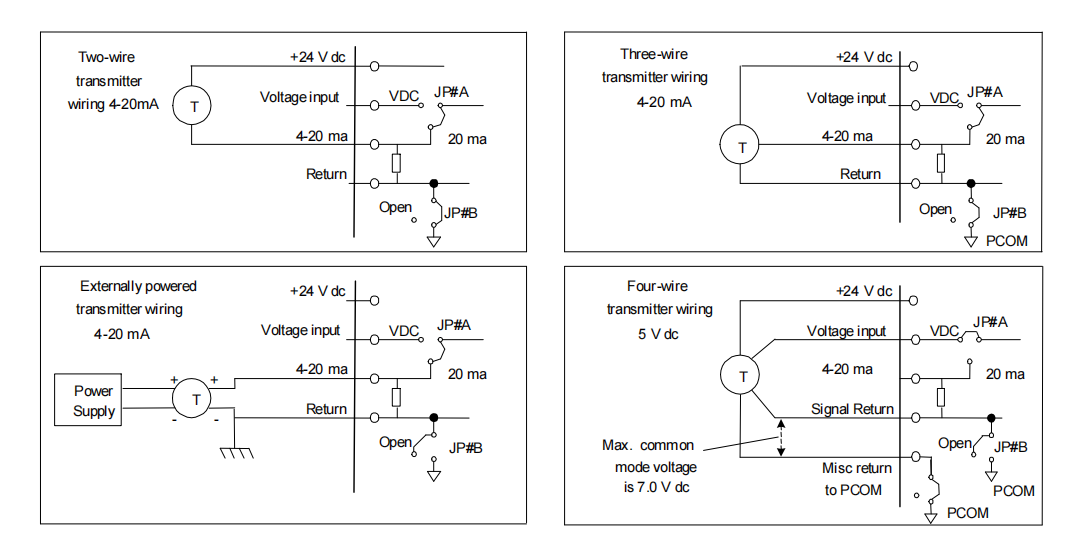

The core function of this terminal board is to serve as the electrical and physical bridge between the PAIC Analog I/O Module and field devices. It is responsible for receiving analog signals from various types of transmitters, providing them with operating power, and transmitting the controller's analog output commands to actuators. The IS200STAIH1A supports 10 analog inputs and 2 analog outputs, accommodating common wiring configurations in industrial environments such as 2-wire, 3-wire, 4-wire, and externally powered transmitters.

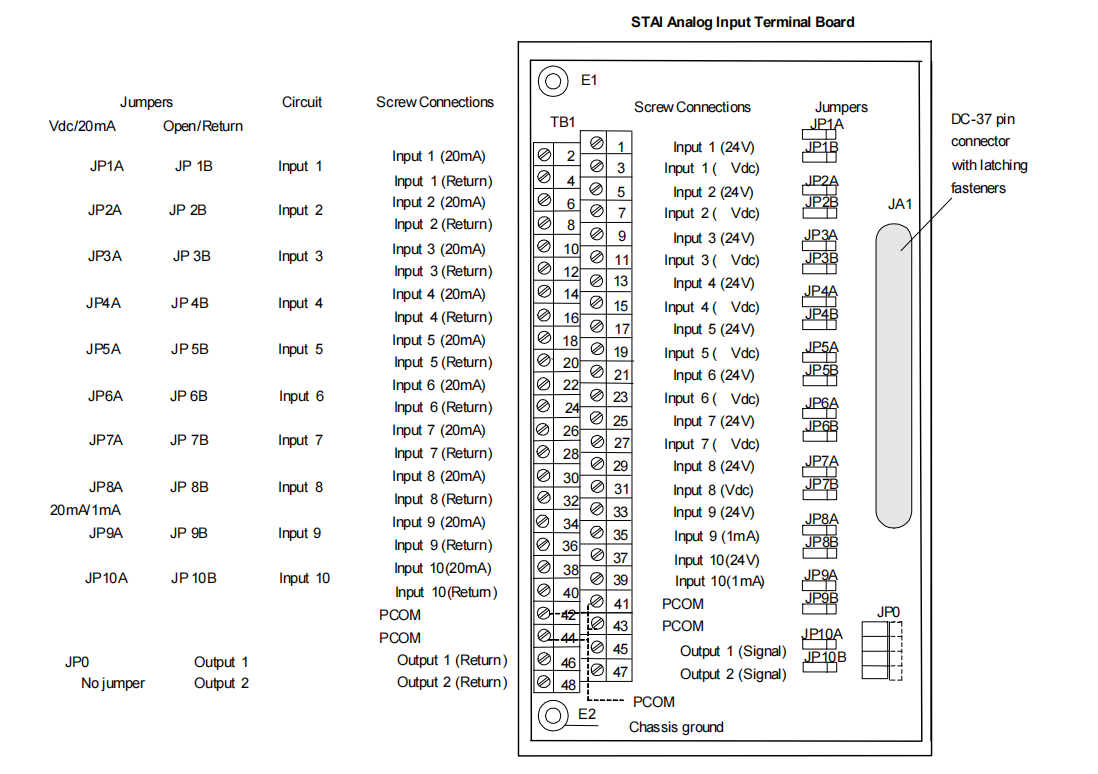

The "H1A" designation in its model number indicates it uses fixed-mount Euro-style terminal blocks with 48 connection points, ensuring connection stability. The IS200STAIH1A is designed specifically for Simplex systems, meaning it operates with a single PAIC I/O module, forming a complete and cost-effective single-channel analog signal processing unit. It is important to note that, according to the compatibility list, the IS200STAIH1A is not compatible with the Mark VIeS YAIC I/O Module used for safety systems.

II. Hardware Structure and Interfaces

The hardware design of the IS200STAIH1A fully considers the needs of industrial applications for compactness, maintainability, and noise immunity.

Mechanical Structure: The terminal board itself is mounted via a plastic insulator onto a metal carrier, which can be snapped onto a standard DIN rail. Alternatively, it can be bolted directly to a cabinet panel using a sheet metal assembly, offering flexible mounting options.

Terminal Blocks: A distinguishing feature of the IS200STAIH1A is its fixed, high-density Euro-style terminal block. This terminal type is robust and provides reliable wire connection, but unlike pluggable models, wiring must be done directly on the terminals during maintenance. The terminal board provides a total of 48 terminal points, typically using #18 AWG shielded twisted pair wires.

System Interfaces:

JA1 (DC-37 Pin Connector): This is the core interface between the terminal board and the PAIC I/O module. This connector plugs directly into the I/O module, transmitting all 10 analog input signals, 2 analog output signals, power, and the ID signal for hardware identification.

Shielding and Grounding: A dedicated shield grounding bar (e.g., E1, E2 SCOM terminals) is provided near the terminal blocks for connecting cable shields, which is crucial for suppressing electromagnetic interference and ensuring signal integrity.

III. Functionality and Operating Principles

The functionality of the IS200STAIH1A extends far beyond simple wiring; it integrates signal conditioning, power distribution, and configuration management. Its operating principle involves a multi-stage, precise process.

1. Operating Principle of Analog Input Channels

The analog input channels are the core of the IS200STAIH1A's processing of signals from field sensors.

Power Supply and Signal Type Selection:

The terminal board provides 24 V DC loop power for the first 8 analog inputs (Input 1-8), used to directly power 2-wire or 3-wire transmitters.

The type of each input (voltage or current) can be flexibly configured via jumpers (JP#A and JP#B). For example, JP1A selects between voltage (±5V/±10V) and current (4-20mA) input; while JP1B selects whether the signal return path is connected to the common terminal (PCOM), which is essential for achieving signal isolation and accommodating different wiring schemes (e.g., 4-wire transmitters).

For Inputs 9 and 10, jumpers (JP9A, JP10A) are used to select between 4-20 mA and ±1 mA current ranges.

Signal Conditioning and Conversion:

Noise Suppression: Each input channel incorporates a noise suppression circuit at the signal entry point. This circuit effectively filters out high-frequency electromagnetic interference (EMI) and suppresses voltage surges, preventing various electrical noises from the field side from affecting signal accuracy.

Current-to-Voltage Conversion: When an input is configured for current mode (e.g., 4-20mA), a precision 250 Ω burden resistor integrated on the terminal board performs the conversion. According to Ohm's Law (V = I × R), the 4-20mA current signal produces a 1-5V voltage drop across this resistor (V=20mA × 250Ω = 5V at 20mA). This voltage signal is the final physical quantity transmitted to the PAIC I/O module for measurement.

Hardware Filtering: Before entering the I/O module, the signal passes through a passive low-pass filter network with a pole at 75.15 Hz, further filtering out power line frequency and its harmonics.

Signal Transmission to the I/O Module: The 10 conditioned and converted analog voltage signals are transmitted in parallel to the PAIC module via the DC-37 connector.

2. Further Processing within the PAIC I/O Module

Once inside the PAIC module, the signal undergoes a second stage of precise processing to convert it into data understandable by the digital world:

Analog Multiplexing and Scaling: The acquisition board inside the PAIC first routes the 10 input signals sequentially through an analog multiplexer. The signal then enters a programmable gain amplifier, which scales it appropriately based on the range configured in ToolboxST (e.g., ±5V, ±10V) to match the optimal input range of the Analog-to-Digital Converter (ADC).

Analog-to-Digital Conversion (ADC): The scaled analog signal is converted into a digital value by a high-precision 16-bit Successive Approximation Register (SAR) ADC. The 16-bit resolution means it can divide the entire range (e.g., 0-5V) into 65,536 discrete levels, providing very high measurement accuracy and the ability to detect minute changes.

Digital Filtering and Data Processing: The converted digital value is then passed through a configurable software digital filter (selectable bandwidths: 0.75, 1.5, 3, 6, 12 Hz) to further smooth the data and suppress random noise. Finally, this digital value, representing the original physical quantity (e.g., pressure, temperature), is sent via Ethernet to the upper-level controller.

3. Operating Principle of Analog Output Channels

The IS200STAIH1A also provides 2 analog outputs for driving actuators such as valve positioners and variable frequency drives.

Command Reception and Digital-to-Analog Conversion (DAC): The controller sends output commands to the PAIC module via Ethernet. A 14-bit Digital-to-Analog Converter (DAC) inside the module converts this digital command into a precise reference voltage.

Current Regulation and Driving: This reference voltage drives a current regulator loop. This loop generates a corresponding 0-20 mA current signal. The output circuit on the IS200STAIH1A terminal board is responsible for transmitting this current signal to the field load.

Output Range Selection (Output 1): The first analog output (Output 1) offers special flexibility. When used with the PAICH2 model I/O module, it can be configured for 0-200 mA output via the JPO jumper on the terminal board, to drive specific devices requiring higher current. Output 2 is fixed at 0-20 mA.

Output Load and Feedback:

The output circuit includes noise suppression.

The maximum load capability is 800 Ω for the 0-20 mA output and 50 Ω for the 0-200 mA output.

The system features advanced output self-diagnostics. The PAIC module monitors not only the current it drives internally ("Individual Current") but also measures the actual total current delivered to the field load ("Total Current Feedback") via a sense resistor on the terminal board. These two values are cross-compared. If a discrepancy beyond the allowed tolerance is detected (possibly due to wire break, short circuit, or module failure), a diagnostic alarm is triggered.

4. The "Suicide Relay" Mechanism in TMR Systems

Although the IS200STAIH1A is a Simplex terminal board, understanding the operation of its associated PAIC modules in TMR systems helps appreciate the robustness of its design. In a TMR system, three PAIC modules drive a single load together. Each module's output loop contains a normally open mechanical relay (known as a "suicide relay"). If a PAIC module self-diagnoses an output fault, or if its output disagrees with the voted result from the other two modules, it automatically opens its "suicide relay," thereby physically isolating its faulty output from the common load. This allows the remaining two healthy modules to continue operating normally, ensuring unaffected system output and significantly enhancing system availability.

IV. Installation and Configuration

1. Installation Steps

Securely mount the IS200STAIH1A terminal board onto a DIN rail or cabinet panel using its carrier.

Connect the wires to the corresponding terminals according to the wiring diagram, based on the field device type (2-wire, 3-wire, etc.).

Connect the cable shields to the designated SCOM grounding terminals.

Directly and vertically plug the PAIC I/O module into the terminal board's DC-37 connector (JA1) and secure it mechanically using the side threaded studs.

Connect the Ethernet cable and 28 V DC operating power to the PAIC module.

2. Jumper Configuration

Correct jumper configuration is essential for the terminal board's proper operation:

JP1A-JP8A: Select "Voltage Input" or "20mA Current Input" for Inputs 1-8.

JP1B-JP8B: Select whether the signal return is "Open" or connected to "Common (PCOM)" for Inputs 1-8.

JP9A-JP10A: Select "20mA" or "1mA" current range for Inputs 9-10.

JP9B-JP10B: Select whether the return is "Open" or "Common" for Inputs 9-10.

JPO: (Only when used with PAICH2) Select "20mA" or "200mA" mode for Output 1.

3. Software Configuration

Use the ToolboxST software to configure the PAIC module. It is imperative that the parameters in the software (e.g., input type, range, filter frequency) exactly match the physical jumper settings on the terminal board; otherwise, measurement errors or diagnostic alarms will occur.

V. Diagnostics and Maintenance

The IS200STAIH1A and the PAIC module together form a comprehensive diagnostic system:

Electronic ID Identification: The terminal board contains an embedded read-only ID chip storing the serial number, board type, and revision number. The PAIC module reads this information upon startup and compares it with the configuration in ToolboxST. Any mismatch immediately generates a "hardware incompatibility" fault, preventing erroneous operation.

Output Current Monitoring: As mentioned, by comparing the "Individual Current" and "Total Current Feedback," the system can accurately pinpoint faults in the output loop, such as open circuits, short circuits, or module failure.

Input Limit Checking: The PAIC module can configure hardware and system limit checks for each input signal. If a signal exceeds the preset healthy range (e.g., a 4-20mA signal falls below 3.6mA), the module marks the input as "unhealthy" and generates an alarm.

Calibration Reference Monitoring: The PAIC module measures internal high-precision reference voltages in every scan cycle to continuously verify the health of the ADC circuitry.

All these diagnostic details can be viewed in the ToolboxST software. Diagnostic signals can be latched and can only be reset via the RSTDIAG signal after the fault is resolved.