The IS220PDOAH1B represents an evolutionary step in the PDOA series of discrete output modules within GE's Mark VIe and Mark VIeS Control Systems. It is designed as a functional enhancement over the earlier PDOAH1A model, primarily through the integration of a more advanced BPPC processor board. This module serves as a critical interface node, translating control logic from the system's Ethernet network into physical relay commands for industrial actuators, solenoid valves, and other field devices. Its design emphasizes robustness in harsh environments, advanced diagnostic capabilities, and seamless integration into both new installations and legacy system upgrades where a drop-in replacement with improved performance is required.

2. Hardware Architecture & Component Integration

The IS220PDOAH1B's hardware is a synergy of a common I/O pack architecture and specialized components:

BPPC Processor Board: The core computational unit, which is functionally compatible with but an upgrade from the BPPB found in the IS220PDOAH1A. This processor manages all communication, data processing, and execution of the module's control algorithms.

Application-Specific Acquisition Board: This board is uniquely tailored for discrete output functions. It houses the circuitry for relay driving, feedback sensing, and level shifting, acting as the electrical intermediary between the low-voltage logic of the processor and the higher-power requirements of the terminal board.

Environmental Resilience: A key differentiator of the IS220PDOAH1B is its extended operating temperature range of -40°C to 70°C, making it suitable for a wider array of challenging industrial environments compared to its predecessor.

3. Functional Operation & Advanced Operating Principles

The operational philosophy of the IS220PDOAH1B centers on reliable command execution and comprehensive state verification.

3.1 Command-to-Output Execution Pipeline

The process begins when a command signal is received via the IONet through either the ENET1 or ENET2 port. The BPPC processor decodes this Ethernet frame and validates it. Upon validation, the processor sends a digital command to the acquisition board. Here, the signal undergoes conditioning and is amplified through an open-collector transistor circuit. Each of the 12 output channels incorporates a real-time current monitor that senses when the output is actively driving a load (the relay coil). This provides immediate feedback on the output stage's health, distinguishing between a commanded state and the actual ability to sink current.

3.2 Multi-Layered Feedback Acquisition & Multiplexing

The module's diagnostic prowess is rooted in its sophisticated feedback system. It features 15 inverting level-shifting monitor input circuits. In a standard TRLY terminal board configuration:

Twelve of these circuits are dedicated to relay contact feedback (e.g., confirming the physical state of the relay contacts) or coil monitoring.

The remaining three are used for fuse status monitoring.

A critical advanced feature is the feedback multiplexing control. The IS220PDOAH1B sends a control signal to the terminal board, enabling it to read two distinct sets of 15 feedback signals from the same physical pins. This allows the module to gather a comprehensive dataset—such as separate driver status and contact status—effectively doubling the diagnostic information without requiring additional connector pins.

3.3 System Integrity & Safety Interlocks

To ensure fail-safe operation, the module implements a strict Output Enable protocol. During the power-up sequence, all outputs are forcibly disabled and held in a de-energized state. The module then executes a series of internal self-tests, including RAM/Flash checks, Ethernet PHY initialization, and power supply validation. Only after the successful completion of these tests and the establishment of stable communication with the controller is the internal enable line asserted, permitting output commands to physically reach the terminal board. This prevents spurious or unintended actuator movement during system initialization.

3.4 Advanced Diagnostics and Sequence of Events (SOE)

The IS220PDOAH1B performs continuous, cyclic self-diagnostics that extend beyond basic functionality. It cross-references the commanded state of each relay driver with the feedback from the driver circuit itself, creating a closed-loop verification for every output. Discrepancies are flagged immediately. Furthermore, each relay channel can be individually configured to generate a time-stamped Sequence of Events (SOE) record upon a change-of-state. This high-resolution data is invaluable for post-event analysis and system troubleshooting. The module also reads and processes terminal board-specific electronic ID information, ensuring hardware compatibility and correct application code matching at startup.

4. System Integration & Compatibility Profile

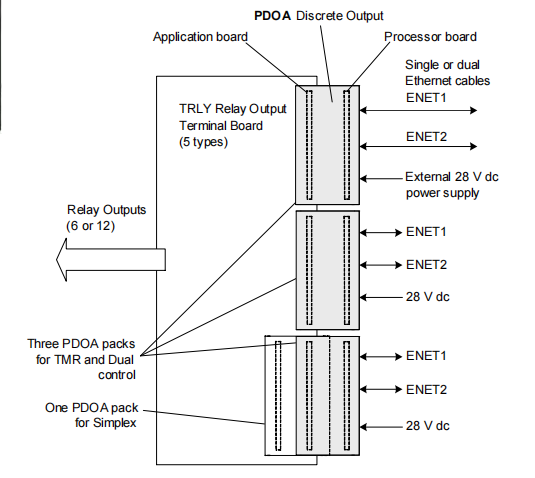

The IS220PDOAH1B is designed for flexible integration into control architectures of varying redundancy levels:

Simplex Configuration: A single IS220PDOAH1B module provides the control path.

TMR (Triple Modular Redundant) Configuration: Three PDOAH1B modules operate in parallel, with the terminal board performing hardware voting on the outputs for maximum availability.

Software & Firmware Requirements:

Terminal Board Compatibility: The module maintains broad compatibility with the TRLY family of terminal boards (e.g., TRLYH1B, 1C, 1D, 1E, 2E, 3E), but it is crucial to consult the compatibility matrix for specific Simplex or TMR applicability.

5. Installation, Configuration, and Commissioning

Physical Installation: The module is designed for direct plug-in mounting onto the terminal board's DC-37 connector. Mechanical stability is ensured by sliding the threaded studs on the module into a dedicated mounting bracket, which must be adjusted to prevent any strain on the electrical connector.

Network & Power:

Dual Ethernet cables can be connected for network redundancy. Standard practice is to connect ENET1 to the network associated with the primary (R) controller.

The 28 V DC power is connected via the 3-pin connector on the module's side. The built-in soft-start circuitry manages inrush current, allowing for hot-plugging without the need to disconnect power.

Software Configuration: Using the ToolboxST Application, engineers can configure numerous parameters, including:

Enabling/disabling individual relay outputs.

Setting the SignalInvert property to define the logic-normal state of the relay.

Configuring SOE reporting for command or feedback signals.

Enabling fuse diagnostics and voting disagreement alarms.

Defining the output's behavior upon loss of controller communication (HoldLastValue, PwrDownMode, or a predefined Output_Value).

6. Diagnostic Visibility & Maintenance Support

The module provides multiple layers of diagnostic visibility:

Status LEDs (1-12): Yellow LEDs provide a direct visual indication of an active command to energize each respective relay.

Processor LEDs: A set of multi-color LEDs report on module power, network status, and overall health.

ToolboxST Diagnostics: The software interface provides detailed, bit-level access to all diagnostic signals, including:

Relay driver vs. command mismatch.

Fuse failure indications.

Voting mismatches in TMR configurations.

Communication link status (LINK_OK_PDOA_X).

Hardware and configuration mismatch alarms.

These diagnostics are latchable and can be reset via the RSTDIAG signal once the underlying fault condition is resolved, streamlining the maintenance process.

7. Detailed Comparison: IS220PDOAH1B vs. IS220PDOAH1A

The IS220PDOAH1B is not merely a direct substitute for the IS220PDOAH1A but a product with distinct enhancements. The following table outlines the key differences that influence selection for a given application.

| Feature/Aspect | IS220PDOAH1B | IS220PDOAH1A | Implication of the Difference |

| Core Processor | BPPC | BPPB | The BPPC in the IS220PDOAH1B offers functional enhancements and is designed for support in later software versions, potentially offering improved processing and diagnostic capabilities. |

| Operating Temperature | -40°C to +70°C | -30°C to +65°C | The IS220PDOAH1B is significantly more robust, suitable for harsher environments and applications with wider ambient temperature swings, such as outdoor or poorly conditioned enclosures. |

| Software Dependency | ControlST V04.04 and later | ControlST V04.04 and later | While both require V04.04+, the PDOAH1B's BPPC is intrinsically linked to the support and feature set of the newer software suite trajectory. |

| Firmware Compatibility | Firmware compatible with BPPC architecture | Firmware compatible with BPPB architecture | The firmware is processor-specific; they are not interchangeable. This impacts stocking spare parts and planning upgrades. |

| Functional Design | Described as "functionally compatible" but with an upgraded processor. | Base model with the BPPB processor. | The IS220PDOAH1B provides a drop-in replacement path with improved hardware, ensuring future compatibility and potentially longer product lifecycle support. |

| Typical Use Case | Preferred for new installations and retrofits in demanding environments. | Often found in legacy systems; suitable for standard industrial environments. | Specifying the IS220PDOAH1B future-proofs an installation and provides a greater margin of safety for temperature-related failures. |

Summary of Differences: The primary differentiators are the superior environmental rating and the advanced BPPC processor of the IS220PDOAH1B. These factors make the IS220PDOAH1B the more versatile and forward-compatible choice, especially for applications where operational reliability in extreme conditions is paramount. When upgrading or replacing modules, the IS220PDOAH1B serves as the logical successor to the IS220PDOAH1A, provided the system software is at the requisite version.