3500/46M Hydro Monitor is a four-channel monitoring module under the 3500 Machinery Protection System, serving as a critical component of the 3500 series. It is specifically designed for comprehensive condition monitoring and protection of hydroelectric turbine generators and other hydraulic machinery. The monitor accepts signals from various sensors including proximity transducers, vibration sensors, dynamic pressure sensors, and air gap sensors. Through high-precision signal conditioning and processing, it provides real-time monitoring of key parameters such as vibration, position, static and dynamic pressure, and features multi-level alarm functions to ensure safe, stable, and efficient operation of hydroelectric units.

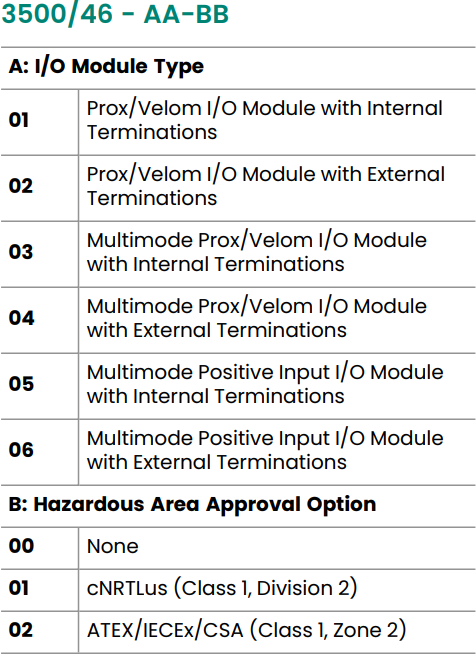

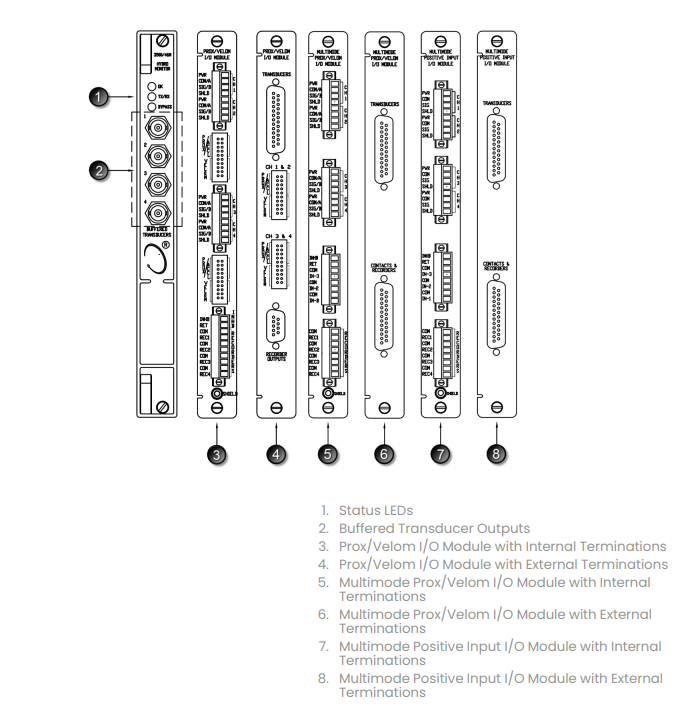

The 3500/46M consists of a front card (176449-06) and six types of I/O rear cards (see the Ordering page for details). The front card can be combined with any rear card to form a complete system.

The 3500/46M monitor is designed with full consideration of the characteristics of hydraulic machinery, such as low speed, high amplitude, and multi-mode operation. It supports various specialized monitoring functions including Hydro Radial Vibration, Air Gap monitoring, and Stator End Winding (SEW) monitoring. It is widely used in hydroelectric power plants, pumped storage power stations, hydraulic equipment manufacturing, and maintenance fields.

Key Features

The 3500/46M monitor offers highly specialized configuration capabilities and multi-parameter monitoring functions. Users can independently configure each channel via the 3500 Rack Configuration Software to support the following monitoring types:

Hydro Radial Vibration: By combining shaft gap movement with NX amplitude, it provides shear pin failure detection, specifically designed for the structural characteristics of hydroelectric turbine generators, effectively identifying abnormal vibration patterns between the rotor and stator.

Hydro Air Gap Monitoring: Monitors the air gap changes between the rotor and stator in real-time, providing multiple parameters such as average air gap, instantaneous air gap, minimum/maximum air gap, and corresponding pole numbers, ensuring the unit operates within the optimal air gap range.

Hydro Velocity Monitoring: Provides early fault warning, particularly suitable for diagnosing low-frequency, high-amplitude events. Although not suitable for automatic machine protection, it is highly valuable for predictive maintenance.

Hydro Acceleration Monitoring: Monitors high-frequency vibration events, supporting both non-integrated and integrated processing methods, with a frequency range from 3 Hz to 30,000 Hz.

Hydro Thrust Monitoring: Monitors axial displacement, with selectable sensitivity of 3.94 mV/μm, 7.87 mV/μm, or 11.22 mV/μm.

Hydro Dynamic Pressure Monitoring: Monchanges in water flow dynamic pressure, providing static and dynamic pressure parameters.

Stator End Winding (SEW) Monitoring: Specifically monitors the vibration state of the stator end winding, providing direct values and pole pass amplitude parameters.

Multimode Operation: Supports multimode configuration for all the above functions. Each channel can be configured with up to eight sets of alarm parameters, with each set corresponding to a specific machine operating mode, such as start-up, power generation, phase modulation, shutdown, and other different working conditions.

The four channels of the monitor operate in pairs, allowing two different monitoring functions to be performed simultaneously. For example, channels 1 and 2 can monitor hydro radial vibration, while channels 3 and 4 can monitor air gap or thrust position. This flexible configuration enables a single monitor to meet the diverse monitoring needs of complex hydraulic mechanical systems.

The system supports multiple methods for switching operating modes: either through hardware contacts on the multimode I/O modules or via software commands sent through a communication gateway. This design allows the monitor to adapt to the frequently changing operating conditions of hydroelectric units, providing comprehensive protection for different types of hydraulic machinery, including conventional turbine units, pumped storage units, and large pumps.

Working Principle

The core workflow of the 3500/46M monitor includes four stages: signal input, conditioning, parameter calculation, and alarm judgment.

Signal Input

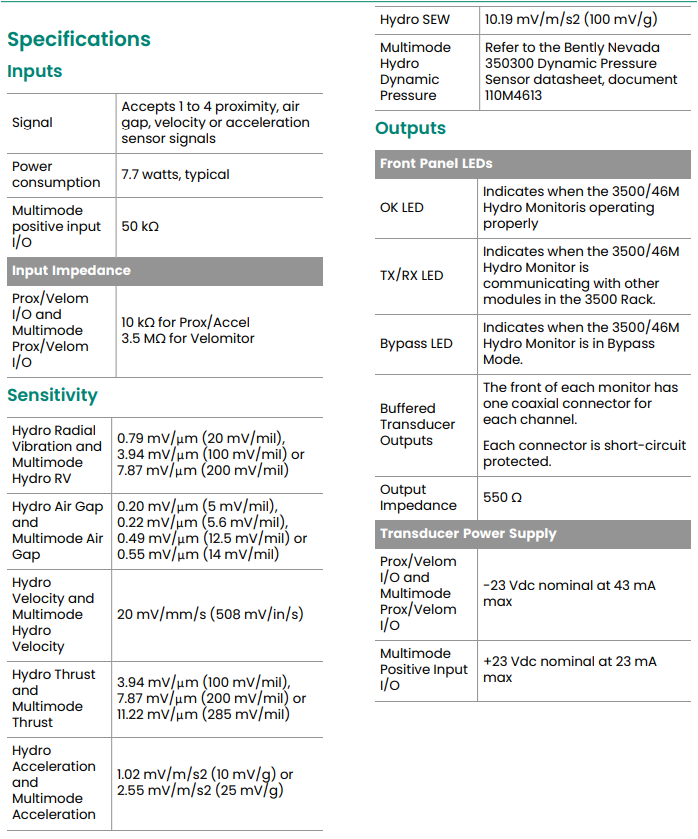

Proximity Transducer/Velocity Sensor: -23 Vdc, max 43 mA

Dynamic Pressure Sensor: +23 Vdc, max 23 mA

Signal Conditioning

Input signals are processed through amplification, filtering, integration, etc., and converted into engineering values (e.g., μm, mm/s, m/s²). The system provides multiple filtering methods:

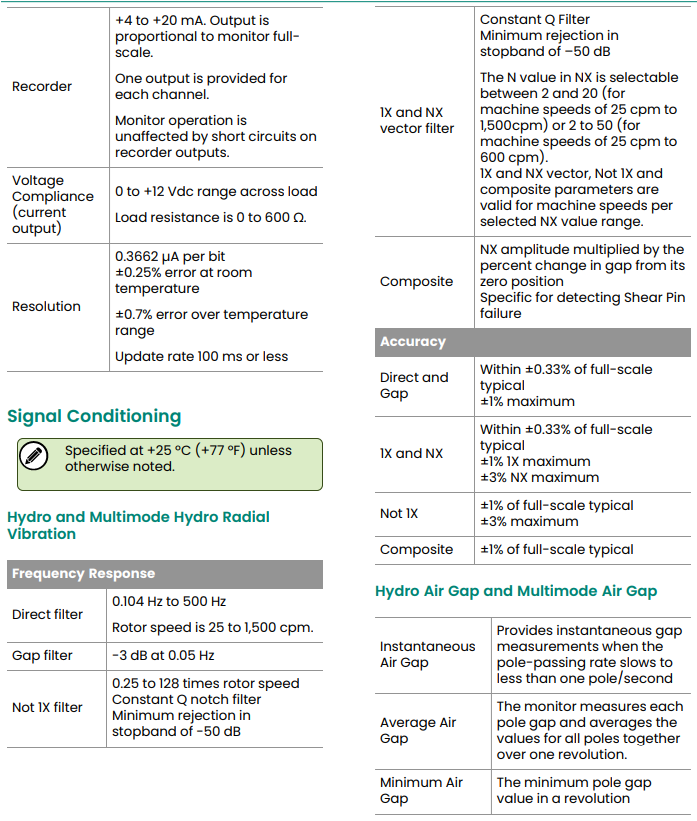

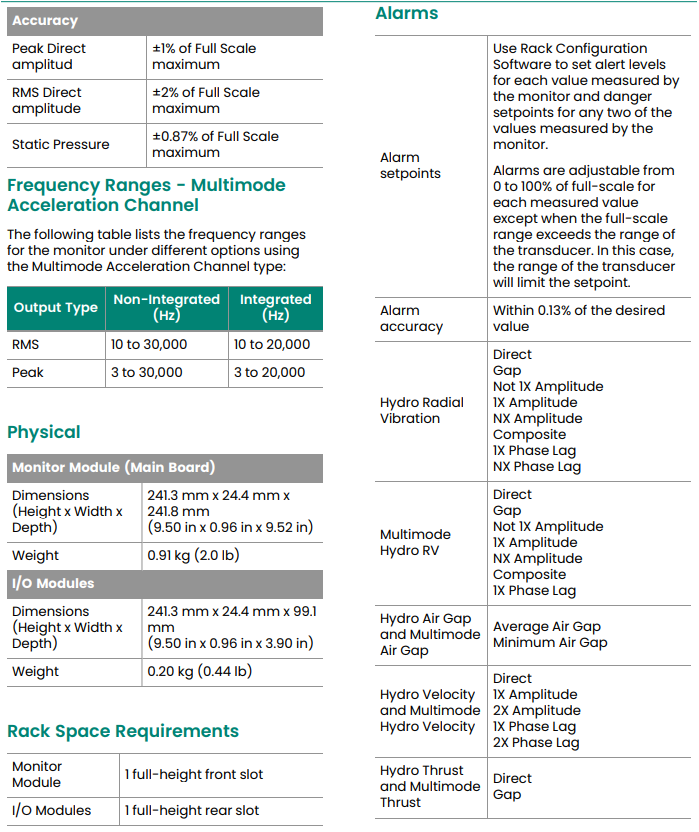

Direct Filter: Suitable for hydro radial vibration, frequency response 0.104–500 Hz (corresponding to speed 25–1500 cpm)

Gap Filter: -3 dB cutoff frequency at 0.05 Hz

Not 1X Filter: 0.25–128 times rotational speed, minimum stopband rejection of 50 dB

1X and NX Vector Filter: Constant Q value, minimum stopband rejection of 50 dB, NX value selectable between 2–20 or 2–50

Signal conditioning also includes sensitivity adjustments, such as:

Hydro Radial Vibration: 0.79 mV/μm, 3.94 mV/μm, or 7.87 mV/μm

Hydro Air Gap: 0.20 mV/μm, 0.22 mV/μm, 0.49 mV/μm, or 0.55 mV/μm

Hydro Velocity: 20 mV/(mm/s)

Hydro Thrust: 3.94 mV/μm, 7.87 mV/μm, or 11.22 mV/μm

Parameter Calculation

Based on the configured monitoring type, the module calculates the following Measured Variables:

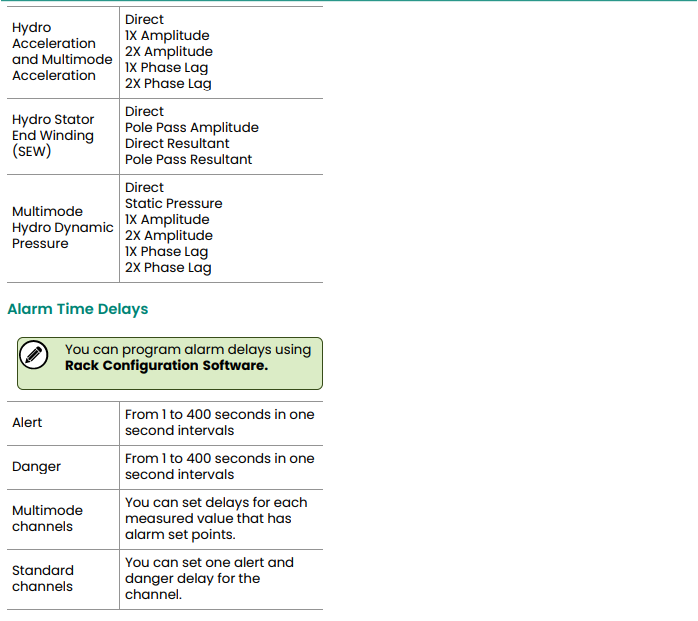

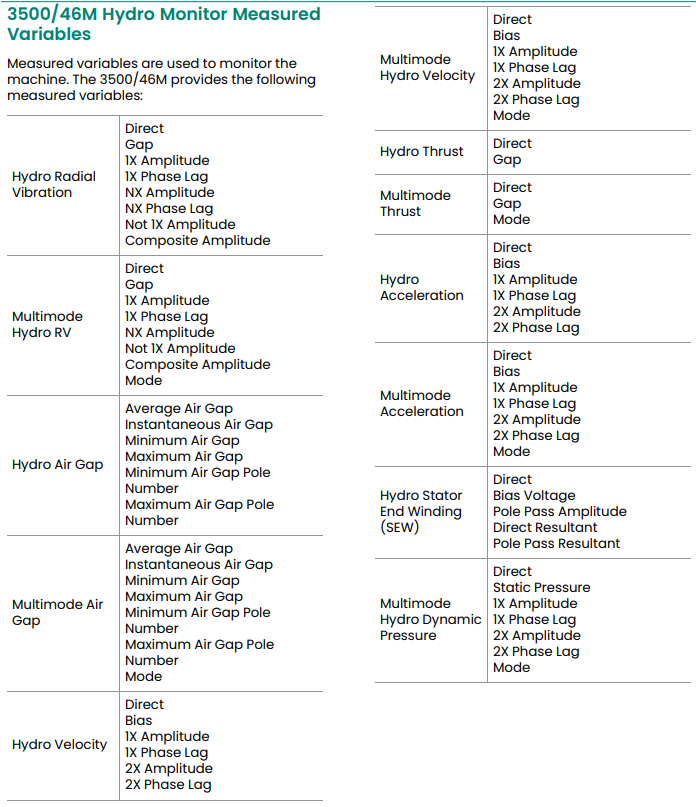

Hydro Radial Vibration: Direct, Gap, 1X Amplitude, NX Amplitude, Not 1X Amplitude, Composite

Hydro Air Gap: Average Air Gap, Instantaneous Air Gap, Minimum/Maximum Air Gap, Min/Max Air Gap Pole Number

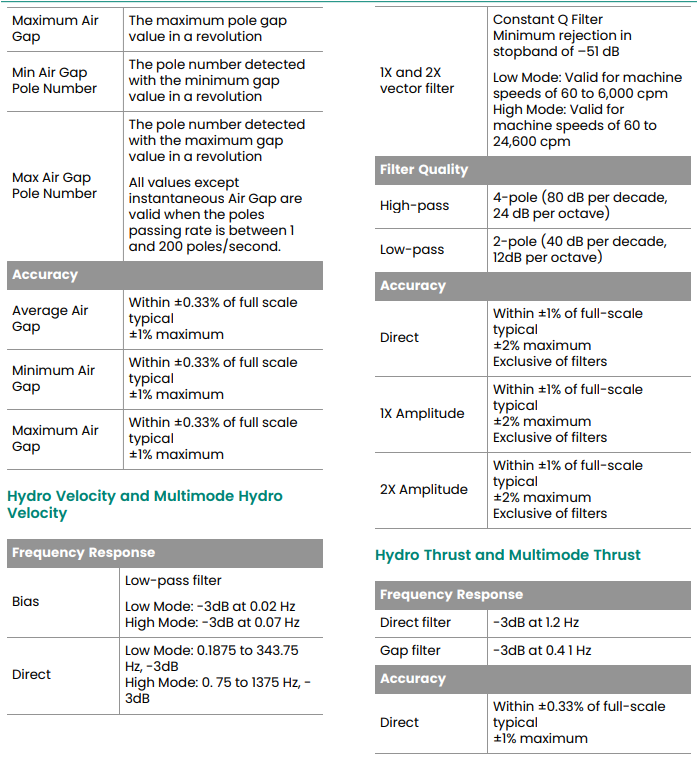

Hydro Velocity: Direct, Bias, 1X Amplitude, 2X Amplitude, 1X/2X Phase Lag

Hydro Thrust: Direct, Gap

Hydro Acceleration: Direct, 1X/2X Amplitude, 1X/2X Phase Lag

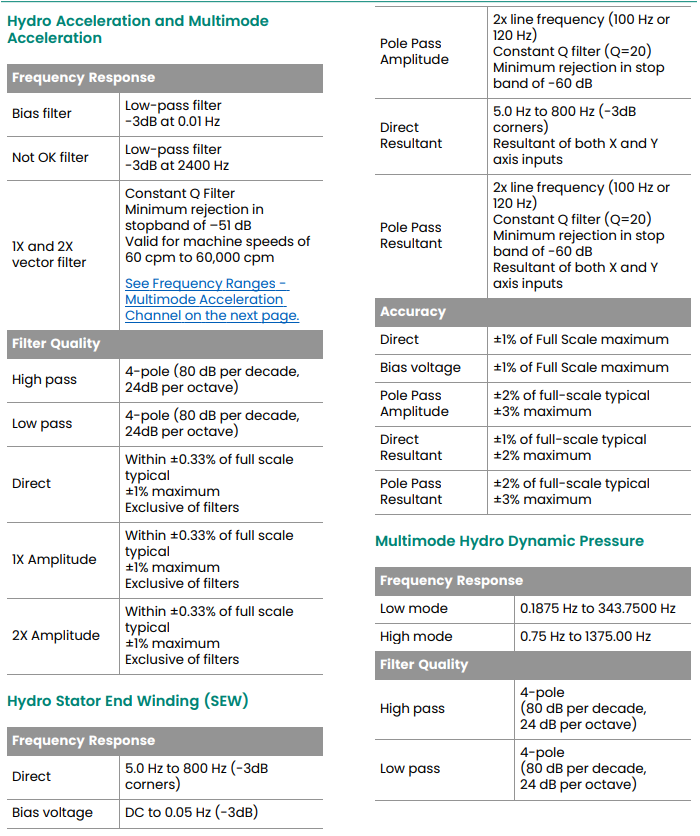

Stator End Winding (SEW): Direct, Pole Pass Amplitude, Direct Resultant

Hydro Dynamic Pressure: Direct, Static Pressure, 1X/2X Amplitude, 1X/2X Phase Lag

Alarm Judgment

Each measured variable can be set with Alert and Danger alarm points. Alarm delays are configurable:

Alert Delay: 1–400 seconds (in 1-second intervals)

Danger Delay: 1–400 seconds (in 1-second intervals)

Alarm accuracy is as high as ±0.13% of the set value, ensuring timely and reliable response.

Outputs & Communication

Front Panel Indicators: Equipped with OK (operational status), TX/RX (communication status), and Bypass (bypass status) LEDs.

Buffered Transducer Outputs: One coaxial connector per channel, with short-circuit protection.

Recorder Outputs: 4–20 mA current signal, proportional to full scale, independent output per channel. Short circuits do not affect operation.

Communication Interface: Communicates with other modules in the 3500 rack via the backplane, supporting remote monitoring and data integration.

Technical Characteristics

High-Precision Measurement: Typical accuracy for most measurement types is ±0.33% of full scale, with a maximum of ±1%.

Multi-Sensor Compatibility: Supports proximity transducers, velocity sensors, accelerometers, dynamic pressure sensors, air gap sensors, and more.

Specialized Hydro Monitoring Functions: Includes hydro radial vibration, air gap monitoring, SEW monitoring, etc., specifically designed for hydroelectric units.

Multimode Support: Supports 8 sets of alarm parameters, adapting to various operating conditions of hydroelectric units.

Advanced Signal Conditioning: Includes direct filtering, gap filtering, Not 1X filtering, vector tracking filtering, etc., adapting to the low-frequency, high-amplitude characteristics of hydraulic machinery.

Environmental Adaptability: Operating temperature range from -30°C to +65°C, suitable for harsh environments in hydroelectric power plants.

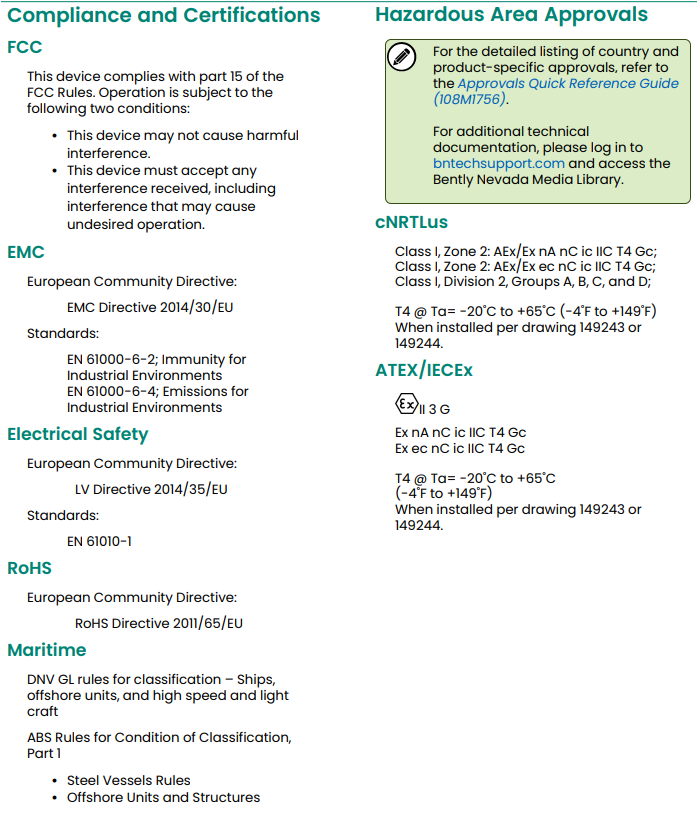

Safety Certifications: Complies with FCC, EMC, LV Directive, RoHS, ATEX, IECEx, CSA, and other international standards for use in hazardous areas.