The 3500/42M Proximitor Seismic Monitor is a highly integrated and powerful four-channel monitoring module within the Bently Nevada™ 3500 Series Machinery Condition Monitoring System. It represents an advanced level of machinery protection technology, capable of simultaneously processing signals from both proximity transducers and seismic transducers, enabling synchronous and comprehensive monitoring and protection of both shaft relative vibration and bearing housing absolute vibration in rotating machinery.

This monitor continues the high-reliability design philosophy of the 3500 system. Its core mission is to provide uninterrupted protection for critical mechanical assets by continuously comparing monitored parameters against user-programmable alarm setpoints to drive alarms; simultaneously, it communicates essential machine information to operations and maintenance personnel in real-time, providing data support for condition-based maintenance and fault diagnosis.

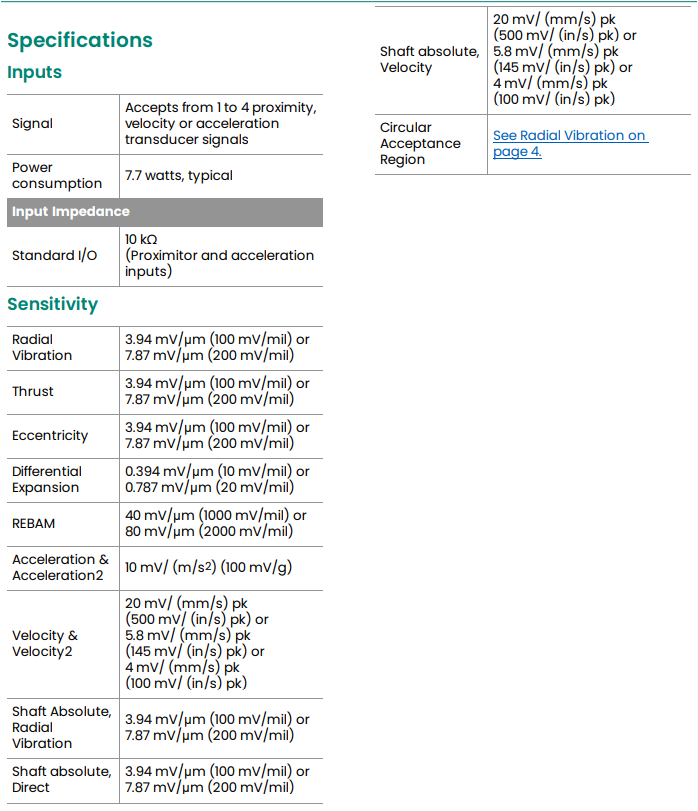

The high flexibility of the 3500/42M is a standout feature. Users can configure each channel via the 3500 Rack Configuration Software to perform one of several monitoring functions, including: Radial Vibration, Thrust Position, Differential Expansion, Eccentricity, REBAM, Acceleration, Velocity, Shaft Absolute Vibration, and Circular Acceptance Region. Similar to other monitors in the series, its four channels are managed and configured in "Channel Pairs," allowing a single module to execute two different monitoring functions simultaneously (e.g., Channels 1 & 2 for Radial Vibration, Channels 3 & 4 for Bearing Housing Velocity).

2. Core Features and Detailed Functional Principles

2.1 Core Function: Multi-Sensor Signal Fusion and Integrated Diagnostics

The core value of the 3500/42M lies in its ability to break the limitation of traditional monitors that only handle single sensor types, acting as an integrated data fusion center. Its workflow is as follows:

Multi-Type Signal Input and Power Supply: The module can accept signals from up to four sensors, which can be:

Proximity Transducers: For measuring shaft vibration and position relative to the bearing housing.

Accelerometers: For measuring high-frequency vibration acceleration of the bearing housing.

Velocity Transducers: For measuring mid-to-low frequency vibration velocity of the bearing housing.

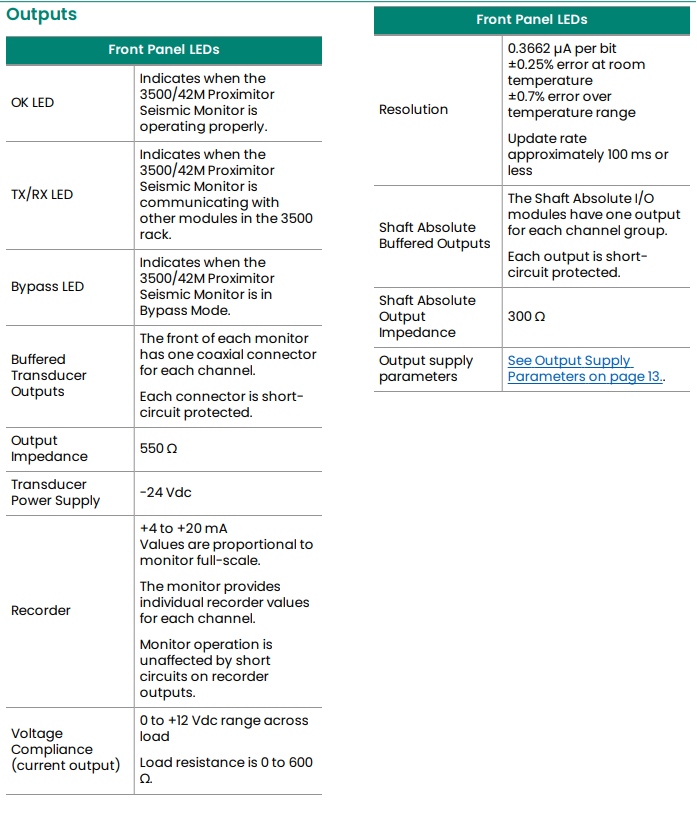

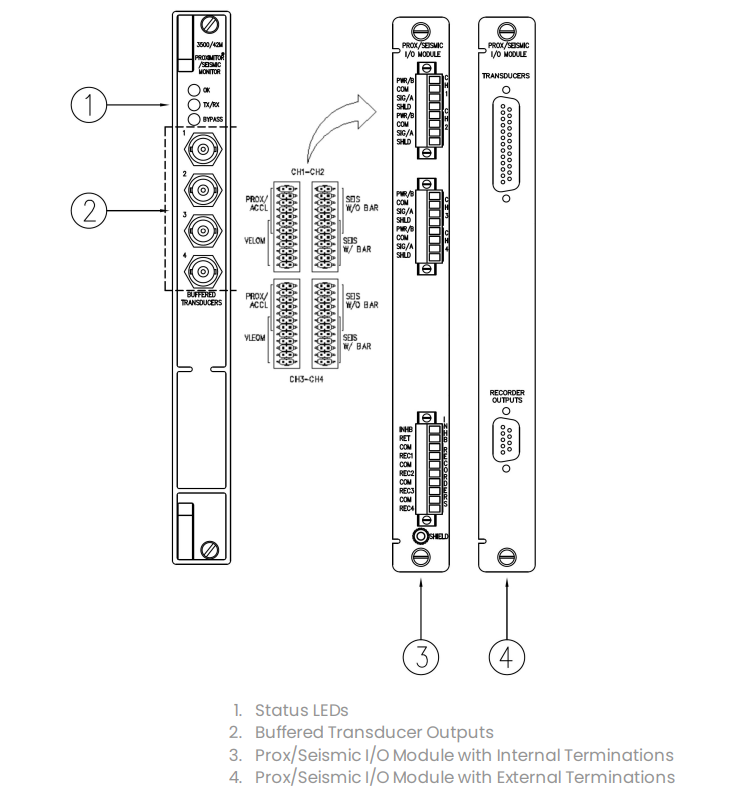

The module front panel provides a Buffered Transducer Output coaxial connector for each channel, supplies -24 Vdc excitation power for proximity transducers, and provides a constant current source or voltage source for accelerometers, simplifying system integration.

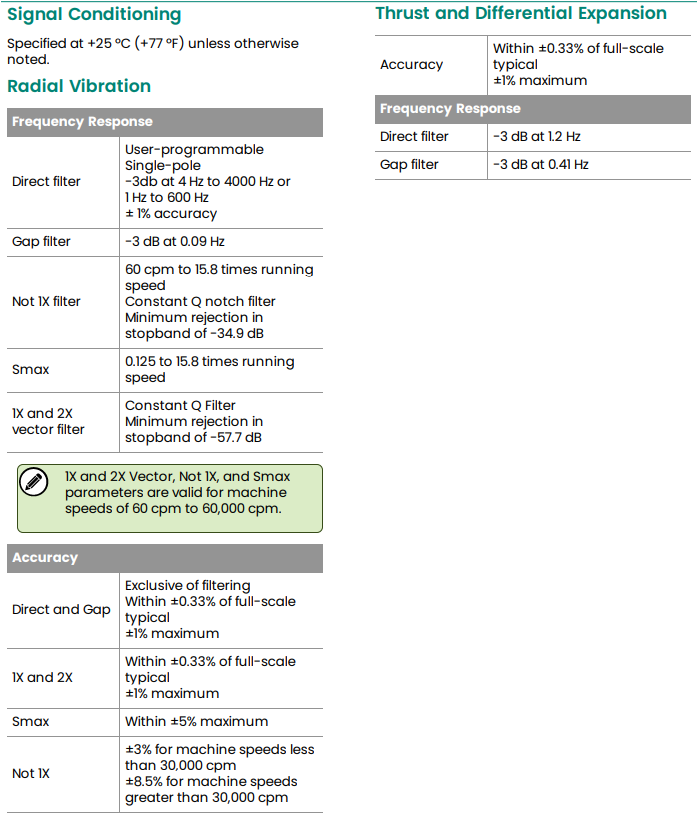

Dedicated Signal Conditioning Paths: For different sensor types and monitoring objectives, the module establishes parallel and independent signal conditioning paths. Each configuration corresponds to an optimized set of filter banks and algorithms, ensuring the extraction of the most relevant and accurate feature information from the raw signals.

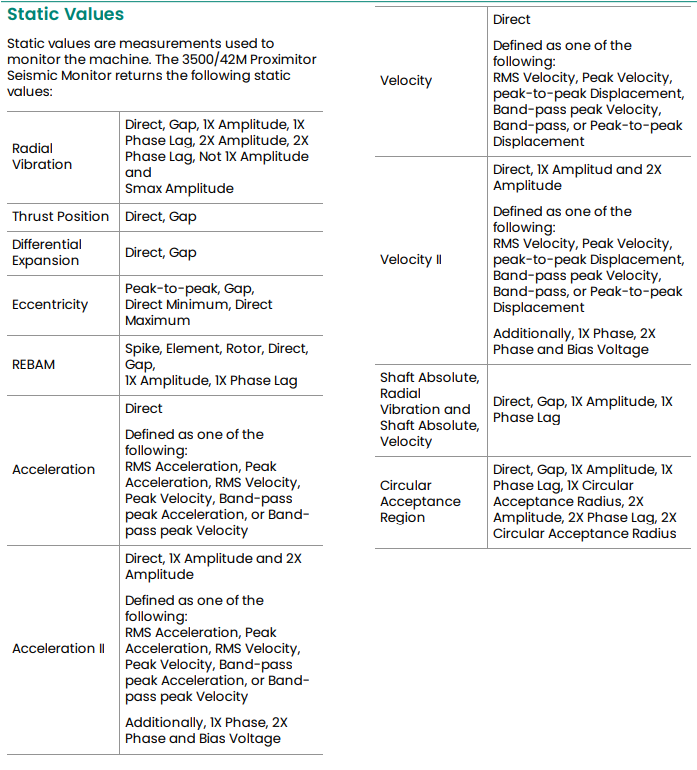

Static Values Calculation and Derivation: The conditioned signals are used to calculate key parameters known as Static Values. These values are the cornerstone for alarm decisions and equipment condition assessment. The 3500/42M can generate an extensive range of static values, for example:

A Radial Vibration channel can generate: Direct, Gap, 1X Amplitude/Phase, 2X Amplitude/Phase, Not 1X Amplitude, Smax Amplitude.

A Velocity II channel can generate: Direct (e.g., RMS/Peak Velocity), 1X Amplitude/Phase, 2X Amplitude/Phase, Bias Voltage.

The Shaft Absolute Vibration function uses internal algorithms to synthesize data from both proximity and seismic transducers, deriving the absolute vibration of the shaft.

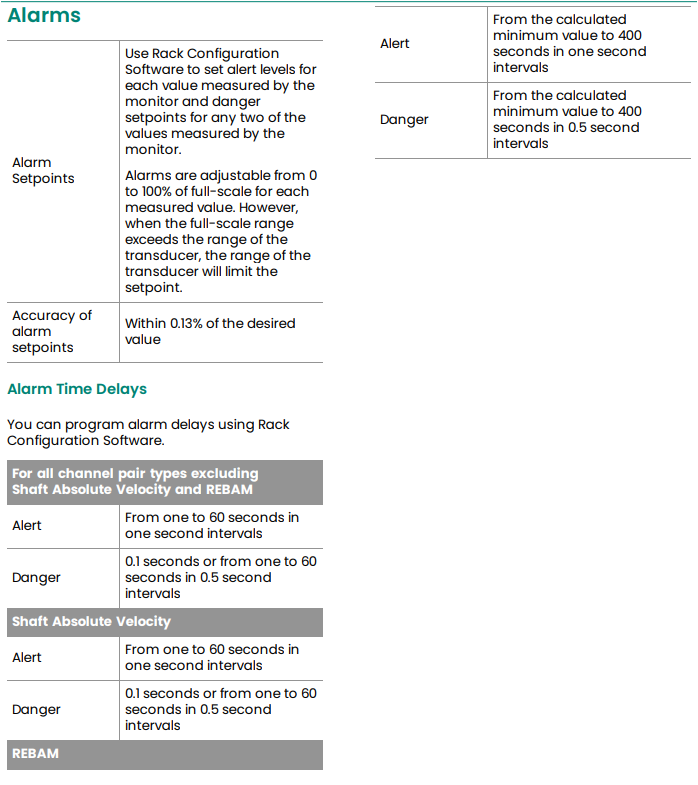

Alarm Management and Output: Users can set Alert alarms for each active static value and select any two of the most critical static values for Danger alarms. The module continuously performs comparisons and triggers alarm outputs upon exceedances. It also features programmable Alarm Time Delays (e.g., Alert: 1-60 seconds, Danger: 0.1 seconds or 1-60 seconds) to effectively prevent false alarms. Additionally, the module provides 4-20 mA Recorder Outputs for connection to DCS or recording devices.

2.2 Key Monitoring Functions: Working Principles and Technological Innovations

a) Shaft Absolute Vibration Monitoring

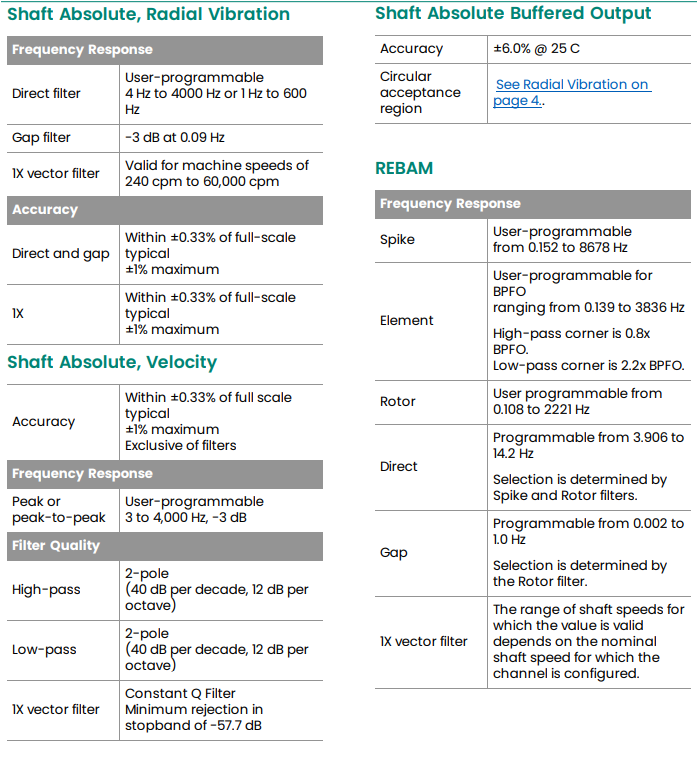

Principle: This is one of the most distinctive features of the 3500/42M. It uses vector summation to combine the signal from the proximity transducer (measuring shaft relative vibration) with the signal from the seismic transducer (measuring bearing housing absolute vibration), calculating the absolute vibration of the rotor relative to inertial space. The formula can be simplified as: Shaft Absolute Vibration = Shaft Relative Vibration + Bearing Housing Absolute Vibration.

Value: This parameter is crucial for units with flexible foundations (e.g., marine engines), lightweight structures, or significant high-frequency vibration. It more accurately reflects the actual vibration severity of the rotor, avoiding measurement distortion caused by case vibration, and is an advanced monitoring method compliant with API standards.

b) Seismic Signal Processing

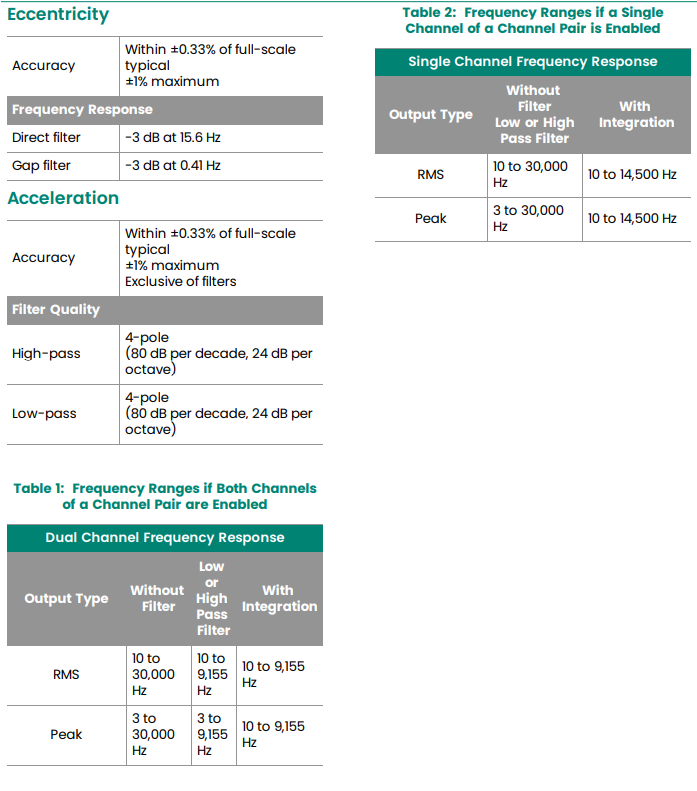

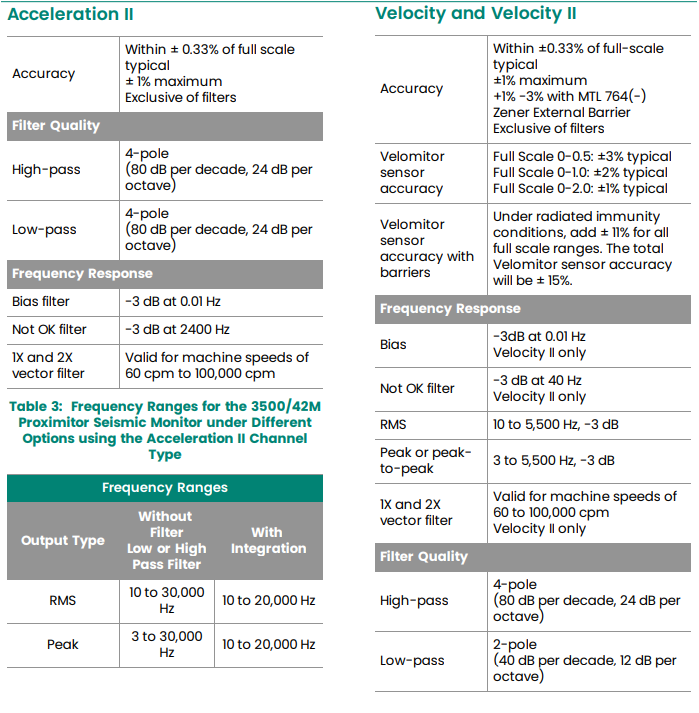

Acceleration Signal Processing: The module offers two acceleration processing modes.

Standard Acceleration Mode: Uses 4-pole high-pass and low-pass filters with a wide frequency response range (e.g., 10 Hz to 30,000 Hz for RMS output), suitable for capturing high-frequency impact signals, often used for early fault diagnosis in gearboxes or rolling element bearings.

Acceleration II Mode: Beyond basic processing, it can also provide 1X and 2X Vector components and Bias Voltage, and supports the Filter Tracking/Stepping function, making it suitable for scenarios requiring precise analysis of running speed-related vibration components.

Velocity Signal Processing: Similarly offers both Standard and Velocity II modes. The Velocity II mode possesses more powerful capabilities, including generating 1X and 2X Vectors, Bias Voltage, and supporting a wider machine speed range (60 to 100,000 cpm). The module internally uses digital integration circuits to integrate acceleration to velocity, or differentiate/integrate velocity to displacement, providing users with multiple vibration unit options (acceleration, velocity, displacement) for display and alarm selection.

c) Circular Acceptance Region

Principle: This is an advanced rotor balancing aid. It defines a circular "safe zone" on a polar plot (with 1X Amplitude as the radial coordinate and 1X Phase as the angular coordinate). The machine condition is considered acceptable when the endpoint of the rotor's 1X vibration vector lies within this circle.

Value: Compared to traditional single-amplitude alarms, CAR considers the combined effect of amplitude and phase, allowing more effective monitoring and warning of dynamic changes like rotor unbalance or thermal bow, especially during machine startup and coastdown, providing a more accurate condition assessment.

d) REBAM and Advanced Filtering Technology

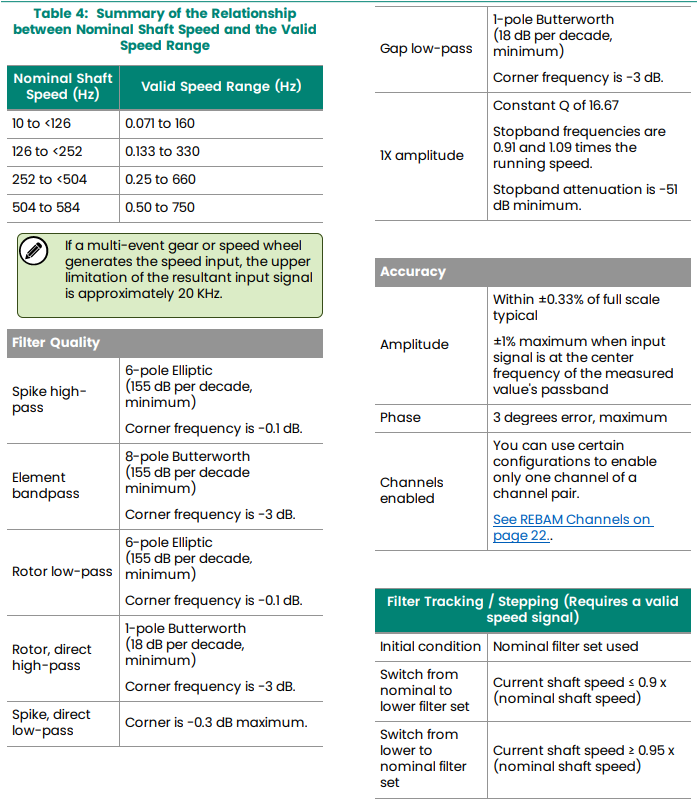

REBAM: Its principle is consistent with the 3500/40M, using a dedicated set of filters to extract the characteristic fault frequencies of rolling element bearings. The 3500/42M documentation further provides detailed configuration charts illustrating the maximum machine speed supported under different bearing roller counts and single/dual channel configurations, offering crucial reference for user setup.

Filter Tracking/Stepping: For speed-dependent filters, the module can automatically switch between preset "Nominal," "Lower," and "Higher" filter sets based on the actual shaft speed. For instance, it switches to the low-speed filter set when speed drops to 90% of the nominal value, and to the high-speed filter set when speed rises to 110% of the nominal value. This ensures that the filter's center frequency accurately tracks speed changes throughout the entire machine operating range, guaranteeing precise measurement of synchronous components like 1X and 2X.

2.3 Accuracy and Reliability Assurance

The 3500/42M delivers industry-leading measurement accuracy. At +25°C, for most Direct, Gap, 1X, and 2X Vector values, the typical accuracy is as high as ±0.33% of full scale, with a maximum error not exceeding ±1% of full scale. The phase measurement error for the 1X Vector is a maximum of 3 degrees. The accuracy of the alarm setpoints is within ±0.13% of the desired value. This high precision lays a solid foundation for reliable protection decisions and accurate fault diagnosis.

3. Hardware Architecture and Safety Features

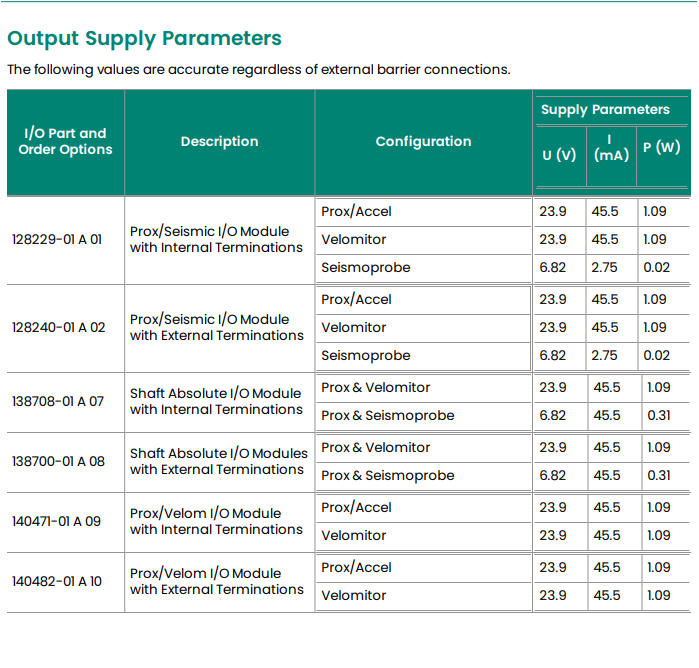

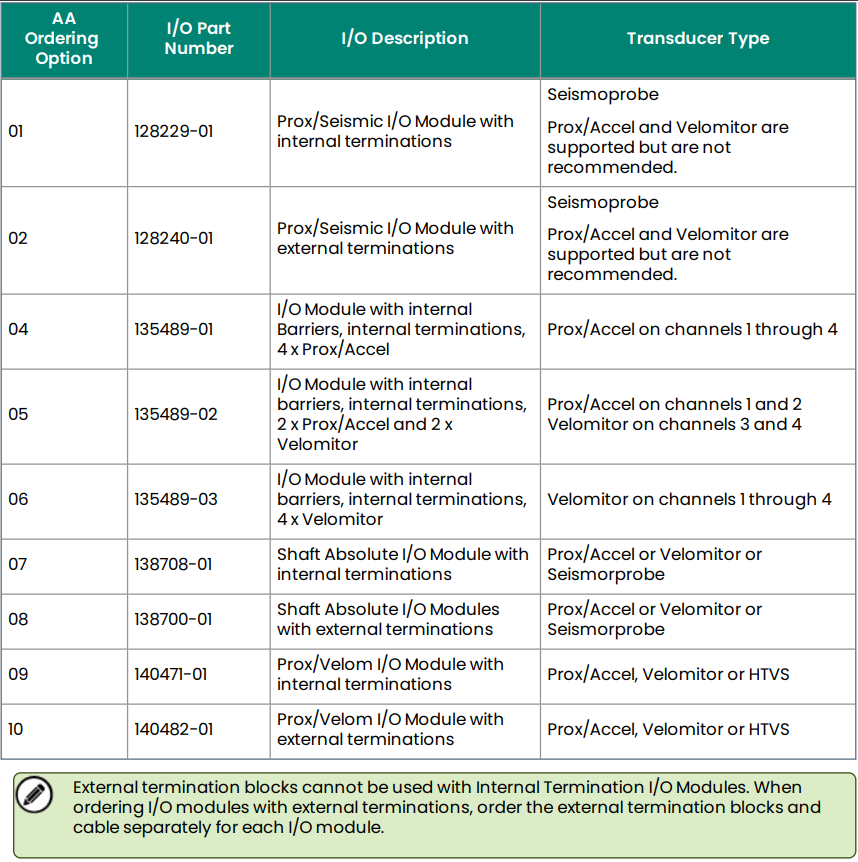

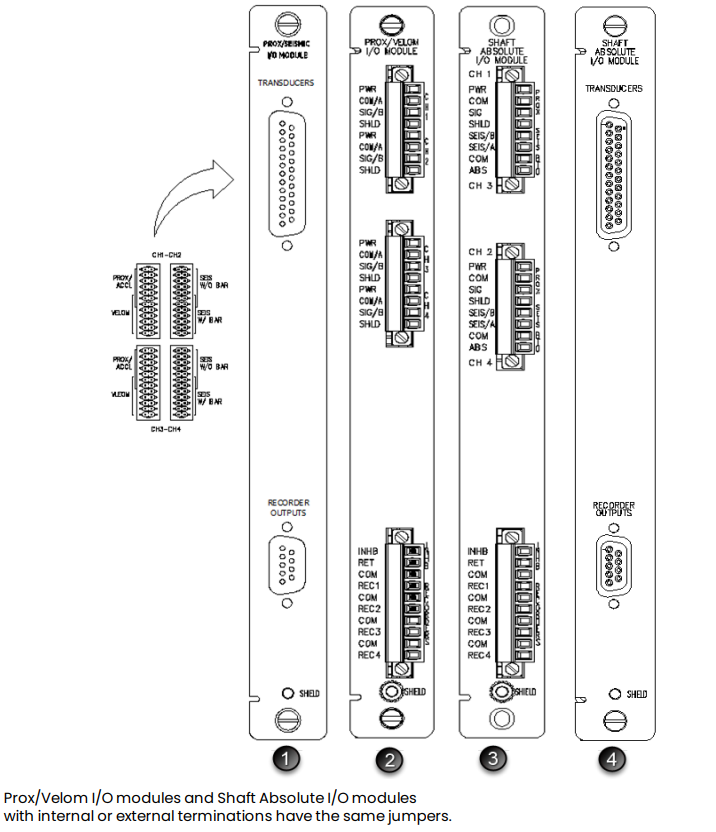

Modular Structure: Consists of a full-height Main Monitor Module and a matching I/O Module. A variety of I/O module types are available to meet different application needs:

Prox/Seismic I/O Modules: Support mixed connection of proximity and seismic transducers.

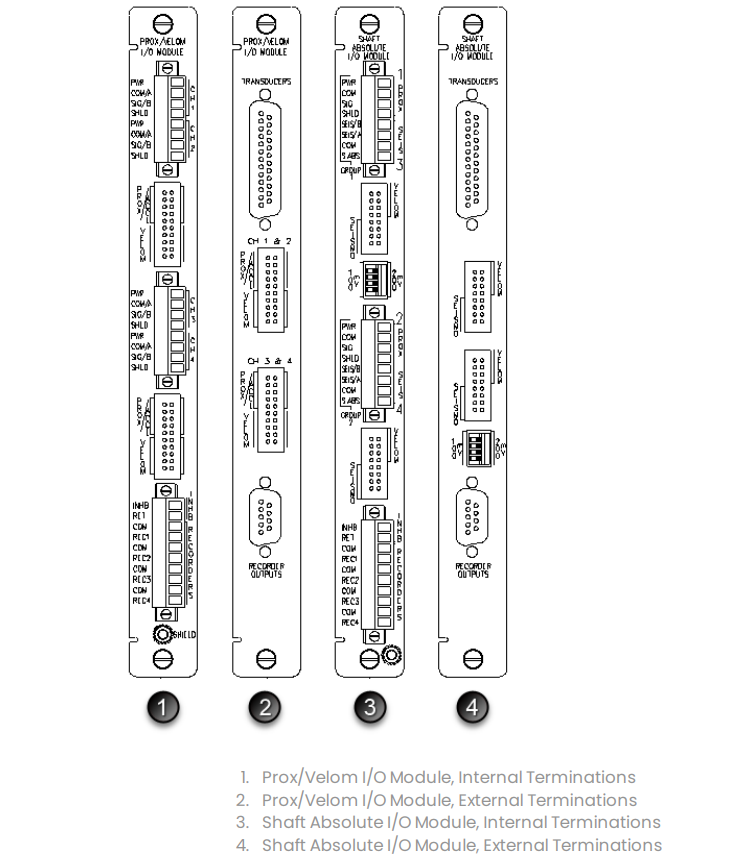

Shaft Absolute I/O Modules: Specifically designed for Shaft Absolute Vibration measurement, providing synthesized buffered outputs.

Prox/Velom I/O Modules: Dedicated for proximity and velocity transducers.

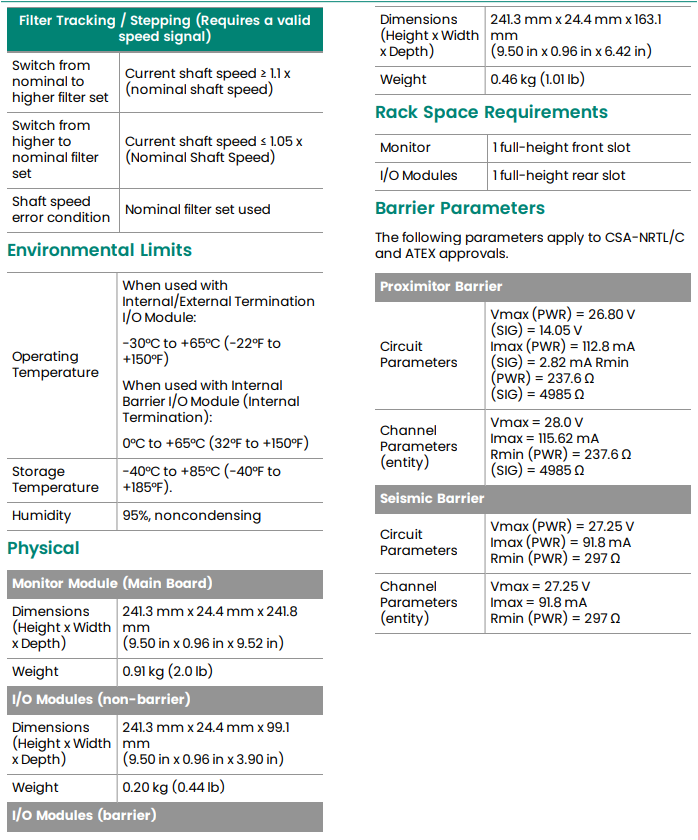

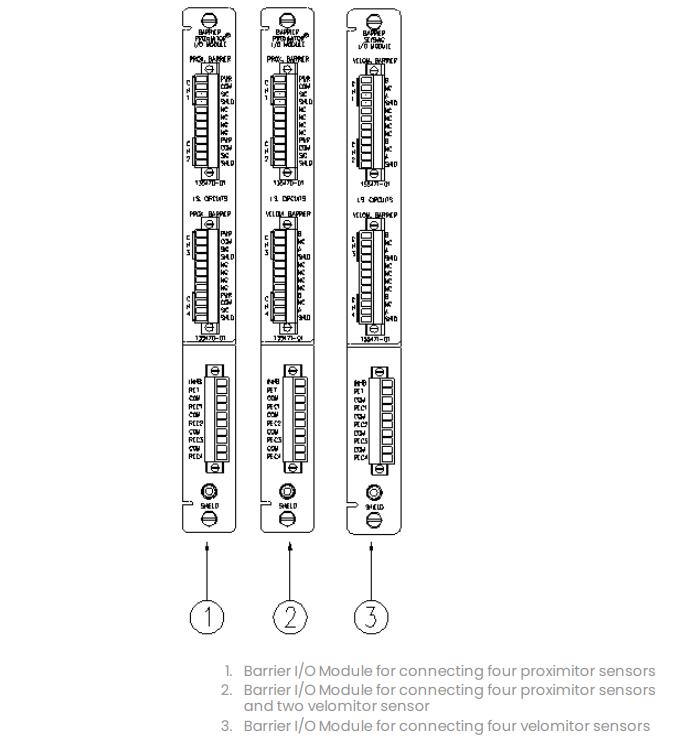

I/O Modules with Internal Barriers: Integrate intrinsic safety barriers, allowing direct use in Class I, Division 2 / Zone 2 hazardous areas, and are certified to stringent standards like cNRTLus, ATEX, and IECEx. The documentation details the barrier entity parameters (e.g., Vmax, Imax) for intrinsic safety system calculations.

Environmental Suitability: Wide operating temperature range: -30°C to +65°C with standard I/O modules, and 0°C to +65°C with Internal Barrier I/O modules, enabling adaptation to harsh industrial environments.

4. Application Scenarios

The 3500/42M is an ideal solution for complex monitoring requirements, widely used in:

Power Generation: Steam turbines, gas turbines, generators (simultaneously monitoring shaft and casing vibration).

Oil & Gas: Pipeline compressors, gas turbine-driven equipment.

Marine Propulsion Systems: Main turbines, gearboxes, and diesel engines, where foundation flexibility makes Shaft Absolute Vibration monitoring particularly important.

Chemical and Process Industries: Various large compressors and turbomachinery requiring comprehensive vibration analysis.