The 3500/64M Dynamic Pressure Monitor is a high-performance, industrial-grade dynamic pressure monitoring device under the 3500 Machinery Protection Systems, serving as a critical component of the 3500 series. This single-slot module provides four channels of dynamic pressure monitoring capability, specifically designed to accept input signals from high-temperature pressure transducers and drive alarm systems.

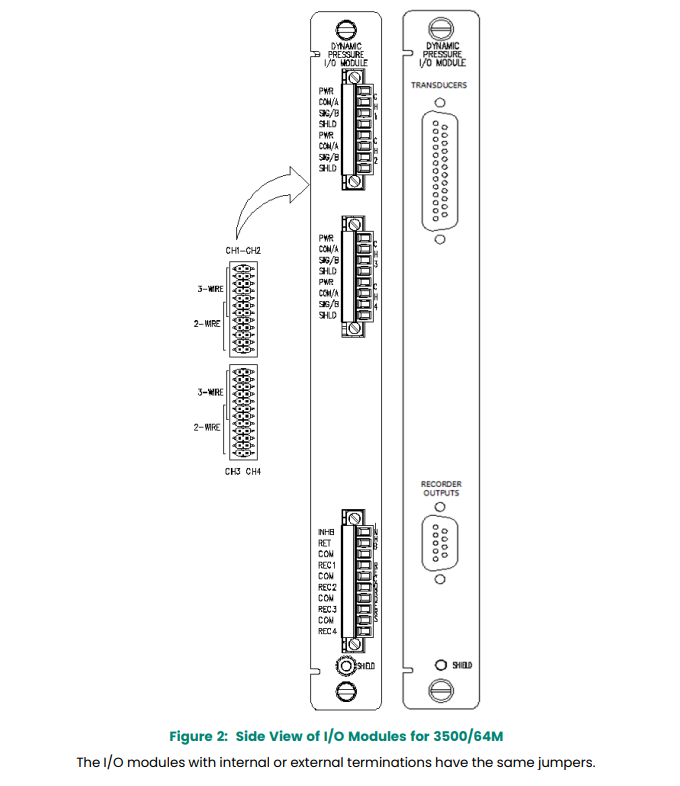

The 3500/64M consists of a fixed front module (P/N 176449-05) and two different types of rear I/O modules (refer to the Ordering page for details). The 176449-05 can form a complete system when combined with any one of the rear I/O modules.

The core monitoring variable of the 3500/64M is bandpass dynamic pressure, primarily used to provide machinery protection and deliver essential machine information to operations and maintenance personnel. Using the 3500 Rack Configuration Software, users can configure bandpass corner frequencies and additional notch filters to meet various complex monitoring requirements. The module also provides recorder output functionality for connectivity to control system applications.

Features & Functions

1. Multi-Channel Dynamic Pressure Monitoring

Provides 4 independent monitoring channels, each dedicated to monitoring bandpass dynamic pressure.

Supports 2-wire and 3-wire pressure transducer connection methods.

Offers high input sensitivity: 100 mV/psi (1.45 mV/mBar).

Each channel features a front-panel coaxial connector for buffered transducer output, equipped with short-circuit protection.

2. Advanced Signal Processing Capabilities

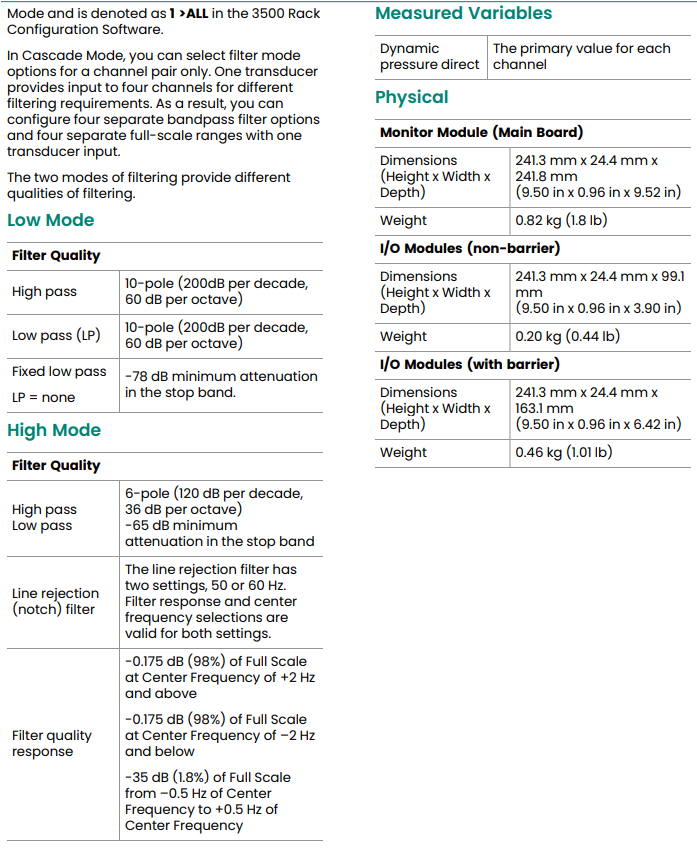

Offers two filtering modes: Low Mode (5 Hz to 4 kHz) and High Mode (10 Hz to 14.75 kHz).

Channels are configured in pairs (Channels 1-2 and Channels 3-4); channels within a pair must operate in the same filtering mode.

Supports line rejection (notch) filters with selectable center frequencies of 50 or 60 Hz.

Excellent filter characteristics: 6-pole design (120 dB/decade, 36 dB/octave) with a minimum stopband attenuation of -65 dB.

3. Cascade Mode Operation

Unique Cascade Mode (1 > ALL) allows a single transducer input to be distributed to all four channels.

In Cascade Mode, four different bandpass filter options and four different full-scale ranges can be configured for one transducer signal.

Significantly enhances system configuration flexibility and cost-effectiveness.

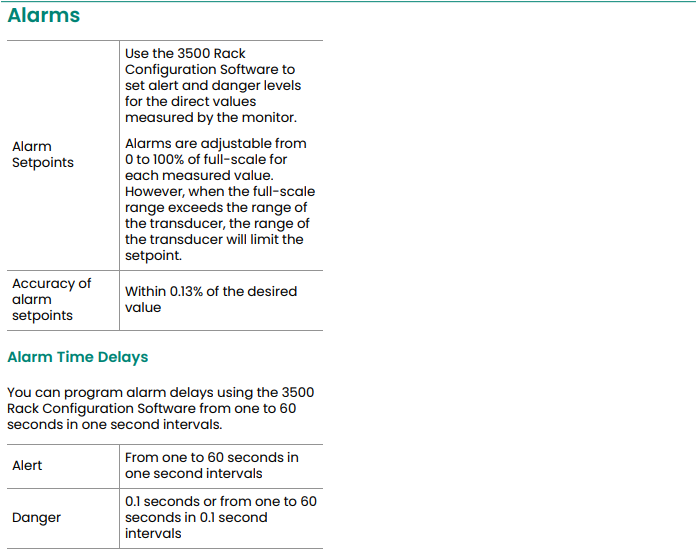

4. Programmable Alarm Function

Each channel supports independent dual setpoints: Alert and Danger.

High alarm setpoint accuracy: 0.13%, adjustable from 0 to 100% of full-scale.

Programmable alarm delays: Alert delay: 1-60 seconds (1-second increments); Danger delay: 0.1 seconds or 1-60 seconds (0.1-second increments).

Effectively prevents false alarms caused by transient interference.

5. Comprehensive Output Capabilities

Provides +4 to +20 mA recorder output for each channel independently.

Output value is proportional to the monitor's full-scale; load resistance: 0-600 Ω.

Voltage compliance: 0 to +12 Vdc; resolution: 0.3662 μA/bit.

Short circuits on recorder outputs do not affect normal monitor operation.

6. Transducer Power Supply Capability

3-wire transducer supply: -24 Vdc.

2-wire transducer supply: 3.3 mA current source @ 22 Vdc (nominal).

Optimized input impedance: 10 kΩ for 3-wire; 1.5-3.5 MΩ for 2-wire.

Working Principle

1. Signal Acquisition and Input Processing

Dynamic pressure signals are accessed through dedicated I/O modules. Signals from 2-wire transducers are received via a high-impedance (1.5-3.5 MΩ) input circuit, ensuring accurate signal acquisition, while 3-wire transducers use a 10 kΩ impedance matching design. The module provides stable excitation power: -24 Vdc voltage source for 3-wire and a 3.3 mA constant current source for 2-wire, ensuring reliable operation for various transducer types.

2. Signal Conditioning and Filtering Processing

Input signals first undergo pre-amplification and impedance matching before entering multi-stage filtering. The module offers two filter mode choices: Low Mode covers 5 Hz to 4 kHz, and High Mode covers 10 Hz to 14.75 kHz. The 6-pole filter design provides a roll-off of 120 dB/decade, ensuring minimum stopband attenuation of -65 dB. The unique notch filter effectively suppresses 50 Hz or 60 Hz power line interference, maintaining 98% of full-scale output at ±2 Hz from the center frequency and attenuating to 1.8% of full-scale at ±0.5 Hz from the center frequency.

3. Cascade Signal Distribution

In Cascade Mode, the input signal from Channel 1 is replicated to all four channels via an internal high-precision distribution network. Each channel can be independently configured with different bandpass filter parameters and full-scale ranges, enabling multi-dimensional analysis of the same physical quantity. This design allows users to extract multiple characteristic frequency components from a single high-quality transducer signal, significantly enhancing system analysis capabilities while reducing hardware costs.

4. Alarm Processing Logic

The filtered signal is compared in real-time against user-defined alarm setpoints. Digital filtering technology eliminates signal jitter, ensuring comparison accuracy. Alarm delay timers use an independent clock source for precise timing control. Alert and Danger alarms utilize different delay step accuracies (1-second and 0.1-second), balancing response speed and anti-interference capability. Alarm status is transmitted via backplane communication to the system framework, triggering corresponding relay actions and event logging.

5. Output Signal Generation

The module provides multiple output signals: Buffered transducer output provides an isolated signal with 550 Ω impedance via front-panel coaxial connectors; Recorder output generates a 4-20 mA analog signal via a high-precision DAC, with an update rate of approximately 100 ms ensuring real-time performance. All output circuits feature short-circuit protection, ensuring normal operation of the primary monitoring function is unaffected under fault conditions.

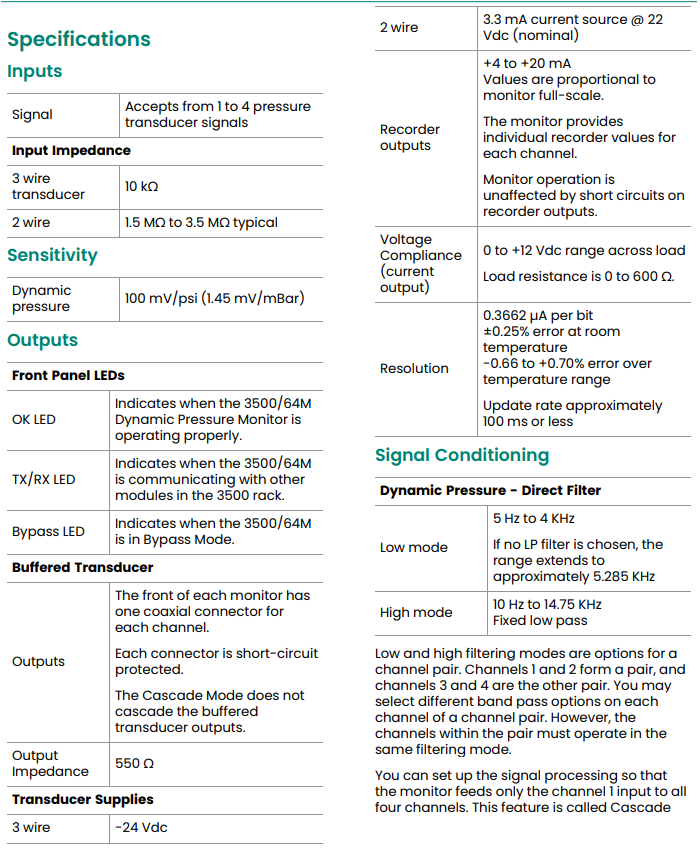

Technical Specifications

| Parameter | Specification |

| Monitoring Channels | 4-channel dynamic pressure monitoring |

| Input Signal | Pressure transducer signal |

| Input Sensitivity | 100 mV/psi (1.45 mV/mBar) |

| Input Impedance | 3-wire: 10 kΩ; 2-wire: 1.5-3.5 MΩ |

| Filtering Range | Low Mode: 5 Hz - 4 kHz; High Mode: 10 Hz - 14.75 kHz |

| Filter Characteristics | 6-pole filtering, 120 dB/decade, stopband attenuation -65 dB |

| Recorder Output | 4-20 mA, load capability 0-600 Ω |

| Output Impedance (Buffered) | 550 Ω |

| Transducer Power Supply | 3-wire: -24 Vdc; 2-wire: 3.3 mA @ 22 Vdc |

| Alarm Accuracy | ±0.13% of setpoint value |

| Alarm Delay | Alert: 1-60s (1s increments); Danger: 0.1s or 1-60s (0.1s increments) |

| Operating Temperature | -30°C to +65°C |

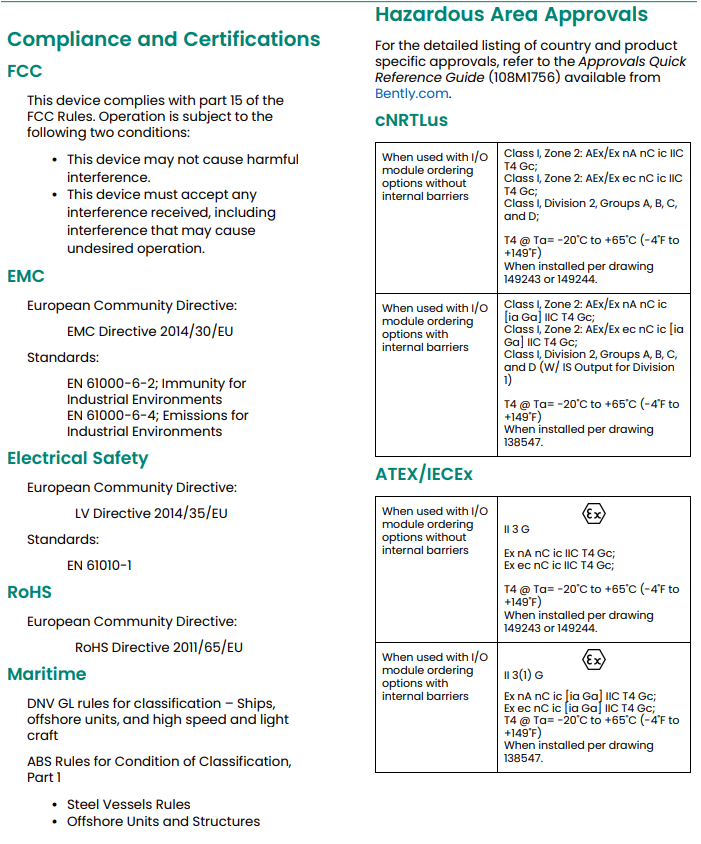

| Safety Certifications | ATEX, IECEx, CSA, CE, FCC, RoHS, DNV GL, ABS |

Application Scenarios

The 3500/64M Dynamic Pressure Monitor is particularly suitable for the following industrial scenarios:

Gas and Steam Turbines: Monitoring combustion chamber pressure fluctuations, airflow pulsations.

Compressor Systems: Detecting surge phenomena, airflow pulsations, valve vibrations.

Pump Equipment: Monitoring cavitation phenomena, fluid pressure pulsations.

Engine Testing: Cylinder pressure monitoring, combustion analysis.

Pipeline Systems: Detecting water hammer phenomena, flow pulsations.

Rotating Machinery: Monitoring blade pass frequency, vortex phenomena.