The IS200VVIBH1A assembly serves as the principal vibration monitoring and safeguarding element within the GE Mark VI turbine management framework. Functioning as the system's dedicated sensing apparatus, it executes the critical tasks of gathering, interpreting, and evaluating diverse vibration and positional data originating from vital turbine components, including bearings, shaft journals, and thrust collars. This module interfaces with TVIB or DVIB termination units, accommodating a maximum of fourteen distinct Bently Nevada® sensor variants—encompassing proximity transducers, velocity pickups, accelerometers, seismic sensors, and Keyphasor® probes—to deliver uninterrupted, high-fidelity surveillance of turbine operational integrity. Its fundamental objective is to preempt mechanical failure and uphold the secure and consistent performance of substantial rotational equipment by identifying aberrant oscillatory motions and positional deviations, thereby initiating prompt cautions or protective shutdown commands.

2. Core Operational Capabilities and Methodologies

The IS200VVIBH1A's operational scope significantly surpasses elementary signal gathering, embedding sophisticated processing routines and tiered safeguarding protocols deeply rooted in transducer technology, digital signal manipulation, and control system architecture.

2.1 Multi-Channel Data Acquisition and Conversion

This capability underpins all advanced system functionalities, establishing the IS200VVIBH1A as a high-performance, multi-input data collection unit.

Technical Execution:

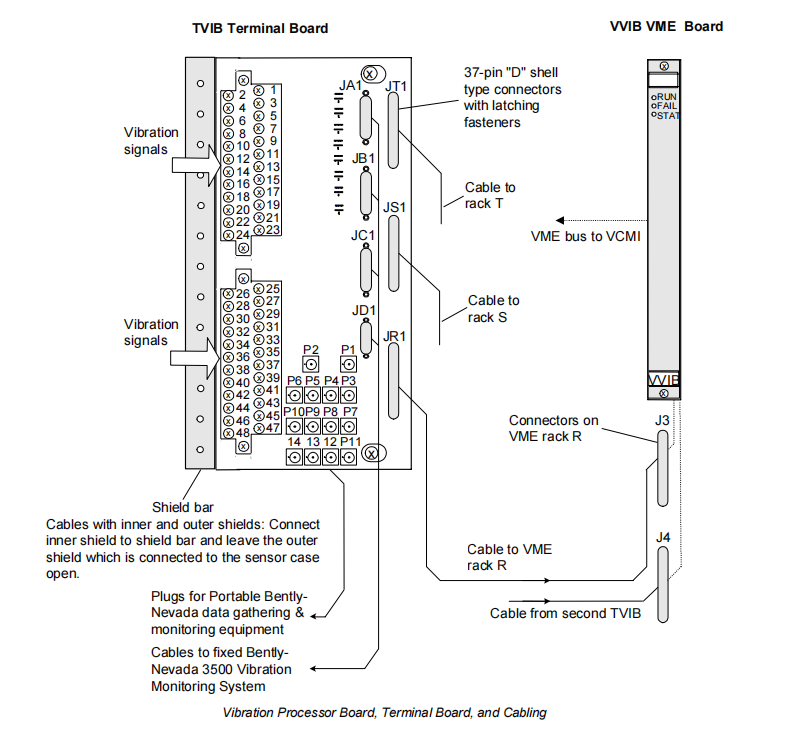

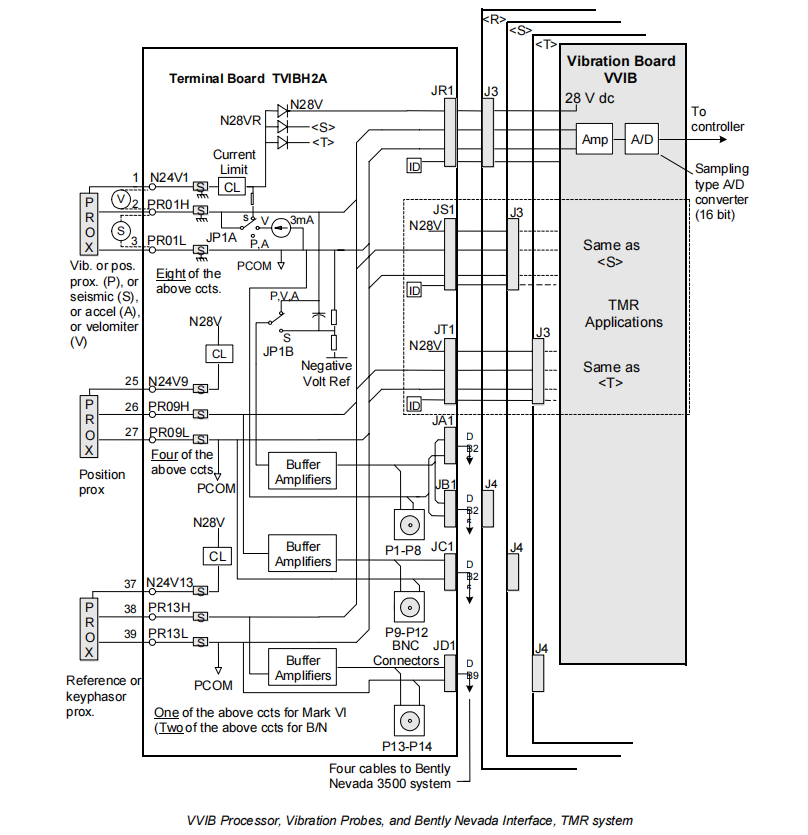

Connectivity and Scalability: A solitary IS200VVIBH1A processing card can interface concurrently with dual TVIB termination units, effectively amplifying the aggregate surveillance pathways to twenty-six. Individual TVIB units furnish thirteen distinct channels: eight allocated for oscillatory measurement, four for positional assessment, and one reserved exclusively for Keyphasor signaling, catering to complex machinery with multiple bearing points.

Signal Refinement and Power Distribution: TVIB units not only offer terminal connection points but also deliver the requisite -28 V DC excitation energy for active probes (such as Proximitors). Within TMR configurations, power supply redundancy is achieved through a diode high-selection network, safeguarding monitoring continuity against single-source power failure. Integrated buffer amplifiers perform initial conditioning on raw analog inputs from detectors, preserving signal fidelity over extended transmission paths.

Precision Analog-to-Digital Transformation: Conditioned analog waveforms are relayed to the IS200VVIBH1A card via shielded conduits. The board utilizes a 16-bit successive approximation A/D converter (providing 14-bit effective resolution) to perform high-velocity, concurrent sampling across all input paths. Sampling frequency adapts dynamically to active channel count: a 4.6 kHz rapid scan mode operates with eight or fewer active vibration channels, descending to 2.3 kHz for higher channel counts to maintain processing equilibrium. This synchronous data capture mechanism is fundamental for accurate subsequent phase scrutiny and peak value identification.

2.2 Vibration and Displacement Parameter Derivation

The IS200VVIBH1A's essential processing routines transform digitized primary signals into actionable engineering parameters through sequential computational stages.

Technical Execution:

Peak-to-Peak Determination and Signal Conditioning: For oscillatory data (paths 1-8), the system employs a 160-millisecond temporal window to encapsulate signal dynamics. The firmware persistently records the signal's upper (Vmax) and lower (Vmin) extremes within this period, computing their differential as the raw peak-to-peak magnitude (Vpp). To enhance signal clarity and isolate specific frequency bands, the data traverses configurable digital filters. The selection of filter characteristics (FilterType) is sensor-dependent, offering No Filter, Low-pass, High-pass, or Band-pass options. For seismic and velocity transducers, configurable filters with up to 8-pole steep attenuation are available for precise frequency response shaping.

Gap/Position DC Element Isolation: Proximity probe outputs comprise a DC element (indicating mean clearance or position) superimposed on an AC element (representing vibration). A second-order low-pass filter with 8 Hz cutoff cleanly extracts the DC component for positional monitoring applications like rotor axial displacement, differential expansion, and eccentricity.

Engineering Unit Transformation: Derived voltage parameters (both AC Vpp and DC Vgap) are converted into physically meaningful units via user-defined scaling multipliers (VIB_Scale) and baseline adjustments (ScaleOff), for instance, mils for displacement and inches/second for velocity, enabling direct interpretation by control algorithms and operational staff.

2.3 Keyphasor Interpretation and Rotational Velocity Assessment

Channel 13 is specially engineered for Keyphasor signal interpretation, forming the basis for sophisticated vibration diagnostics.

Technical Execution:

Keyphasor Operating Principle: This component typically consists of a proximity detector aligned with a shaft keyway or raised feature. Each passage of the feature past the probe generates a distinct gap variation, producing a reference pulse corresponding to each rotational cycle.

Pulse Identification and Velocity Computation: A hardware comparator circuit featuring software-adjustable hysteresis precisely detects the rising edge of each Keyphasor pulse. These timing markers are processed by an FPGA, where embedded chronometers measure inter-pulse duration with high accuracy. The firmware translates this interval into immediate rotational velocity (RPM). During very low-speed operation where hardware comparison becomes inconsistent, the operational code analyzes the fundamental gap signal on channel 13 (GAP13_KPH1) for pulse enumeration, guaranteeing speed measurement integrity across the entire operational spectrum.

2.4 Advanced Oscillation Diagnostics (1X, 2X, and Adaptive Filters)

The IS200VVIBH1A provides capabilities exceeding basic overall vibration tracking, enabling decomposition of vibration vectors for diagnostic insights.

Technical Execution:

Modulation and Filtering Stages: The primary vibration signal (e.g., from channel 1) is multiplied by sine and cosine reference waveforms generated from the Keyphasor signal (at 1X or 2X rotational frequency). This procedure shifts the vibration component at the target frequency down to a DC level, while other spectral constituents are shifted to higher frequencies.

Vector Component Resolution: The modulated outputs pass through an exceptionally narrow low-pass filter (0.25 Hz cutoff, 4-pole), eliminating high-frequency artifacts and yielding two DC signals representing the real and imaginary constituents of the 1X vibration vector.

Amplitude and Phase Angle Calculation: The peak magnitude (Vib1Xy) of the 1X vibration is derived from the square root of the summed squares of the vector components. The phase angle (Vib1xPHy) between the vibration vector and the Keyphasor reference is obtained from the arctangent of the component ratio, providing crucial data for identifying rotor imbalance or misalignment orientation.

1X and 2X Vibration Vector Analysis: This functionality determines the amplitude and phase relationship of vibration components synchronized with (1X) or at twice (2X) the operational speed, utilizing synchronous demodulation (phase-sensitive detection) technology.

Adaptive Tracking Filters: Designed for applications such as LM series gas turbines employing accelerometers, this function operates similarly to 1X/2X analysis but dynamically follows three independent speed references (LM_RPM_A, B, C) supplied by the controller. It extracts the vibration amplitude (LMVibxA, B, C) at these specified velocities in real-time, proving particularly valuable for monitoring multi-shaft arrangements or vibrational characteristics during transit through critical speeds.

2.5 Tiered Protection and Threshold Monitoring

All processed information ultimately feeds into the protection schema.

Technical Execution:

Configuration Flexibility: Operators can activate (SysLimxEnable), define threshold values (SysLimitx), choose comparison logic (≥ or ≤, SysLimxType), and set latching behavior (SysLimxLatch) for each limit. The latching feature ensures that an activated alarm state persists until manual acknowledgment, preventing oversight of transient anomalies.

Operational Implementation: These thresholds initiate graduated responses: exceeding Limit1 may trigger a warning alert for maintenance awareness, while surpassing the more critical Limit2 typically commands an immediate unit shutdown to prevent severe damage.

System Threshold Verification: Every vibration and position channel includes two fully configurable system limit modules.

Intelligent Malfunction Management: The architecture incorporates logical interlocks. For example, identification of a probe fault based on DC component analysis (e.g., open circuit) can automatically disable the vibration trip based on the AC component, averting unnecessary shutdowns stemming from sensor integrity issues rather than genuine mechanical distress.

3. Physical Specifications and Interfacing

Input Capacity: Accommodates up to two TVIB termination units, providing twenty-six total monitoring paths.

Sensor Support: Fully compatible with Bently Nevada proximity, velocity, accelerometer, seismic, and Keyphasor probes.

Signal Digitization: 16-bit A/D converter, supporting simultaneous sampling at rates up to 4.6 kHz.

Power Provision: Supplies redundant -28 V DC power for Proximitors on the termination units.

Physical Interconnection: Communicates with the VME rack controller and termination units via latching 37-pin "D"-subminiature connectors.

Auxiliary Outputs: The TVIBH2A termination unit provides BNC ports for routing buffered signals to external portable data collection devices or permanent Bently Nevada 3500 monitoring systems, facilitating data duplication and specialized analysis.

4. System Diagnostics and Integrity Verification

The IS200VVIBH1A incorporates comprehensive self-testing and system diagnostic functions.

Hardware Health Monitoring: Continuously verifies A/D converter calibration integrity for measurement precision; validates termination unit ID chips to prevent configuration errors; scans input signals for fault conditions (open or short circuit).

Operational Status Indication: Front-panel LEDs provide immediate visual status for power, operational readiness, communication links, diagnostic alerts, and thermal warnings.

Software Diagnostic Reporting: All system limit states and probe fault data are accessible to the Mark VI controller via specific variables (e.g., L3DIAG_VVIB) and can be displayed and archived within the WorkstationST environment, supporting efficient troubleshooting and operational analysis.