The IS200TRLYH1B Relay Output Terminal Board (with Coil Sensing) is a critical digital output interface component within General Electric's (GE) Mark VI and Mark Vle gas turbine control systems. It is designed for industrial field control applications requiring high-reliability electrical isolation and high-power driving capability, serving as a "bridge" and "guardian" between the controller and field actuators such as solenoid valves, motor contactors, indicator lights, ignition transformers, etc.

The core of this board lies in its integration of 12 plug-in magnetic latching relays and the unique coil sensing technology, enabling real-time and precise monitoring of the relay's operational status (whether the coil is energized), rather than solely relying on command issuance. This design significantly enhances the reliability and maintainability of the output circuit, ensuring the control system can "know" whether its commands have been correctly executed. The IS200TRLYH1B supports flexible configuration: its first six outputs can be configured via jumpers as dry contacts (passive contacts) or solenoid driver circuits; the next five are standard dry contacts; and the 12th output is reserved for high-current special applications (e.g., ignition transformers), perfectly adapting to the diverse load requirements in gas turbine control systems.

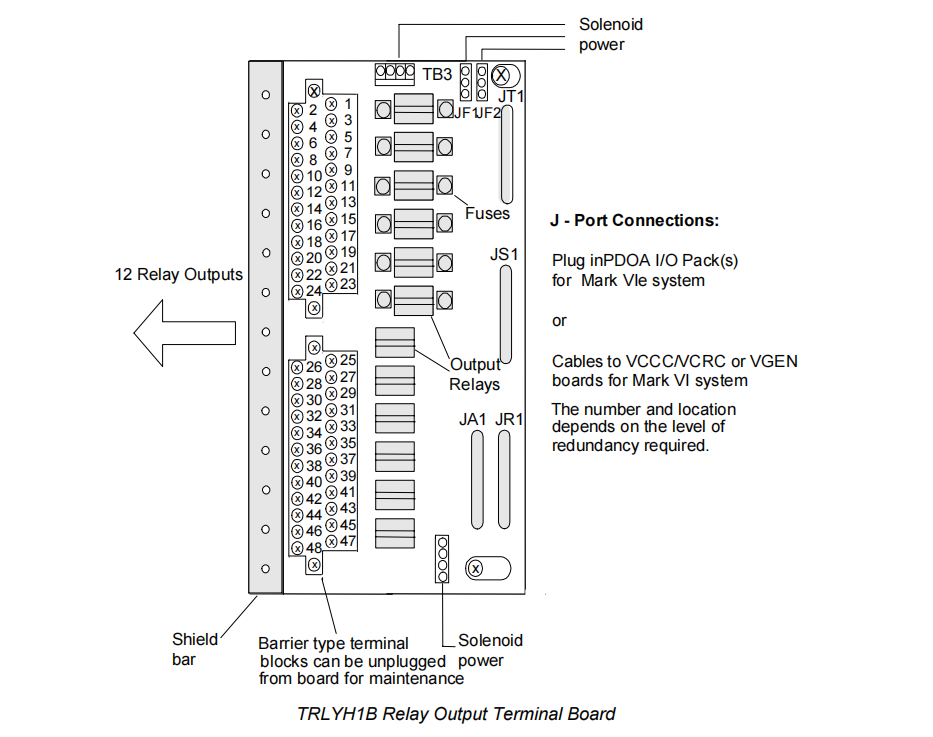

The board design fully considers the harshness of industrial environments, incorporating built-in fuses, transient suppression devices (MOVs), and high-frequency snubbers, providing robust overcurrent and overvoltage protection. It is compatible with both Simplex and Triple Modular Redundancy (TMR) system architectures, communicating with I/O processor boards such as VCCC, VCRC, VGEN, or PDOA via different connectors (JA1 for Simplex, JR1/JS1/JT1 for TMR), ensuring comprehensive coverage from basic applications to the highest safety-level applications.

Core Functions and Features

The IS200TRLYH1B integrates multiple advanced features, making it excel in the field of industrial control outputs:

1. Twelve-Channel Flexible Output Configuration:

Channels 1-6 (Configurable Channels): This is the most flexible part of the board. By installing or removing jumpers (JP1-JP6), each channel can be switched between two modes:

Solenoid Driver Mode: When the jumper is installed, this circuit provides an external power source (connected via JF1/JF2/TB3), which, via onboard fuses (FU1-FU6 & FU7-FU12) and relay contacts, directly drives field inductive loads like solenoid valves. Onboard Metal Oxide Varistors (MOVs) provide transient voltage suppression.

Dry Contact Mode: When the jumper is removed, the relay provides only a set of isolated, passive Form-C (Normally Open/Normally Closed/Common) contacts. The user connects external power and load, suitable for switching signal transmission or driving low-power devices.

Channels 7-11 (Standard Dry Contacts): These five channels provide purely electrically isolated Form-C dry contact outputs with no internal power supply or monitored power, dedicated to low-power control signals requiring complete electrical isolation.

Channel 12 (Special Application Channel): This is an independent Form-C contact output with a dedicated power interface (JG1). Its relay contacts have a higher-rated capacity (e.g., supports ignition transformers: 6A @115VAC or 3A @230VAC), typically used for special critical equipment like gas turbine ignition requiring high instantaneous current.

2. Advanced Coil Sensing and Diagnostics:

Core Monitoring Function: The core value of the IS200TRLYH1B lies in its "coil sensing" capability. The I/O processor board not only sends commands to "close" or "open" the relay but also reads the actual current flowing through the relay coil in real-time via a monitoring circuit.

Command-Feedback Verification: The system compares the feedback signal of the coil current with the issued command every control cycle (frame rate). If a mismatch between command and feedback is detected for two consecutive cycles (e.g., command to close but no coil current, or command to open but current persists), the system latches a diagnostic alarm. This effectively detects issues like relay coil open circuit, drive circuit failure, fuse blown, or power loss, achieving true "closed-loop" output diagnostics.

Power Supply Voltage Monitoring: For channels configured as solenoid drivers (1-6), the board also monitors the voltage on the power supply bus after the fuses. If the voltage drops below a threshold (e.g., below 12V DC), an alarm is also triggered, indicating a power supply fault.

3. Comprehensive Safety and Protection Mechanisms:

Fail-Safe Design: When a communication cable is unplugged or communication with the associated I/O processor is lost, the system forces the corresponding relay to de-energize via internal logic voting, returning it to a safe state (typically open). This is a crucial fail-safe feature.

Multiple Electrical Protections:

Fuse Protection: Each solenoid driver circuit (Channels 1-6 and 12) is equipped with dual fuses (e.g., Output 1 corresponds to FU1 and FU7), providing reliable overcurrent protection.

Transient Suppression: A 250V Metal Oxide Varistor (MOV) is connected in parallel between the Normally Open contact and the power return terminal for relays in Channels 1-6, effectively absorbing transient high voltages generated when inductive loads are switched off, protecting relay contacts and downstream circuits.

High-Frequency Snubbers (explicit in TRLYH1C version, similar design considered in H1B): High-frequency snubbers across the NO and SOL terminals in solenoid driver circuits suppress high-frequency noise and voltage spikes.

TMR System Diode-OR Power Sharing: In TMR applications, all three I/O processors (R, S, T) provide relay coil power. These power sources are "OR-ed" together via diodes, ensuring that the relay receives drive power as long as any one of the three processor power supplies is healthy, greatly enhancing power supply redundancy.

4. Robust Compatibility and Maintainability Design:

Wide-Range Power Supply Support: External solenoid driver power supports multiple standard industrial power sources: 125 V DC, 24 V DC, 115 V AC, or 230 V AC, with a maximum load current capability of 3.0A (AC/24VDC) or 0.6A (125VDC). Connection is flexible via TB3 terminals or pluggable connectors (JF1/JF2).

Modularity and Easy Maintenance: Relays are plug-in type for easy replacement. The barrier-type terminal blocks can be unplugged from the board, facilitating maintenance or board replacement without disconnecting wires. All jumpers and fuses are plug-in type for intuitive configuration.

Hardware Identification: Connectors (JR1, JS1, JT1, JA1) have built-in read-only ID chips storing the terminal board's serial number, type, revision, and location information. The I/O processor reads and verifies this information upon startup. A mismatch with the configuration results in a hardware incompatibility fault, preventing incorrect installation.

Working Principle

The workflow of the IS200TRLYH1B is a complete closed-loop process from digital command to physical action to status feedback verification.

1. Command Reception and Voting (in TMR Systems):

Simplex System: The I/O processor (e.g., VCCC) sends the 12 relay on/off commands, generated by the control logic, directly to the corresponding relay driver circuits on the TRLYH1B via the JA1 connector.

TMR System: Three redundant I/O processors (R, S, T) send their respective control commands to the TRLYH1B via connectors JR1, JS1, and JT1. The logic circuit on the board (or within the I/O processors before sending) performs a "2-out-of-3" or similar safety voting on the three command sets. Only the command achieving a majority consensus (typically 2/3) is allowed to execute, thereby masking random errors from a single processor. This is a key step in achieving high-reliability TMR architecture.

2. Relay Driving and Load Control:

The validated effective command acts on a solid-state relay driver chip or transistor circuit, controlling the current flowing through the coil of the corresponding electromechanical relay.

For Channels Configured as Solenoid Drivers (1-6, jumper installed):

When the drive circuit conducts, the relay coil is energized, its internal mechanical mechanism actuates, switching the Form-C contact state (Common COM connects from Normally Closed NC to Normally Open NO).

At this point, the power provided by the external supply terminals (e.g., P125/24V DC introduced via JF1) forms a complete circuit through the now-closed relay contacts (NO-COM) and the series-connected fuse, driving the field solenoid valve connected to the "SOL" terminal.

The onboard MOV, connected in parallel between the NO contact and the power return, is ready to absorb back-EMF spikes from the load inductance.

For Channels Configured as Dry Contacts (1-6 jumper removed, and 7-11):

The relay coil is similarly energized or de-energized based on the command, controlling the physical state of its Form-C contacts.

The user needs to connect the external load and power source in series to the "COM", "NO", "NC" terminals provided on the terminal block. The board does not provide power internally; it acts only as a reliable, electrically isolated switch.

3. Coil Status Sensing and Diagnostics (Core Principle):

A precision sense resistor (or other non-inductive sensing technique) is connected in series within the relay coil circuit. When coil current flows, it creates a small voltage drop across this resistor proportional to the current.

This voltage signal is acquired and conditioned (possibly including filtering, amplification) by a dedicated monitoring circuit, then sent back in real-time to the I/O processor board via dedicated feedback lines on the connector (JA1 or JR1/JS1/JT1).

The I/O processor's internal firmware performs the following diagnostics every control cycle:

Consistency Check: Compares the received coil current/voltage feedback signal (typically converted to a "high/low" level or digital value) with the relay command issued for that cycle. When the command is "ON," the feedback should indicate "current present"; when "OFF," it should indicate "no current."

Fault Determination: If a mismatch occurs for two consecutive cycles, a fault is declared for that relay output channel, and the corresponding diagnostic bit is set. This design effectively filters out occasional electrical noise.

Power Supply Monitoring: For solenoid driver circuits, the processor also monitors the power supply voltage signal fed back from the board to ensure it is within the valid range (e.g., >12V DC).

4. Fail-Safe and Failure Handling:

Communication Loss: If the I/O processor detects a communication link interruption with the TRLY board (e.g., cable fault), or if a processor in a TMR system goes offline, the system logic treats this as one of the most dangerous faults. In response, the I/O processor (or the board's own logic) triggers the safe-state drive for all related relays, typically removing the drive signal to de-energize the relay coils, allowing the contacts to return to their safe open (or normally closed) position, thereby preventing the equipment from being in an uncontrolled state.

Diagnostic Reporting: The individual diagnostic status of all channels (coil disagreement, power undervoltage), along with board-level faults like communication errors and ID verification failures, are aggregated into a composite diagnostic signal (e.g., L3DIAG_xxxx) reported to the main controller. Detailed fault codes and descriptions are provided in the engineer station's Toolbox software, guiding maintenance personnel to quickly locate the issue, such as replacing a fuse, relay, or checking field wiring.

Key Differences from the IS200TRLYH1C Version

The IS200TRLYH1C/H2C variants mentioned at the end of the document are derivatives of the IS200TRLYH1B, with the main design changes being:

Replaces Coil Monitoring with Contact Voltage Monitoring: H1C/H2C removed the coil current monitoring function for relays and instead added monitoring of the voltage across the relay output contacts. This allows direct confirmation of whether the load circuit is actually opened or closed, suitable for applications with extremely high requirements for verifying contact status.

Removes Some Configuration Jumpers: Removed the jumper option to configure the first 6 channels as dry contacts; these circuits are fixed as solenoid driver modes.

Standard High-Frequency Snubbers: High-frequency snubbers are standardly equipped in the driver circuits.

Therefore, the core advantage of the IS200TRLYH1B lies in its preventive diagnostics on the health of the drive side (coil), while the IS200TRLYH1C focuses on verifying the actual state of the load side (contacts). Users can choose based on the specific application's safety philosophy and diagnostic needs.

Application and Summary

The IS200TRLYH1B Relay Output Terminal Board is the execution endpoint for critical functions such as gas turbine start-up sequencing control, fuel valve control, auxiliary system start/stop, alarms, and indications. Its coil sensing technology upgrades traditional "open-loop" digital output to "closed-loop" monitoring, achieving a leap from "command sent" to "command execution confirmed," significantly enhancing the control system's transparency and reliability. Combined with its flexible configuration, robust protection, seamless integration with TMR architecture, and comprehensive diagnostics, the IS200TRLYH1B is not merely a command-executing switch but a cornerstone safeguarding the safe and reliable operation of the entire control system. Whether in new projects or retrofit upgrades, it is an indispensable high-performance output solution for building highly available industrial automation systems.