The IS200VTCCH1C Thermocouple Input Board is a high-precision temperature signal acquisition and processing core component within General Electric's (GE) Mark VI and Mark Vle gas turbine control systems. In gas turbines, steam turbines, and various industrial process controls, temperature monitoring of critical locations (such as turbine inlet temperature, bearing temperature, exhaust temperature, etc.) is paramount, directly impacting equipment safety, efficiency, and lifespan. The IS200VTCCH1C board is precisely designed for such demanding applications. It is responsible for high-precision acquisition, amplification, linearization, cold junction compensation, and final conversion of the weak millivolt (mV)-level voltage signals generated by field thermocouple sensors into accurate digital temperature values, which are then provided to the control system for monitoring, regulation, and protection.

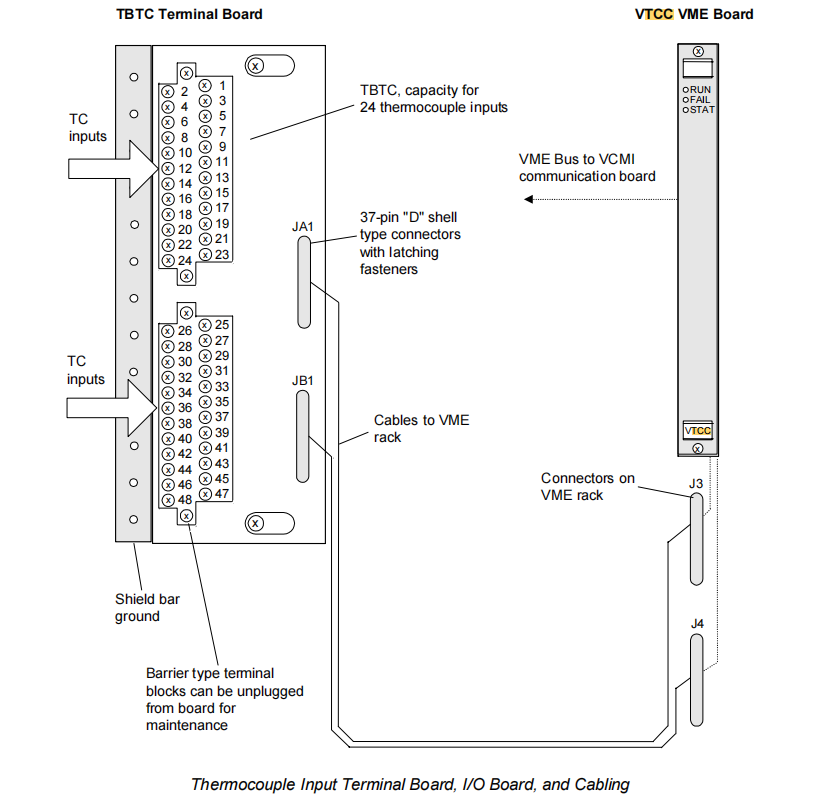

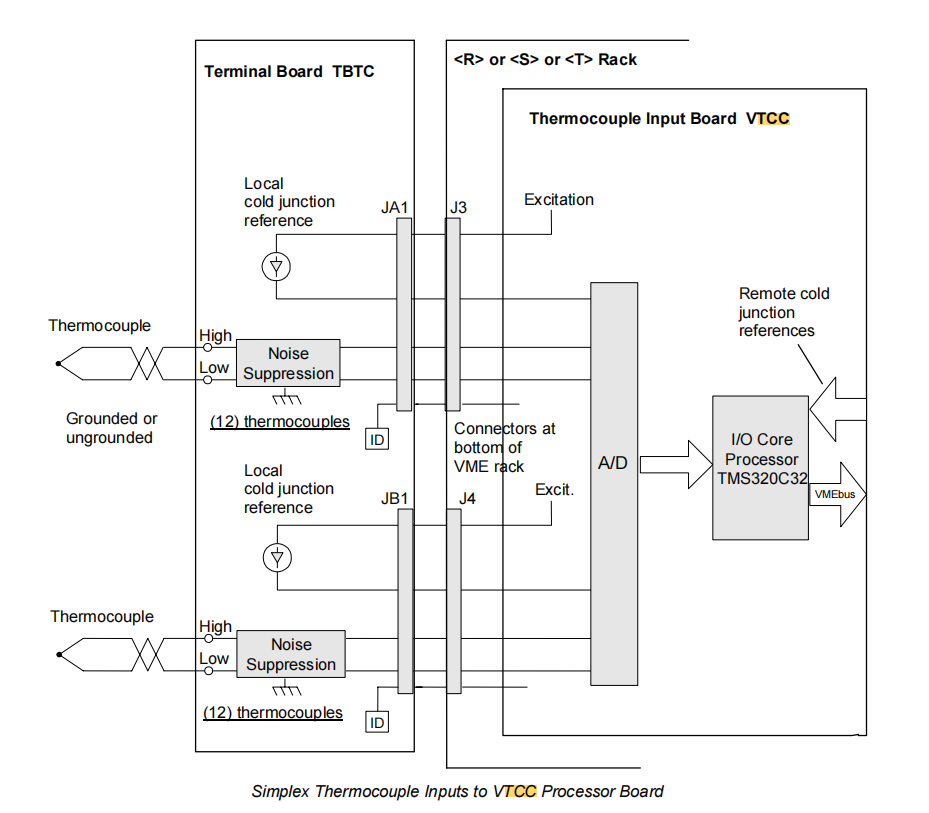

This board adopts a standard VME 6U architecture, installed in control racks and connected to field-located TBTC or DTTC terminal boards via dedicated cables. A single IS200VTCCH1C board can process up to 24 thermocouple inputs, offering high channel density. Notably, VTCC is optimized into two main versions based on application scenarios: IS200VTCCH1C is optimized for gas turbine control applications, supporting E, J, K, S, and T-type thermocouples; IS200VTCCH2C serves as a general-purpose version, additionally supporting B, N, and R-type thermocouples and featuring a wider signal range to adapt to a broader spectrum of industrial temperature measurement scenarios. Both versions use the same terminal boards, providing users with flexible choices and upgrade paths.

Core Functions and Features

The VTCC Thermocouple Input Board integrates advanced signal conditioning technology, a powerful processor, and intelligent diagnostic algorithms, possessing the following core functions and features:

1. Multi-Type, Wide-Range Thermocouple Support:

VTCCH1 Version: Specifically optimized for typical gas turbine temperature ranges, it supports E, J, K, S, T-type thermocouples and direct millivolt (mV) signal inputs (-8mV to +45mV). Its range covers a wide spectrum from extremely low temperatures (e.g., -60°F/-51°C) to ultra-high temperatures (e.g., S-type up to 3200°F/1760°C), meeting the needs of various temperature monitoring points from startup to full load in gas turbines.

VTCCH2 Version: As a more versatile version, it adds support for B, N, and R-type thermocouples to the H1 version and expands the millivolt signal input range to -20mV to +95mV. This enables it to handle more extreme industrial high-temperature measurements (e.g., B-type up to 3272°F/1800°C) and a wider range of industrial process applications.

2. High-Precision Measurement and Advanced Signal Processing:

16-Bit High-Resolution A/D Conversion: Utilizes a sampling-type 16-bit analog-to-digital converter with an effective resolution better than 14 bits, capable of resolving microvolt-level changes in thermocouple voltage, laying the hardware foundation for high-precision temperature measurement.

Powerful Anti-Interference Capability:

Common-Mode Rejection Ratio (CMRR): As high as 110 dB @ 50/60 Hz (with balanced input impedance), effectively suppressing common-mode interference at power-line frequencies common in the field.

Normal-Mode Rejection: 80 dB rejection capability against 250 mV RMS normal-mode interference at 50/60 Hz.

Onboard Noise Suppression: Each group of thermocouple inputs on the TBTC terminal board is equipped with a high-frequency noise suppression circuit, ensuring a high signal-to-noise ratio for long-distance transmission signals.

Automatic Linearization: For each thermocouple type (E, J, K, etc.), the onboard TMS320C32 Digital Signal Processor (DSP) of the VTCC runs specialized linearization algorithms (typically based on NIST standard tables), accurately converting the measured nonlinear millivolt voltage into linear temperature engineering values (°F or °C).

3. Intelligent Redundant Cold Junction Compensation (CJC):

Cold junction compensation is crucial for the accuracy of thermocouple measurements. The VTCC system employs a redundant, configurable, and highly reliable CJC scheme:

Dual Redundant References: Each VTCC board corresponds to two cold junction reference points (usually located in the JA1 and JB1 areas of the TBTC terminal board), each containing an independent temperature sensor (e.g., a semiconductor temperature IC).

Flexible Compensation Source Selection (New Firmware Feature): For boards with firmware version VTCC-100100C and above, users can select the compensation source for each CJ reference point:

Local: Uses the reading from the physical temperature sensor on the terminal board.

Remote: Uses a temperature value obtained via the VME bus from another location in the system (e.g., another module with stable temperature). The two CJ reference points can be mixed in configuration (one local, one remote).

Intelligent Arbitration Logic:

If both CJ readings are within the configurable reasonable limits, their average is used for compensation, yielding the highest accuracy.

If only one CJ reading is valid, that value is used.

If both CJs fail (e.g., open circuit, short circuit, or exceeding the hardware's 32-158°F safety range), a backup value is activated. The backup value can originate from CJ readings on other terminal boards or use a preset default value, ensuring the system can still provide valid (though possibly less accurate) temperature readings under extreme conditions.

High-Precision CJ Measurement: Cold junction temperature measurement accuracy is ±1.1°C (2°F). Combined with software linearization error (max 0.25°F), it ensures overall temperature measurement accuracy. A 1°F error in CJ compensation directly causes a 1°F error in the thermocouple reading, highlighting its importance.

4. Comprehensive Online Diagnostics and Safety Protection:

Hardware Limit Checking: Each thermocouple type has preset (non-configurable) hardware high/low voltage limits set near the ends of the operating range. Once an input signal exceeds these limits, the channel is immediately removed from the scan list to prevent faulty signals (e.g., high voltage due to short circuits) from affecting the normal operation of other channels on the board or the A/D converter's reference.

System (Software) Limit Checking: Users can configure enabled high/low temperature alarm limits (SysLimit) for each channel and choose whether to latch the alarm. This is used for process monitoring and early warning.

TMR System Differential Comparison: In Triple Modular Redundant (TMR) systems, VTCC continuously compares readings from the same thermocouple across R, S, T redundant channels. If any reading differs from the 2-out-of-3 voted median value by more than the preset TMR_DiffLimit, the system flags that specific channel as faulty, providing maintenance personnel with early warning of potential issues, enabling predictive maintenance.

Comprehensive Self-Diagnostics: The system continuously monitors and diagnoses the following key parameters:

Raw A/D count values for each thermocouple input (detecting overrange, open/short circuits).

Readings from the two cold junction references.

Onboard calibration reference voltage and zero reference voltage.

Any anomalies trigger corresponding diagnostic alarms and are aggregated into a board-level composite diagnostic signal, L3DIAG_VTCC.

Hardware Identity Verification: Both terminal boards and I/O boards are equipped with read-only ID chips. The VTCC processor reads and verifies the serial number, board type, revision, and connector location information stored in the chips upon power-up. A mismatch with the system configuration triggers a hardware incompatibility fault, preventing incorrect board installation.

5. Robust System Compatibility and Flexibility:

Supports Long-Distance Wiring: Thermocouple sensors can be installed up to 300 meters (984 feet) from the control cabinet, with a maximum allowed two-wire loop resistance of 450 Ω, accommodating the layout needs of large plants.

Grounded/Floating Compatible: Supports grounded or insulated (floating) thermocouples, providing wiring flexibility for users.

Supports Millivolt Signal Input: Besides thermocouples, channels can also be configured to directly read millivolt signals (range varies by version), facilitating connection to other types of transmitters or for maintenance debugging.

Compatible with Multiple System Architectures: Perfectly supports Simplex and Triple Modular Redundancy (TMR) systems. In TMR applications, the TBTCH1B terminal board is used, fanning out signals to three independent VTCC processors via six cables, achieving physical redundancy of signal inputs.

Working Principle

The working principle of the VTCC thermocouple input system is a precise, multi-step signal chain processing journey from physical effect to digital value:

1. Signal Acquisition and Primary Conditioning:

A field thermocouple generates a tiny DC voltage (µV to mV level) proportional to the temperature difference between its hot junction (measurement point) and cold junction (termination point) based on the Seebeck effect.

This signal is transmitted via twisted-pair shielded cable to the TBTC terminal board. The noise suppression circuit on the terminal board first filters out high-frequency interference.

For thermocouple open-circuit detection, the system applies a tiny bias voltage (±0.25V) through a 10 kΩ resistor. If the thermocouple opens, this bias voltage will be detected, triggering a "raw counts low" diagnostic alarm.

2. Cold Junction Compensation and Signal Multiplexing:

The conditioned 24 thermocouple analog signals are sent to the VTCC board via 37-pin "D"-type connectors (J3, J4) with latching fasteners.

Simultaneously, signals from the two (six in TMR systems) cold junction temperature sensors on the TBTC terminal board are also sent to the VTCC. These sensors accurately measure the temperature at the terminal block connection point (i.e., the thermocouple's "cold junction").

The analog front-end circuit on the VTCC board performs high-precision multiplexing and amplification of these multiple signals in preparation for A/D conversion.

3. High-Precision Analog-to-Digital Conversion and Digital Processing:

A/D Conversion: A high-performance 16-bit successive-approximation (SAR) or Δ-Σ type A/D converter samples and digitizes each multiplexed signal at high speed (120 times per second @ 60Hz system), converting the weak analog voltage into high-resolution digital "raw count values."

Automatic Calibration and Error Correction: Each scan cycle or periodically, the VTCC firmware controls the internal multiplexer to read the onboard high-precision reference voltage source and zero reference voltage. Using these known reference values, the system calculates and corrects the A/D converter's gain and offset errors in real-time, ensuring long-term measurement stability and accuracy. This is a key internal step for achieving high precision.

4. Software Linearization and Temperature Calculation (Completed in the DSP):

5. Limit Checking, Voting, and Output:

The calculated temperature value is immediately subjected to hardware limit and configurable system limit checks. Out-of-limit signals are flagged and may trigger alarms or be removed from scanning.

In TMR Systems: The three temperature readings for the same thermocouple from the <R>, <S>, <T> VTCC boards are sent to the upper-level controller (e.g., VCMI) for median value voting. The middle value is selected as the "correct" value for that thermocouple and output to the control logic. Simultaneously, the system continuously compares the differences between the three readings, enabling channel-level fault detection.

Finally, all valid temperature values for the 24 channels, cold junction temperature values, diagnostic statuses, etc., are transmitted in real-time via the VME bus to the VCMI communication board, which then distributes them to various controllers and application software within the control system.

6. Continuous Diagnostic Monitoring:

The entire workflow is monitored by a parallel, powerful diagnostic engine. It continuously compares A/D raw counts, CJ readings, and internal reference voltages against preset safety ranges. Any deviation is immediately captured and indicated via front panel LEDs (RUN green flashing, FAIL red steady, STATUS orange steady indicates a diagnostic alarm) and reported diagnostic variables, ensuring operators and maintenance personnel are always aware of the board's health status.

Application and Summary

The VTCC Thermocouple Input Board is the absolute mainstay of the temperature monitoring layer in the GE Mark VI/Vle control systems. It is widely used for precise measurement of hundreds of critical points in gas and steam turbines, such as Turbine Inlet Temperature, Bearing Temperature, Wheelspace Temperature, and Exhaust Temperature. These temperature data are the fundamental basis for the control system to implement advanced functions like Overtemperature Protection, Thermal Stress Control, Performance Optimization, and Sequential Startup.

Its value is reflected in:

Exceptional Accuracy and Reliability: Provides stable, trustworthy temperature data in harsh industrial electromagnetic environments through high-resolution A/D, auto-calibration, intelligent cold junction compensation, and linearization algorithms.

High Safety and Availability: Multi-level diagnostics (hardware limits, system limits, TMR differences), fault channel isolation, and redundant backup design for CJC ensure that failures of a single measurement point or even partial hardware do not lead to system malfunctions or loss of monitoring capability.

Flexible Configuration and Powerful Compatibility: Supports multiple thermocouple types, long/short distance wiring, and Simplex/TMR architectures, enabling seamless integration into systems ranging from simple to the most complex.