The IQS450 signal conditioner is the core component of TQ403 proximity measurement system. It is a high-precision electronic device specifically designed to process eddy current sensor signals. As the intelligent processing center of the complete proximity measurement system, the IQS450 is responsible for providing excitation signals to the TQ403 sensor and receiving and processing the returned measurement signals, converting them into standardized voltage or current outputs for monitoring systems.

The IQS450 utilizes advanced electronic technology and sophisticated signal processing algorithms, offering exceptional measurement accuracy, stable performance, and broad environmental adaptability. Its compact aluminum housing design and multiple installation options enable easy integration into various industrial monitoring systems, meeting diverse application requirements from conventional machinery protection to precision condition monitoring.

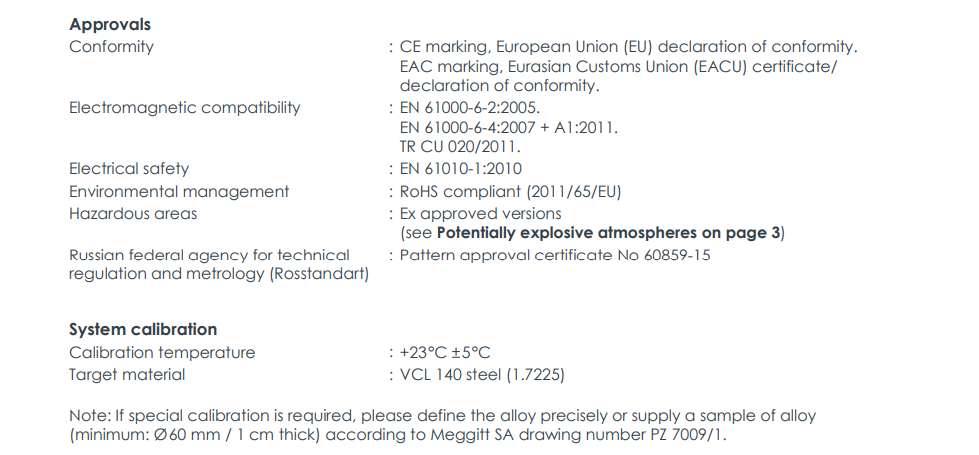

The signal conditioner supports two output modes (voltage and current), provides comprehensive protection functions (including short-circuit protection and reverse polarity protection), and is available in multiple explosion-proof certified versions for safe use in hazardous areas. Whether used in power generation, petrochemical, or heavy industry applications, the IQS450 delivers reliable and accurate measurement solutions.

Working Principle

The working principle of the IQS450 signal conditioner is based on high-frequency signal modulation-demodulation technology and sophisticated signal processing algorithms. Its workflow can be divided into the following key stages:

1. High-Frequency Excitation Signal Generation

The IQS450 contains a high-performance high-frequency oscillator that generates stable and precise high-frequency AC signals (typically 1-2 MHz). This signal is transmitted through the output circuit to the TQ403 sensor, providing the necessary excitation power to the sensor coil. The oscillator features temperature compensation design, ensuring frequency and amplitude stability across different environmental temperatures, providing a reliable foundation for accurate measurements.

2. Signal Modulation and Demodulation

When the high-frequency excitation signal drives the sensor coil, it generates an electromagnetic field around it. When a metal target approaches the sensor, eddy currents are induced on the target surface according to the eddy current effect. These eddy currents generate a reverse electromagnetic field that alters the impedance of the sensor coil. This impedance change modulates the high-frequency carrier signal. The phase-sensitive demodulation circuit (PSD) inside the IQS450 accurately extracts this modulation information and converts it into a DC signal related to distance.

3. Signal Conditioning and Linearization Processing

The signals returned from the sensor typically exhibit nonlinear characteristics. The IQS450 uses advanced digital processing technology to linearize the raw signals. Through polynomial fitting algorithms and digital temperature compensation technology, the conditioner converts nonlinear input signals into highly linear output signals. The system also includes a programmable gain amplifier (PGA) that can adjust signal amplification according to different application requirements, ensuring optimal signal-to-noise ratio and measurement accuracy.

4. Temperature Compensation and Drift Correction

The IQS450 incorporates precision temperature sensors and advanced temperature compensation algorithms that monitor environmental temperature changes in real time and compensate the measurement results. This compensation mechanism effectively eliminates the impact of temperature on system performance, ensuring stable measurement accuracy across a wide temperature range (-35°C to +85°C). Compensation parameters are stored in non-volatile memory, remaining effective even after power loss.

5. Output Signal Generation and Protection

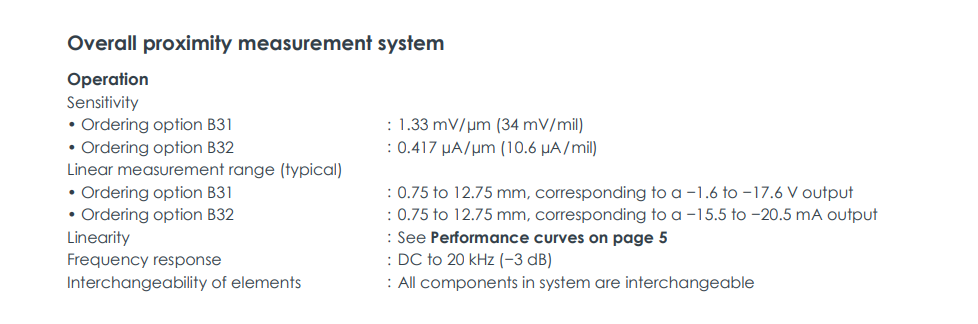

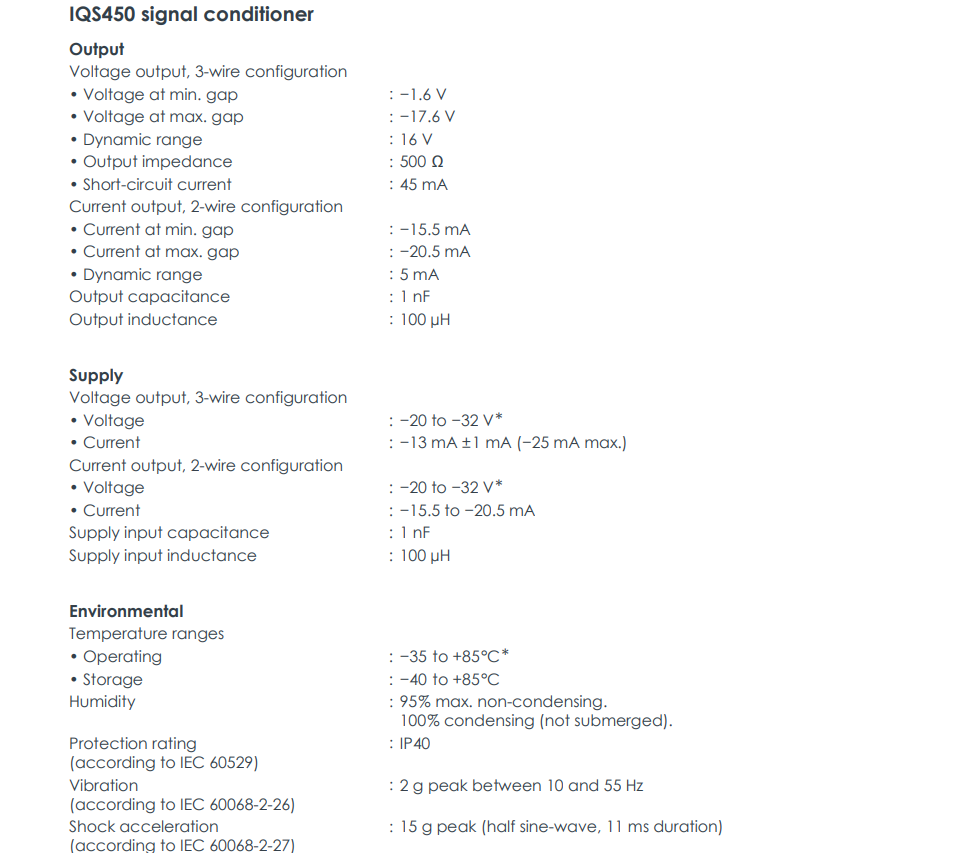

The processed signals are output in two ways: voltage output mode provides a linear output from -1.6V to -17.6V, corresponding to a measurement range of 0.75mm to 12.75mm; current output mode provides a two-wire current signal from -15.5mA to -20.5mA. Both output modes feature comprehensive protection functions, including short-circuit protection, overload protection, and reverse polarity protection, ensuring equipment safety under abnormal conditions.

6. Power Management and Thermal Management

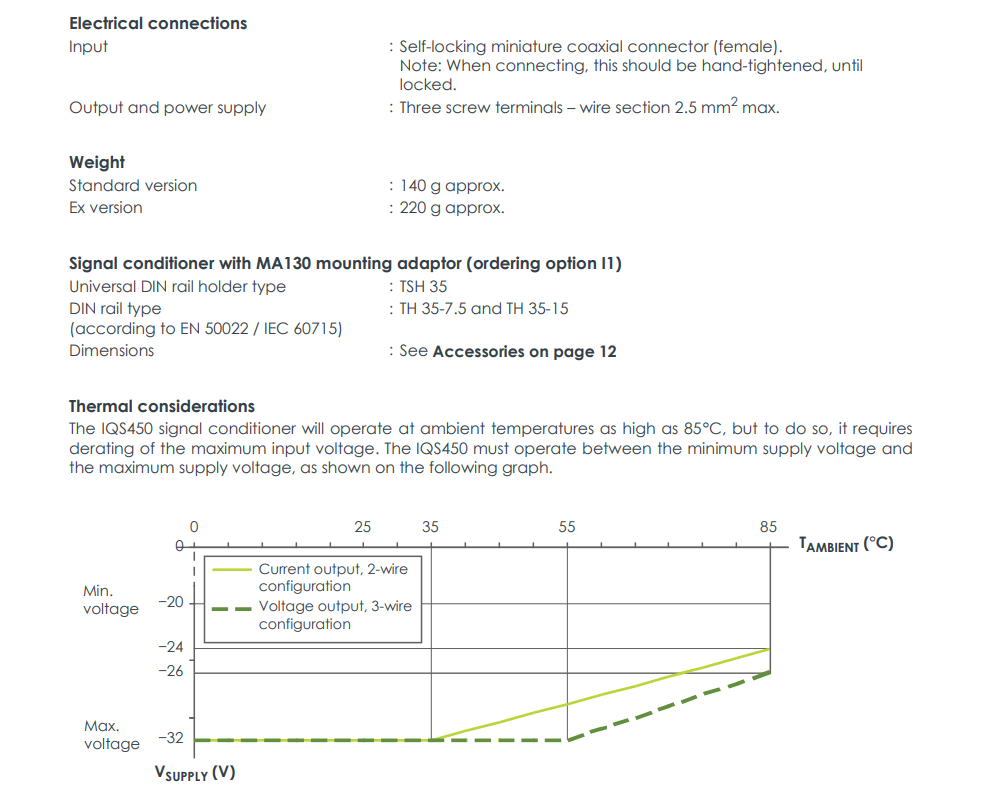

The IQS450 employs efficient power management design, supporting a wide range of supply voltages (-20V to -32V). The device includes a thermal management system that automatically adjusts operating parameters when ambient temperature rises, ensuring stable operation even at maximum operating temperature (+85°C). The power input circuit includes filtering and protection components that effectively suppress power noise and surges.

7. System Integration and Communication

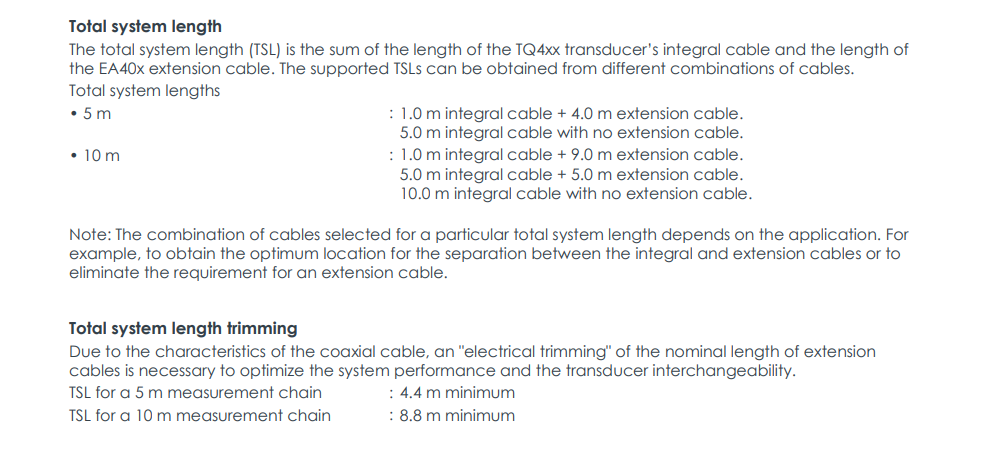

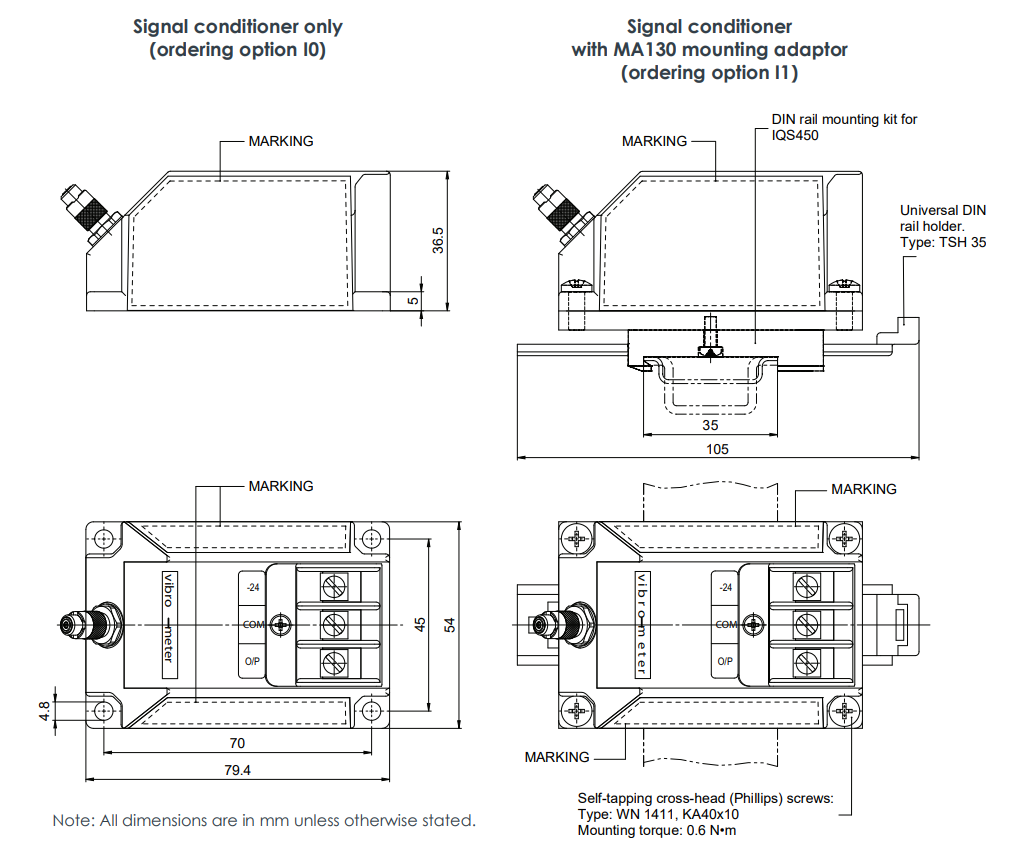

The signal conditioner provides standard interface connection methods, enabling seamless integration with various monitoring systems . Self-locking miniature coaxial connectors ensure reliable sensor connections, while screw terminal blocks facilitate power and output signal connections. The device also supports DIN rail mounting (via MA130 mounting adapter), facilitating layout and maintenance within control cabinets.

Features

The IQS450 signal conditioner integrates multiple advanced functions, providing high-performance signal processing solutions for industrial measurement systems:

1. Dual Output Mode Flexibility

The device supports both voltage and current output modes, meeting the interface requirements of different systems. The voltage output mode provides a 16V dynamic range with 500Ω output impedance, suitable for short-distance transmission; the current output mode provides a 4-20mA type signal (actually -15.5mA to -20.5mA) using two-wire connection, with strong anti-interference capability suitable for long-distance transmission.

2. High-Precision Measurement Performance

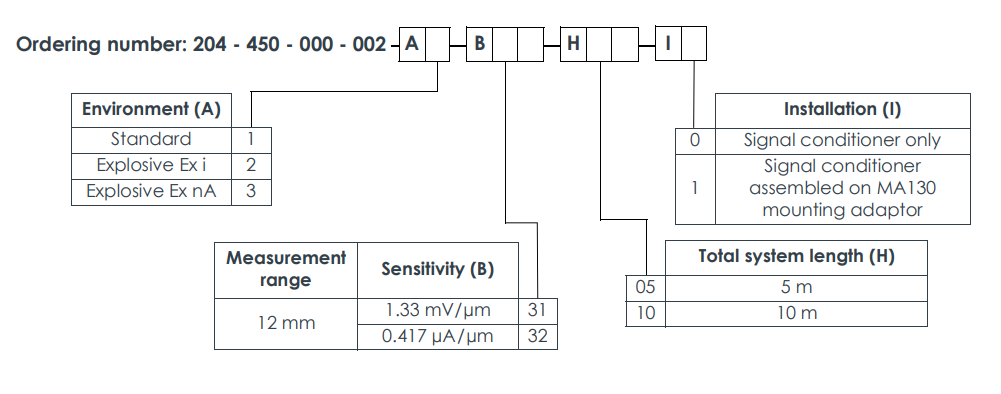

The IQS450 delivers exceptional measurement accuracy, maintaining highly linear output across the entire measurement range. Device sensitivity is selectable: 1.33 mV/μm (ordering option B31) or 0.417 μA/μm (ordering option B32). The frequency response range reaches DC to 20kHz (-3dB), capable of capturing the dynamic characteristics of high-speed rotating machinery.

3. Wide Operating Temperature Range

The device operates normally in ambient temperatures from -35°C to +85°C, with a storage temperature range of -40°C to +85°C. The intelligent temperature management system ensures stable performance under extreme temperature conditions, with temperature drift minimized.

4. Comprehensive Protection Functions

The IQS450 provides multiple protection measures: output short-circuit protection can withstand continuous short circuits without damage; reverse polarity protection prevents damage from incorrect power connection; overload protection ensures equipment safety under abnormal operating conditions. These protection features significantly enhance system reliability and service life.

5. Explosion-Proof Certification and Safety Compliance

The device is available in multiple explosion-proof certified versions, including Ex ia (intrinsically safe) and Ex nA (non-sparking) types, meeting international standards such as ATEX, IECEx, and cCSAus, enabling safe use in Zone 0/1/2 or Zone 2 hazardous areas.

6. Compact and Robust Mechanical Design

The housing uses injection-molded aluminum construction, providing excellent electromagnetic shielding and superior thermal conductivity. The device weighs only approximately 140g (standard version) or 220g (explosion-proof version), with two or four M4 screw mounting holes supporting various installation methods.

7. Easy Integration and Maintenance

Standard connector interfaces and screw terminal blocks make installation and wiring quick and easy. The device supports DIN rail mounting (via MA130 mounting adapter), facilitating centralized layout within control cabinets. All components are fully interchangeable and can be replaced without recalibration, significantly reducing maintenance costs and downtime.

8. Low Power Consumption Design

The device employs efficient power management design, with voltage output mode consuming only -13mA ±1mA (maximum -25mA), and current output mode consumption matching the output current (-15.5mA to -20.5mA), reducing overall system energy consumption.

Technical Specifications Summary

| Item | Specification |

| Output Modes | Voltage output (3-wire) / Current output (2-wire) |

| Output Voltage Range | -1.6 V to -17.6 V |

| Output Current Range | -15.5 mA to -20.5 mA |

| Dynamic Range | 16 V (voltage mode) / 5 mA (current mode) |

| Output Impedance | 500 Ω (voltage mode) |

| Frequency Response | DC to 20 kHz (-3 dB) |

| Supply Voltage | -20 V to -32 V |

| Operating Current | -13 mA ±1 mA (voltage mode) / -15.5 to -20.5 mA (current mode) |

| Operating Temperature | -35°C to +85°C |

| Storage Temperature | -40°C to +85°C |

| Protection Rating | IP40 (according to IEC 60529) |

| Connectors | Self-locking miniature coaxial connector (female) |

| Terminals | Screw terminals, maximum wire size 2.5 mm² |

| Weight | Approx. 140 g (standard) / 220 g (Ex version) |

| Mounting Options | 2 or 4 M4 screws / DIN rail (using MA130 adapter) |

Application Areas

The IQS450 signal conditioner is widely used in the following industrial fields:

Power Generation Equipment: Vibration and position monitoring systems for steam turbines, gas turbines, and hydroelectric generating units

Petrochemical Industry: Condition monitoring and protection of rotating machinery such as compressors, pumps, and fans

Heavy Industry: Mechanical health monitoring for equipment including rolling mills, mining machinery, and heavy-duty pumps

Aerospace: Testing and monitoring of aircraft engines and auxiliary power units

Scientific Research: Displacement and vibration measurements in precision measurement and laboratory research