The IPC704 is a high-performance signal conditioner from Meggit product line, specifically designed for piezoelectric accelerometers (CAxxx series) and dynamic pressure sensors (CPxxx series). This device primarily converts charge signals from sensors into standard current or voltage signals for long-distance transmission to subsequent processing systems (such as data acquisition cards, PLCs, or monitoring systems). With highly configurable filtering functions, multiple output options, and versatile installation methods, the IPC704 is suitable for demanding environments in industrial, energy, aerospace, and other sectors.

Key Features

1. Signal Conversion and Transmission

The core function of the IPC704 is to convert high-impedance charge signals from piezoelectric sensors into low-impedance current or voltage signals. It supports two output modes:

2-Wire Current Transmission: Outputs a 4–20 mA standard signal with a maximum dynamic range of ±5 mA and a quiescent current of 12 mA. Ideal for long-distance transmission (up to 1 km) with strong noise immunity.

3-Wire Voltage Transmission: Outputs a 0–10 V standard signal with a maximum dynamic range of ±5 V and a quiescent voltage of 7.5 V. The output impedance is 750 Ω, making it suitable for short-distance, high-precision measurements.

2. Configurable Filtering Functions

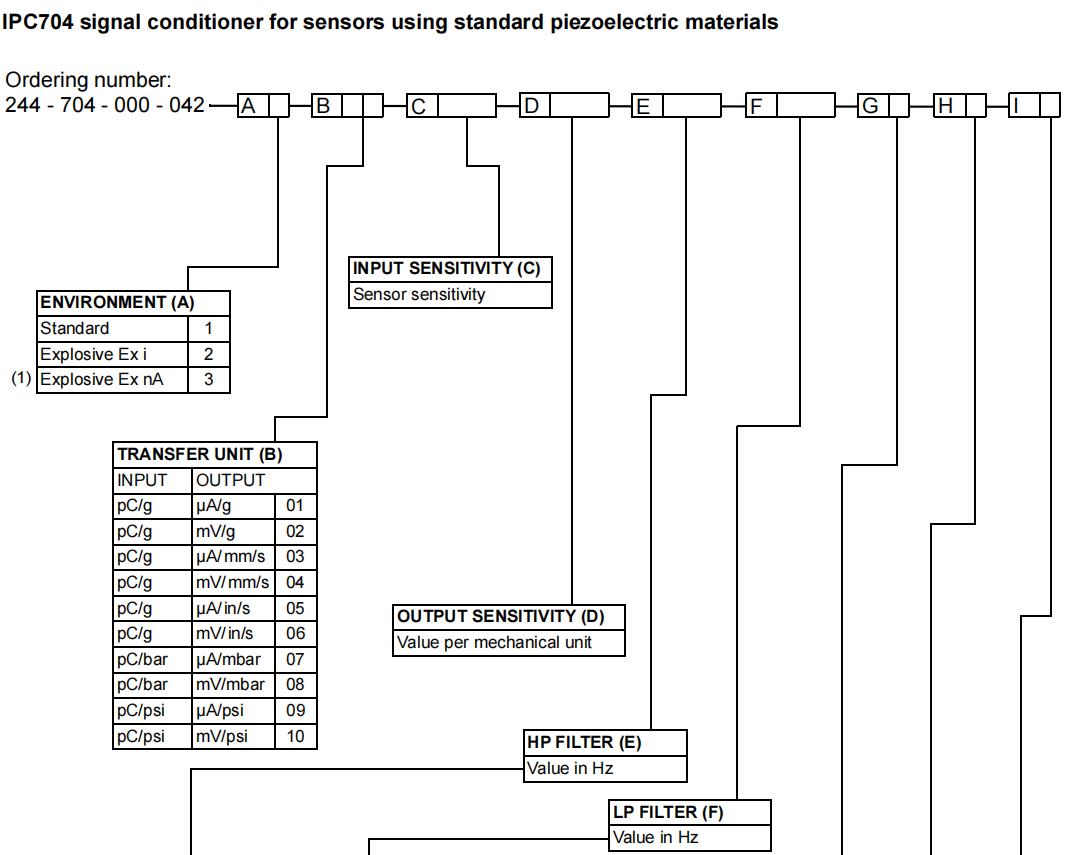

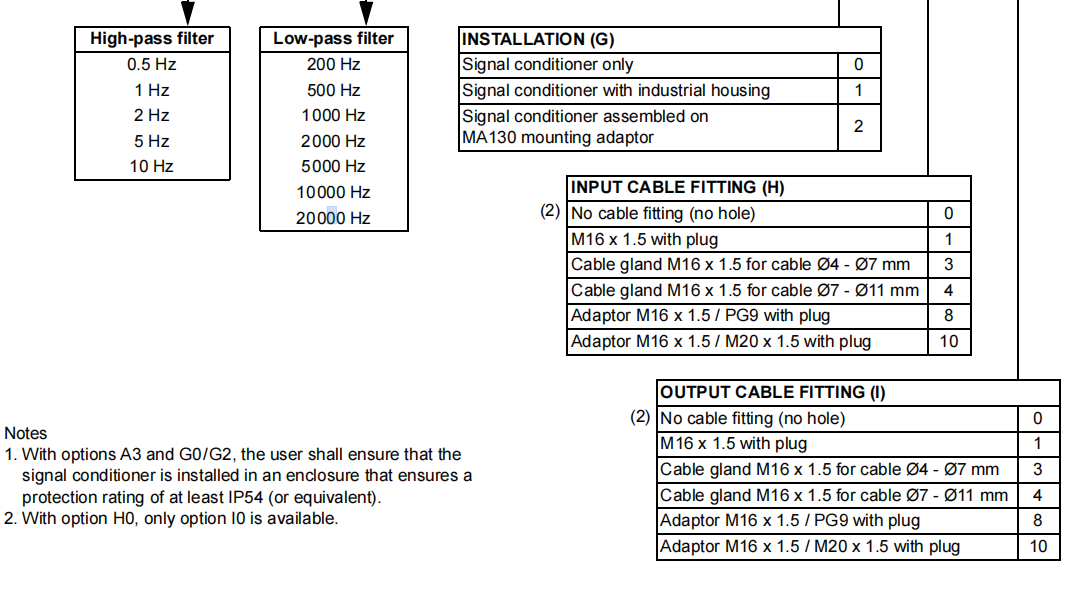

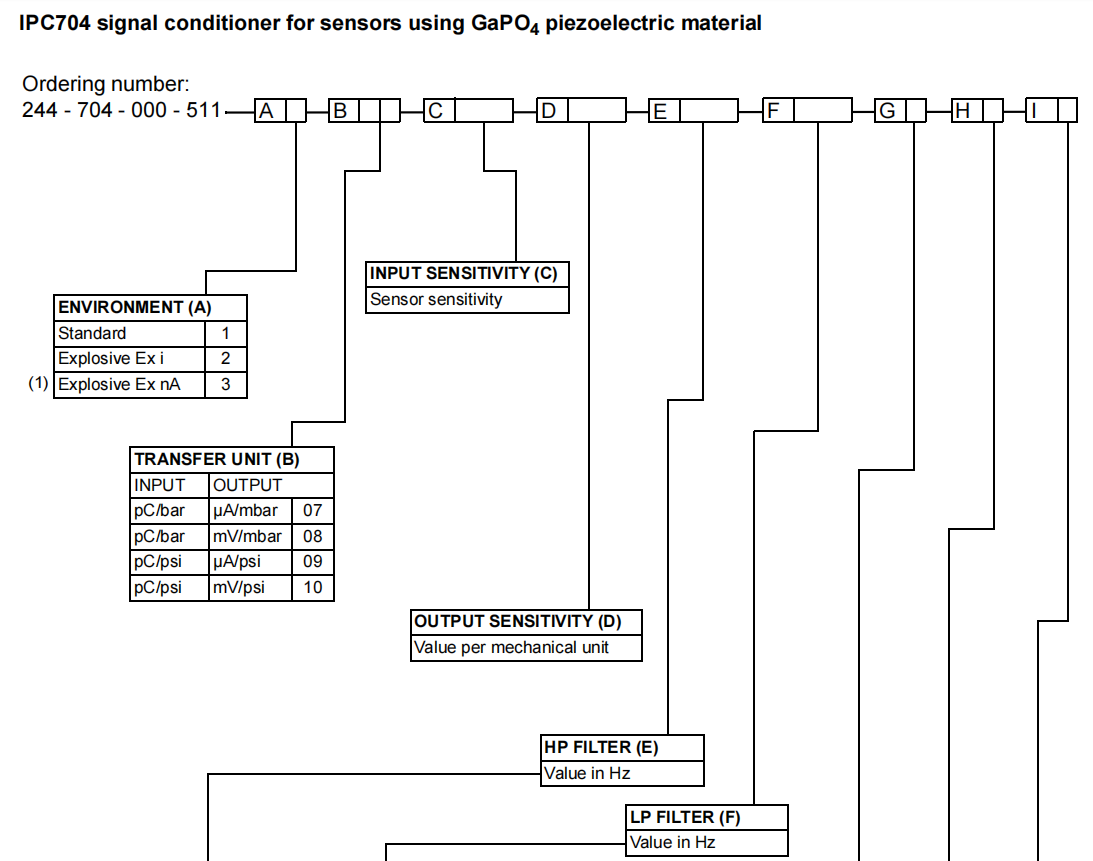

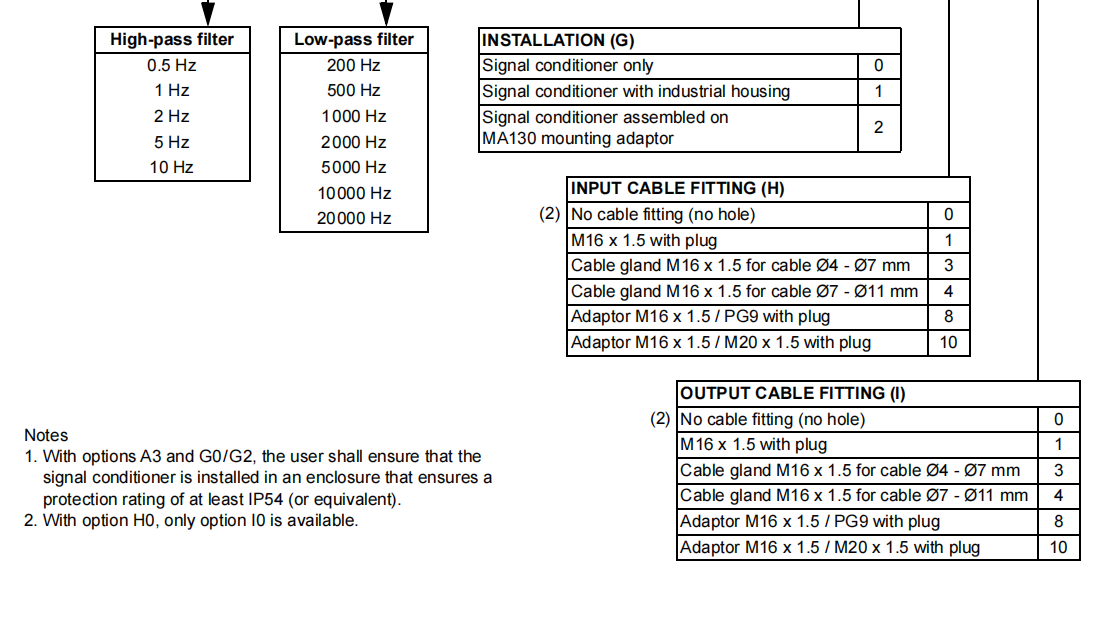

The device features configurable high-pass filters (HPF) and low-pass filters (LPF), allowing users to select cutoff frequencies based on application requirements:

High-Pass Filter: Offers five cutoff frequencies (0.5, 1, 2, 5, and 10 Hz at the -3 dB point), each with a slope of 24 dB/octave (fourth-order).

Low-Pass Filter: Provides seven cutoff frequencies (200, 500, 1000, 2000, 5000, 10000, and 20000 Hz at the -1 dB point), each with a slope of 12 dB/octave (second-order).

3. Optional Integrator Function

The IPC704 can be equipped with an integrator to convert acceleration signals into velocity signals, making it suitable for vibration velocity measurements. The phase difference between acceleration and velocity outputs is 90°.

4. Environmental Adaptability and Protection Rating

Operating Temperature: -30°C to +85°C

Storage Temperature: -40°C to +85°C

Humidity: Up to 95% (non-condensing)

Protection Rating:

Standard Version: IP40

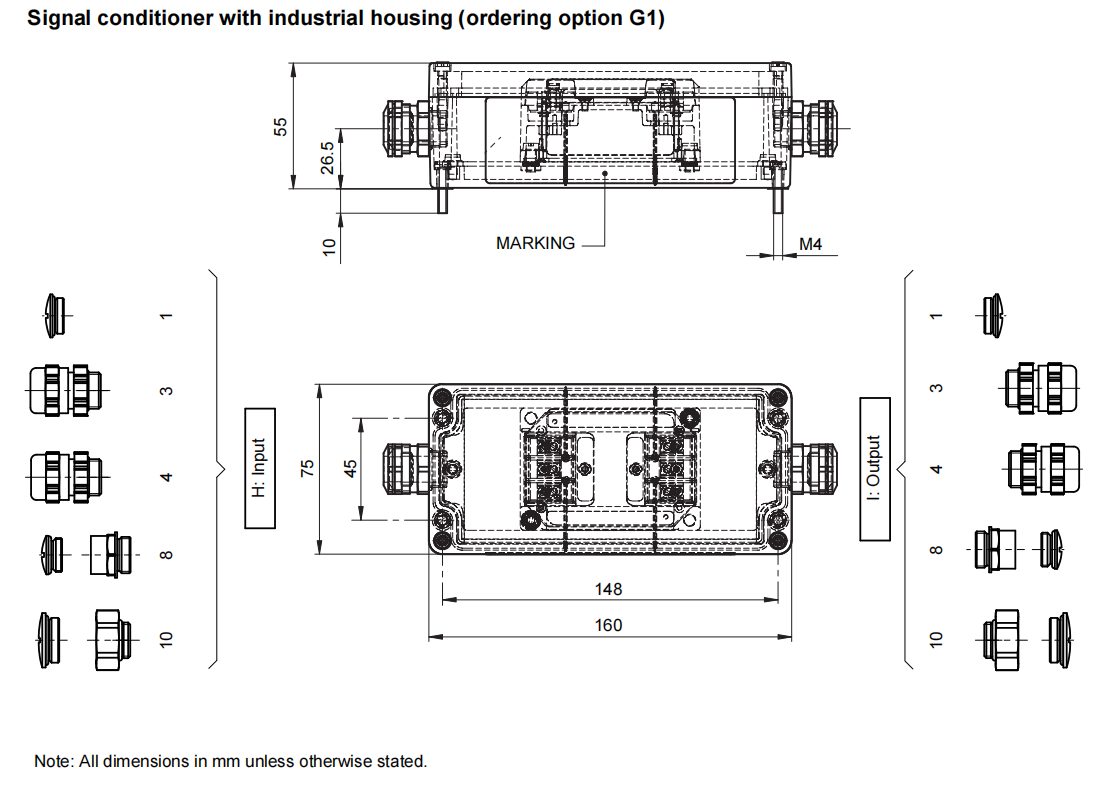

Industrial Housing Version (Option G1): IP66, with excellent resistance to chemicals (seawater, acids, alkalis, gasoline, and oils)

5. Explosion-Proof Certifications

The IPC704 is available in multiple explosion-proof certified versions for hazardous environments:

Ex i Intrinsic Safety: Suitable for Zone 1/2 (certified in Europe, North America, IECEx, China NEPSI, and Korea KGS)

Ex nA Non-Sparking: Suitable for Zone 2 (certified in Europe, North America, and IECEx)

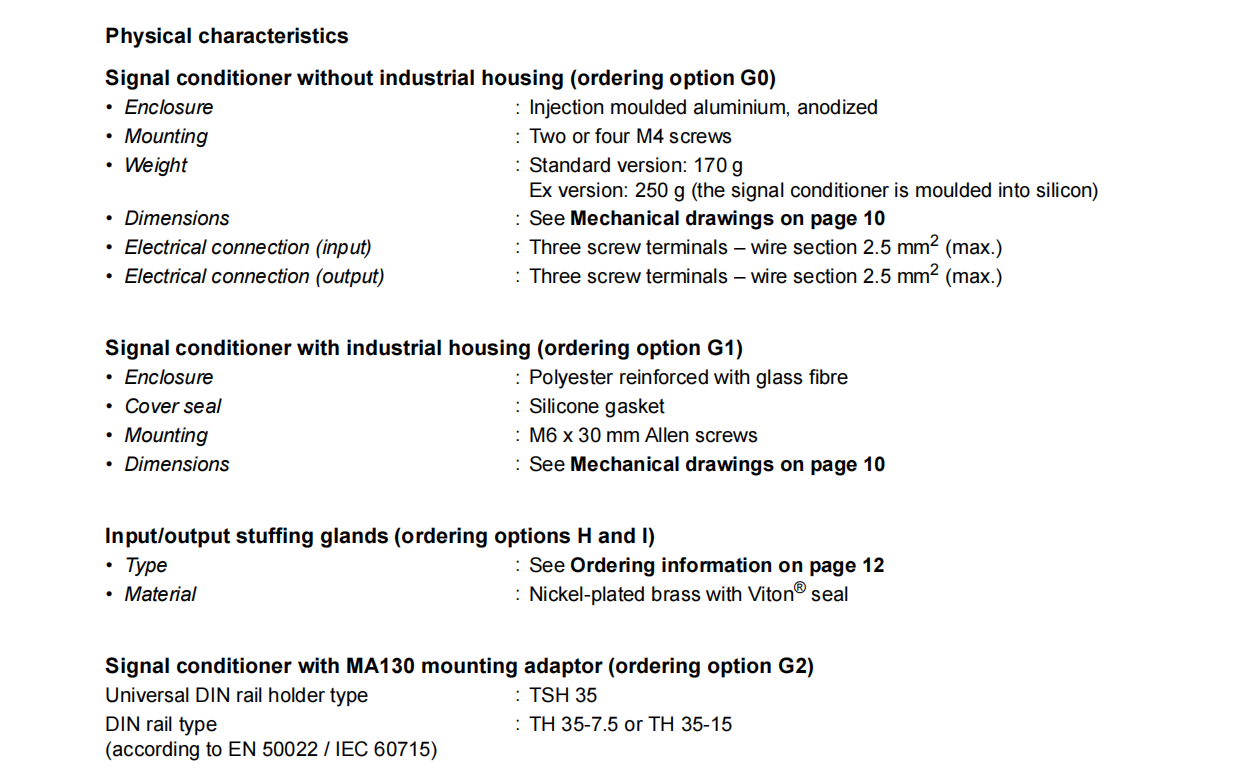

6. Installation Flexibility

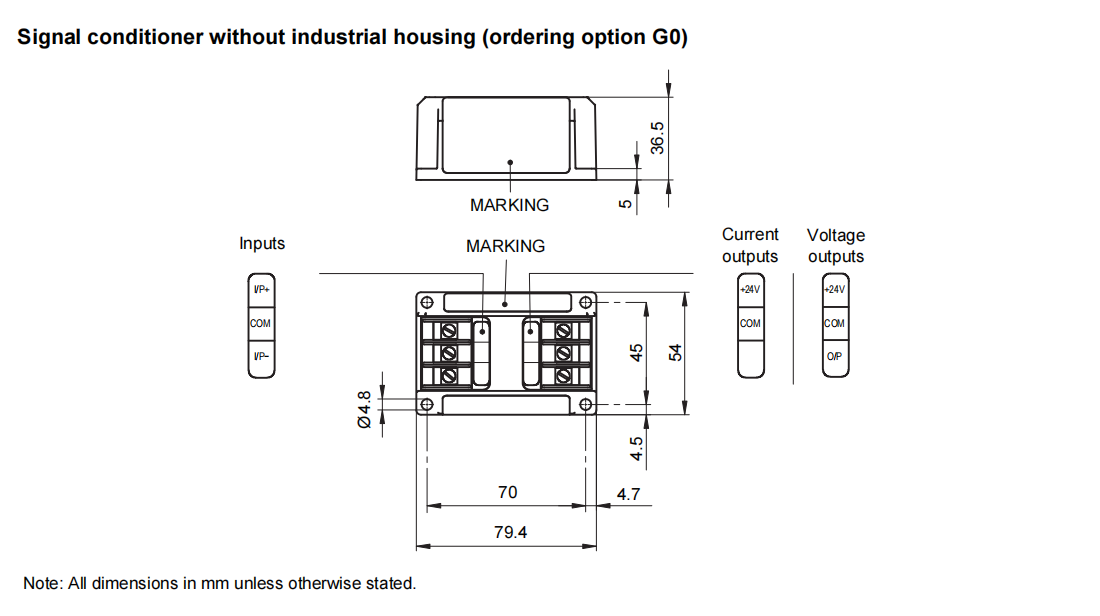

Standard aluminum housing (electrically conductive)

Industrial polyester housing (Option G1)

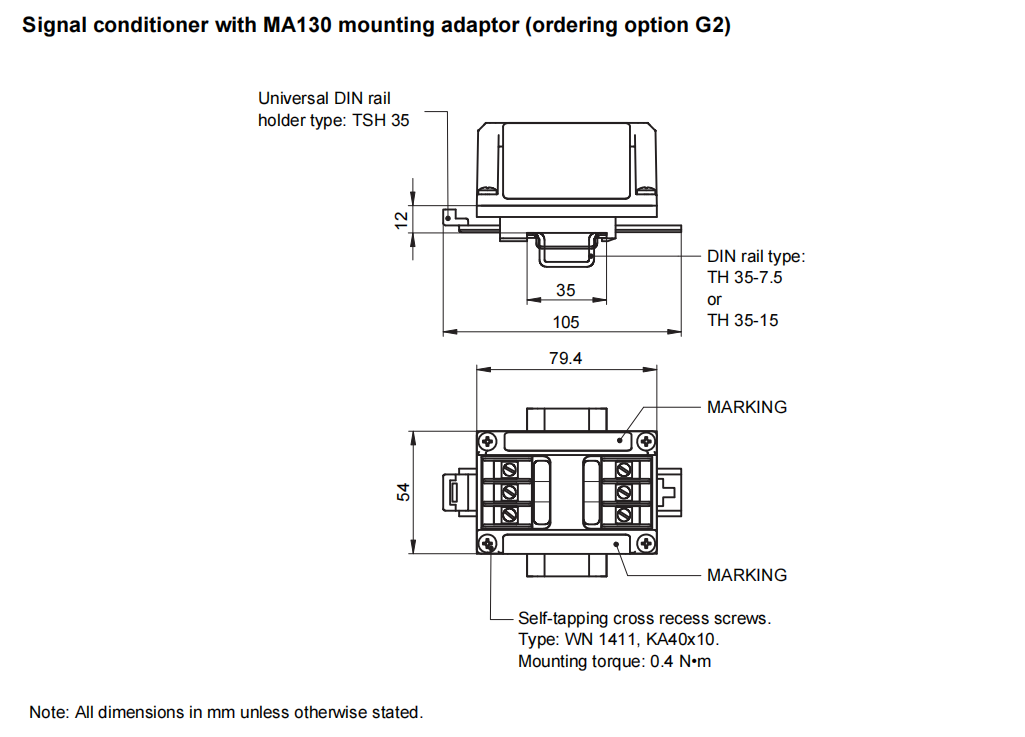

DIN rail mounting adapter (Option G2)

Multiple cable interface options (M16, PG9, M20, etc.)

7. Electrical Characteristics

Power Supply: 18–30 VDC, maximum current 25 mA

Linearity Error: ≤0.2%

Temperature Stability: Typical value 100 ppm/°C

Input Dynamic Range: Up to 100,000 pC (peak)

Working Principle

Charge Amplification and Signal Conditioning

The core of the IPC704 is a high-precision, high-performance charge amplifier system designed to address fundamental challenges in transmitting signals from piezoelectric sensors. Piezoelectric materials generate a charge proportional to mechanical stress (such as vibration, impact, or pressure changes). However, this charge signal has high impedance and is highly susceptible to cable capacitance, electromagnetic interference, and environmental noise, leading to signal attenuation, distortion, and reduced signal-to-noise ratio.

The IPC704 addresses these issues through a carefully designed signal chain, which operates in the following key stages:

1. Input Stage and Charge Amplification

The input stage employs a symmetric differential charge amplifier design with very high input impedance (≥50 kΩ) and very low output impedance. This design minimizes loading effects on the signal source, preserving signal integrity. The charge amplifier is essentially an operational amplifier circuit with capacitive feedback, where the output voltage is proportional to the input charge.

When the charge signal from the piezoelectric sensor is transmitted via cable to the IPC704's input, the charge amplifier accumulates this charge on the feedback capacitor and converts it into a corresponding voltage signal. The conversion ratio (sensitivity) can be configured externally, ranging from 0.1 to 50 mV/pC or μA/pC, depending on the sensor type and measurement requirements. This design not only provides signal conversion but also acts as an impedance transformer, converting a high-impedance charge source into a low-impedance voltage source, laying the foundation for subsequent signal processing.

2. Filtering System

The IPC704 features a highly configurable filtering system, including high-pass (HPF) and low-pass (LPF) filters, allowing users to select appropriate cutoff frequencies for specific applications.

The High-Pass Filter (HPF) uses a fourth-order Butterworth or Chebyshev filter design, providing a steep roll-off of 24 dB/octave. These filters offer five cutoff frequency options (0.5, 1, 2, 5, and 10 Hz at the -3 dB point), primarily used to eliminate low-frequency noise and DC offset components. In vibration measurement, mechanical systems often exhibit very low-frequency drift and temperature effects, which can occupy dynamic range and potentially cause amplifier saturation. The HPF effectively removes these interferences while preserving the frequency components of interest.

The Low-Pass Filter (LPF) uses a second-order design with a roll-off of 12 dB/octave, offering seven cutoff frequency options from 200 to 20,000 Hz (at the -1 dB point). These filters are mainly used for anti-aliasing and high-frequency noise suppression. In data acquisition systems, signal bandwidth must be limited according to the Nyquist sampling theorem to prevent frequency aliasing. Additionally, the LPF suppresses high-frequency interference such as radio frequency interference (RFI) and switching noise, improving signal quality.

Filter selection requires careful consideration of the measured object's frequency characteristics, sampling rate, and noise environment. The multiple options provided by the IPC704 allow users to optimize system performance.

3. Integration Function (Optional)

For applications requiring vibration velocity measurement, the IPC704 offers an optional integrator function. The integrator converts acceleration signals into velocity signals through mathematical integration. Physically, acceleration is the derivative of velocity, so this conversion process requires precise integration.

The IPC704's integrator uses a precision analog integration circuit design, typically based on an operational amplifier and feedback capacitor structure. This design provides highly linear integration characteristics over a wide frequency band, ensuring accurate conversion from acceleration to velocity. The integration process introduces a 90° phase delay, consistent with the mathematical properties of integration: for sinusoidal signals, integration corresponds to a 90° phase shift.

The integrator function is particularly useful for applications focused on vibration energy (proportional to the square of velocity) rather than单纯的 acceleration values, such as mechanical condition monitoring and fatigue analysis.

4. Output Stage Design

The IPC704 provides two output configurations to meet the needs of different application scenarios:

The 2-wire current transmission uses a 4-20 mA standard industrial current loop, with a maximum dynamic range of ±5 mA and a quiescent current of 12 mA. This design offers excellent noise immunity and long-distance transmission capabilities. Current signals are insensitive to cable resistance and inductance, allowing transmission to receiving devices up to 1 km away without significant attenuation. Additionally, current loops inherently provide short-circuit protection, enhancing system reliability.

The 3-wire voltage transmission provides a 0-10 V standard voltage signal, with a maximum dynamic range of ±5 V, a quiescent voltage of 7.5 V, and an output impedance of 750 Ω. Voltage output is suitable for short-distance, high-precision measurements and can be directly connected to most data acquisition systems and PLC analog input modules. Voltage mode offers higher signal bandwidth and faster settling time, making it suitable for high-frequency dynamic measurements.

Both output modes include precision output driver circuits to ensure high linearity and stability during signal transmission.

5. RFI/EMI Protection Mechanism

The IPC704 is equipped with symmetric LC radio frequency interference (RFI) filter networks at both the input and output. These filters are specifically designed to suppress high-frequency electromagnetic interference, including radio frequency interference, power supply switching noise, and digital circuit noise. The RFI filters use a balanced design, providing suppression against both differential-mode and common-mode interference, protecting signal integrity.

RFI protection at the input stage is particularly important because piezoelectric sensor signals are extremely weak and susceptible to external electromagnetic fields. RFI filtering at the output stage ensures that the output signal is not contaminated by subsequent cable and environmental noise.

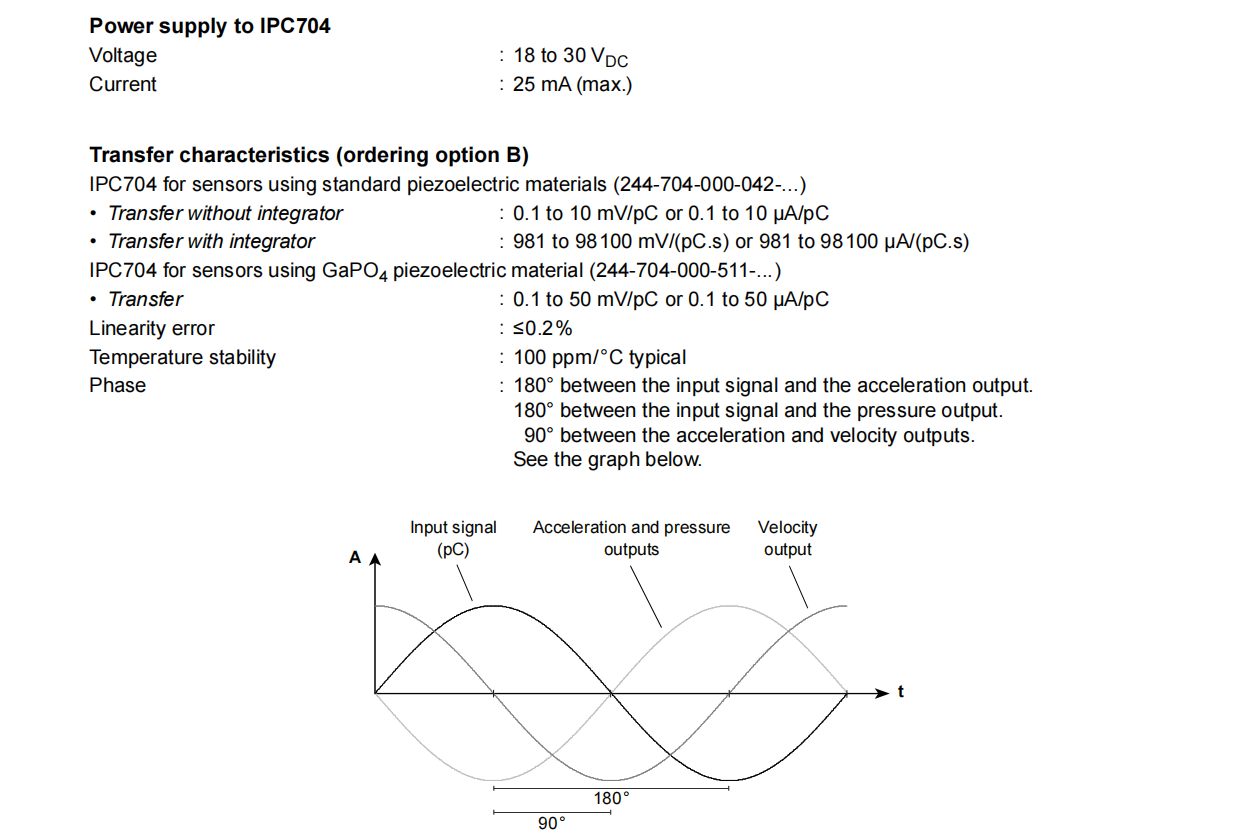

6. Phase Characteristics Maintenance

The IPC704 carefully maintains phase consistency throughout the signal chain:

Acceleration and pressure outputs maintain a 180° phase relationship with the input signal.

Velocity output maintains a 90° phase difference with the acceleration output (consistent with the integration relationship).

This phase consistency is crucial for multi-channel measurements, phase-sensitive analysis, and control system integration.

7. Power Management and Stability

The device operates from an 18-30 VDC wide-range power supply and includes efficient voltage regulation and filtering circuits. The power management module ensures stable operating voltages under various input voltage conditions while suppressing noise and ripple on the power lines. Good power design is the foundation of the device's high-precision performance, with temperature stability typically reaching 100 ppm/°C, ensuring consistent performance across different environmental temperatures.

Compatible Sensor Types

The IPC704 supports two types of piezoelectric material sensors:

Standard Piezoelectric Materials (e.g., CAxxx, CP10x, CP2xx)

GaPO₄ Piezoelectric Materials (e.g., CP50x)

Each type has corresponding order numbers and configuration options to ensure optimal matching and performance. GaPO₄ sensors offer higher operating temperatures and better stability, making them suitable for extreme environment applications.

Application Areas

Rotating Machinery Monitoring: Vibration monitoring of steam turbines, compressors, pumps, and fans

Aerospace: Engine vibration testing, structural health monitoring

Energy Industry: Condition monitoring of nuclear, hydroelectric, and thermal power equipment

Industrial Automation: Dynamic pressure measurement in process control

R&D Testing: High-frequency dynamic signal acquisition in laboratories